ASTM E1124-97(2004)

(Test Method)Standard Test Method for Field Measurement of Sound Power Level by the Two-Surface Method

Standard Test Method for Field Measurement of Sound Power Level by the Two-Surface Method

SCOPE

1.1 This test method covers the field, or in situ measurement of sound power level by the two-surface method. The test method is designed to minimize the effects of reverberant conditions, directivity of the noise source under consideration, and the effects of ambient noise from other nearby equipment operating at the same time.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E1124 – 97 (Reapproved 2004)

Standard Test Method for

Field Measurement of Sound Power Level by the Two-

1

Surface Method

This standard is issued under the fixed designation E1124; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.2 constituent surface area—a portion of the conformal

surface.

1.1 Thistestmethodcoversthefield,or in situmeasurement

of sound power level by the two-surface method. The test

4. Summary of Test Method

method is designed to minimize the effects of reverberant

4.1 The average one-third or full octave band sound pres-

conditions, directivity of the noise source under consideration,

sure levels are measured over two different conformal surfaces

and the effects of ambient noise from other nearby equipment

which envelop the equipment. These conformal surfaces

operating at the same time.

should be selected to consist of rectangular, cylindrical, and

1.2 This standard does not purport to address all of the

hemispherical constituent surfaces so that the surface areas

safety concerns, if any, associated with its use. It is the

may be easily calculated. From the difference between the two

responsibility of the user of this standard to establish appro-

average sound pressure levels taken at each surface and from

priate safety and health practices and determine the applica-

the areas of the surfaces, the sound power level may be

bility of regulatory limitations prior to use.

calculated. The calculation accounts for both the effect of the

2. Referenced Documents reverberant field and the noise of other equipment. It is

2

permissible to define conformal surfaces that completely en-

2.1 ASTM Standards:

velope the source, yet only measure over a portion of the

C634 Terminology Relating to Building and Environmental

conformalsurfaceduetorestrictionsfromprocessconnections

Acoustics

3

or accessibility.

2.2 ANSI Standard:

S1.4 Specification for Sound Level Meters

5. Significance and Use

3. Terminology 5.1 The function and operation of equipment in the field

often preclude the measurement of the free-field sound pres-

3.1 Definitions—For definitions of terms used in this test

4 sure levels of a single piece of equipment in the absence of

method, refer to Terminology C634.

interfering sound from other equipment operating at the same

3.2 Definitions of Terms Specific to This Standard:

time. The two-surface method will provide, in most cases, a

3.2.1 conformal surface—the locus of points which lie at a

reliable estimate of the normal sound power levels of a

fixed distance from the reference surface of a piece of

specimen operating in an adverse environment.

equipment. Two conformal surfaces are used in this test

5.2 This test method is intended for use in the field in the

method. These are surfaces over which the measuring micro-

presence of what is normally regarded as interfering back-

phones are swept. They are located at two different distances

ground noise. This test method is based upon the work of

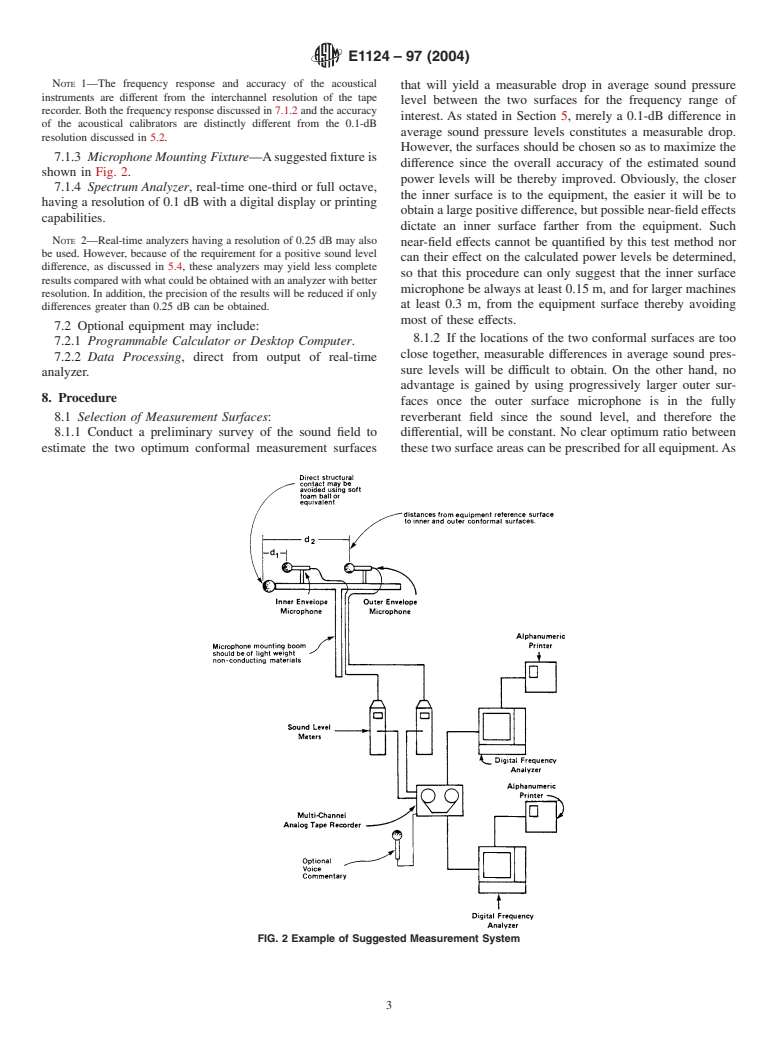

from the equipment. Fig. 1 shows a typical arrangement of

,

56 7

Hubner and Diehl, but differs from all other current sound

these surfaces for a generalized piece of equipment.

power measurement procedures by requiring simultaneous

measurement at both conformal surfaces and by resolving

1

This test method is under the jurisdiction of ASTM Committee E33 on

time-averaged sound pressure levels at both surfaces to within

EnvironmentalAcousticsandisthedirectresponsibilityofSubcommitteeE33.08on

Mechanical and Electrical System Noise.

Current edition approved April 1, 2004. Published April 2004. Originally

approved in 1986. Last previous edition approved in 1997 as E1124–97. DOI:

5

10.1520/E1124-97R04. Hubner,G.,“AnalysisofErrorsinMeasuringMachineNoiseUnderFreeField

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Conditions,” Journal of the Acoustical Society of America,Vol 54, No. 4, 1973, pp.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 967–977.

6

Standards volume information, refer to the standard’s Document Summary page on Hubner, G., “Qualification Procedures for Free Field Conditions for Sound

the ASTM website. Power Determination of Sound Sources and Methods for the Determination of the

3

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., Appropriate Environmental Correction,” Journal of the Acoustical Society of

4th Floor, New York, NY 10036. America, Vol 61, No. 2, 1977, pp. 456–464.

4 7

Terminology C634 – 85 was the edition used during the development of this Diehl, G. M., Machinery Acoustics, J. Wiley and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.