ASTM C876-91(1999)

(Test Method)Standard Test Method for Half-Cell Potentials of Uncoated Reinforcing Steel in Concrete (Withdrawn 2008)

Standard Test Method for Half-Cell Potentials of Uncoated Reinforcing Steel in Concrete (Withdrawn 2008)

SCOPE

1.1 This test method covers the estimation of the electrical half-cell potential of uncoated reinforcing steel in field and laboratory concrete, for the purpose of determining the corrosion activity of the reinforcing steel.

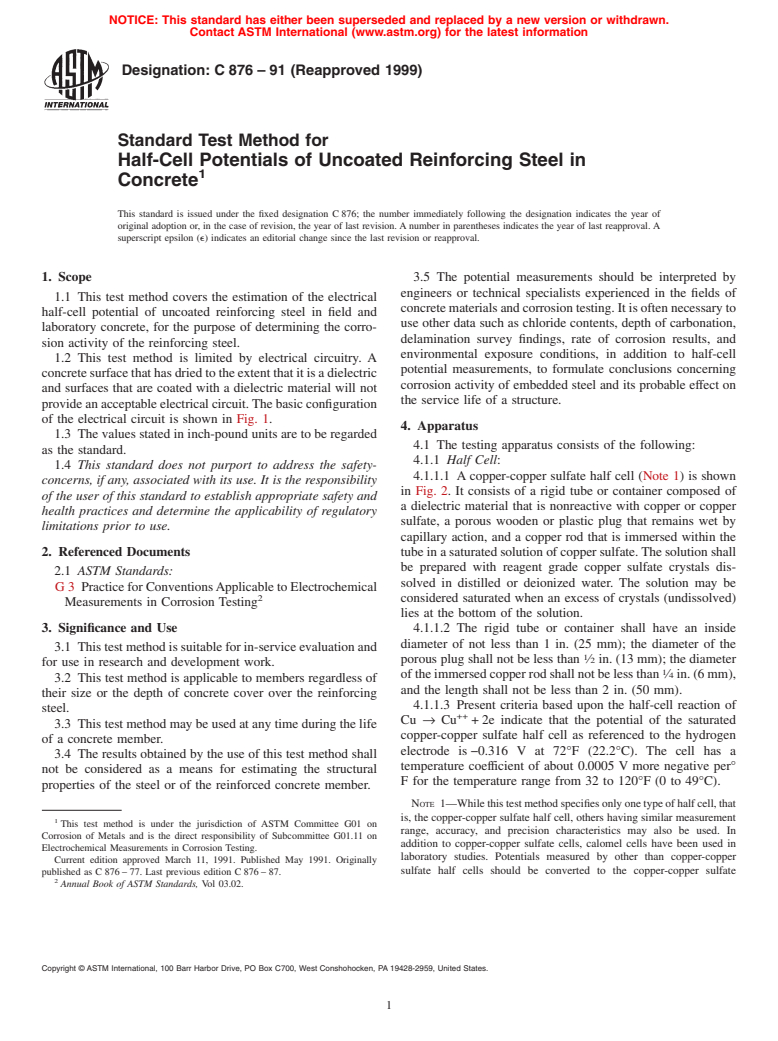

1.2 This test method is limited by electrical circuitry. A concrete surface that has dried to the extent that it is a dielectric and surfaces that are coated with a dielectric material will not provide an acceptable electrical circuit. The basic configuration of the electrical circuit is shown in Fig. 1.

1.3 The values stated in inch-pound units are to be regarded as the standard.

1.4 This standard does not purport to address the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the estimation of the electrical half-cell potential of uncoated reinforcing steel in field and laboratory concrete, for the purpose of determining the corrosion activity of the reinforcing steel.

Formerly under the jurisdiction of Committee G01 on Corrosion of Metals, this test method was withdrawn in August 2008 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C876–91 (Reapproved 1999)

Standard Test Method for

Half-Cell Potentials of Uncoated Reinforcing Steel in

Concrete

This standard is issued under the fixed designation C876; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.5 The potential measurements should be interpreted by

engineers or technical specialists experienced in the fields of

1.1 This test method covers the estimation of the electrical

concretematerialsandcorrosiontesting.Itisoftennecessaryto

half-cell potential of uncoated reinforcing steel in field and

use other data such as chloride contents, depth of carbonation,

laboratory concrete, for the purpose of determining the corro-

delamination survey findings, rate of corrosion results, and

sion activity of the reinforcing steel.

environmental exposure conditions, in addition to half-cell

1.2 This test method is limited by electrical circuitry. A

potential measurements, to formulate conclusions concerning

concretesurfacethathasdriedtotheextentthatitisadielectric

corrosion activity of embedded steel and its probable effect on

and surfaces that are coated with a dielectric material will not

the service life of a structure.

provideanacceptableelectricalcircuit.Thebasicconfiguration

of the electrical circuit is shown in Fig. 1.

4. Apparatus

1.3 Thevaluesstatedininch-poundunitsaretoberegarded

4.1 The testing apparatus consists of the following:

as the standard.

4.1.1 Half Cell:

1.4 This standard does not purport to address the safety-

4.1.1.1 Acopper-copper sulfate half cell (Note 1) is shown

concerns, if any, associated with its use. It is the responsibility

in Fig. 2. It consists of a rigid tube or container composed of

of the user of this standard to establish appropriate safety and

a dielectric material that is nonreactive with copper or copper

health practices and determine the applicability of regulatory

sulfate, a porous wooden or plastic plug that remains wet by

limitations prior to use.

capillary action, and a copper rod that is immersed within the

2. Referenced Documents tubeinasaturatedsolutionofcoppersulfate.Thesolutionshall

be prepared with reagent grade copper sulfate crystals dis-

2.1 ASTM Standards:

solved in distilled or deionized water. The solution may be

G3 PracticeforConventionsApplicabletoElectrochemical

2 considered saturated when an excess of crystals (undissolved)

Measurements in Corrosion Testing

lies at the bottom of the solution.

3. Significance and Use 4.1.1.2 The rigid tube or container shall have an inside

diameter of not less than 1 in. (25 mm); the diameter of the

3.1 Thistestmethodissuitableforin-serviceevaluationand

porous plug shall not be less than ⁄2 in. (13 mm); the diameter

for use in research and development work.

oftheimmersedcopperrodshallnotbelessthan ⁄4in.(6mm),

3.2 This test method is applicable to members regardless of

and the length shall not be less than 2 in. (50 mm).

their size or the depth of concrete cover over the reinforcing

4.1.1.3 Present criteria based upon the half-cell reaction of

steel.

++

Cu→ Cu +2e indicate that the potential of the saturated

3.3 Thistestmethodmaybeusedatanytimeduringthelife

copper-copper sulfate half cell as referenced to the hydrogen

of a concrete member.

electrode is−0.316 V at 72°F (22.2°C). The cell has a

3.4 The results obtained by the use of this test method shall

temperature coefficient of about 0.0005 V more negative per°

not be considered as a means for estimating the structural

F for the temperature range from 32 to 120°F (0 to 49°C).

properties of the steel or of the reinforced concrete member.

NOTE 1—Whilethistestmethodspecifiesonlyonetypeofhalfcell,that

is, the copper-copper sulfate half cell, others having similar measurement

This test method is under the jurisdiction of ASTM Committee G01 on

range, accuracy, and precision characteristics may also be used. In

Corrosion of Metals and is the direct responsibility of Subcommittee G01.11 on

addition to copper-copper sulfate cells, calomel cells have been used in

Electrochemical Measurements in Corrosion Testing.

laboratory studies. Potentials measured by other than copper-copper

Current edition approved March 11, 1991. Published May 1991. Originally

sulfate half cells should be converted to the copper-copper sulfate

published as C876–77. Last previous edition C876–87.

Annual Book of ASTM Standards, Vol 03.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C876–91 (1999)

FIG. 1 Copper-Copper Sulfate Half Cell Circuitry

G3 and it is also described in most physical chemistry or half-cell

technology text books.

4.1.2 Electrical Junction Device—An electrical junction

deviceshallbeusedtoprovidealowelectricalresistanceliquid

bridge between the surface of the concrete and the half cell. It

shall consist of a sponge or several sponges pre-wetted with a

low electrical resistance contact solution. The sponge may be

folded around and attached to the tip of the half cell so that it

provides electrical continuity between the porous plug and the

concrete member.

4.1.3 Electrical Contact Solution—In order to standardize

thepotentialdropthroughtheconcreteportionofthecircuit,an

electrical contact solution shall be used to wet the electrical

junctiondevice.Onesuchsolutioniscomposedofamixtureof

95mLofwettingagent(commerciallyavailablewettingagent)

or a liquid household detergent thoroughly mixed with 5 gal

(19 L) of potable water. Under working temperatures of less

than about 50°F (10°C), approximately 15% by volume of

either isopropyl or denatured alcohol must be added to prevent

clouding of the electrical contact solution, since clouding may

FIG. 2 Sectional View of a Copper-Copper Sulfate Half Cell

inhibit penetration of water into the concrete to be tested.

4.1.4 Voltmeter—The voltmeter shall have the capacity of

equivalent potential. The conversion technique can be found in Practice beingbatteryoperatedandhave 63%end-of-scaleaccuracyat

C876–91 (1999)

thevoltagerangesinuse.Theinputimpedanceshallbenoless steel can be established by measuring the resistance between

than 10 MV when operated at a full scale of 100 mV. The widely separated steel components on the deck. Where dupli-

divisions on the scale used shall be such that a potential cate test measurements are continued over a long period of

difference of 0.02 V or less can be read without interpolation. time, identical connection points should be used each time for

4.1.5 Electrical Lead Wires—The electrical lead wire shall a given measurement.

beofsuchdimensionthatitselectricalresistanceforthelength 6.3 Electrical Connection to the Half Cell—Electrically

used will not disturb the electrical circuit by more than 0.0001

connect one end of the lead wire to the half cell and the other

V.Thishasbeenaccomplishedbyusingnomorethanatotalof end of this same lead wire to the negative (ground) terminal of

500 linear ft (150 m) of at least AWG No. 24 wire. The wire

the voltmeter.

shall be suitably coated with direct burial type of insulation.

6.4 Pre-Wetting of the Concrete Surface:

6.4.1 Under certain conditions, the concrete surface or an

5. Calibration and Standardization

overlaying material, or both, must be pre-wetted by either of

5.1 CareoftheHalfCell—Theporousplugshallbecovered

the two methods described in 6.4.3 or 6.4.4 with the solution

when not in use for long periods to ensure that it does not

described in 4.1.3 to decrease the electrical resistance of the

become dried to the point that it becomes a dielectric (upon

circuit.

drying, pores may become occluded with crystalline copper

6.4.2 A test to determine the need for pre-wetting may be

sulfate). If cells do not produce the reproducibility or agree-

made as follows:

ment between cells described in Section 11, cleaning the

6.4.2.1 Placethehalfcellontheconcretesurfaceanddonot

copper rod in the half cell may rectify the problem. The rod

move.

may be cleaned by wiping it with a dilute solution of

6.4.2.2 Observe the voltmeter for one of the following

hydrochloricacid.Thecoppersulfatesolutionshallberenewed

conditions:

either monthly or before each use, whichever is the longer

(a) The measured value of the half-cell potential does not

period.Atnotimeshallsteelwooloranyothercontaminantbe

change or fluctuate with time.

used to clean the copper rod or half-cell tube.

(b) The measured value of the half-cell potential changes or

fluctuates with time.

6. Procedure

6.4.2.3 Ifcondition(a)isobserved,pre-wettingtheconcrete

6.1 Spacing Between Measurements—While there is no

surfaceisnotnecessary.However,ifcondition(b)isobserved,

pre-defined minimum spacing between measurements on the

pre-wetting is required for an amount of time such that the

surface of the concrete member, it is of little value to take two

voltage reading is stable (60.02 V) when observed for at least

measurements from virtually the same point. Conversely,

5 min. If pre-wetting cannot obtain condition ( a), either the

measurementstakenwithverywidespacingmayneitherdetect

electrical resistance of the circuit is too great to obtain valid

corrosion activity that is present nor result in the appropriate

half-cell potential measurements of the steel, or stray current

accumulation of data for evaluation. The spacing shall there-

fromanearbydirectcurrenttractionsystemorotherfluctuating

fore be consistent with the member being investigated and the

direct-current,suchasarcwelding,isaffectingthereadings.In

intended end use of the measurements (Note 2).

either case, the half-cell method should not be used.

NOTE 2—A spacing of 4 ft (1.2 m) has been found satisfactory for

6.4.3 Method A for Pre-Wetting Concrete Surfaces—Use

evaluation of bridge decks. Generally, larger spacings increase the

Method A for those conditions where a minimal amount of

probability that localized corrosion areas will not be detected. Measure-

pre-wetting is required to obtain condition (a) as described in

ments may be taken in either a grid or a random pattern. Spacing between

6.4.2.2. Accomplish this by spraying or otherwise wetting

measurements should generally be reduced where adjacent readings

either the entire concrete surface or only the points of mea-

exhibit algebraic reading differences exceeding 150 mV (areas of high

corrosion activity). Minimum spacing generally should provide at least a surement as described in 6.1 with the solution described in

100-mV difference between readings.

4.1.3.Nofreesurfacewatershouldremainbetweengridpoints

when potential measurements are initiated.

6.2 Electrical Connection to the Steel:

6.4.4 Method B for Pre-Wetting Concrete Surfaces—In this

6.2.1 Make a direct electrical connection to the reinforcing

method, saturate sponges with the solution described in 4.1.3

steel by means of a compression-type ground clamp, or by

and place on the concrete surface at locations described in 6.1.

brazing or welding a protruding rod.To ensure a low electrical

Leave the sponges in place for the period of time necessary to

resistance connection, scrape the bar or brush the wire before

obtain condition (a) described in 6.4.2.2. Do not remove the

connecting to the reinforcing steel. In certain cases, this

sponges from the concrete surface until after the half-cell

technique may require removal of some concrete to expose the

potential reading is made. In making the half-cell potential

reinforcing steel. Electrically connect the reinforcing steel to

measurements,placetheelectricaljunctiondevicedescribedin

the positive terminal of the voltmeter.

4.1.2 firmly on top of the pre-wetting sponges for the duration

6.2.2 Attachment must be made directly to the reinforcing

of the measurement.

steel except in cases where it can be documented that an

6.5 Underwater, Horizontal, and Vertical Measurements:

exposed steel member is directly attached to the reinforcing

steel. Certain members, such as expansion dams, date plates, 6.5.1 Potential measurements detect corrosion activity, but

lift works, and parapet rails may not be attached directly to the not necessarily the location of corrosion activity. The precise

reinforcing steel and, therefore, may yield invalid readings. location of corrosion activity requires knowledge of the elec-

Electrical continuity of steel components with the reinforcing trical resistance of the material between the half cell and the

C876–91 (1999)

corroding steel. While underwater measurements are possible, 8.1.2 Cumulative Frequency Distribution— To determine

results regarding the location of corrosion must be interpreted the distribution of the measured half-cell potentials for the

verycarefully.Oftenitisnotpossibletopreciselylocatepoints concretemember,makeaplotofthedataonnormalprobability

of underwater corrosion activity in salt water environments paper in the following manner:

because potential readings along the member appear uniform. 8.1.2.1 Arrange and consecutively number all half-cell po-

However, the magnitude of readings does serve to indicate tentials by ranking from least negative potential to greatest

whether or not active corrosion is occurring. Take care during negative potential.

allunderwatermeasurementsthatthehalfcelldoesnotbecome 8.1.2.2 Determine the plotting position of each numbered

contaminated and that no part other than the porous tip of the half-cell potential in accordance with the following equation:

copper-copper sulfate electrode half cell comes in contact with

r

f 5 3100 (1)

water. x

(n 11

6.5.2 Perform horizontal and vertically upward measure-

where:

ments exactly as vertically downward measurements. How-

f = plotting position of total observations for the ob-

x

ever, additionally ensure that the copper-copper sulfate solu-

served value,%,

tion in the half cell makes simultaneous electrical contact with

r = rank of individual half-cell potential, and

the porous plug and the copper rod at all times.

(n = total number of observations.

8.1.2.3 Label the ordinate of the probability paper “Half-

7. Recording Half-Cell Potential Values

Cell Potential (Volts, CSE),” where CSE is the designation for

7.1 Record the electrical half-cell potentials to the nearest

copper-copper sulfate electrode. Label the abscissa of the

0.01V.Reportallhalf-cellpotentialvaluesinvoltsandcorrect

probability paper “Cumulative Frequency (%).” Draw two

fortemperatureifthehalf-celltemperatureisoutsidetherange

horizontal parallel lines intersecting the−0.20 and−0.3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.