ASTM A803/A803M-10

(Specification)Standard Specification for Welded Ferritic Stainless Steel Feedwater Heater Tubes

Standard Specification for Welded Ferritic Stainless Steel Feedwater Heater Tubes

ABSTRACT

This specification covers standard requirements for welded ferritic stainless steel feedforward heater tubes including those bent, if specified, into the form of U-tubes for application in tubular feed-water heaters. All finished straight tubing or straight tubing ready for U-bending shall be furnished in the solution-annealed condition. The steel shall conform to the required chemical composition for carbon, manganese, phosphorus, sulfur, silicon, nickel, chromium, molybdenum, aluminum, copper, nitrogen, titanium, and columbium. The material shall also conform to tensile properties such as tensile strength, yield strength, and elongation. The steel shall meet the specified values for Brinell and Rockwell hardness. The steel shall undergo mechanical tests such as tension test, hardness test, reverse flattening test, flange test, pressure test, hydrostatic test, and air underwater test. Corrosion resisting properties of the sample tube shall also be determined.

SCOPE

1.1 This specification covers welded ferritic stainless steel feedwater heater tubes including those bent, if specified, into the form of U-tubes for application in tubular feedwater heaters.

1.2 The tubing sizes covered shall be 5/8 to 1 in. [15.9 to 25.4 mm] inclusive, in outside diameter, and average or minimum wall thicknesses of 0.028 in. [0.7 mm] and heavier.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A803/A803M – 10

Standard Specification for

1

Welded Ferritic Stainless Steel Feedwater Heater Tubes

This standard is issued under the fixed designationA803/A803M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 4. Ordering Information

1.1 This specification covers welded ferritic stainless steel 4.1 It is the responsibility of the purchaser to specify all

feedwater heater tubes including those bent, if specified, into requirements that are necessary for material under this speci-

the form of U-tubes for application in tubular feedwater fication.Suchrequirementsmayinclude,butarenotlimitedto,

heaters. the following:

5

1.2 Thetubingsizescoveredshallbe ⁄8to1in.[15.9to25.4 4.1.1 Quantity (length or number of pieces),

mm] inclusive, in outside diameter, and average or minimum 4.1.2 Material description,

wall thicknesses of 0.028 in. [0.7 mm] and heavier. 4.1.3 Dimensions (outside diameter, wall thickness (mini-

1.3 The values stated in either SI units or inch-pound units mum or average wall), and length),

are to be regarded separately as standard. Within the text, the 4.1.4 Grade (chemical composition) (Table 1), and

SI units are shown in brackets. The values stated in each 4.1.5 U-bend requirements, if order specifies bending,

system may not be exact equivalents; therefore, each system U-bend schedules or drawings shall accompany the order.

shall be used independently of the other. Combining values 4.2 Optional Requirements—Purchaser shall specify

from the two systems may result in nonconformance with the whether annealing of the U-bends is required or whether tubes

specification. The inch-pound units shall apply unless the “M” are to be hydrotested or air-tested (see 10.5).

designation of this specification is specified in the order. 4.3 Supplementary Requirements—Purchaser shall specify

onthispurchaseorderifmaterialistobeeddy-currenttestedin

2. Referenced Documents

accordance with Supplementary Requirement S1 or S2, and if

2

2.1 ASTM Standards:

specialtestreportsarerequired,underSupplementaryRequire-

A480/A480M Specification for General Requirements for ment S3, and,

Flat-Rolled Stainless and Heat-Resisting Steel Plate,

4.4 Any special requirements.

Sheet, and Strip

5. General Requirements

A763 Practices for Detecting Susceptibility to Intergranular

Attack in Ferritic Stainless Steels 5.1 Material furnished to this specification shall conform to

A941 Terminology Relating to Steel, Stainless Steel, Re- the applicable requirements of the latest published edition of

lated Alloys, and Ferroalloys Specification A1016/A1016M unless otherwise provided

A1016/A1016M Specification for General Requirements herein.

for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stain-

6. Materials and Manufacture

less Steel Tubes

6.1 The tube shall be made from flat-rolled steel by an

3. Terminology

automatic welding process with no addition of filler metal.

3.1 Definitions—For definitions of terms used in this speci- 6.2 Surface contaminants may have detrimental effects on

fication, refer to Terminology A941. high temperature properties or corrosion resistance of tubing.

Contamination by copper, lead, mercury, zinc, chlorides, or

sulfur may be detrimental to stainless steels.The manufacturer

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

shall employ techniques which minimize surface contamina-

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

tion by these elements.

A01.10 on Stainless and Alloy Steel Tubular Products.

Current edition approved May 1, 2010. Published June 2010. Originally

7. Cleaning Before Annealing

approved in 1982. Last previous edition approved in 2008 as A803/A803M–08.

DOI: 10.1520/A0803_A0803M-10.

7.1 All lubricants or coatings used in the manufacture of

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

straight-lengthtubeorinthebendingshallberemovedfromall

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

surfaces prior to any annealing treatments. U-bends on which

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. a lubricant had been applied to the inside surface during

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A803/A803M – 10

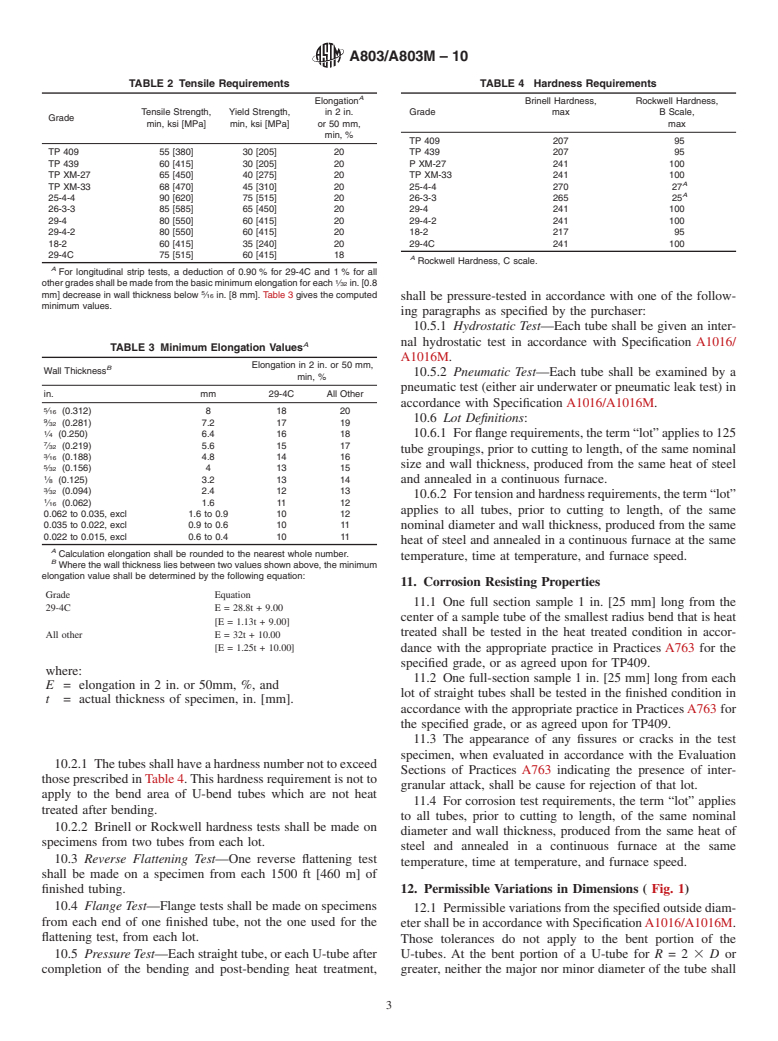

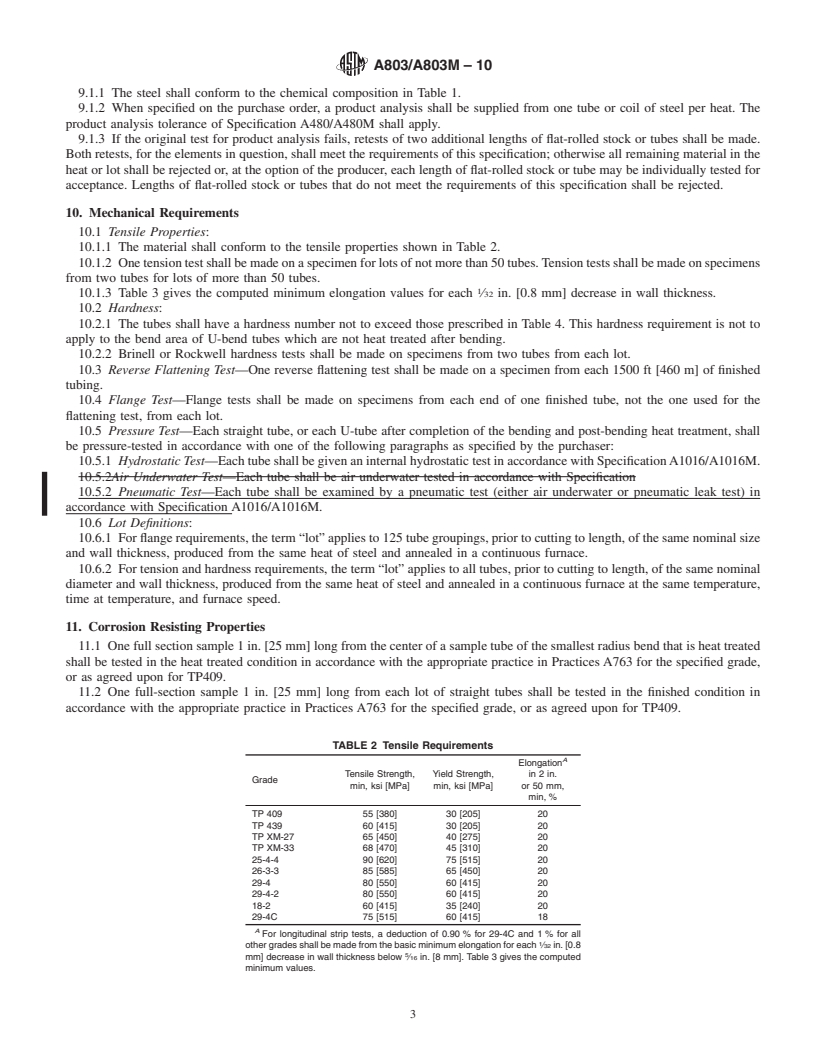

TABLE 1 Chemical Requirements

Grade UNS UNS S 43035 UNS UNS S 44626 UNS S 44635 UNS S 44660 UNS UNS UNS S 44400 UNS

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A803/A803M–08 Designation: A803/A803M – 10

Standard Specification for

1

Welded Ferritic Stainless Steel Feedwater Heater Tubes

This standard is issued under the fixed designationA803/A803M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 Thisspecificationcoversweldedferriticstainlesssteelfeedwaterheatertubesincludingthosebent,ifspecified,intotheform

of U-tubes for application in tubular feedwater heaters.

5

1.2 Thetubingsizescoveredshallbe ⁄8to1in.[15.9to25.4mm]inclusive,inoutsidediameter,andaverageorminimumwall

thicknesses of 0.028 in. [0.7 mm] and heavier.

1.3 The values stated in either inch-poundSI units or SIinch-pound units are to be regarded separately as standard. Within the

text, the SI units are shown in brackets. The values stated in each system aremay not be exact equivalents; therefore, each system

mustshall be used independently of the other. Combining values from the two systems may result in nonconformance with the

specification. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

2. Referenced Documents

2

2.1 ASTM Standards:

A480/A480M SpecificationforGeneralRequirementsforFlat-RolledStainlessandHeat-ResistingSteelPlate,Sheet,andStrip

A763 Practices for Detecting Susceptibility to Intergranular Attack in Ferritic Stainless Steels

A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

A1016/A1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel

Tubes

3. Terminology

3.1 Definitions—For definitions of terms used in this specification, refer to Terminology A941.

4. Ordering Information

4.1 It is the responsibility of the purchaser to specify all requirements that are necessary for material under this specification.

Such requirements may include, but are not limited to, the following:

4.1.1 Quantity (length or number of pieces),

4.1.2 Material description,

4.1.3 Dimensions (outside diameter, wall thickness (minimum or average wall), and length),

4.1.4 Grade (chemical composition) (Table 1), and

4.1.5 U-bend requirements, if order specifies bending, U-bend schedules or drawings shall accompany the order.

4.2 Optional Requirements—Purchaser shall specify whether annealing of the U-bends is required or whether tubes are to be

hydrotested or air-tested (see 10.5).

4.3 Supplementary Requirements—Purchaser shall specify on this purchase order if material is to be eddy-current tested in

accordance with Supplementary Requirement S1 or S2, and if special test reports are required, under Supplementary Requirement

S3, and,

4.4 Any special requirements.

5. General Requirements

5.1 Material furnished to this specification shall conform to the applicable requirements of the latest published edition of

Specification A1016/A1016M unless otherwise provided herein.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeA01onSteel,StainlessSteelandRelatedAlloysandisthedirectresponsibilityofSubcommitteeA01.10

on Stainless and Alloy Steel Tubular Products .

Current edition approved MarchMay 1, 2008.2010. Published March 2008.June 2010. Originally approved in 1982. Last previous edition approved in 20032008 as

A803/A803M–03.A803/A803M–08. DOI: 10.1520/A0803_A0803M-108.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A803/A803M – 10

TABLE 1 Chemical Requirements

Grade UNS UNS S 43035 UNS UNS S 44626 UNS S 44635 UNS S 44660 UNS UNS UNS S 44400 UNS S 44735

S 40900 TP439 S 44627 TP XM-33 25-4-4 26-3-3 S 44700 S 44800 18-2 29-4C

TP409 TP XM-27 29-4 29-4-2

Element Composition, %

A

C, max 0.08 0.07 0.01 0.06 0.025 0.030 0.010 0.010 0.025 0.030

Mn, max 1.00 1.00 0.40 0.75 1.00 1.00 0.30 0.30 1.00 1.00

P, max 0.045 0.040 0.02 0.040 0.040 0.040 0.025 0.025 0.040 0.040

S, max 0.030 0.030 0.02 0.020 0.030 0.030 0.020 0.020 0.030 0.030

Si, max 1.00 1.00 0.40 0.75 0.75 1.00 0.20

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A803/A803M–08 Designation: A803/A803M – 10

Standard Specification for

1

Welded Ferritic Stainless Steel Feedwater Heater Tubes

This standard is issued under the fixed designationA803/A803M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 Thisspecificationcoversweldedferriticstainlesssteelfeedwaterheatertubesincludingthosebent,ifspecified,intotheform

of U-tubes for application in tubular feedwater heaters.

5

1.2 Thetubingsizescoveredshallbe ⁄8to1in.[15.9to25.4mm]inclusive,inoutsidediameter,andaverageorminimumwall

thicknesses of 0.028 in. [0.7 mm] and heavier.

1.3 The values stated in either inch-poundSI units or SIinch-pound units are to be regarded separately as standard. Within the

text, the SI units are shown in brackets. The values stated in each system aremay not be exact equivalents; therefore, each system

mustshall be used independently of the other. Combining values from the two systems may result in nonconformance with the

specification. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

2. Referenced Documents

2

2.1 ASTM Standards:

A480/A480M SpecificationforGeneralRequirementsforFlat-RolledStainlessandHeat-ResistingSteelPlate,Sheet,andStrip

A763 Practices for Detecting Susceptibility to Intergranular Attack in Ferritic Stainless Steels

A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

A1016/A1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel

Tubes

3. Terminology

3.1 Definitions—For definitions of terms used in this specification, refer to Terminology A941.

4. Ordering Information

4.1 It is the responsibility of the purchaser to specify all requirements that are necessary for material under this specification.

Such requirements may include, but are not limited to, the following:

4.1.1 Quantity (length or number of pieces),

4.1.2 Material description,

4.1.3 Dimensions (outside diameter, wall thickness (minimum or average wall), and length),

4.1.4 Grade (chemical composition) (Table 1), and

4.1.5 U-bend requirements, if order specifies bending, U-bend schedules or drawings shall accompany the order.

4.2 Optional Requirements—Purchaser shall specify whether annealing of the U-bends is required or whether tubes are to be

hydrotested or air-tested (see 10.5).

4.3 Supplementary Requirements—Purchaser shall specify on this purchase order if material is to be eddy-current tested in

accordance with Supplementary Requirement S1 or S2, and if special test reports are required, under Supplementary Requirement

S3, and,

4.4 Any special requirements.

5. General Requirements

5.1 Material furnished to this specification shall conform to the applicable requirements of the latest published edition of

Specification A1016/A1016M unless otherwise provided herein.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeA01onSteel,StainlessSteelandRelatedAlloysandisthedirectresponsibilityofSubcommitteeA01.10

on Stainless and Alloy Steel Tubular Products .

Current edition approved MarchMay 1, 2008.2010. Published March 2008.June 2010. Originally approved in 1982. Last previous edition approved in 20032008 as

A803/A803M–03.A803/A803M–08. DOI: 10.1520/A0803_A0803M-108.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A803/A803M – 10

TABLE 1 Chemical Requirements

Grade UNS UNS S 43035 UNS UNS S 44626 UNS S 44635 UNS S 44660 UNS UNS UNS S 44400 UNS S 44735

S 40900 TP439 S 44627 TP XM-33 25-4-4 26-3-3 S 44700 S 44800 18-2 29-4C

TP409 TP XM-27 29-4 29-4-2

Element Composition, %

A

C, max 0.08 0.07 0.01 0.06 0.025 0.030 0.010 0.010 0.025 0.030

Mn, max 1.00 1.00 0.40 0.75 1.00 1.00 0.30 0.30 1.00 1.00

P, max 0.045 0.040 0.02 0.040 0.040 0.040 0.025 0.025 0.040 0.040

S, max 0.030 0.030 0.02 0.020 0.030 0.030 0.020 0.020 0.030 0.030

Si, max 1.00 1.00 0.40 0.75 0.75 1.00 0.20

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.