ASTM A82-97ae1

(Specification)Standard Specification for Steel Wire, Plain, for Concrete Reinforcement

Standard Specification for Steel Wire, Plain, for Concrete Reinforcement

SCOPE

1.1 This specification covers cold-drawn steel wire, as-drawn or galvanized, to be used as such, or in fabricated form, for the reinforcement of concrete, in sizes not less than 2.03 mm (0.080 in.) nominal diameter.

1.2 Supplement S1 describes high-strength wire, which shall be furnished when specifically ordered. It shall be permissible to furnish high-strength wire in place of regular wire if mutually agreed to by the purchaser and the supplier.

1.3 The values stated in either inch-pound units or SI units are to be regarded as standard. Within the text the inch-pound units are shown in parentheses. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: A 82 – 97a American Association State Highway and Transportation Officials

Standard AASHTO No.: M 32

Standard Specification for

1

Steel Wire, Plain, for Concrete Reinforcement

This standard is issued under the fixed designation A 82; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

e NOTE—Editorial changes were made in June 2001.

1. Scope MIL-STD-163 Steel Mill Products Preparation for Ship-

7

ment and Storage

1.1 This specification covers cold-drawn steel wire, as-

2.3 U.S. Federal Standard:

drawn or galvanized, to be used as such, or in fabricated form,

7

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

for the reinforcement of concrete, in sizes not less than 2.03

2.4 Other Standard:

mm (0.080 in.) nominal diameter.

ACI 318 Building Code Requirements for Structural Con-

1.2 Supplement S1 describes high-strength wire, which

8

crete

shall be furnished when specifically ordered. It shall be

permissible to furnish high-strength wire in place of regular

3. Ordering Information

wire if mutually agreed to by the purchaser and the supplier.

3.1 Orders for material to this specification should include

1.3 The values stated in either inch-pound units or SI units

the following information:

are to be regarded as standard. Within the text the inch-pound

3.1.1 Quantity (weight),

units are shown in parentheses. The values stated in each

3.1.2 Name of material (cold-drawn steel wire for concrete

system are not exact equivalents; therefore, each system must

reinforcement),

be used independently of the other. Combining values may

3.1.3 Wire size number (see Section 8),

result in nonconformance with the specification.

3.1.4 Packaging (see Section 15), and

2. Referenced Documents 3.1.5 ASTM designation and year of issue.

3.1.6 Special requirements, if any. (See Supplement S1.)

2.1 ASTM Standards:

A 185 Specification for Steel Welded Wire Fabric, Plain, for

NOTE 1—A typical ordering description is as follows: 100 000 lb

2

Concrete Reinforcement

cold-drawn steel wire for concrete reinforcement, Size No. W5 in 500 lb

secured coils, to ASTM – _________.

A 370 Test Methods and Definitions for Mechanical Testing

3

of Steel Products

4. Materials and Manufacture

A 641 Specification for Zinc-Coated (Galvanized) Carbon

4

4.1 The steel shall be made by one of the following

Steel Wire

processes: open-hearth, electric furnace, or basic-oxygen.

A 700 Practices for Packaging, Marking, and Loading

5

4.2 The wire shall be cold drawn from rods that have been

Methods for Steel Products for Domestic Shipment

hot rolled from billets.

E 83 Practice for Verification and Classification of Exten-

6

4.3 Unless otherwise specified, the wire shall be supplied

someters

uncoated. When specified as galvanized, it shall be galvanized

2.2 U.S. Military Standards:

7

at finish size.

MIL-STD-129 Marking for Shipment and Storage

5. Mechanical Property Requirements

5.1 Tension Tests:

1

This specification is under the jurisdiction of ASTM Committee A-1 on Steel, 5.1.1 When tested as described in Test Methods and Defi-

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

nitions A 370, the material, except as specified in 5.1.2, shall

A01.05 on Steel Reinforcement.

conform to the tensile property requirements in Table 1 based

Current edition approved December 10, 1997. Published November 1998.

on nominal area of wire.

Originally published as A 82 – 21 T. Last previous edition A 82 – 97.

2

Annual Book of ASTM Standards, Vol 01.04.

5.1.2 The yield strength shall be determined as described in

3

Annual Book of ASTM Standards, Vol 01.03.

Test Methods and Definitions A 370 at an extension of 0.5 % of

4

Annual Book of ASTM Standards, Vol 01.06.

5

Annual Book of ASTM Standards, Vol 01.05.

6

Annual Book of ASTM Standards, Vol 03.01.

7

8

Available from Standardization Documents Order Desk, Bldg. 4, Section D,

Available from American Concrete Institute, P. O. Box 9094, Farmington Hills,

700 Robbins Ave., Philadelphia, PA 19111-5094.

MI 48333–9094.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A82

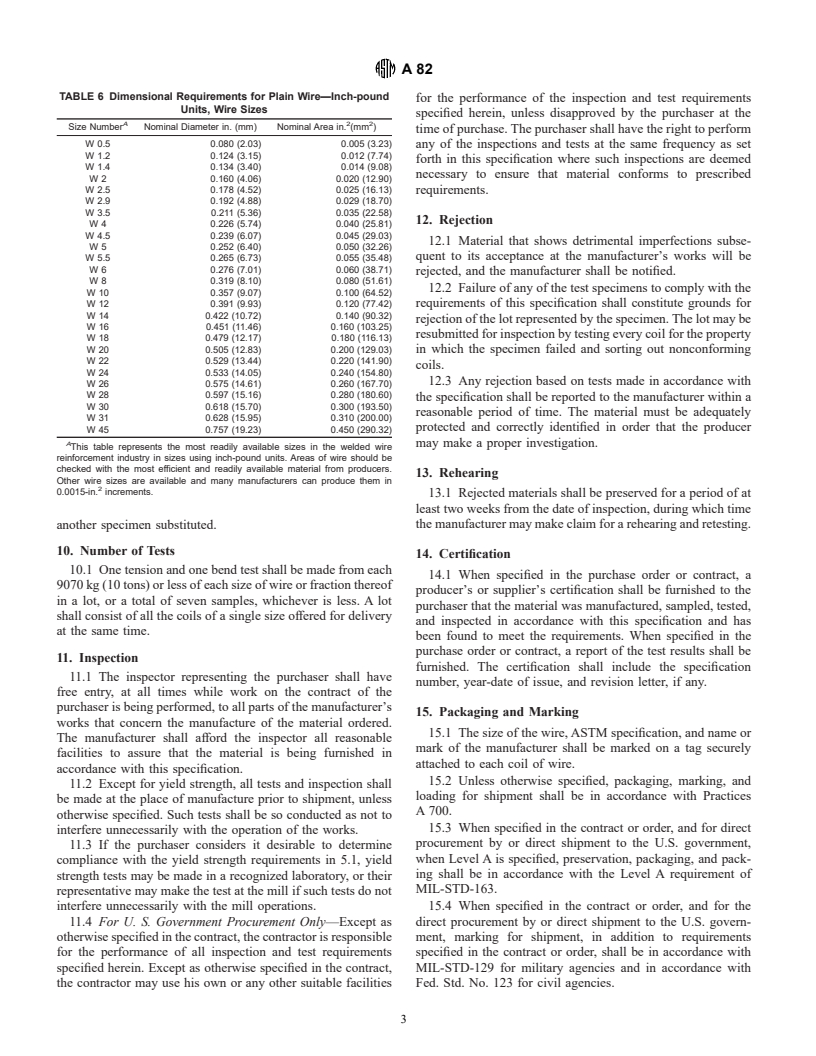

TABLE 1 Tension Test Requirements TABLE 3 Bend Test Requirements

Tensile strength, min, ksi (MPa) 80 (550) Size Number

Bend Test

Yield strength, min, ksi (MPa) 70 (485) of Wire

A

W7 and smaller Bend around a pin the diameter that is equal to the

Reduction of area, min, % 30

diameter of the specimen

A

For material testing over 100 ksi (690 MPa) ten

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.