ASTM F2141-07(2019)

(Test Method)Standard Test Method for Performance of Self-Serve Hot Deli Cases

Standard Test Method for Performance of Self-Serve Hot Deli Cases

SIGNIFICANCE AND USE

5.1 The energy input rate is used to confirm that the deli case is operating properly prior to further testing.

5.2 Holding temperature range is useful for food service operators in selecting a unit that matches their holding requirements.

5.3 Capacity is used by food service operators to choose a deli case that matches their food holding requirements.

5.4 Preheat energy and time can be useful to food service operators to manage energy demands and to know how quickly the deli case can be ready for operation.

5.5 Holding energy rate and idle energy rate can be used by the food service operator to estimate deli case energy consumption.

SCOPE

1.1 This test method evaluates the energy consumption and performance of self-serve hot deli cases. The food service operator can use this evaluation to select a deli case and understand its energy consumption and performance.

1.2 This test method is applicable to electric, fully open or partially open, hot deli cases that have been designed to hold and merchandise prepackaged hot food. For staff-serve hot deli cases, refer to Test Method F2472.

1.3 The deli case can be evaluated with respect to the following (where applicable):

1.3.1 Energy input rate (10.2),

1.3.2 Energy and temperature at the minimum setting (10.3),

1.3.3 Energy and temperature at the maximum setting (10.3),

1.3.4 Energy and temperature at the manufacturer's recommended setting (10.3),

1.3.5 Holding capacity (10.4),

1.3.6 Holding temperature calibration (10.4),

1.3.7 Preheat energy rate (10.5),

1.3.8 Idle energy rate (10.6), and

1.3.9 Holding energy rate (10.7).

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2141 − 07 (Reapproved 2019) An American National Standard

Standard Test Method for

Performance of Self-Serve Hot Deli Cases

This standard is issued under the fixed designation F2141; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This test method evaluates the energy consumption and

performance of self-serve hot deli cases. The food service

2. Referenced Documents

operator can use this evaluation to select a deli case and

2.1 ASTM Standards:

understand its energy consumption and performance.

A36/A36MSpecification for Carbon Structural Steel

1.2 This test method is applicable to electric, fully open or

F2472Test Method for Performance of Staff-Serve Hot Deli

partially open, hot deli cases that have been designed to hold

Cases

andmerchandiseprepackagedhotfood.Forstaff-servehotdeli

cases, refer to Test Method F2472.

3. Terminology

1.3 The deli case can be evaluated with respect to the 3.1 calibrated temperature, n—temperaturesettingatwhich

following (where applicable): the lowest temperature of the water in the holding pans is at

1.3.1 Energy input rate (10.2), 142 6 2°F (61 6 1°C).

1.3.2 Energy and temperature at the minimum setting 1

3.2 capacity, n—the amount of ⁄6 size containers the deli

(10.3),

case will hold in a single layer at one time.

1.3.3 Energy and temperature at the maximum setting

3.3 deli case, n—an appliance designed for the display of

(10.3),

hot food product.

1.3.4 Energy and temperature at the manufacturer’s recom-

3.4 energy input rate, n—peak rate at which a deli case

mended setting (10.3),

consumes energy (kW), typically reflected during preheat.

1.3.5 Holding capacity (10.4),

1.3.6 Holding temperature calibration (10.4), 3.5 factory setting, n—recommended control setting by the

1.3.7 Preheat energy rate (10.5), manufacturer.

1.3.8 Idle energy rate (10.6), and

3.6 holding energy, n—energy consumed by the deli case as

1.3.9 Holding energy rate (10.7).

it is used to hold cooked food product under full load

conditions.

1.4 Thevaluesstatedininch-poundunitsaretoberegarded

as standard. The values given in parentheses are mathematical

3.7 holding energy rate, n—average rate of energy con-

conversions to SI units that are provided for information only

sumption (kW) during the holding energy tests.

and are not considered standard.

3.8 idle energy rate, n—the rate of energy consumed (kW)

1.5 This standard does not purport to address all of the

by the deli case while “holding” or maintaining the heated

safety concerns, if any, associated with its use. It is the

surface at the thermostat set point.

responsibility of the user of this standard to establish appro-

3.9 maximum setting, n—settingatwhichmaximumsurface

priate safety, health, and environmental practices and deter-

temperature is achieved.

mine the applicability of regulatory limitations prior to use.

3.10 minimumsetting,n—settingatwhichminimumsurface

1.6 This international standard was developed in accor-

temperature is achieved.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 3.11 preheat energy, n—amount of energy consumed by the

Development of International Standards, Guides and Recom- deli case while preheating the heated surface from ambient

room temperature (75 6 5°F (24 6 3°C)) to a temperature at

the calibrated setting.

This test method is under the jurisdiction of ASTM Committee F26 on Food

Service Equipment and is the direct responsibility of Subcommittee F26.06 on

Productivity and Energy Protocol. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2019. Published June 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2001. Last previous edition approved in 2013 as F2141–07 (2013). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/F2141-07R19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2141 − 07 (2019)

3.12 preheat rate, n—average rate (°F/min (°C/min)) at 6.2 Data Acquisition System, for measuring energy and

which the deli case’s holding surface is heated from ambient temperatures, capable of multiple channel displays updating at

temperature (75 6 5°F (24 6 3°C)) to holding temperature least every 2 s.

with the thermostat set to the calibrated setting.

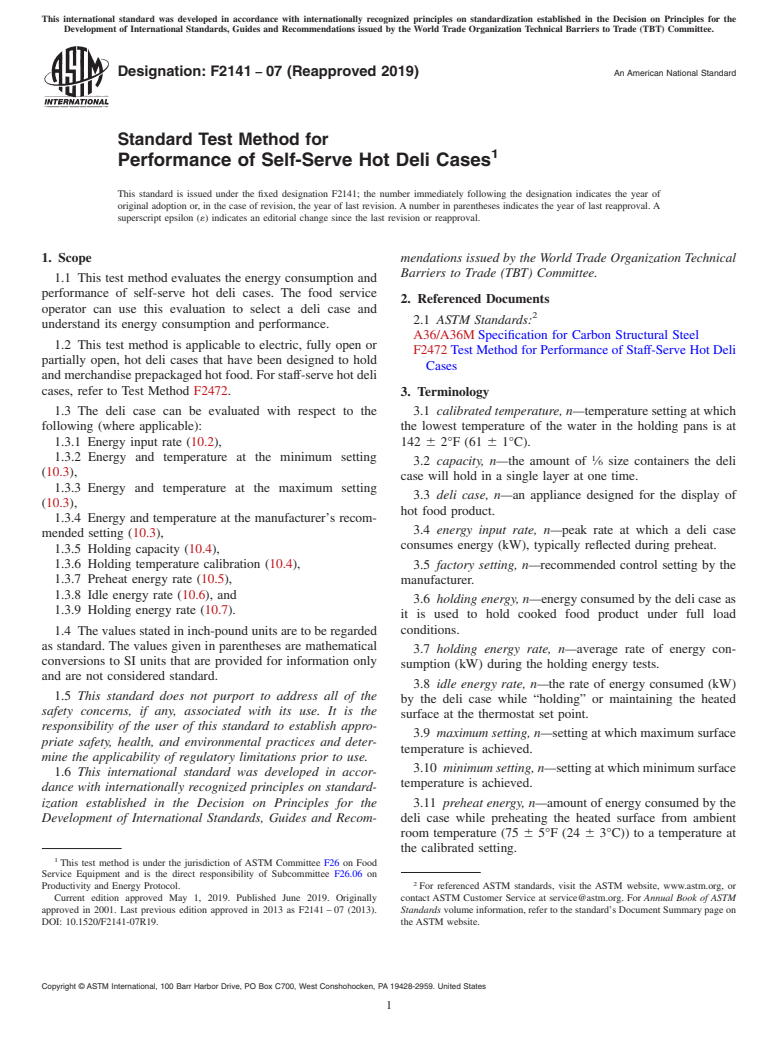

6.3 Metal Discs, (one for each hexagonal section of the deli

3.13 preheat time, n—time required for the deli case to case or one for each square foot of the deli case) composed of

preheat from ambient room temperature (75 6 5°F (24 6

structural-grade carbon steel in accordance to Specification

3°C)) to the calibrated setting. A36/A36M, free of rust or corrosion, 5 in. (127 mm) in

diameter, and ⁄4 in. (6 mm) thick. The discs shall be flat to

3.14 uncertainty, n—measure of systematic and precision

within 0.010 in. (0.2 mm) over the diameter.

errors in specified instrumentation or measure of repeatability

of a reported test result.

6.4 Strain Gage Welder, capable of welding thermocouples

to steel.

4. Summary of Test Method

6.5 Thermocouple(s), industry standard type T or type K

4.1 The deli case is connected to the appropriate metered thermocouple wire with a range of 0 to 250°F (−18 to 121°C)

energy source, and energy input rate is determined to confirm and an uncertainty of 61°F (60.56°C).

that the appliance is operating within 5% of the nameplate

6.6 Thermocouple Probe, “fast response” type T or type K

energy input rate.

thermocouple probe, ⁄16-in. or smaller diameter, with a 3-s or

4.2 Thedelicaseholdingsurfaceismonitoredatmaximum, fasterresponsetime,capableofimmersionwitharangeof0to

250°F (−18 to 121°C) and an uncertainty of 61°F (60.56°C).

minimum, and factory recommended (if provided) settings

using a predetermined number of 5-in. (127-mm) metal discs The thermocouple probe’s active zone shall be at the tip of the

probe.

distributed equally over the heating surface of the deli case.

6.7 Watt-Hour Meter, for measuring the electrical energy

4.3 Capacityisdeterminedbyloadingthedelicasefullof ⁄6

consumptionofadelicase,shallhavearesolutionofatleast10

size containers.

Wh and a maximum uncertainty no greater than 1.5% of the

4.4 The calibrated setting is determined by using ⁄6 size

measured value for any demand greater than 100 W. For any

plastic pans filled with water and setting the surface tempera-

demandlessthan100W,themetershallhavearesolutionofat

ture of the deli case such that lowest temperature in the water

least 10Wh and a maximum uncertainty no greater than 10%.

containers is 142 6 2°F (61 6 1°C).

7. Reagents and Materials

4.5 The amount of energy and time required to preheat the

deli case to calibrated setting is determined.

7.1 Binder Clips, ⁄4 in. (19 mm) size.

4.6 The idle energy rate is determined with the deli case set 7.2 Macaroni and Cheese, a sufficient quantity of frozen,

at calibrated setting.

ready-to-cook, traditional macaroni and cheese, in ⁄2 size pans

weighting approximately 4 lb (1.8 kg) obtained from a food

4.7 The deli case is used to hold ⁄6 size containers filled

distributor.

with hot food for 3 h. Food temperature and deli case energy

1 3 15

consumption are monitored during this testing. 7.3 Pans with Covers, Cambro ⁄6 size, 6 ⁄8×6 ⁄16 in. (162

3 15

× 176 mm) black plastic pans with 6 ⁄8×6 ⁄16 in. (162 × 176

mm) plastic amber colored cover able to accommodate tem-

5. Significance and Use

peratures up to 375°F (191°C).

5.1 The energy input rate is used to confirm that the deli

7.4 Water, with a maximum hardness of less than 3 grains/

case is operating properly prior to further testing.

gal.

5.2 Holding temperature range is useful for food service

operatorsinselectingaunitthatmatchestheirholdingrequire- 8. Sampling, Test Units

ments.

8.1 DeliCase—Selectarepresentativeproductionmodelfor

5.3 Capacity is used by food service operators to choose a performance testing.

deli case that matches their food holding requirements.

9. Preparation of Apparatus

5.4 Preheat energy and time can be useful to food service

9.1 Install the deli case according to the manufacturer’s

operatorstomanageenergydemandsandtoknowhowquickly

instructions in an appropriate space. All sides of the deli case

the deli case can be ready for operation.

shall be a minimum of 3 ft (0.9 m) from any side wall, side

5.5 Holding energy rate and idle energy rate can be used by

partition, or other operating appliance. The associated heating

thefoodserviceoperatortoestimatedelicaseenergyconsump-

orcoolingsystemforthespaceshallbecapableofmaintaining

tion.

an ambient temperature of 75 6 5°F (24 6 3°C) within the

testing environment.

6. Apparatus

9.2 Connectthedelicasetoacalibratedenergytestmeter.A

6.1 Analytical Balance Scale, for measuring weights up to voltage regulator may be required during tests if the voltage

20 lb (9 kg), with a resolution of 0.01 lb (0.004 kg) and an supply is not within 62.5% of the manufacturer’s nameplate

uncertainty of 0.01 lb (0.004 kg). voltage.

F2141 − 07 (2019)

9.3 Confirm (while the elements are energized) that the 10.3.3 Setthecontrolstothelowestpossiblesettingwithout

supply voltage is within 62.5% of the operating voltage being turned off.

specified by the manufacturer. Record the test voltage for each

10.3.4 Allow the unit to stabilize for 1 h, then monitor

test. temperature and energy consumption for an additional 2 h,

recording the temperatures at least once every minute.

NOTE 1—It is the intent of the testing procedure herein to evaluate the

10.3.5 Repeat10.3.4withthecontrolssettotheirmaximum

performance of a deli case at its rated electric voltage. If the unit is rated

dual voltage (that is, designed to operate at either 240 or 480 V with no

setting.

change in components), the voltage selected by the manufacturer and/or

10.3.6 Repeat 10.3.4 with the controls set to the manufac-

testershallbereported.Ifadelicaseisdesignedtooperateattwovoltages

turer’s recommended settings (if applicable).

without a change in the resistance of the heating elements, the perfor-

mance of the unit (for example, preheat time) may differ at the two

10.4 Holding Temperature Calibration:

voltages.

10.4

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.