ASTM C716-06(2015)

(Specification)Standard Specification for Installing Lock-Strip Gaskets and Infill Glazing Materials

Standard Specification for Installing Lock-Strip Gaskets and Infill Glazing Materials

ABSTRACT

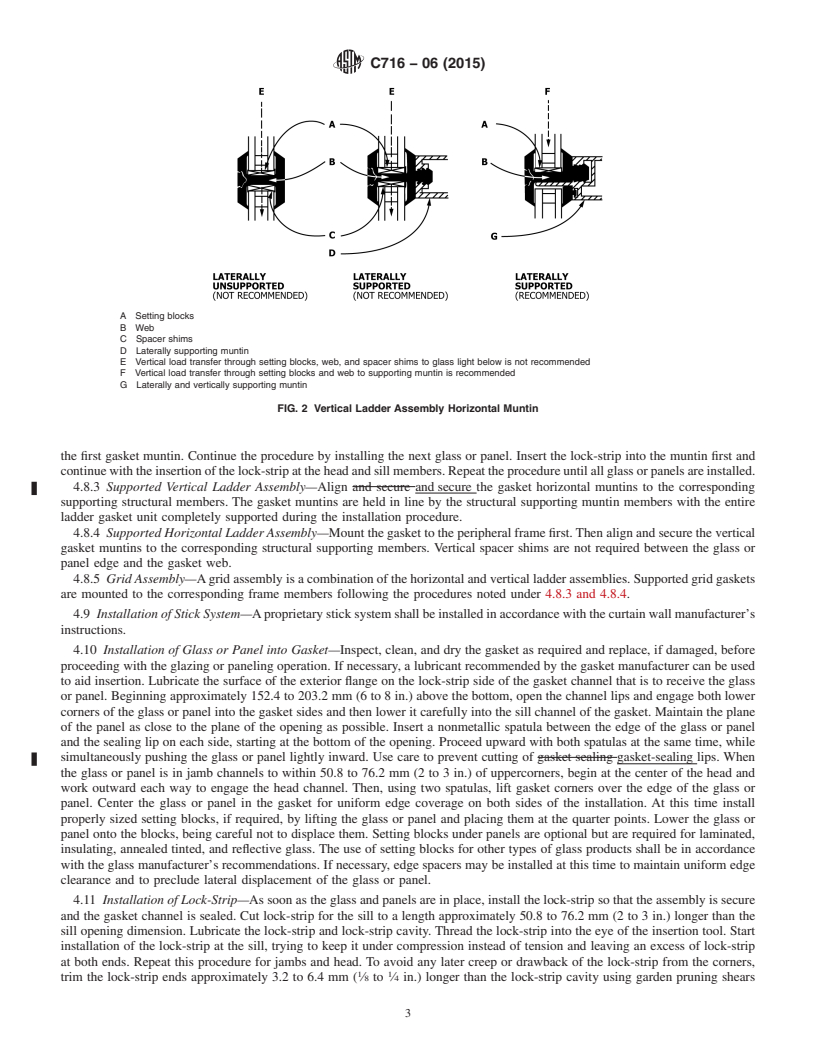

This specification covers installation procedures for lock-strip gaskets and for infill glazing materials in lock-strip gasket glazing applications used in building walls. The prime performance considerations are weathertightness against air and water infiltration, and structural integrity under wind loads. H-type gasket and reglet-type gasket are types of single-opening gasket systems which should be installed according to the specified requirements. Installation of multiple-opening gasket systems shall be classified as: unsupported vertical ladder assembly; unsupported horizontal ladder assembly; supported vertical ladder assembly; supported horizontal ladder assembly; and grid assembly. Installation of stick system, glass or panel into gasket, and lock-strip shall be in accordance with the requirements specified.

SIGNIFICANCE AND USE

3.1 This specification can be referred to in contract documents as a method and workmanship standard for the installation of lock-strip gasket glazing systems. See also related standards (Specifications C542 and C963, Guide C964, and Terminology C717).

SCOPE

1.1 This specification covers installation procedures for lock-strip gaskets that comply with Specification C542 and for infill glazing materials in lockstrip gasket glazing applications used in building walls which are not more than 15° from a vertical plane. The prime performance considerations are weathertightness against air and water infiltration, and structural integrity under wind loads.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are provided for information only.

1.3 The committee with jurisdiction over this standard is not aware of any comparable standards published by other organizations.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C716 −06 (Reapproved 2015)

Standard Specification for

Installing Lock-Strip Gaskets and Infill Glazing Materials

This standard is issued under the fixed designation C716; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope are within specified dimensional tolerances and not out-of-

squareorplane,andcheckallgasketsfortype,dimensions,and

1.1 This specification covers installation procedures for

defects such as misalignment at molded corners and damaged

lock-strip gaskets that comply with Specification C542 and for

lips. Installation shall not proceed until corrections have been

infill glazing materials in lockstrip gasket glazing applications

made.

used in building walls which are not more than 15° from a

vertical plane. The prime performance considerations are 4.2 Environmental Conditions—Maximum efficiency and

weathertightness against air and water infiltration, and struc- sealing capability of gaskets is achieved in a clean, dry, warm

tural integrity under wind loads. environment, with the gasket kept resilient during the entire

installation process. During cold weather the use of temporary

1.2 The values stated in SI units are to be regarded as

enclosures around the units to be glazed or paneled will

standard. The values given in parentheses are provided for

facilitate temperature control and also aid in keeping open

information only.

gasket channels clean and dry.

1.3 The committee with jurisdiction over this standard is not

4.3 Preparation and Conditioning of Gaskets—Lock-strip

aware of any comparable standards published by other orga-

gaskets require conditioning prior to installation in order to

nizations.

restore maximum resiliency and remove deformations after

prolonged storage in a coiled or stressed position. Gaskets shall

2. Referenced Documents

be unpacked from their containers and conditioned for 24 h in

2.1 ASTM Standards:

a temperature not lower than 21.1°C (70°F) by being placed

C542 Specification for Lock-Strip Gaskets

flat or hung on racks to permit recovery of their original

C717 Terminology of Building Seals and Sealants

shapes. Racks shall be free of rough surfaces, projections,

C963 Specification for Packaging, Identification, Shipment,

sharp edges, and other conditions that could damage the

and Storage of Lock-Strip Gaskets

gaskets. When the ambient temperature is 10°C (50°F) or

C964 Guide for Lock-Strip Gasket Glazing

below and a heated space is not available, gaskets shall be

heated by other means to remove deformations and provide a

3. Significance and Use

high degree of flexibility and resiliency. This may be done by

3.1 This specification can be referred to in contract docu-

warming them in hot water or heated containers. Gaskets shall

ments as a method and workmanship standard for the installa-

not be heated by being draped over heated units or placed in

tion of lock-strip gasket glazing systems. See also related

direct contact with a flame or fired heating device. The

standards (Specifications C542 and C963, Guide C964, and

installation of glass, panel, and lock-strip shall be completed

Terminology C717).

while the gasket is still warm and pliable and with the gasket

channels clean and dry.

4. Installation

4.4 Use of Tools—To minimize the possibility of damage,

4.1 Inspection of Components—Before installing gaskets,

sharp or pointed tools or implements such as screwdrivers or

the installer shall check the mounting frames to see that they

putty knives shall not be used on lock-strip gaskets. Suitable

gasket installation tools, such as nonmetallic spatulas and

engineered lock-strip insertion devices, are available from the

This specification is under the jurisdiction of ASTM Committee C24 on

Building Seals and Sealantsand is the direct responsibility of Subcommittee C24.73 gasket manufacturer.

on Compression Seal and Lock Strip Gaskets.

4.5 Use of Lubricants—If necessary a lubricant may be

Current edition approved Dec. 1, 2015. Published December 2015. Originally

applied to the contact surfaces of the gasket to ease the

approved in 1973. Last previous edition approved in 2011 as C716 – 06 (2011).

DOI: 10.1520/C0716-06R15.

installation and help prevent damage to the gasket, glass, or

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

panel. The lubricant shall be nonstaining, nontoxic,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

noncorrosive, chemically stable, compatible with all contact

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. components, easily removable from exposed surfaces by dry

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C716−06 (2015)

wiping or with water, and acceptable to the manufacturer of the

supporting frame, panel, and gasket.

4.6 UseofSupplementaryWetSealants—The use of supple-

mentary wet sealants in conjunction with lock-strip gasket

installations is only required under certain conditions. Such a

condition would occur when the outer lip of the gasket extends

over a butt joint in the supporting frame. The void formed

between the gasket and frame shall be sealed at the time of

installation with a wet sealant. However, the sealant may be

omitted if the system is designed to drain any water that enters

to the exterior, and the omission of a wet sealant is agreeable

to the purchaser and seller.Another condition would be at field

butt joints in gaskets. Such joints require the use of a sealant

FIG. 1 Gasket Systems

installed in, rather than on top of, the joint at the time of the

gasket installation. The wet sealant used, as well as the sealant

manufacturer’s requirements for cleaning and priming the

center line of the vertical gasket muntin. Install the jamb

surfaces to be sealed, shall be compatible with the components

section first, then work along the head and sill to the first

in contact with it and acceptable to the manufacturers of the

muntin.Align each gasket muntin with the center lines marked

components. The use of wet sealants to remedy a defective or

on the head and sill. Install the glass or panel. The installation

damaged gasket or improperly fabricated supporting frame

of setting blocks and edge spacers can be performed as

shall not be permitted, unless agreeable to the purchaser and

described in 4.10.Then insert the lock-strip at the sill and head,

seller.

running to within a few inches of the first gasket muntin.

4.7 Installation of Single-Opening Gasket Systems:

Continue the procedure by installing the next glass or panel.

4.7.1 H-Type Gasket—Install the upper gasket corners first,

Insert the lock-strip into the muntin first and continue with the

and then install the lower gasket corners onto the supporting

insertion of the lock-strip at the head and sill members. Repeat

frame. To avoid slippage, engage both horizontal and vertical

the procedure until all glass or panels are installed.

members for about 304.8 mm (1 ft) in both directions from the

4.8.3 Supported Vertical Ladder Assembly—Align and se-

corners, and work the gasket until the web is snug against head

cure the gasket horizontal muntins to the corresponding sup-

and jambs and the corners are square.Then work the remainder

porting structural members.The gasket muntins are held in line

of the gasket onto the supporting frame by starting from each

by the structural supporting muntin

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C716 − 06 (Reapproved 2011) C716 − 06 (Reapproved 2015)

Standard Specification for

Installing Lock-Strip Gaskets and Infill Glazing Materials

This standard is issued under the fixed designation C716; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers installation procedures for lock-strip gaskets that comply with Specification C542 and for infill

glazing materials in lockstrip gasket glazing applications used in building walls which are not more than 15° from a vertical plane.

The prime performance considerations are weathertightness against air and water infiltration, and structural integrity under wind

loads.

1.2 The values stated in inch-poundSI units are to be regarded as the standard. The SI unitsvalues given in parentheses are

provided for information only.

1.3 The committee with jurisdiction over this standard is not aware of any comparable standards published by other

organizations.

2. Referenced Documents

2.1 ASTM Standards:

C542 Specification for Lock-Strip Gaskets

C717 Terminology of Building Seals and Sealants

C963 Specification for Packaging, Identification, Shipment, and Storage of Lock-Strip Gaskets

C964 Guide for Lock-Strip Gasket Glazing

3. Significance and Use

3.1 This specification can be referred to in contract documents as a method and workmanship standard for the installation of

lock-strip gasket glazing systems. See also related standards (Specifications C542 and C963, Guide C964, and Terminology C717).

4. Installation

4.1 Inspection of Components—Before installing gaskets, the installer shall check the mounting frames to see that they are

within specified dimensional tolerances and not out-of-square or plane, and check all gaskets for type, dimensions, and defects such

as misalignment at molded corners and damaged lips. Installation shall not proceed until corrections have been made.

4.2 Environmental Conditions—Maximum efficiency and sealing capability of gaskets is achieved in a clean, dry, warm

environment, with the gasket kept resilient during the entire installation process. During cold weather the use of temporary

enclosures around the units to be glazed or paneled will facilitate temperature control and also aid in keeping open gasket channels

clean and dry.

4.3 Preparation and Conditioning of Gaskets—Lock-strip gaskets require conditioning prior to installation in order to restore

maximum resiliency and remove deformations after prolonged storage in a coiled or stressed position. Gaskets shall be unpacked

from their containers and conditioned for 24 h in a temperature not lower than 21.1°C (70°F) by being placed flat or hung on racks

to permit recovery of their original shapes. Racks shall be free of rough surfaces, projections, sharp edges, and other conditions

that could damage the gaskets. When the ambient temperature is 10°C (50°F) or below and a heated space is not available, gaskets

shall be heated by other means to remove deformations and provide a high degree of flexibility and resiliency. This may be done

by warming them in hot water or heated containers. Gaskets shall not be heated by being draped over heated units or placed in

This specification is under the jurisdiction of ASTM Committee C24 on Building Seals and Sealantsand is the direct responsibility of Subcommittee C24.73 on

Compression Seal and Lock Strip Gaskets.

Current edition approved June 1, 2011Dec. 1, 2015. Published August 2011December 2015. Originally approved in 1973. Last previous edition approved in 20062011

as C716 – 06.C716 – 06 (2011). DOI: 10.1520/C0716-06R11.10.1520/C0716-06R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C716 − 06 (2015)

direct contact with a flame or fired heating device. The installation of glass, panel, and lock-strip shall be completed while the

gasket is still warm and pliable and with the gasket channels clean and dry.

4.4 Use of Tools—To minimize the possibility of damage, sharp or pointed tools or implements such as screwdrivers or putty

knives shall not be used on lock-strip gaskets. Suitable gasket installation tools, such as nonmetallic spatulas and engineered

lock-strip insertion devices, are available from the gasket manufacturer.

4.5 Use of Lubricants—If necessary a lubricant may be applied to the contact surfaces of the gasket to ease the installation and

help prevent damage to the gasket, glass, or panel. The lubricant shall be nonstaining, nontoxic, noncorrosive, chemically stable,

compatible with all contact components, easily removable from exposed surfaces by dry wiping or with water, and acceptable to

the manufacturer of the supporting frame, panel, and gasket.

4.6 Use of Supplementary Wet Sealants—The use of supplementary wet sealants in conjunction with lock-strip gasket

installations is only required under certain conditions. Such a condition would occur when the outer lip of the gasket extends over

a butt joint in the supporting frame. The void formed between the gasket and frame shall be sealed at the time of installation with

a wet sealant. However, the sealant may be omitted if the system is designed to drain any water that enters to the exterior, and the

omission of a wet sealant is agreeable to the purchaser and seller. Another condition would be at field butt joints in gaskets. Such

joints require the use of a sealant installed in, rather than on top of, the joint at the time of the gasket installation. The wet sealant

used, as well as the sealant manufacturer’s requirements for cleaning and priming the surfaces to be sealed, shall be compatible

with the components in contact with it and acceptable to the manufacturers of the components. The use of wet sealants to remedy

a defective or damaged gasket or improperly fabricated supporting frame shall not be permitted, unless agreeable to the purchaser

and seller.

4.7 Installation of Single-Opening Gasket Systems:

4.7.1 H-Type Gasket—Install the upper gasket corners first, and then install the lower gasket corners onto the supporting frame.

To avoid slippage, engage both horizontal and vertical members for about 304.8 mm (1 ft) in both directions from the corners, and

work the gasket until the web is snug against head and jambs and the corners are square. Then work the remainder of the gasket

onto the supporting frame by starting from each corner and working towards the center of each side, making sure the gasket web

is firmly seated against the frame and that the sealing lips are not curled under, particularly at the corners. Pull each corner of outer

flange about 6.4 mm ( ⁄4 in.) away from the supporting frame with thumb or nonmetallic spatula and then release to ensure

uncurling any corner lips hidden from view.

4.7.2 Reglet-Type Gasket—Insert the upper gasket corners first, and then install the lower gasket corners into the groove or reglet

of the supporting frame, seating them firmly with a resiliently faced hammer and a wooden or metal block having smooth, rounded

edges and corners. Then, on each side, insert the gasket into the groove at the center of each side working from t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.