ASTM F442/F442M-99(2005)e1

(Specification)Standard Specification for Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Pipe (SDR–PR)

Standard Specification for Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Pipe (SDR<span class='unicode'>–</span>PR)

ABSTRACT

This specification covers chlorinated poly(vinyl chloride) (CPVC) pipes made in standard thermoplastic pipe dimension ratios and pressure rated for water. These pipes are intended for use in the distribution of pressurized liquids only, which are chemically compatible with the piping materials. Established here are the criteria for classifying both CPVC plastic pipe materials and finished CPVC plastic pipe products, as well as the requirements and associated test methods for the material, workmanship, dimensions, sustained pressure, burst pressure, flattening resistance, and extrusion quality.

SCOPE

1.1 This specification covers chlorinated poly(vinyl chloride) (CPVC) pipe made in standard thermoplastic pipe dimension ratios and pressure rated for water (see Appendix). Included are criteria for classifying CPVC plastic pipe materials and CPVC plastic pipe, and requirements and test methods for materials, workmanship, dimensions, sustained pressure, burst pressure, flattening, and extrusion quality. Methods of marking are also given.

Note 1—The CPVC pipe covered by this specification was covered previously in Specification D 2241.

Note 2—The sustained and burst pressure test requirements and the pressure ratings in the Appendix are calculated from stress values obtained from tests made on pipe 2 in. (50 mm) and smaller. However, tests on larger pipe have shown these stress values to be valid.

1.2 The products covered by this specification are intended for use with the distribution of pressurized liquids only, which are chemically compatible with the piping materials. Due to inherent hazards associated with testing components and systems with compressed air or other compressed gases some manufacturers do not allow pneumatic testing of their products. Consult with specific product/component manufacturers for their specific testing procedures prior to pneumatic testing.

Note 3—Pressurized (compressed) air or other compressed gases contain large amounts of stored energy which present serious saftey hazards should a system fail for any reason.

1.3 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.Within the text, the SI units are shown in brackets.

1.5 The following safety hazards caveat pertains only to the test methods portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. A specific precautionary statement is given in Note 5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

´1

Designation: F 442/F 442M – 99 (Reapproved 2005)

Standard Specification for

Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Pipe

(SDR–PR)

This standard is issued under the fixed designation F 442/F 442M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—Sections 4.1 and 4.2 were editorially revised in August 2008.

1. Scope each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining

1.1 This specification covers chlorinated poly(vinyl chlo-

values from the two systems may result in non-conformance

ride) (CPVC) pipe made in standard thermoplastic pipe dimen-

with the standard.Within the text, the SI units are shown in

sion ratios and pressure rated for water (see Appendix).

brackets.

Included are criteria for classifying CPVC plastic pipe mate-

1.5 The following safety hazards caveat pertains only to the

rials and CPVC plastic pipe, and requirements and test meth-

test methods portion, Section 8, of this specification: This

ods for materials, workmanship, dimensions, sustained pres-

standard does not purport to address all of the safety concerns,

sure, burst pressure, flattening, and extrusion quality. Methods

if any, associated with its use. It is the responsibility of the user

of marking are also given.

of this standard to establish appropriate safety and health

NOTE 1—The CPVC pipe covered by this specification was covered

practices and determine the applicability of regulatory limita-

previously in Specification D 2241.

tions prior to use. A specific precautionary statement is given

NOTE 2—The sustained and burst pressure test requirements and the

in Note 5.

pressureratingsintheAppendixarecalculatedfromstressvaluesobtained

from tests made on pipe 2 in. (50 mm) and smaller. However, tests on

2. Referenced Documents

larger pipe have shown these stress values to be valid.

2.1 ASTM Standards:

1.2 The products covered by this specification are intended

D 618 Practice for Conditioning Plastics for Testing

for use with the distribution of pressurized liquids only, which

D 1598 Test Method for Time-to-Failure of Plastic Pipe

are chemically compatible with the piping materials. Due to

Under Constant Internal Pressure

inherent hazards associated with testing components and sys-

D 1599 Test Method for Resistance to Short-Time Hydrau-

tems with compressed air or other compressed gases some

lic Pressure of Plastic Pipe, Tubing, and Fittings

manufacturersdonotallowpneumatictestingoftheirproducts.

D 1600 Terminology for Abbreviated Terms Relating to

Consult with specific product/component manufacturers for

Plastics

their specific testing procedures prior to pneumatic testing.

D 1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

NOTE 3—Pressurized (compressed) air or other compressed gases

Compounds and Chlorinated Poly(Vinyl Chloride)

contain large amounts of stored energy which present serious saftey

(CPVC) Compounds

hazards should a system fail for any reason.

D 2122 Test Method for Determining Dimensions of Ther-

1.3 The text of this specification references notes, footnotes,

moplastic Pipe and Fittings

and appendixes which provide explanatory material. These

D 2241 Specification for Poly(Vinyl Chloride) (PVC)

notesandfootnotes(excludingthoseintablesandfigures)shall

Pressure-Rated Pipe (SDR Series)

not be considered as requirements of the specification.

D 2837 Test Method for Obtaining Hydrostatic Design

1.4 The values stated in either SI units or inch-pound units

Basis forThermoplastic Pipe Materials or Pressure Design

are to be regarded separately as standard. The values stated in

Basis for Thermoplastic Pipe Products

F 412 Terminology Relating to Plastic Piping Systems

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.25 on Vinyl

Based Pipe. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2005. Published November 2005. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

published as part of D 2241 – 74. Last previous edition approved in 1999 as Standards volume information, refer to the standard’s Document Summary page on

F 442 – 99. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

F 442/F 442M – 99 (2005)

2.2 Federal Standard: When the design stress code contains less than two figures, a

Fed. Std. No. 123 Marking for Shipment (Civil Agencies) cipher shall be used before the number. Thus a complete

2.3 Military Standard: material code shall consist of four letters and four figures for

MIL-STD-129 Marking for Shipment and Storage CPVC plastic pipe materials (see Section 5 and X1.2.1).

2.4 NSF Standards:

Standard No. 14 for Plastic Piping Components and Related 4. Classification

Materials

4.1 General—This specification covers CPVC pipe made

Standard No. 61 for Drinking Water Systems

fromoneCPVCplasticpipematerialinsixstandarddimension

Components—Health Effects

ratios and water pressure ratings for nonthreaded pipe.

4.2 Standard Thermoplastic Pipe Dimension Ratios

3. Terminology

(SDR)—This specification covers CPVC pipe in six standard

3.1 Definitions—Definitions are in accordance with Termi-

dimension ratios, namely, 11, 13.5, 17, 21, 26, and 32.5, which

nology F 412, and abbreviations are in accordance with Ter-

are uniform for all nominal pipe sizes for each material and

minologyD 1600,unlessotherwisespecified.Theabbreviation

pressure rating. These are referred to as SDR11, SDR13.5,

for chlorinated poly(vinyl chloride) plastic is CPVC.

SDR21, SDR17, SDR26, and SDR32.5, respectively. The

3.2 Definitions of Terms Specific to This Standard:

pressure rating is uniform for all nominal pipe sizes for a given

3.2.1 hydrostatic design stress— the estimated maximum

CPVC pipe material and SDR (see Table X1.1).

tensile stress the material is capable of withstanding continu-

4.3 Hydrostatic Design Stresses—This specification covers

ously with a high degree of certainty that failure of the pipe

CPVC pipe made from CPVC plastic as defined by hydrostatic

will not occur. This stress is circumferential when internal

design stresses developed on the basis of long-term tests (see

hydrostatic water pressure is applied.

Appendix).

3.2.2 pressure rating (PR)—the estimated maximum water

pressure the pipe is capable of withstanding continuously with

5. Materials

ahighdegreeofcertaintythatfailureofthepipewillnotoccur.

5.1 General—Chlorinatedpoly(vinylchloride)plasticsused

3.2.3 relation between standard dimension ratio, hydro-

to make pipe meeting the requirements of this specification are

static design stress, and pressure rating—thefollowingexpres-

categorized by means of two criteria, namely, (1) short-term

sion, commonly known as the ISO equation, is used in this

strength tests, and (2) long-term hydrostatic strength tests at

specification to relate standard dimension ratio, hydrostatic

both 73 and 180° F [23 and 82° C].

design stress, and pressure rating:

5.2 Basic Materials—This specification covers CPVC pipe

2 S/P 5 R 21or2 S/P5~D /t!21

o made from compounds meeting the requirements of Class

23447 as defined in Specification D 1784. The materials shall

where:

have an established HDS (Hydrostatic Design Stress) equal to

S = hydrostatic design stress, psi [MPa],

or greater than 2000 psi [13.80 MPa] at 73° F [23° C] and 500

P = pressure rating, psi [kPa],

psi[3.45MPa)at180° F[82° C]whenevaluatedinaccordance

D = average outside diameter, in. [mm]

o

with Test Method D 2837.

t = minimum wall thickness, in. [mm], and

5.3 Rework Material—The manufacturers shall use only

R = standard thermoplastic pipe dimension ratio (D /t

o

their own clean rework pipe material and the pipe produced

for CPVC pipe), also known as SDR.

shall meet all the requirements of this specification.

3.2.4 standard thermoplastic pipe dimension ratio (SDR)—

the standard thermoplastic pipe dimension ratio (SDR) is the

6. Requirements Requirements

ratio of pipe diameter to wall thickness. For CPVC pipe it is

calculated by dividing the average outside diameter of the pipe

6.1 Dimension and Tolerances:

in millimetres or in inches by the minimum wall thickness in

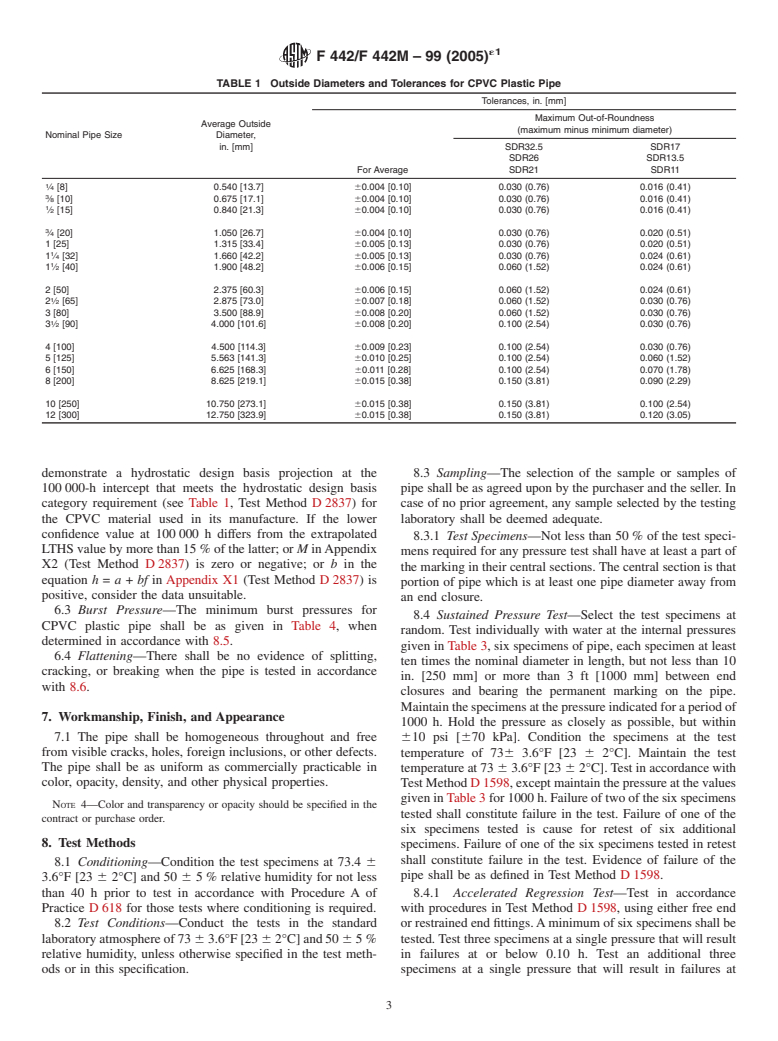

6.1.1 Outside Diameters—The outside diameters and toler-

millimetres or in inches. If the wall thickness calculated by this

ances shall be as shown in Table 1 when measured in

formula is less than 0.060 in. [1.52 mm], it shall be arbitrarily accordance with Test Method D 2122. The tolerances on

increased to 0.060 in. [1.52 mm]. The SDR values shall be

out-of-roundness shall apply only to pipe prior to shipment.

rounded to the nearest 0.5. 6.1.2 Wall Thickness—The wall thicknesses and tolerances

3.2.5 standard thermoplastic pipe materials designation

shall be as shown in Table 2 when measured in accordance

code—the pipe materials designation code shall consist of the with Test Method D 2122.

abbreviation CPVC for the type of plastic, followed by the

6.1.3 Wall Thickness Range—Thewallthicknessrangeshall

ASTM type and grade inArabic numerals and the design stress

be within 12 % when measured in accordance with Test

in units of 100 psi [690 kPa] with any decimal figures dropped.

Method D 2122.

6.2 Sustained Pressure—The pipe shall not fail, balloon,

burst, or weep as defined in Test Method D 1598 at the test

pressures given in Table 3 when tested in accordance with 8.4.

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

6.2.1 Accelerated Regression Test—At the option of the

Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd.,Ann

manufacturer, the accelerated regression test may be used as a

Arbor, MI 48113-0140.

substitute for both pressure tests—sustained and burst.The test

See ISO R161-1960: Pipes of Plastics Materials for the Transport of Fluids

(Outside Diameters and Nominal Pressures) Part 1, Metric Series. shall be conducted in accordance with 8.4.1. The pipe shall

´1

F 442/F 442M – 99 (2005)

TABLE 1 Outside Diameters and Tolerances for CPVC Plastic Pipe

Tolerances, in. [mm]

Maximum Out-of-Roundness

Average Outside

(maximum minus minimum diameter)

Nominal Pipe Size Diameter,

in. [mm] SDR32.5 SDR17

SDR26 SDR13.5

For Average SDR21 SDR11

⁄4 [8] 0.540 [13.7] 60.004 [0.10] 0.030 (0.76) 0.016 (0.41)

⁄8 [10] 0.675 [17.1] 60.004 [0.10] 0.030 (0.76) 0.016 (0.41)

⁄2 [15] 0.840 [21.3] 60.004 [0.10] 0.030 (0.76) 0.016 (0.41)

⁄4 [20] 1.050 [26.7] 60.004 [0.10] 0.030 (0.76) 0.020 (0.51)

1 [25] 1.315 [33.4] 60.005 [0.13] 0.030 (0.76) 0.020 (0.51)

1 ⁄4 [32] 1.660 [42.2] 60.005 [0.13] 0.030 (0.76) 0.024 (0.61)

1 ⁄2 [40] 1.900 [48.2] 60.006 [0.15] 0.060 (1.52) 0.024 (0.61)

2 [50] 2.375 [60.3] 60.006 [0.15] 0.060 (1.52) 0.024 (0.61)

2 ⁄2 [65] 2.875 [73.0] 60.007 [0.18] 0.060 (1.52) 0.030 (0.76)

3 [80] 3.500 [88.9] 60.008 [0.20] 0.060 (1.52) 0.030 (0.76)

3 ⁄2 [90] 4.000 [101.6] 60.008 [0.20] 0.100 (2.54) 0.030 (0.76)

4 [100] 4.500 [114.3] 60.009 [0.23] 0.100 (2.54) 0.030 (0.76)

5 [125] 5.563 [141.3] 60.010 [0.25] 0.100 (2.54) 0.060 (1.52)

6 [150] 6.625 [168.3] 60.011 [0.28] 0.100 (2.54) 0.070 (1.78)

8 [200] 8.625 [219.1] 60.015 [0.38] 0.150 (3.81) 0.090 (2.29)

10 [250] 10.750 [273.1] 60.015 [0.38] 0.150 (3.81) 0.100 (2.54)

12 [300] 12.750 [323.9] 60.015 [0.38] 0.150 (3.81) 0.120 (3.05)

demonstrate a hydrostatic design basis projection at the 8.3 Sampling—The selection of the sample or samples of

100 000-h intercept that meets the hydrostatic design basis pipe shall be as agreed upon by the purchaser and the seller. In

category requirement (see Table 1, Test Method D 2837) for case of no prior agreement, any sample selected by the testing

the CPVC material used in its manufacture. If the lower laboratory shall be deemed adequate.

confidence value at 100 000 h differs from the extrapolated

8.3.1 Test Specimens—Not less than 50 % of the test speci-

LTHS value by more than 15 % of the latter; or M inAppendix

mens required for any pressure test shall have at least a part of

X2 (Test Method D 2837) is zero or negative; or b in the

the marking in their central sections. The central section is that

equation h = a + bf in Appendix X1 (Test Method D 2837)is

portion of pipe which is at least one pipe diameter away from

positive, consider the data unsuitable.

an end closure.

6.3 Burst Pressure—The minimum burst pressures for

8.4 Sustained Pressure Test—Select the test specimens at

CPVC plastic pipe shall be as given in Table 4, when

random. Test individually with water at the internal pressures

determined in accordance with 8.5.

given in Table 3, six specimens of pipe, each specimen at least

6.4 Flattening—There shall be no evidence of splitting,

ten times the nominal diameter in length, but not less than 10

cracking, or breaking when the pipe is tested in accordance

in. [250 mm] or more than 3 ft [1000 mm] between end

with 8.6.

closures and bearing the permanent marking on the pipe.

Maintainthespecimensatthepressureindicatedforaperiodof

7. Workmanship, Finish, and Appearance

1000 h. Hold the pressure as closely as possible, but within

7.1 The pipe shall be homogeneous throughout and free 610 psi [670 kPa]. Condition the specimens at the test

from visible cracks, holes, foreign inclusions, or other defects.

temperature of 736 3.6°F [23 6 2°C]. Maintain the test

The pipe shall be as uniform as commercially practicable in

temperature at 73 6 3.6°F [23 6 2°C].Test in accordance with

color, opacity, density, and other physical properties.

TestMethodD 1598,exceptmaintainthepressureatthevalues

giveninTable3for1000h.Failureoftwoofthesixspecimens

NOTE 4—Color and transparency or opacity should be specified in the

tested shall constitute failure in the test. Failure of one of the

contract or purchase order.

six specimens tested is cause for retest of six additional

8. Test Methods

specimens. Failure of one of the six specimens tested in retest

shall constitute failure in the test. Evidence of failure of the

8.1 Conditioning—Condition the test specimens at 73.4 6

pipe shall be as defined in Test Method D 1598.

3.6°F [23 6 2°C] and 50 6 5 % relative humidity for not less

than 40 h prior to test in accordance with Procedure A of 8.4.1 Accelerated Regression Test—Test in accordance

Practice D 618

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.