ASTM C1715-09

(Test Method)Standard Test Method for Evaluation of Water Leakage Performance of Masonry Wall Drainage Systems

Standard Test Method for Evaluation of Water Leakage Performance of Masonry Wall Drainage Systems

SIGNIFICANCE AND USE

This test method is suitable for use on walls to determine the ability of masonry wall drainage systems to collect water penetrating the exterior wythe and to direct this water back to the exterior surface of the exterior wythe. Removal of a portion of the interior wall finishes is desirable to observe leakage into backup walls. Even with removal of interior finishes, in many cases it is not practical to observe surfaces behind spandrel beams, columns, or other obstructions. Potential areas where leakage may occur but that are not visible during the test shall be considered when interpreting the results of the test and shall be recorded in the report.

This test method is suitable for use on mock-up walls to determine the performance of masonry wall drainage systems.

This test method is suitable for evaluating the effectiveness of flashing repairs.

SCOPE

1.1 This test method describes a standard procedure for determining the ability of masonry wall drainage systems to collect water that penetrates the exterior masonry wythe during rainstorms and to direct this water back to the exterior surface of the wall.

1.2 This test method is applicable to wall systems that contain an exterior masonry wythe with a drainage space on the interior face of the exterior wythe. It is not applicable to single-wythe drainage walls.

1.3 This test method is not applicable to masonry barrier walls or other masonry walls that are designed without drainage spaces behind the exterior wythe.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:C1715–09

Standard Test Method for

Evaluation of Water Leakage Performance of Masonry Wall

Drainage Systems

This standard is issued under the fixed designation C1715; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E631. For definitions of terms relating to masonry, brick and

clay tile, and concrete masonry units used in this test method,

1.1 This test method describes a standard procedure for

see Terminology C1232.

determining the ability of masonry wall drainage systems to

3.2 Definitions of Terms Specific to This Standard:

collect water that penetrates the exterior masonry wythe during

3.2.1 back-up wall, n—the portion of the wall system

rainstorms and to direct this water back to the exterior surface

located on the interior side of the drainage space.

of the wall.

3.2.2 drainage space, n—the space located between the

1.2 This test method is applicable to wall systems that

interior face of the exterior wythe of masonry and the exterior

containanexteriormasonrywythewithadrainagespaceonthe

face of the back-up wall or the water-resistive barrier placed on

interior face of the exterior wythe. It is not applicable to

the exterior face of the back-up wall to facilitate the flow of

single-wythe drainage walls.

water to a flashing or water collection system.

1.3 This test method is not applicable to masonry barrier

3.2.2.1 Discussion—The drainage space may contain mate-

walls or other masonry walls that are designed without

rials or components designed to permit water movement.

drainage spaces behind the exterior wythe.

3.2.3 flashing, n—an impervious material placed at speci-

1.4 The values stated in inch-pound units are to be regarded

fied locations in a masonry wall drainage system to collect and

as standard. The values given in parentheses are mathematical

direct water penetrating through the exterior wythe of masonry

conversions to SI units that are provided for information only

to the exterior face of the exterior wythe of masonry by means

and are not considered standard.

of a weep system.

1.5 This standard does not purport to address all of the

3.2.4 masonry barrier wall, n—single or multi-wythe ma-

safety concerns, if any, associated with its use. It is the

sonry wall system that does not contain a drainage space

responsibility of the user of this standard to establish appro-

directly behind the exterior masonry wythe.

priate safety and health practices and determine the applica-

3.2.5 masonry drainage wall, n—masonry wall system

bility of regulatory limitations prior to use.

designed with a drainage space immediately behind the exte-

2. Referenced Documents

rior masonry wythe that allows water penetrating the masonry

to flow down the drainage space where the water is collected

2.1 ASTM Standards:

and diverted by flashing to the exterior face of the exterior

C1232 Terminology of Masonry

wythe or collected and drained by some other water collection

C1601 Test Method for Field Determination of Water Pen-

system.

etration of Masonry Wall Surfaces

3.2.5.1 Discussion—This wall type includes: masonry cav-

E514 Test Method for Water Penetration and Leakage

ity walls; anchored masonry veneer walls; insulated cavity

Through Masonry

walls; and any other masonry wall systems with a drainage

E631 Terminology of Building Constructions

space.

3. Terminology

3.2.6 masonry wall drainage system, n—the drainage space,

the water resistive barrier (where included), the flashing or

3.1 Definitions—For definitions of terms relating to build-

other water collection devices, and the weep system in a

ing construction used in this test method, see Terminology

masonrydrainagewalldesignedtocollectwaterthatpenetrates

the exterior masonry wythe and direct it back to the exterior

This test method is under the jurisdiction of ASTM Committee C15 on

face of the exterior masonry wythe.

Manufactured Masonry Units and is the direct responsibility of Subcommittee

C15.04 on Research.

3.2.6.1 Discussion—The masonry wall drainage system in-

Current edition approved July 1, 2009. Published July 2009. DOI: 10.1520/

cludes any other devices within the wall system that facilitate

C1715-09.

2 the flow of water within the drainage space and to the weeps or

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

that prevent mortar from blocking weeps.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1715–09

3.2.7 masonry wall system, n—all components of an exte- 6. Apparatus

rior wall including the exterior masonry wythe, wall ties or

6.1 Major components:

anchors, the drainage system (if included), the back-up wall,

6.1.1 Water Source—a source of potable water under pres-

insulation, and wall finishes.

sure such as the local pressurized water supply, a water supply

3.2.7.1 Discussion—By definition in this standard, a ma-

connected to a pump, or water from an elevated storage tank.

sonry wall system shall consist of at least an exterior masonry

6.1.2 Flow Meter—a device capable of measuring the water

wythe exposed to weather.

flow with sufficient accuracy to meet the permitted variations

3.2.8 water leakage, n—penetration of water beyond the

listed in Section 7. The flow meter shall be either integral with

innermostplaneboundingthemasonrywalldrainagesystemor

or following the flow regulator. Flow meters are connected to

water penetration below or behind flashings.

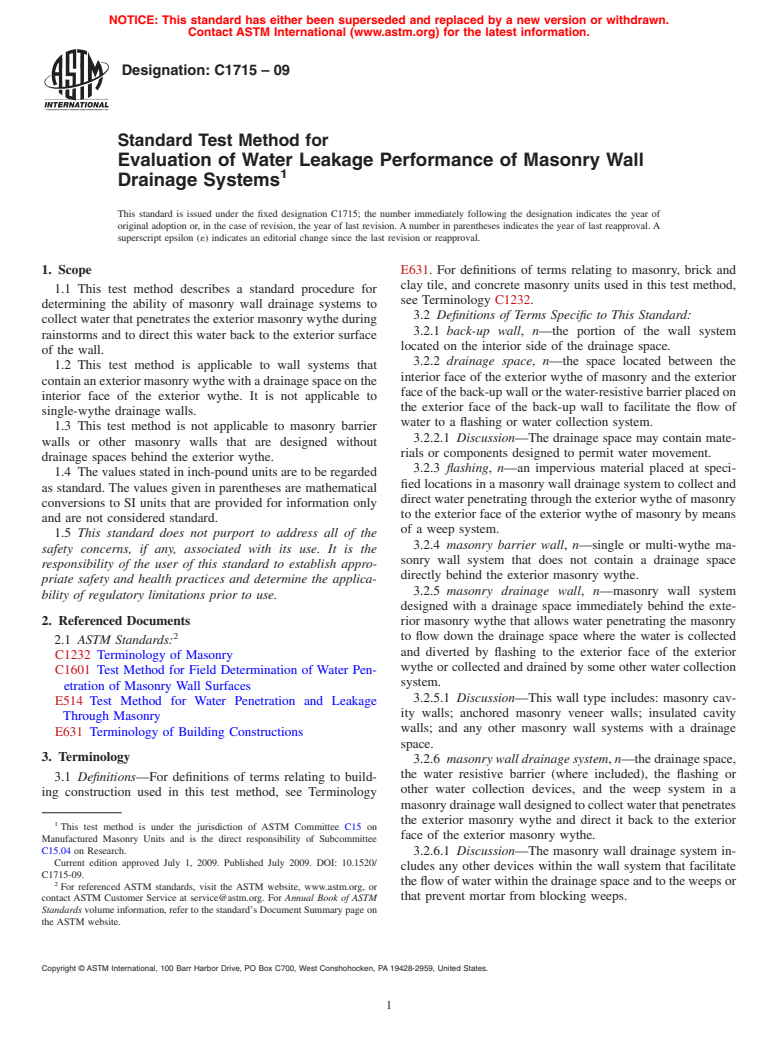

each water entry point (Type l as shown in Fig. 1). If all water

3.2.9 water collection system, n—a trough system or similar

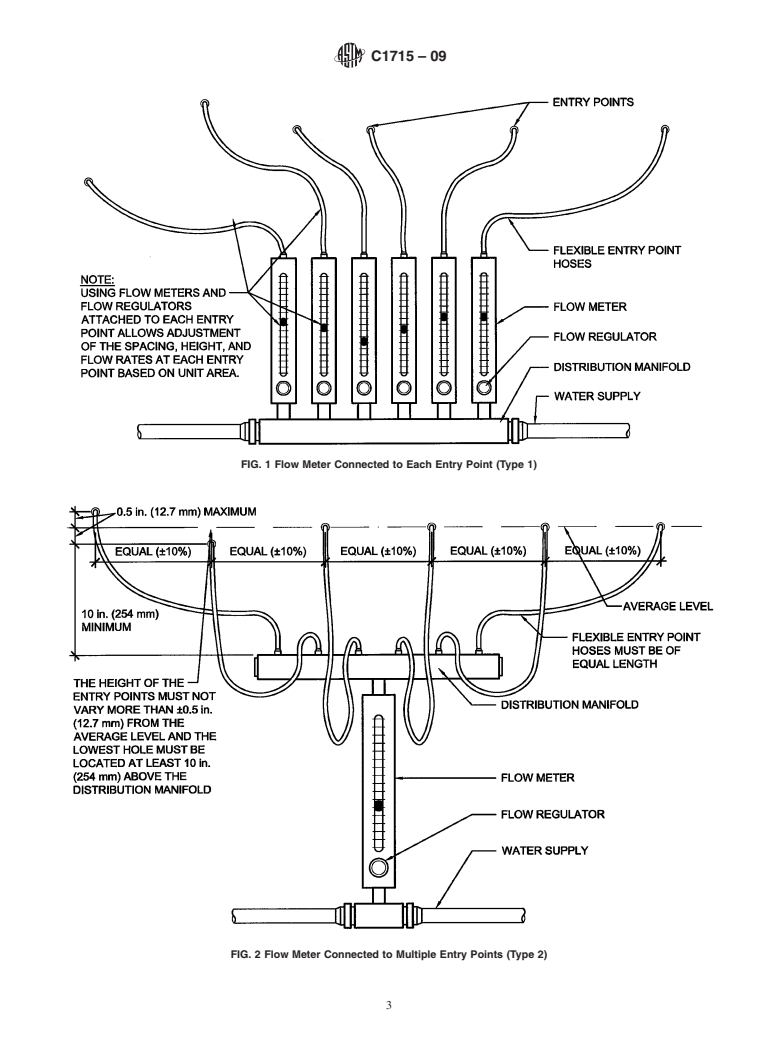

entry points are located within 0.5 in. (12.7 mm) from the

system at the base of a drainage space or a portion of that

average height of water entry points, the flow meter is

trough system, used in lieu of flashing, intended to collect any

permittedtobeattachedtoadistributionmanifoldconnectedto

water that penetrates the exterior wythe of masonry and direct

multiple entry points (Type 2 as shown in Fig. 2) provided the

that water to a drainage system.

top of the distribution manifold is located at least 10 in. (254

3.2.10 water resistive barrier, n—acoatingormembraneon

mm) below the lowest entry point, the entry point hoses are the

the exterior surface of the back-up wall that is intended to

samelength(within1.0in.(25.4mm)),andtheentrypointsare

prevent water, which has penetrated the exterior masonry

evenly spaced (within 10 % of average spacing).

wythe and has bridged the air space, from reaching the surface

NOTE 1—Using separate flow meters and flow regulators attached to

of the back-up wall and to direct this water into the flashing or

each entry point allows adjustment of the spacing, height, and flow rates

water collection system below.

at the entry points based on the tributary area of the wall represented by

3.2.11 weep system, n—a series of openings, tubes, wicks,

each entry point. When using a manifold attached to a single flow meter

vents, or other devices at the top surface of the flashing that

and flow regulator, the spacing, height, and flow rates at each entry point

facilitate the flow of water that collects on the flashing back to

supplied by the manifold must be approximately equal. To ensure that the

flowratesfromtheentrypointhosesarewithinthespecifiedtolerance,the

the exterior surface of the wall.

heights of the entry points above the flow meter need to be approximately

4. Summary of Test Method equal, the lowest entry point must exceed the minimum height above the

distribution manifold, and the length of each hose need to be approxi-

4.1 This test method introduces water directly into the

mately equal. Conformance to the specified tolerance is verified during

masonry wall drainage system through holes drilled in the

calibration.

exterior masonry wythe. Water is introduced along the interior

6.1.3 Flow Regulator—a valve, either integral with the flow

face of the exterior masonry wythe by means of hoses at each

meters or separate, to control the rate of water flow.

entry point. These hoses are connected to a common water

6.1.4 Entry Point Hoses—hoses attached directly to the

source. The flow rates are controlled by flow regulators

flow meter or to a distribution manifold for the purpose of

attached to each of the entry point hoses or to a manifold that

supplying water into the masonry wall drainage system. The

distributes water uniformly to multiple hoses. This standard

diameter of these hoses shall be large enough to ensure that the

sets limits for several parameters to control the velocity and

exterior face of the water flow shall extend no farther than 0.25

volume of the water at points of entry as well as limits on the

in. (6.4 mm) horizontally beyond the end of the hose at a

minimum number and maximum spacing of entry points to

distance of 20 in. (508 mm) below the end of the hose (Fig. 3).

provide uniform distribution of water along the interior face of

the exterior masonry wythe. Interior and exterior observations NOTE 2—High velocity water leaving small diameter hoses may cause

water to project beyond the interior face of the exterior wythe. This

are performed before, during, and after the test to detect water

requirement is intended to ensure that water will flow down the interior

leakage and to observe the discharge of water to the exterior.

surface of the exterior wythe.

5. Significance and Use

6.1.5 Distribution Manifold—a series of pipes, tees, elbows

and other plumbing connections used to distribute water from

5.1 This test method is suitable for use on walls to deter-

the water source to each of the water entry points.

mine the ability of masonry wall drainage systems to collect

water penetrating the exterior wythe and to direct this water 6.1.6 Graduated Cylinder—a clear plastic or glass cylinder

which is sealed at one end and contains graduations to measure

back to the exterior surface of the exterior wythe. Removal of

a portion of the interior wall finishes is desirable to observe quantities of water with an accuracy of 0.034 oz (1 mL).

6.1.7 Entry Point—a hole drilled through a mortar head

leakage into backup walls. Even with removal of interior

joint in the exterior wythe of masonry through which water is

finishes, in many cases it is not practical to observe surfaces

directed into the drainage space during the test. Drill entry

behind spandrel beams, columns, or other obstructions. Poten-

point holes at a 30 6 5° angle downward (Fig. 4).

tial areas where leakage may occur but that are not visible

during the test shall be considered when interpreting the results

NOTE 3—The 30° downward angle is intended to prevent water from

of the test and shall be recorded in the report.

flowing back to the exterior through the entry points during the test.

5.2 This test method is suitable for use on mock-up walls to

7. Calibration

determine the performance of masonry wall drainage systems.

5.3 This test method is suitable for evaluating the effective- 7.1 Verify the ability of the test apparatus to meet the

ness of flashing repairs. applicable requirements by setting up and testing the apparatus

C1715–09

FIG. 1 Flow Meter Connected to Each Entry Point (Type 1)

FIG. 2 Flow Meter Connected to Multiple Entry Points (Type 2)

C1715–09

FIG. 3 Entry Point Hose

in a laboratory. Perform the calibration after initial fabrication points are located at the same level (within 0.08 in. (2 mm))

and at least once per year. Verify three test levels during each except that one entry point is positioned 0.5 in. (12.7 mm)

calibration: the highest flow rate at which the apparatus is abovetheaveragelevelandoneentrypointispositioned0.5in.

designed to operate, the lowest flow rate at which the apparatus (12.7 mm) below the average level. Set the height between the

is designed to operate, and the midpoint between these two test average level of the entry points and the top of the flow meter

flow rates. at the specified minimum level specified in 6.1.2.

7.2 Position the ends of the water entry hoses at the 7.5 Verify the flow rate at each entry point in either the

specified angle listed in 6.1.7 (Fig. 4). Type 1 or the Type 2 apparatus using a graduated cylinder by

7.3 Check the horizontal projection of water flow from the collecting water for a minimum of 30 s after the system has

end of at least one of the hoses to demonstrate that the hose been operating for a minimum of 5 min. The measured flow

conformstotherequirementsof6.1.4.Locatethemeasurement rate at any entry point hose shall not vary more than 25 % from

device a minimum of 20 in. (508 mm) below the hose. The the test flow rate at each entry point. The total flow rate,

measurement device is used to measure the distance from a determined by adding the flow rates from each of the entry

point directly below the lower edge of the tip of the water entry point hoses, shall not vary more than 15 % from the test flow

hose to the outer edge of the water flow within an accuracy of rate at each entry point multiplied by the total number of entry

0.04 in. (l mm), as shown in Fig. 3. The exterior face of the points.

water flow shall extend no farther than 0.25 in. (6.4 mm)

8. Weather Conditions

horizontally beyond the end of the hose. Perform this check at

the maximum flow rate at which the water entry hose will be 8.1 Conduct test when the temperatures of the exterior air

used. and of the exterior surface of the masonry are not less than

7.4 For an apparatus that uses a flow meter and flow 40°F (5°C).

regulator attached to a distribution manifold connected to 8.2 Conduct test when the surface of the wall is visibly dry

multiple entry points (Type 2), calibrate the apparatus by orincludeinthereportthelocationandtheextentormagnitude

setting up the system in a laboratory so that the water entry ofmoisturepresentonorwithinthetestwallwithphotographs,

C1715–09

FIG. 4 Entry Point with Hose Inserted

moisture measurements, drawings or notes so that any change 9.5 Attach the distribution manifolds, flow meters, and flow

in the moisture throughout the test is visible. regulators beneath the water entry points.

9.6 Insert entry point hoses into the holes at each water

9. Preparation of Test Apparatus

entry point. Hold the hoses at least 0.375 in. (9.5 mm) back

9.1 Install entry points

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.