ASTM D6372-05(2010)

(Practice)Standard Practice for Design, Testing, and Construction of Micro-Surfacing

Standard Practice for Design, Testing, and Construction of Micro-Surfacing

SIGNIFICANCE AND USE

This micro-surfacing practice is written as a guide and should not be construed as a specification. End use specifications should be adapted to conform to job and user requirements.

SCOPE

1.1 This practice covers the design, testing, and construction of mixtures of polymer modified asphalt emulsion, mineral aggregate, mineral filler, water, and other additives, properly proportioned, mixed and spread on a paved surface. It is written as a guide and should be used as such. End use specifications should be adapted to conform to job and user requirements.

Note 1—This practice references test methods outside the jurisdiction of ASTM that may or may not have a precision statement.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6372 −05(Reapproved 2010)

Standard Practice for

Design, Testing, and Construction of Micro-Surfacing

This standard is issued under the fixed designation D6372; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ISSA Documents:

ISSATechnicalBulletinNo.100,TestMethodforWetTrack

1.1 Thispracticecoversthedesign,testing,andconstruction

Abrasion of Slurry Surfaces

of mixtures of polymer modified asphalt emulsion, mineral

ISSATechnical Bulletin No. 109,Test Method for Measure-

aggregate, mineral filler, water, and other additives, properly

mentofExcessAsphaltinBituminousMixturesbyUseof

proportioned, mixed and spread on a paved surface. It is

a Loaded Wheel Tester and Sand Adhesion

written as a guide and should be used as such. End use

ISSATechnical Bulletin No. 139, Test Method to Classify

specifications should be adapted to conform to job and user

EmulsifiedAsphalt/Aggregate Mixture Systems by Modi-

requirements.

fied Cohesion Tester, Measurement of Set and Cure

NOTE 1—This practice references test methods outside the jurisdiction 3

Characteristics

of ASTM that may or may not have a precision statement.

ISSAA143 Revised May 2003 Recommended Performance

1.2 The values stated in SI units are to be regarded as the

Guidelines For Micro-Surfacing

standard.

ISSATechnical Bulletin No. 144, Test Method for Classifi-

cation of Aggregate Filler—Bitumen Compatability by

1.3 This standard does not purport to address all of the

Schultze-Breuer and Ruck Procedures

safety concerns, if any, associated with its use. It is the

ISSATechnical Bulletin No. 147, Test Methods for Mea-

responsibility of the user of this standard to establish appro-

surements of Stability and Resistance to Compaction,

priate safety and health practices and determine the applica-

Vertical and Lateral Displacement of Multilayered Fine

bility of regulatory limitations prior to use.

Aggregate Cold Mixes

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions of Terms Specific to This Standard:

C88Test Method for Soundness of Aggregates by Use of

3.1.1 polymer modified emulsified asphalt micro-surfacing

Sodium Sulfate or Magnesium Sulfate

mixtures—asrelatedtothispractice,mixturesoffineaggregate

C131Test Method for Resistance to Degradation of Small-

with mineral filler, mixing water, and field control additive,

Size CoarseAggregate byAbrasion and Impact in the Los

uniformly mixed with polymer modified emulsified asphalt.

Angeles Machine

4. Summary of Practice

D2397Specification for Cationic Emulsified Asphalt

D2419Test Method for Sand Equivalent Value of Soils and

4.1 This practice outlines the basic properties for materials,

Fine Aggregate

mix design procedures, and application techniques for the

D3910Practices for Design, Testing, and Construction of

design and application of micro-surfacing. The mix developed

Slurry Seal

through this practice should be capable of being spread in

E145Specification for Gravity-Convection and Forced-

variable thick cross sections, which after curing and initial

Ventilation Ovens

traffic consolidation, resist compaction through the entire

design tolerance range of bitumen content and variable thick-

nesstobeencountered.Theendproductshouldmaintainahigh

friction surface and variable thick sections throughout its

This practice is under the jurisdiction ofASTM Committee D04 on Road and

Paving Materials and is the direct responsibility of Subcommittee D04.24 on

surface life. The mix should be a quick traffic system and

Bituminous Surface Treatments.

should be able to accept rolling traffic on a 12.7 mm thick

Current edition approved Dec. 1, 2010. Published December 2010. Originally

surface within 1 h after placement in 24°C temperature and

approved in 1999. Last previous edition approved in 1999 as D6372–05. DOI:

50% or less humidity.

10.1520/D6372-05R10.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from International Slurry Surfacing Association, 3 Church Circle,

the ASTM website. PMB 250, Annapolis, MD 21401.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6372−05 (2010)

5. Significance and Use trafficona12.7mmthicksurfacewithin1hafterplacementat

24°Ctemperatureand50%orlesshumidity.Themixtureshall

5.1 This micro-surfacing practice is written as a guide and

conformtooneofthegradationtypeslistedinTable1.TypeII

should not be construed as a specification. End use specifica-

issuitableforurbanandresidentialstreetsandairportrunways.

tions should be adapted to conform to job and user require-

It shall be applied at the minimum rate of 5.4 to 8.1 kg/m .

ments.

Type III is suitable for primary and interstate routes and to fill

wheel ruts. It shall be applied at the rate of 8.1 to 16.2 kg/m .

6. Design

forprimaryandinterstateroutes.Theapplicationforwheelruts

6.1 Aggregates—The aggregate shall be a manufactured

shall be as prescribed in Appendix X1.

crushed stone such as granite, slag, limestone, chat, or other

high quality aggregate or combination thereof. The aggregate

8. Test Procedures For Mix Design of Polymer Modified

shall be totally crushed with 100% of the parent aggregate

Emulsified Asphalt Micro-Surfacing Systems

being larger than the largest stone in the gradation to be used.

8.1 Cohesion Test:

Recommended grading requirements are shown in Table 1.

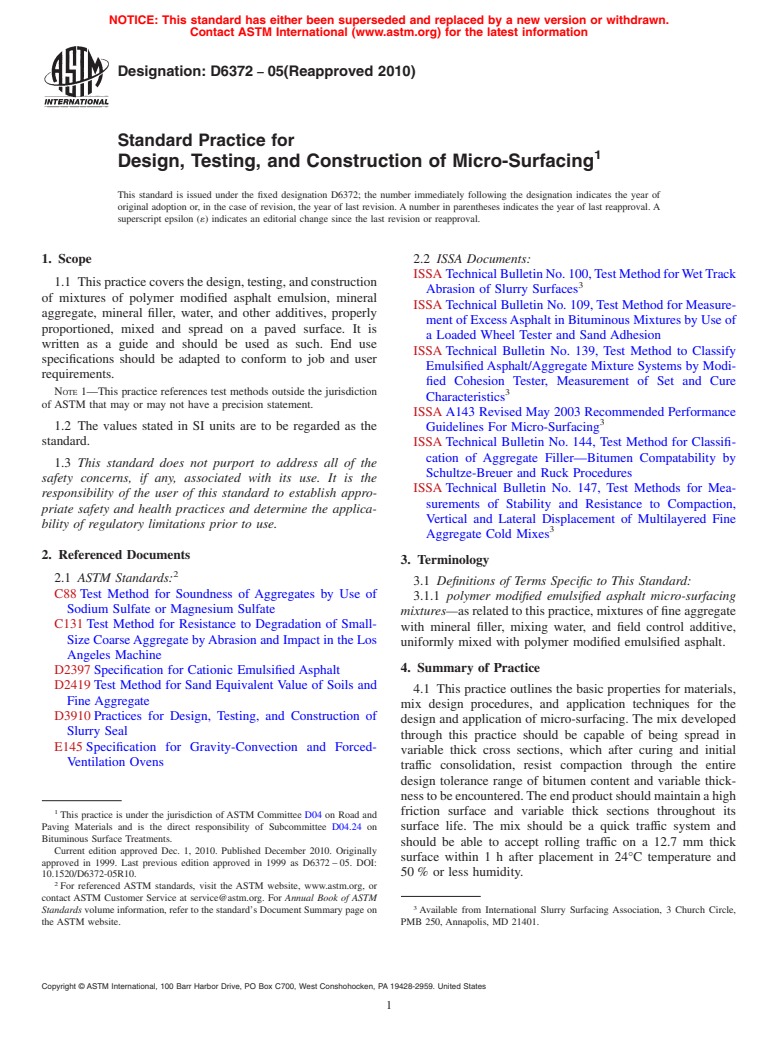

8.1.1 This test procedure is used to determine various set

When tested by Test Method D2419, the combined aggregate

times of the micro surfacing mixture. It measures torque of a

prior to the addition of any chemically active mineral filler

microsurfacing mixture as it coalesces and develops cohesive

shallhaveasandequivalentofnotlessthan65.Whentestedby

strength. The amount of torque developed plotted over time

Test Method C88 the aggregate shall have a weighed average

shows how the mixture is developing resistance to movement.

loss not greater than 15% using sodium sulfate or 25% using

Specific torque and time values are defined as “set time” and

magnesium sulfate. Testing by Test Method C131 shall show

“early rolling traffic time” (see Fig. 1).

an abrasion resistance of 30% maximum.

8.1.2 Set time is defined as the lapsed time after casting a

6.2 Mineral Filler—Mineral filler shall be any recognized

specimen of the microsurfacing mixture that it cannot be

brand of nonairentrained portland cement or hydrated lime.

remixed homogeneously (there is no free emulsion to lubricate

The mineral filler shall be free of lumps and accepted upon

the system) and no lateral displacement is possible when it is

visualinspection.Thetypeandamountofmineralfillerneeded

compacted. It is further defined as the time when there are no

shall be determined by a laboratory mix design and will be

signs of free emulsion when pressed with an absorptive paper

considered as part of the aggregate gradation.

towel and there is no free emulsion diluted and washed away

6.3 Emulsified Asphalt—The emulsified asphalt shall be a when rinsed with water.

8.1.3 Earlyrollingtraffictimeisdefinedasthetimeatwhich

quicksetpolymermodifiedasphaltemulsionconformingtothe

requirements of Specification D2397 for CSS-1h or section the micro-surfacing mixture will accept rolling traffic without

picking or deformation.

377, SSIA. The polymer material shall be milled or blended

into the asphalt or emulsifier solution prior to the emulsifica- 8.1.4 Set times for the micro-surfacing mixture shall be

determined as outlined in 6.3 of Practice D3910.

tion process. The cement mixing test shall be waived for this

emulsion.Thefivedaysettlementtestmaybewaived.Referto

NOTE 2—Referenced ISSATechnical Bulletin No. 139.

ISSA Document A143.

8.2 Wet Track Abrasion Test:

8.2.1 This test procedure is used to determine the minimum

7. Composition of Micro-Surfacing Mixtures

asphalt content and resistance to stripping.

7.1 A job mixture shall be selected that conforms to the

specificationsforaquicktrafficsystem,meaningthatitwillbe

able to accept traffic after a short period of time and is capable

ofbeingspreadinvariablecrosssections,wedges,ruts,scratch

courses, and surfaces and that after curing and initial traffic

consolidation resists compaction throughout the entire design

tolerancerangeofbitumencontentandvariablethicknesstobe

encountered. The mixture should maintain a high friction

surface, and variable thick sections throughout the service life

of the mixture. The mixture shall be able to accept rolling

TABLE 1 Grading Requirements

Type II Percent Type III Percent

Sieve Size Stockpile Tolerance

Passing Passing

9.5 mm 100 100

4.75 mm 90 to 100 70 to 90 ± 5 %

2.36 mm 65 to 90 45 to 70 ± 5 %

1.18 mm 45 to 70 28 to 50 ± 5 %

600 µm 30 to 50 19 to 34 ± 5 %

330 µm 18 to 30 12 to 25 ± 4 %

150 µm 10 to 21 7 to 18 ± 3 %

75 µm 5 to 15 5 to 15 ± 2 % FIG. 1Classification of Mix Systems by Modified Cohesion Test

Curves

D6372−05 (2010)

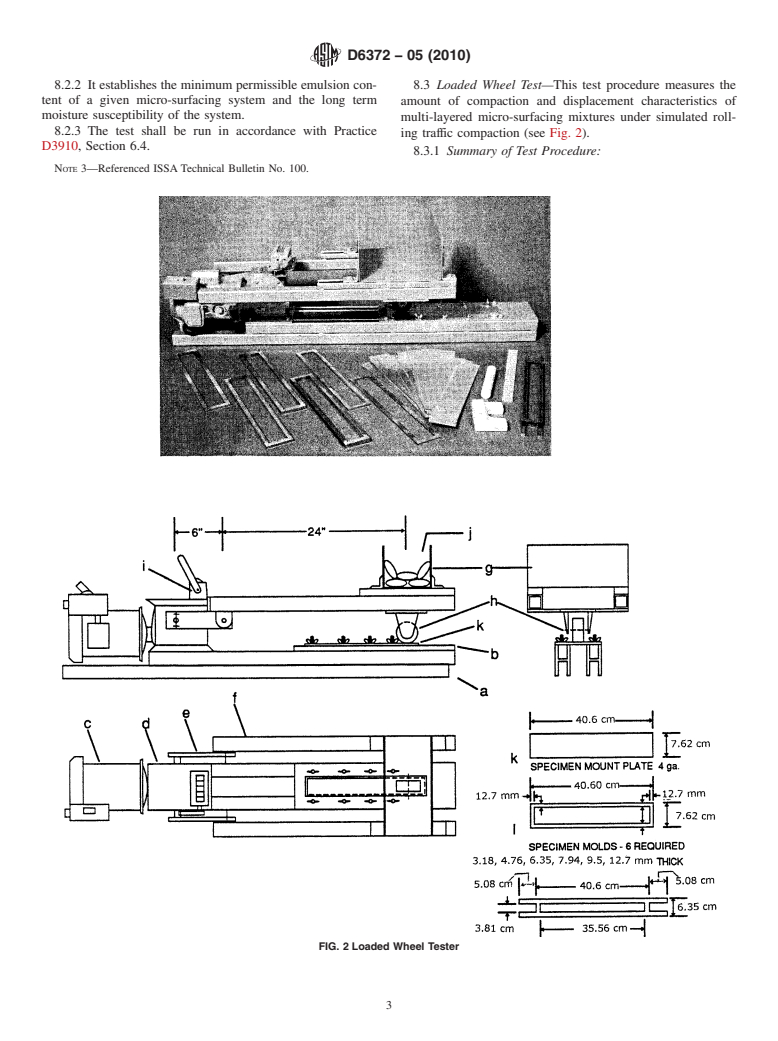

8.2.2 It establishes the minimum permissible emulsion con- 8.3 Loaded Wheel Test—This test procedure measures the

tent of a given micro-surfacing system and the long term amount of compaction and displacement characteristics of

moisture susceptibility of the system.

multi-layered micro-surfacing mixtures under simulated roll-

8.2.3 The test shall be run in accordance with Practice

ing traffic compaction (see Fig. 2).

D3910, Section 6.4.

8.3.1 Summary of Test Procedure:

NOTE 3—Referenced ISSATechnical Bulletin No. 100.

FIG. 2Loaded Wheel Tester

D6372−05 (2010)

8.3.1.1 A 500 g dry aggregate weight mixture is prepared 8.3.3.4 After cooling for2hto room temperature, measure

using 0/#4 or other gradation aggregate and the desired the specimen with the calipers for net lateral thickness.

quantitiesoffillers,wateradditivesandasphaltemulsion.After

8.3.3.5 Then mount the specimen in the loaded wheel tester

30 s of vigorous mixing, the mixture is cast into 12.7 by 50.8

machine and subject it to 1000 cycles of compaction at a

mm by 38.1 cm mold centered over a 0.60 mm mounting plate

temperature of 226 2°C.

and immediately struck-off uniformly with a wooden dowel or

8.3.3.6 Then remove the specimen from the loaded wheel

U shaped wooden screed using a sawing action. The inside

tester machine and immediately remeasure laterally.

surfaces of the mold may be coated with a thin coating of

8.3.3.7 Reference Document ISSA Technical Bulletin No.

petroleum or a mixture of glycerin and talc as a mold release

147.

to prevent sticking.

8.4 Classification Test—This test procedure covers the de-

8.3.1.2 As soon as the mixture is sufficiently set to prevent

termination of the relative compatibility between aggregate

free flow, the mold is carefully removed without disturbing the

filler of specific gradation and emulsified asphalt residue.

specimen. The specimen is air cured for 24 h, then dried to a

8.4.1 Summary of Test Procedure—The test procedure pro-

constant weight in a forced draft oven at 60°C for 18 to 20 h.

vides a rating system or grading values for abrasion loss,

After cooling, the specimen is measured centrally for width

adhesion, and high temperature cohesion characteristics of a

and net thickness. The net weight of the specimen is obtained

specified aggregate-bitumen combination for comparison with

and recorded. The specimen is then mounted in the loaded

test values of referenced combinations.

wheel track machine and subjected to 1000, 56.7 kg cycles of

8.4.2 Apparatus:

compaction. The specimen is then removed and immediately

8.4.2.1 Balance, capable of weighing 1000 g sensitive to

remeasuredlaterallyinthewheelpathandtheresultsrecorded.

0.01 6 0.005 g.

Thelateraldisplacementisexpressedasthepercentincreaseof

8.4.2.2 Oven,forceddraftconstanttemperaturethermostati-

the original width. The specific gravity should be expressed as

callycontrolledat60 63°C.SeeSpecificationE145TypeIIB.

the increase by percent after compaction of the specimen.

8.4.2.3 Suitable Heavy Gage Round Bottom Bowl, to con-

8.3.2 Apparatus:

tain 200 g of mixture.

8.3.2.1 Balance, capable of weighing 2000 g or more to

8.4.2.4 Suitable Mixing Spatula, or long handled metal

within 6 1.0 g.

spoon.

8.3.2.2 Loaded Wheel Tester, (as described in ISSATB109)

8.4.2.5 Metal Pill Mold, consisting of a base, a case 30 mm

consistingofa7.62cmdiametersoftrubberwheelloadedwith

inside diameter by 70 mm height and a 29 mm diameter ram.

56.7 kg which reciprocates through a 30.48 cm horizontal path

8.4.2.6 Constant Force Press,capableofexertingaconstant

at the rate of 44 cycles per minute.

force of 1000 kg.

8.3.2.3 Suitable Heavy Gage Round Bottom Bowl, suitable

8.4.2.7 Shuttle Cylinders,consistingofacrylictubes16mm

to prepare 500 gram mixes.

insidediameterby400mminsidelengthcontaining1100 625

8.3.2.4 Long Handled Steel Spoon, or suitable spatula for

mm.Volume enclosed with water tight metal caps at each end,

mixing of aggregate emulsion mixtures.

one of which is readily removable.

8.3.2.5 Specimen Mounting Plate, (0.60 mm galvanized

8.4.2.8 Abrasion Machine, capable of holding at least two

steel 7.62 by 40.6 cm, deburred).

pairs of shuttle cylinders and rotating them end for end about

8.3.2.6 Specimen Mold, 12.7 mm thick by 76.2 mm × 40.6

a central axis at 20 rpm (see Fig. 3).

cm outside and 50.8 mm by 38.1 cm inside dimensions.

8.4.2.9 Open Top 6 mm Galvanized Hardware Cloth

8.3.2.7 Calipers, capable of measuring specimen width to

Baskets, 50 mm diameter by 50 mm high with suitable means

within 0.01 mm.

for suspension in boiling water.

8.3.2.8 Oven,forceddraftconstanttemperaturethermostati-

8.4.2.10 Hot Plate, capable of heating 500 ml of water to

cally controlled at 60 6 3°C. See specification E145Type IIB.

boiling.

8.3.3 Preparation of Test Specimen:

8.4.2.11 800 ml Metal or Glass Beaker, capable of holding

boiling water.

8.3.3.1 A 500 gram dry weight aggregate mixture is pre-

pared using the 4.75 mm and smaller fractions, the desired

8.4.3 Preparation of Test Specimen:

quantities of fillers, water additives, and asphalt emulsion.

8.4.3.1 The aggregate to be used shall be dry sieved and

8.3.3.2 After 30 s of vigorous mixing, cast the mixture into regraded as prescribed (see Table 2).

the mold, centered over the 0.60 mm mounting plate and

8.4.3.2 Weigh into the mixing bowl 200 g of the prepared

immediately struck-off uniformly with a wooden dowel or U aggregate,2gT

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.