ASTM A996/A996M-16

(Specification)Standard Specification for Rail-Steel and Axle-Steel Deformed Bars for Concrete Reinforcement

Standard Specification for Rail-Steel and Axle-Steel Deformed Bars for Concrete Reinforcement

ABSTRACT

This specification covers rail-steel and axle-steel deformed bars for concrete reinforcement. The standard sizes and dimensions of deformed bars and their number designation are presented. The carbon determination, deformation requirements and deformation measurement are provided. The material shall conform to the requirements prescribed by the specification. The yield point or yield strength shall be determined by either drop of the beam or halt in the gage of the testing machine, or by extension under load using an autographic diagram method. For all bar sizes a tension test, a bend test and a set of dimensional property tests including bar weight and spacing, height, and gap of deformations shall be made from each lot of 10 tons.

SCOPE

1.1 This specification covers rail-steel and axle-steel bars for concrete reinforcement. Three types of product are included, designated with a “rail symbol,” and an “R” for bars made of rail-steel and with an “A” for bars made of axle-steel. The standard sizes and dimensions of deformed bars and their number designations are given in Table 1. All sizes and grades of all types may not be readily available; manufacturers should be consulted to verify availability. (A) The nominal dimensions of a deformed bar are equivalent to those of a plain round bar having the same weight [mass] per foot [metre] as the deformed bar.(B) 9 [29] – 11 [36] axle-steel bars only.

1.2 The text of this specification references notes and footnotes that provide explanatory material. These notes and footnotes, excluding those in tables and figures, shall not be considered as requirements of the specification.

1.3 Type “rail symbol” and Type R are of two minimum yield strength levels, namely 50 000 psi [350 MPa] and 60 000 psi [420 MPa] designated as Grade 50 [350] and Grade 60 [420], respectively. Type A is of two minimum yield levels, namely 40 000 psi [280 MPa] and 60 000 psi [420 MPa] designated as Grade 40 [280] and Grade 60 [420], respectively.

1.4 The weldability of the steel is not a requirement of this specification.

1.5 This specification is applicable for orders in either inch-pound units (Specification A996) or SI units (Specification A996M).

1.6 The values stated in either inch-pound units or SI units are to be regarded as standard. Within the text, the SI units are shown in brackets. The values stated must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A996/A996M −16

Standard Specification for

Rail-Steel and Axle-Steel Deformed Bars for Concrete

1

Reinforcement

This standard is issued under the fixed designationA996/A996M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This specification covers rail-steel and axle-steel bars 2.1 ASTM Standards:

for concrete reinforcement. Three types of product are A370 Test Methods and Definitions for Mechanical Testing

included, designated with a “rail symbol,” and an “R” for bars of Steel Products

made of rail-steel and with an “A” for bars made of axle-steel. A700 Guide for Packaging, Marking, and Loading Methods

The standard sizes and dimensions of deformed bars and their for Steel Products for Shipment

number designations are given in Table 1.All sizes and grades A751 Test Methods, Practices, and Terminology for Chemi-

of all types may not be readily available; manufacturers should cal Analysis of Steel Products

be consulted to verify availability. E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

1.2 The text of this specification references notes and

E290 Test Methods for Bend Testing of Material for Ductil-

footnotes that provide explanatory material. These notes and

ity

footnotes, excluding those in tables and figures, shall not be

3

2.2 Military Standard:

considered as requirements of the specification.

MIL-STD-129 Marking for Shipment and Storage

1.3 Type “rail symbol” and Type R are of two minimum

3

2.3 Federal Standard:

yield strength levels, namely 50 000 psi [350 MPa] and 60 000

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

psi [420 MPa] designated as Grade 50 [350] and Grade 60

[420], respectively. Type A is of two minimum yield levels,

3. Terminology

namely 40 000 psi [280 MPa] and 60 000 psi [420 MPa]

3.1 Definitions of Terms Specific to This Specification:

designated as Grade 40 [280] and Grade 60 [420], respectively.

3.1.1 deformations, n—transverse protrusions on a de-

1.4 The weldability of the steel is not a requirement of this

formed bar.

specification.

3.1.2 deformed bar, n—steelbarwithtransverseprotrusions;

1.5 This specification is applicable for orders in either

a bar that is intended for use as reinforcement in reinforced

inch-pound units (Specification A996) or SI units (Specifica-

concrete construction.

tion A996M).

3.1.2.1 Discussion—The surface of the bar is provided with

1.6 The values stated in either inch-pound units or SI units protrusions that inhibit longitudinal movement of the bar

relative to the concrete surrounding the bar in such construc-

are to be regarded as standard. Within the text, the SI units are

shown in brackets. The values stated must be used indepen- tion. The protrusions conform to the provisions of this speci-

fication.

dently of the other. Combining values from the two systems

may result in nonconformance with the specification.

3.1.3 rib, n—longitudinal protrusion on a deformed bar.

1.7 This standard does not purport to address all of the

4. Ordering Information

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.1 Orders for rail-steel or axle-steel reinforcing bars under

priate safety and health practices and determine the applica-

this specification shall contain the following information:

bility of regulatory limitations prior to use.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee Standards volume information, refer to the standard’s Document Summary page on

A01.05 on Steel Reinforcement. the ASTM website.

3

Current edition approved Jan. 15, 2016. Published March 2016. Originally Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

approved in 1998. Last previous edition approved in 2015 as A996/A996M – 15. Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

DOI: 10.1520/A0996_A0996M-16. www.dodssp.daps.mil.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ------------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A996/A996M − 15 A996/A996M − 16

Standard Specification for

Rail-Steel and Axle-Steel Deformed Bars for Concrete

1

Reinforcement

This standard is issued under the fixed designation A996/A996M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers rail-steel and axle-steel bars for concrete reinforcement. Three types of product are included,

designated with a “rail symbol,” and an “R” for bars made of rail-steel and with an “A” for bars made of axle-steel. The standard

sizes and dimensions of deformed bars and their number designations are given in Table 1. All sizes and grades of all types may

not be readily available; manufacturers should be consulted to verify availability.

1.2 The text of this specification references notes and footnotes that provide explanatory material. These notes and footnotes,

excluding those in tables and figures, shall not be considered as requirements of the specification.

1.3 Type “rail symbol” and Type R are of two minimum yield strength levels, namely 50 000 psi [350 MPa] and 60 000 psi

[420 MPa] designated as Grade 50 [350] and Grade 60 [420], respectively. Type A is of two minimum yield levels, namely 40 000

psi [280 MPa] and 60 000 psi [420 MPa] designated as Grade 40 [280] and Grade 60 [420], respectively.

1.4 The weldability of the steel is not a requirement of this specification.

1.5 This specification is applicable for orders in either inch-pound units (Specification A996) or SI units (Specification A996M).

1.6 The values stated in either inch-pound units or SI units are to be regarded as standard. Within the text, the SI units are shown

in brackets. The values stated must be used independently of the other. Combining values from the two systems may result in

nonconformance with the specification.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A700 Guide for Packaging, Marking, and Loading Methods for Steel Products for Shipment

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E290 Test Methods for Bend Testing of Material for Ductility

3

2.2 Military Standard:

MIL-STD-129 Marking for Shipment and Storage

3

2.3 Federal Standard:

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

3. Terminology

3.1 Definitions of Terms Specific to This Specification:

3.1.1 deformations, n—transverse protrusions on a deformed bar.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.05

on Steel Reinforcement.

Current edition approved July 1, 2015Jan. 15, 2016. Published August 2015March 2016. Originally approved in 1998. Last previous edition approved in 20142015 as

A996/A996M – 14a.A996/A996M – 15. DOI: 10.1520/A0996_A0996M-15.10.1520/A0996_A0996M-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://www.dodssp.daps.mil.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A996/A996M − 16

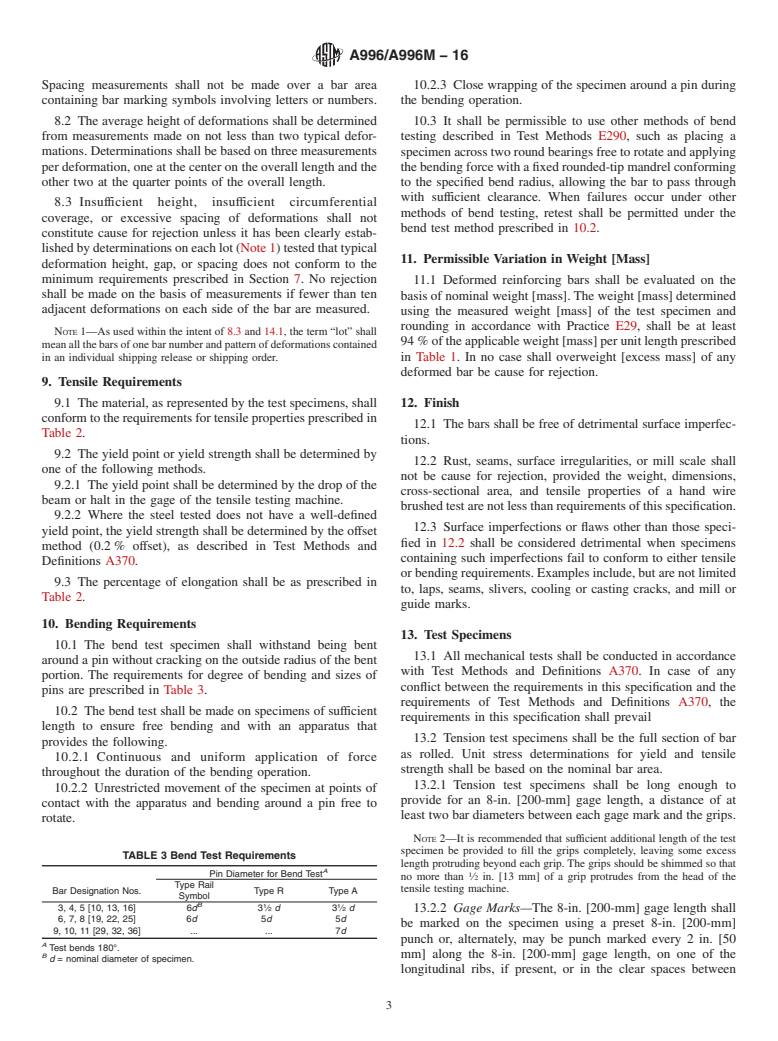

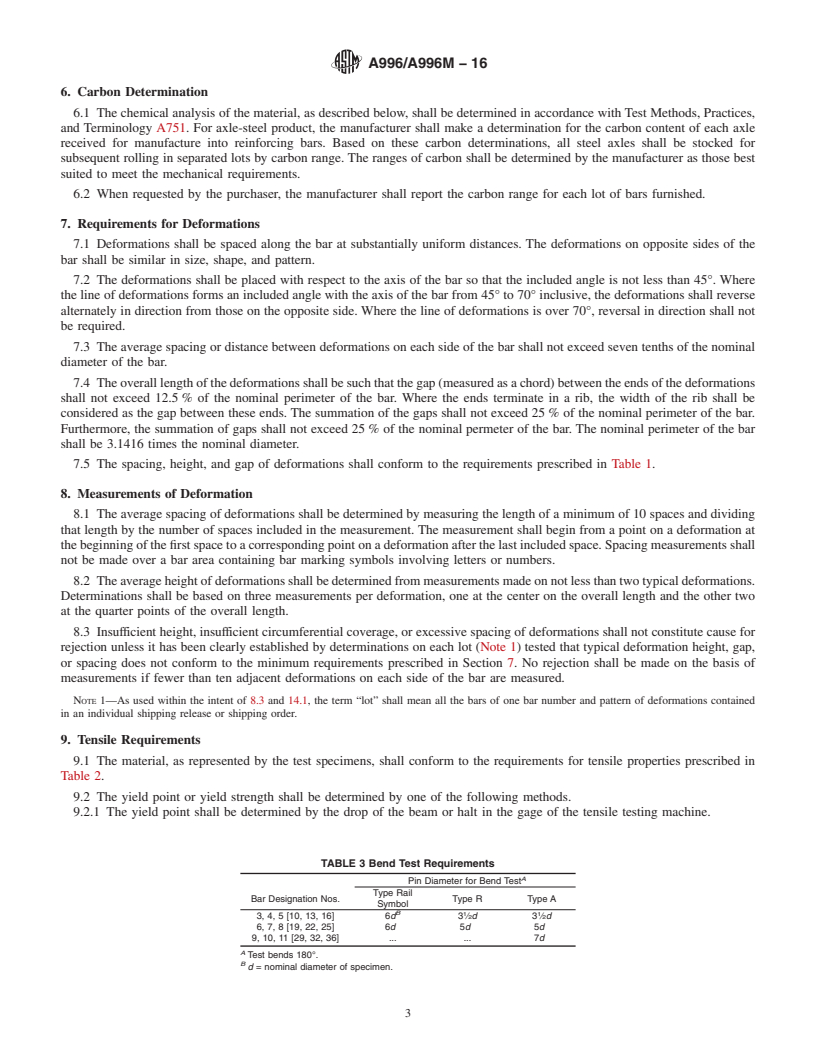

TABLE 1 Deformed Bar Designation Numbers, Nominal Weights [Masses], Nominal Dimensions, and Deformation Requirements

A

Nominal Nominal Dimensions Deformation Requirements, in. [mm]

Weight,

Maximum

Bar Cross-

lb/ft Maximum Minimum Gap (Chord

Designation Diameter, Sectional Perimeter,

[Nominal Average Average of 12.5 % of

B

No. in. [mm] Area in. [mm]

Mass, Spacing Height Nominal

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.