ASTM A135/A135M-06

(Specification)Standard Specification for Electric-Resistance-Welded Steel Pipe

Standard Specification for Electric-Resistance-Welded Steel Pipe

ABSTRACT

This specification covers two grades of electric-resistance-welded steel pipe intended for conveying gas, vapor, water or other liquid. The steel shall be made by either or both basic-oxygen or electric-furnace processes. Steel may be cast in ingots or may be strand cast. The pipe shall be manufactured from flat rolled steel in individual lengths or continuous length by electric-resistance or electric-induction welding without the addition of extraneous material. The weld seam of electric-resistance welded pipe to Grade B pipe shall be heat treated after welding or processed in such a manner that no untempered martensite remains. Tensile and chemical requirements of the steel are provided. Specimens of the steel pipes are subject to flattening test and hydrostatic test. A nondestructive electric test, either electromagnetic (eddy current) or ultrasonic test, may be preferred as an alternate to the hydrostatic test.

SCOPE

1.1 This specification covers two grades of electric-resistance-welded steel pipe in NPS 2 to NPS 30 [DN 50 to DN 750] inclusive, with nominal (average) wall thickness up to 0.500 in. [12.70 mm], inclusive, and in nominal sizes NPS 3/ 4 to NPS 5 [DN 20 to DN 125] inclusive with nominal (average) wall thickness 0.083 in. [2.11 mm] to 0.134 in. [3.40 mm], depending on size. Pipe having other dimensions (Note 0) may be furnished provided such pipe complies with all other requirements of this specification. The pipe is intended for conveying gas, vapor, water or other liquid; only Grade A is adapted for flanging and bending (Note 0). The suitability of pipe for various purposes is somewhat dependent upon its dimensions, properties, and conditions of service, so that the purpose for which the pipe is intended should be stated in the order. The pipe may be furnished either nonexpanded or cold expanded at the option of the manufacturer. When pipe is cold expanded, the amount of expansion shall not exceed 1.5 % of the outside diameter pipe size. Note 0A comprehensive listing of standardized pipe dimensions is contained in ASME B36.10M. Note 0

This provision is not intended to prohibit the cold bending of Grade B pipe.

1.2 The values stated in either SI or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system is to be used independently of the other.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A135/A135M – 06

Standard Specification for

1

Electric-Resistance-Welded Steel Pipe

This standard is issued under the fixed designationA135/A135M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* A370 Test Methods and Definitions for Mechanical Testing

2 of Steel Products

1.1 This specification covers two grades of electric-

A700 PracticesforPackaging,Marking,andLoadingMeth-

resistance-weldedsteelpipeinNPS2toNPS30[DN50toDN

ods for Steel Products for Shipment

750] inclusive, with nominal (average) wall thickness up to

3 A751 Test Methods, Practices, andTerminology for Chemi-

0.500 in. [12.70 mm], inclusive, and in nominal sizes NPS ⁄4

cal Analysis of Steel Products

toNPS5[DN20toDN125]inclusivewithnominal(average)

A865 Specification for Threaded Couplings, Steel, Black or

wall thickness 0.083 in. [2.11 mm] to 0.134 in. [3.40 mm],

Zinc-Coated (Galvanized) Welded or Seamless, for Use in

depending on size. Pipe having other dimensions (Note 1) may

Steel Pipe Joints

be furnished provided such pipe complies with all other

A941 Terminology Relating to Steel, Stainless Steel, Re-

requirements of this specification. The pipe is intended for

lated Alloys, and Ferroalloys

conveying gas, vapor, water or other liquid; only Grade A is

E6 TerminologyRelatingtoMethodsofMechanicalTesting

adapted for flanging and bending (Note 2). The suitability of

E29 Practice for Using Significant Digits in Test Data to

pipe for various purposes is somewhat dependent upon its

Determine Conformance with Specifications

dimensions, properties, and conditions of service, so that the

E213 Practice for Ultrasonic Testing of Metal Pipe and

purpose for which the pipe is intended should be stated in the

Tubing

order. The pipe may be furnished either nonexpanded or cold

E273 Practice for Ultrasonic Examination of theWeld Zone

expanded at the option of the manufacturer. When pipe is cold

of Welded Pipe and Tubing

expanded, the amount of expansion shall not exceed 1.5 % of

E309 Practice for Eddy-Current Examination of Steel Tu-

the outside diameter pipe size.

bular Products Using Magnetic Saturation

NOTE 1—A comprehensive listing of standardized pipe dimensions is

E1806 Practice for Sampling Steel and Iron for Determina-

contained in ASME B36.10M.

tion of Chemical Composition

NOTE 2—This provision is not intended to prohibit the cold bending of

2.2 ASME Standard:

Grade B pipe.

4

B1.20.1 Pipe Threads, General Purpose

1.2 The values stated in either SI or inch-pound units are to ,

4 5

B36.10M Welded and Seamless Wrought Steel Pipe

be regarded separately as standard. The values stated in each

2.3 Federal Standards:

system may not be exact equivalents; therefore, each system is

6

Fed.STDNo.123 MarkingforShipments(CivilAgencies)

to be used independently of the other.

Fed. STD No. 183 Continuous Identification Marking of

6

Iron and Steel Products

2. Referenced Documents

2.4 Military Standards:

3

2.1 ASTM Standards:

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

A01.09 on Carbon Steel Tubular Products.

Current edition approved March 1, 2006. Published April 2006. Originally

approved in 1931. Last previous edition approved in 2005 as A135 – 05. DOI:

10.1520/A0135_A0135M-06.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

4

cation SA-135 in Section II of that Code. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 4th Floor, New York, NY 10036.

5

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Society of Mechanical Engineers (ASME), ASME

Standards volume information, refer to the standard’s Document Summary page on International Headquarters, Three Park Ave., New York, NY 10016-5990.

6

the ASTM website. Available from General Service Administration, Washington, DC 20405.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

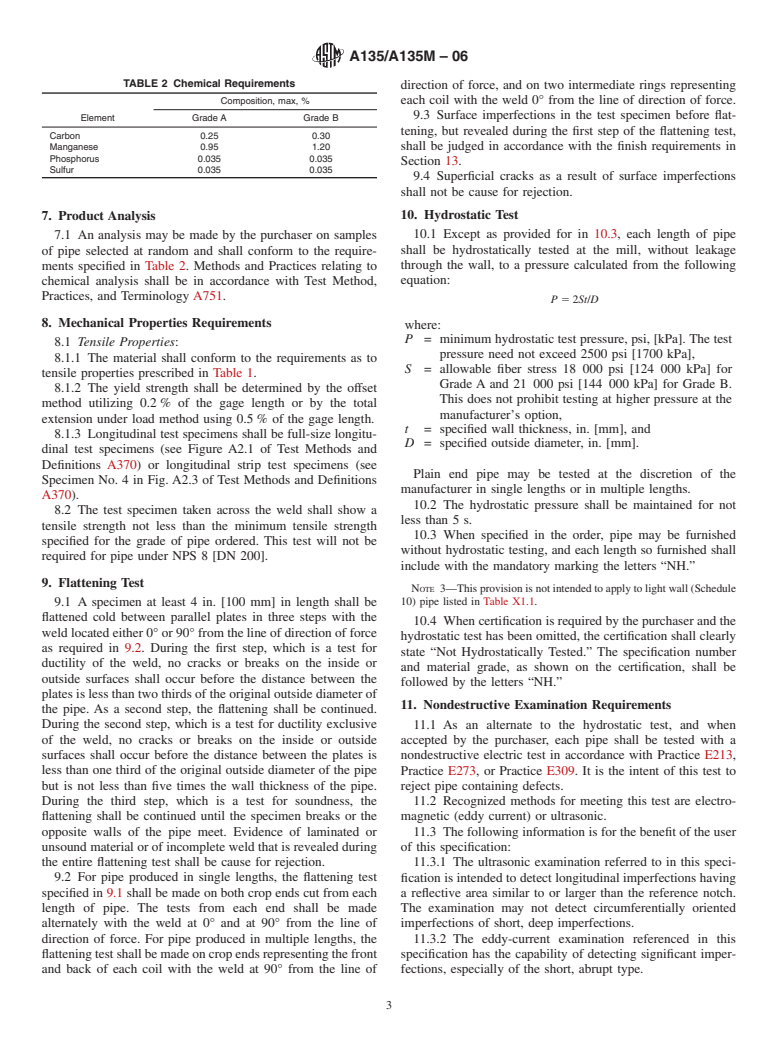

A135/A135M – 06

7

MIL-STD-129 Marking for Shipment and Storage 4.1.7.2 Threads only, if specified,

MIL-STD-163 Steel Mill Products, Preparation for Ship-

4.1.7.3 Plain end, if specified,

7

ment and Storage

4.1.8 Alternative electric test (see Section 11),

4.1.9 Ten

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.