ASTM F1865-02a(2009)

(Specification)Standard Specification for Mechanical Cold Expansion Insert Fitting With Compression Sleeve for Cross-linked Polyethylene (PEX) Tubing

Standard Specification for Mechanical Cold Expansion Insert Fitting With Compression Sleeve for Cross-linked Polyethylene (PEX) Tubing

ABSTRACT

This specification covers mechanical cold expansion insert fitting with compression sleeve for cross-linked polyethylene (PEX) tubing. Fittings shall be made from specific copper alloy for machined brass fittings, forged brass fittings, and compression sleeves. The fitting shall conform to the specified dimensions, tolerances, maximum angular variation, solder joint ends, workmanship, finish, appearance, assembly, quality, and marking.

SCOPE

1.1 This specification covers mechanical cold expansion insert fittings with compression sleeve suitable for use with cross-linked polyethylene PEX plastic tubing in 3/8, ½, 5/8, ¾ , and 1in. and larger nominal diameters that meet the requirements of Specifications F 876 and F 877. These fittings are intended for use in 100 psi (689.5 kPa) cold and hot water distributions systems operating at temperatures up to and including 180° F (82°C). Included are the requirements for materials, workmanship, dimensions, and markings to be used on the fittings and compression sleeves

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: F1865 – 02a (Reapproved 2009)

Standard Specification for

Mechanical Cold Expansion Insert Fitting With Compression

Sleeve for Cross-linked Polyethylene (PEX) Tubing

This standard is issued under the fixed designation F1865; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1600 Terminology for Abbreviated Terms Relating to

Plastics

1.1 This specification covers mechanical cold expansion

D2122 Test Method for Determining Dimensions of Ther-

insert fittings with compression sleeve suitable for use with

moplastic Pipe and Fittings

3 1 5 3

cross-linked polyethylene PEX plastic tubing in ⁄8 , ⁄2 , ⁄8 , ⁄4

E18 Test Methods for Rockwell Hardness of Metallic Ma-

, and 1in. and larger nominal diameters that meet the require-

terials

ments of Specifications F876 and F877. These fittings are

F412 Terminology Relating to Plastic Piping Systems

intended for use in 100 psi (689.5 kPa) cold and hot water

F876 Specification for Crosslinked Polyethylene (PEX)

distributions systems operating at temperatures up to and

Tubing

including 180° F (82°C). Included are the requirements for

F877 Specification for Crosslinked Polyethylene (PEX)

materials, workmanship, dimensions, and markings to be used

Plastic Hot- and Cold-Water Distribution Systems

on the fittings and compression sleeves

2.2 ASME Standards:

1.2 The values stated in inch-pound units are to be regarded

B 1.20.1 Pipe Threads General Purpose (inch)

as standard. The values given in parentheses are mathematical

B 16.18 Cast Copper Alloy Solder Joint Pressure Fittings

conversions to SI units that are provided for information only

B 16.22 Wrought Copper and Copper Alloy Solder Joint

and are not considered standard.

Pressure Fittings

1.3 This standard does not purport to address all of the

2.3 NSF International Standards:

safety concerns, if any, associated with its use. It is the

NSF 14 Plastic Piping Components and Related Materials

responsibility of the user of this standard to establish appro-

NSF 61 DrinkingWater System Components-Health Effects

priate safety and health practices and determine the applica-

2.4 MSS Standard:

bility of regulatory limitations prior to use.

SP-104 Wrought Copper Solder Joint Pressure Fittings

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions: Definitions are in accordance with Termi-

B16/B16M Specification for Free-Cutting Brass Rod, Bar

nology F412 and abbreviations are in accordance with Termi-

and Shapes for Use in Screw Machines

nology D1600 unless otherwise indicated.

B140/B140M Specification for Copper-Zinc-Lead (Red

Brass or Hardware Bronze) Rod, Bar, and Shapes

4. Classification

B283 Specification for Copper and Copper-Alloy Die Forg-

4.1 This specification covers one class of mechanical cold

ings (Hot-Pressed)

expansion insert fittings with compression sleeve suitable for

This specification is under the jurisdiction of CommitteeF17 on Plastic Piping

Systems and is the direct responsibility of SubcommitteeF17.10 on Fittings. Available from American Society of Mechanical Engineers (ASME), ASME

Current edition approved May 1, 2009. Published September 2009. Originally International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

approved in 1998. Last previous edition approved 2002 as F1865–02a. DOI: www.asme.org.

10.1520/F1865-02AR09. Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd.,Ann

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Arbor, MI 48113-0140, http://www.nsf.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

Standards volume information, refer to the standard’s Document Summary page on Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-

the ASTM website. hq.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1865 – 02a (2009)

use with PEX tubing that meets the requirements of Specifi- inclusions, or other defects that are visible to the unmagnified

cation F876 and F877. eye and that may affect the wall integrity.

5. Materials and Manufacture

9. Assembly

5.1 Fittings—The fittings shall be made from one of the

9.1 Joints—MechanicalColdExpansionInsertFittingswith

following metals:

Compression Sleeve shall be joined to the PEX tubing by

5.1.1 Machined Brass Fittings—Machined brass fittings

drawing a compression sleeve over the PEX tubing that has

shall be made from material meeting the requirements of

been cold expanded and into which the fitting has been

Specification B140/B140M copper alloy UNS C31400, Speci-

inserted. This action forces the tubing into annular spaces

fication B16/B16M Copper alloy UNS C38500, or DIN 17660

formed by ribs on the fitting. Fittings and compression sleeves

– CuZn39Pb3.

shall meet the dimensional tolerances of this Specification.

5.1.2 Forged Brass Fittings—Forged brass fittings shall be

PEX tubing shall meet the requirements of Specification F876

made from material meeting the requirements of Specification

or F877.

B283 Copper alloy UNS C37700, or DIN 17660-CuZn40Pb2.

9.1.1 Solder Joints— Soldering of fittings joints shall be

5.1.3 Compression Sleeves—Compression sleeves shall be

completed prior to installation of the PEX tubing. Excessive

made from material meeting the requirements of Specification

heat from the soldering operation will damage the PEX tubing.

B140/B140M copper alloy UNS C37700, Specification B16/

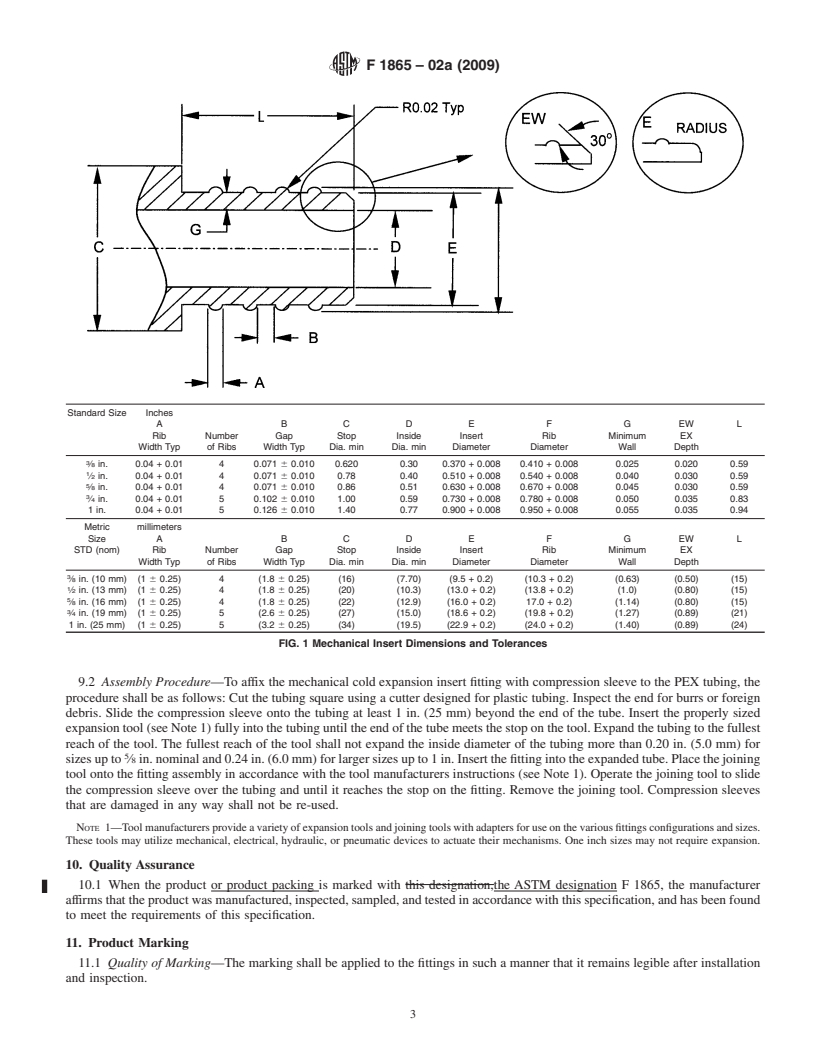

9.2 Assembly Procedure—To affix the mechanical cold

B16MCopperalloyUNSC38500,orDIN17660-CuZn39PB3.

expansion insert fitting with compression sleeve to the PEX

6. General Requirements tubing, the procedure shall be as follows: Cut the tubing square

using a cutter designed for plastic tubing. Inspect the end for

6.1 The following sections of Specification F877 constitute

burrs or foreign debris. Slide the compression sleeve onto the

a part of this specification:

tubing at least 1 in. (25 mm) beyond the end of the tube. Insert

6.1.1 Requirements,

the properly sized expansion tool (see Note 1) fully into the

6.1.2 Test Methods, and

tubing until the end of the tube meets the stop on the tool.

6.1.3 Retest and Rejection

Expand the tubing to the fullest reach of the tool. The fullest

6.2 In addition, when a section with a title identical to that

reach of the tool shall not expand the inside diameter of the

referenced in 6.1, above, appears in this specification, it

tubing more than 0.20 in. (5.0 mm) for sizes up to ⁄8 in.

contains additional requirements that supplement those appear-

nominal and 0.24 in. (6.0 mm) for larger sizes up to 1 in. Insert

ing in F877.

the fitting into the expanded tube. Place the joining tool onto

6.3 Dimensions—Randomly selected fitting or fittings shall

the fitting assembly in accordance with the tool manufacturers

be used to determine dimensions. Measurements shall be made

instructions (see Note 1). Operate the joining tool to slide the

in accordance with Test Method D2122. Determine the diam-

compression sleeve over the tubing and until it reaches the stop

eters by m

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

´1

Designation:F1865–02 Designation: F 1865 – 02a (Reapproved 2009)

Standard Specification for

Mechanical Cold Expansion Insert Fitting With Compression

Sleeve for Cross-linked Polyethylene (PEX) Tubing

This standard is issued under the fixed designation F 1865; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Section 10 was editorially revised in December 2002.

1. Scope

1.1 This specification covers mechanical cold expansion insert fittings with compression sleeve suitable for use with

3 1 5 3

cross-linked polyethuylene PEX plastic tubing in ⁄8 , ⁄2 , ⁄8 , ⁄4 , and 1in. and larger nominal diameters that meet the requirements

of Specifications F 876 and F 877. These fittings are intended for use in 100 psi (689.5 kPa) cold and hot water distributions

systems operating at temperatures up to and including 180° F (82°C). Included are the requirements for materials, workmanship,

dimensions, and markings to be used on the fittings and compression sleeves

1.2 The values stated in inch-pounds units are to be regarded as the standard. The values given in parentheses are mathematical

conversions to SI units whichthat are provided for provided for information only and are not considered the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

B 16/B 16M Specification for Free-Cutting Brass Rod, Bar,Bar and Shapes for Use in Screw Machines

B 140/B 140M Specification for Copper-Zinc-Lead (Leaded Red (Red Brass or Hardware Bronze) Rod, Bar, and Shapes

B 283 Specification for Copper and Copper-Alloy Die Forgings (Hot-Pressed)

D 1600 Terminology for Abbreviated Terms Relating to Plastics

D 2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

E18 Test Method for Rockwell Hardness and Superficial Hardness of Metallic Materials Test Methods for Rockwell Hardness

of Metallic Materials

F 412 Terminology Relating to Plastic Piping Systems

F 876 Specification for Crosslinked Polyethylene (PEX) Tubing

F 877 Specification for Crosslinked Polyethylene (PEX) Plastic Hot- and Cold-Water Distribution Systems

2.2 ASME Standards:

B 1.20.1 Pipe Threads General Purpose (inch)

B 16.18 Cast Copper Alloy Solder Joint Pressure Fittings

B 16.22 Wrought Copper and Copper Alloy Solder Joint Pressure Fittings

2.3 NSF International Standards:

NSF 14 Plastic Piping Components and Related Materials

NSF 61 Drinking Water System Components-Health Effects

2.4 MSS Standard:

This standardspecification is under the jurisdiction of Committee F17 on Plastic Piping Systems and is the direct responsibility of SubcommitteeF17.10 on Fittings.

Current edition approved May 10, 2002. Published July 2002.

Originally published as F1865–98. Last previous edition F1865–98.

Current edition approved May 1, 2009. Published September 2009. Originally approved in 1998. Last previous edition approved 2002 as F 1865–02a.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 02.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 08.01.

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

www.asme.org.

Annual Book of ASTM Standards, Vol 08.04.

Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd., Ann Arbor, MI 48113-0140, http://www.nsf.org.

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1865 – 02a (2009)

SP-104 Wrought Copper Solder Joint Pressure Fittings

3. Terminology

3.1 Definitions: Definitions are in accordance with Terminology F 412 and abbreviations are in accordance with Terminology

D 1600 unless otherwise indicated.

4. Classification

4.1 Thisspecificationcoversoneclassofmechanicalcoldexpansioninsertfittingswithcompressionsleevesuitableforusewith

PEX tubing that meets the requirements of Specification F 876 and F 877.

5. Materials and Manufacture

5.1 Fittings—The fittings shall be made from one of the following metals:

5.1.1 Machined Brass Fittings—Machined brass fittings shall be made from material meeting the requirements of Specification

B 140 copper alloy UNS C31400, Specification B 16 Copper alloy UNS C38500, or DIN 17660 – CuZn39Pb3.

5.1.2 Forged Brass Fittings—ForgedbrassfittingsshallbemadefrommaterialmeetingtherequirementsofSpecificationB 283

Copper alloy UNS C37700, or DIN 17660-CuZn40Pb2.

5.1.3 Compression Sleeves—CompressionsleevesshallbemadefrommaterialmeetingtherequirementsofSpecificationB 140

copper alloy UNS C37700, Specification B 16 Copper alloy UNS C38500, or DIN 17660-CuZn39PB3.

6. General Requirements

6.1 The following sections of Specification F 877 constitute a part of this specification:

6.1.1 Requirements,

6.1.2 Test Methods, and

6.1.3 Retest and Rejection

6.2 In addition, when a section with a title identical to that referenced in 6.1, above, appears in this specification, it contains

additional requirements that supplement those appearing in F 877.

6.3 Dimensions—Randomly selected fitting or fittings shall be used to determine dimensions. Measurements shall be made in

accordance with Test Method D 2122. Determine the diameters by making measurements at four points spaced approximately 45°

apart around the circumference. Inspection and gauging of solder joint ends shall be in accordance with ANSI B16.18, ANSI

B16.22, or MSS SP-104. Inspection and gauging of taper pipe threads shall be in accordance with ANSI/ASME G1.20.1. All

fittings that will be subjected to secondary processes of mechanical marking that affect their dimensional tolerances shall be tested

in their final marked configuration.

7. Dimensions

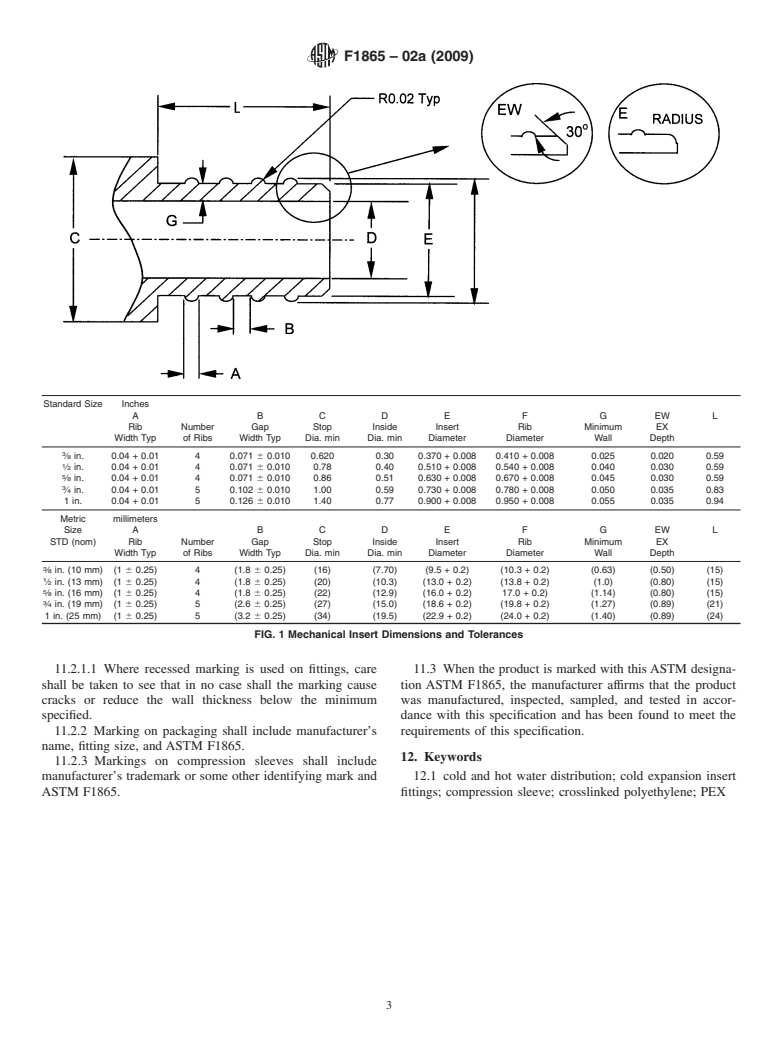

7.1 Dimensions and Tolerances—The dimensions and tolerances of fittings and compression sleeves shall be as shown in Fig.

1 and Fig. 2 when measured in accordance with 6.3.

7.1.1 Alignment—The maximum angular variation of any opening shall not exceed ⁄2 ° off the true centerline axis.

7.1.2 Fittings with Solder Joint Ends—Solder joint ends shall be in accordance with ASME B 16.22, ASME B 16.18 or MSS

SP-104

7.1.3 Tapered Threaded Ends—Fitting threads shall be right-hand conforming to ASME B 1.20.1. They shall be taper threads

(NPT).

8. Workmanship, Finish and Appearance

8.1 Thesealing,matingandthreadedsurfacesofthefitting(s)shallbesmoothandfreeofforeignmaterial.Thefittingwallsshall

be free of cracks, holes, blisters, voids, foreign inclusions, or other defects that are visible to the unmagnified eye and that may

affect the wall integrity.

9. Assembly

9.1 Joints—Mechanical Cold Expansion Insert Fittings with Compression Sleeve shall be joined to the PEX tubing by drawing

a compression sleeve over the PEX tubing that has been cold expanded and into which

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.