ASTM F2472-05

(Test Method)Standard Test Method for Performance of Staff-Serve Hot Deli Cases

Standard Test Method for Performance of Staff-Serve Hot Deli Cases

SCOPE

1.1 This test method evaluates the energy consumption and performance of staff-serve hot deli cases with heated wells located within a fully or partially enclosed heated cavity. The food service operator can use this evaluation to select a staff served hot deli case and understand its energy consumption and performance.

1.2 This test method is applicable to electric powered, hot deli cases that have been designed for staff service of prepared hot food items that are held in open hotel pans.

1.3 The deli case can be evaluated with respect to the following (where applicable):

1.3.1 Energy input rate (10.2),

1.3.2 Holding capacity (10.3),

1.3.3 Holding temperature calibration (10.3),

1.3.4 Preheat energy rate, (10.4),

1.3.5 Idle energy rate (10.5), and

1.3.6 Holding energy rate (10.6).

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This test method may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation:F2472–05

Standard Test Method for

Performance of Staff-Serve Hot Deli Cases

This standard is issued under the fixed designation F2472; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope NSF Listing Food Equipment and Related Components and

Material

1.1 This test method evaluates the energy consumption and

NSF/ANSI 4 Commercial Cooking, Rethermalization and

performance of staff-serve hot deli cases with heated wells

Powered Hot Food Holding and Transport Equipment

located within a fully or partially enclosed heated cavity. The

food service operator can use this evaluation to select a staff

3. Terminology

servedhotdelicaseandunderstanditsenergyconsumptionand

3.1 Definitions:

performance.

3.1.1 calibrated setting, n—temperaturesettingatwhichthe

1.2 This test method is applicable to electric powered, hot

lowest temperature of the food in the holding pans is at 142 6

deli cases that have been designed for staff service of prepared

2°F (61 6 1°C).

hot food items that are held in open hotel pans.

3.1.2 capacity, n—amount of food product that can be held

1.3 The deli case can be evaluated with respect to the

in the unit’s heated wells within standard 4-in. (102-mm) deep

following (where applicable):

steam table pans.

1.3.1 Energy input rate (10.2),

3.1.3 energy input rate, n—peak rate at which a deli case

1.3.2 Holding capacity (10.3),

consumes energy (kW), typically reflected during preheat.

1.3.3 Holding temperature calibration (10.3),

3.1.4 holding energy, n—energy consumed by the deli case

1.3.4 Preheat energy rate, (10.4),

as it is used to hold cooked food product under full load

1.3.5 Idle energy rate (10.5), and

conditions.

1.3.6 Holding energy rate (10.6).

3.1.5 holding energy rate, n—average rate of energy con-

1.4 The values stated in inch-pound units are to be regarded

sumption (kW) during the holding energy tests.

as the standard. The values given in parentheses are for

3.1.6 idle energy rate, n—rateofenergyconsumed(kW)by

information only.

the deli case while holding or maintaining the appliance at the

1.5 This test method may involve hazardous materials,

thermostat set point without any food product.

operations, and equipment. This standard does not purport to

3.1.7 preheat energy, n—amount of energy consumed by

address all of the safety concerns, if any, associated with its

thedelicasewhilepreheatingtheappliancefromambientroom

use. It is the responsibility of the user of this standard to

temperature (73 6 3°F (22 6 2°C)) to a temperature at the

establish appropriate safety and health practices and deter-

calibrated setting.

mine the applicability of regulatory limitations prior to use.

3.1.8 preheat rate, n—average rate (°F/min) at which the

2. Referenced Documents deli case is heated from ambient temperature (73 6 3°F (22 6

2 2°C)) to holding temperature with the thermostat set to the

2.1 ASHRAE Document:

calibrated setting.

ASHRAE Guideline 2-1986 (RA90) Engineering Analysis

3.1.9 preheat time, n—time required for the deli case to

of Experimental Data

preheat from ambient room temperature (73 6 3°F (22 6

2.2 NSF Standards:

2°C)) to the calibrated setting.

3.1.10 staff-serve hot deli case, n—(hereafter referred to as

This test method is under the jurisdiction of ASTM Committee F26 on Food

deli case) an appliance, with heated wells located in a fully or

Service Equipment and is the direct responsibility of Subcommittee F26.06 on

partially enclosed heated cavity, which is designed for the

Productivity and Energy Protocol.

display and service of hot food product in standard hotel pans.

Current edition approved March 1, 2005. Published March 2005. DOI: 10.1520/

F2472-05.

Also known as hot food merchandisers, display merchandisers

Available from the American Society of Heating, Refrigerating, and Air

or hot display cases.

Conditioning Engineers, Inc., 1791 Tullie Circle, NE, Atlanta, GA 30329.

Available from NSF International, P.O. Box 130140, Ann Arbor, MI 48113-

0140.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2472–05

3.1.11 uncertainty, n—measure of systematic and precision 7. Reagents and Materials

errors in specified instrumentation or measure of repeatability

7.1 Macaroni and Cheese, a sufficient quantity of frozen,

of a reported test result.

ready to cook, traditional macaroni and cheese, in half-size

pans weighing approximately 4.5 lb (2.0 kg) obtained from a

4. Summary of Test Method

food distributor.

4.1 The deli case is connected to the appropriate metered

7.2 Pans, a sufficient quantity of stainless steel half-size

energy source, and energy input rate is determined to confirm

steam pans, measuring 10 by 12 by 4 in. (250 by 300 by 100

that the appliance is operating within 5% of the nameplate

mm) and weighing 1.8 6 0.2 lb (0.8 6 0.1 kg), to fill the deli

energy input rate.

case’s heated wells.

4.2 Capacityisdeterminedbyloadingthedelicase’sheated

7.3 SmallPans,asufficientquantityofstainlesssteel ⁄3-size

wells with 4-in. (100-mm) deep half-size steam table pans.

steam pans, measuring 10 by 8 by 4 in. (250 by 200 by 100

4.3 The calibrated setting is determined by using pre-

mm) and weighing 1.5 6 0.2 lb (0.7 6 0.1 kg), to fill the deli

cooked food product (macaroni and cheese) in 4-in. (100-mm)

case’s heated wells as necessary.

deep half-size steam pans and setting controls such that lowest

temperature in the center of the food pans is 142 6 2°F (61 6

8. Sampling and Test Units

1°C).

8.1 Deli Case—Select a representative production model

4.4 The amount of energy and time required to preheat the

for performance testing.

deli case to calibrated setting is determined.

4.5 The idle energy rate is determined with the deli case set

9. Preparation of Apparatus

at calibrated setting and no food in the unit.

9.1 Install the deli case according to the manufacturer’s

4.6 The deli case is used to hold 4-in. (100-mm) deep

instructions in an appropriate space. All sides of the deli case

half-size steam pans filled with hot food for 3 h. Food

shallbeaminimumof12in.(305mm)fromanysidewall,side

temperature and deli case energy consumption are monitored

partition, or other operating appliance. The associated heating

during this testing.

orcoolingsystemforthespaceshallbecapableofmaintaining

5. Significance and Use

an ambient temperature of 73 6 3°F (22 6 2°C) within the

testing environment.

5.1 The energy input rate is used to confirm that the deli

case is operating properly prior to further testing. 9.2 The testing environment during energy tests shall be

maintained in accordance with the section on performance for

5.2 Capacity is used by food service operators to choose a

deli case that matches their food holding requirements. open top hot food holding equipment room specifications of

5.3 Preheat energy and time can be useful to food service NSF/ANSI 4. The NSF/ANSI 4 test room conditions are an

operatorstomanageenergydemandsandtoknowhowquickly ambient temperature of 73 6 3°F (22 6 2°C), no vertical

the deli case can be ready for operation. temperature gradient exceeding 1.5°F/ft (2.5°C/m), and maxi-

mum air current velocity of 50 ft/min (0.25 m/s) across the

5.4 Holding energy rate and idle energy rate can be used by

thefoodserviceoperatortoestimatedelicaseenergyconsump- surfaces of the test pans (partially enclosed units).

9.3 Connectthedelicasetoacalibratedenergytestmeter.A

tion.

voltage regulator may be required during tests if the voltage

6. Apparatus

supply is not within 62.5% of the manufacturer’s nameplate

6.1 Analytical Balance Scale, for measuring weights up to voltage.

20 lb (9 kg), with a resolution of 0.01 lb (0.005 kg) and an 9.4 Confirm (while the elements are energized) that the

uncertainty of 0.01 lb (0.005 kg). supply voltage is within 62.5% of the operating voltage

6.2 Data Acquisition System, for measuring energy and specified by the manufacturer. Record the test voltage for each

temperatures, capable of multiple channel displays updating at test.

least every 2 s.

NOTE 1—It is the intent of the testing procedure in this test method to

6.3 Thermocouple(s), industry standard type T or type K

evaluate the performance of a deli case at its rated electric voltage. If the

thermocouple wire with a range of 0 to 250°F (−17 to 121°C)

unit is rated dual voltage (that is, designed to operate at either 240 or 480

and an uncertainty of 61°F (60.5°C).

V with no change in components), the voltage selected by the manufac-

turer or tester, or both, shall be reported. If a deli case is designed to

6.4 Thermocouple Probe, “fast response” type T or type K

1 operate at two voltages without a change in the resistance of the heating

thermocoupleprobe, ⁄16in.(1.6mm)orsmallerdiameter,with

elements, the performance of the unit (for example, preheat time) may

a 3-s or faster response time, capable of immersion with a

differ at the two voltages.

rangeof0to250°F(−17to121°C)andanuncertaintyof 61°F

(60.5°C).Thethermocoupleprobe’sactivezoneshallbeatthe 9.5 Prepare the half and third-size pans for the holding

tip of the probe. energy rate test by attaching a temperature sensor in the center

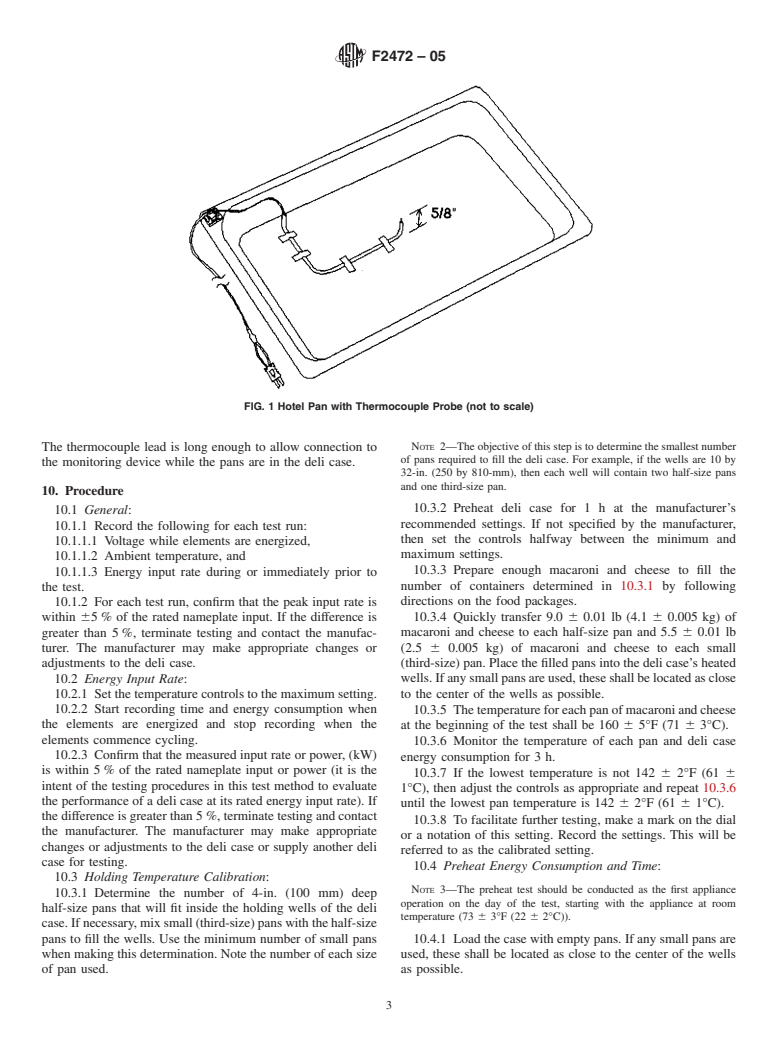

6.5 Watt-Hour Meter, for measuring the electrical energy of each pan, 1.5 in. (38 mm) from the bottom. A convenient

consumptionofadelicase,shallhavearesolutionofatleast10 method is to have thermocouple probes with a stainless-steel

Wh and a maximum uncertainty no greater than 1.5% of the protective sheath fabricated in the shape shown in Fig. 1. The

measured value for any demand greater than 100 W. For any sensing point is exposed and isolated thermally from the

demandlessthan100W,themetershallhavearesolutionofat stainless-steel sheath. The probe is strapped to the pan using

least 10Wh and a maximum uncertainty no greater than 10%. steel shim stock welded to the pan using a strain gage welder.

F2472–05

FIG. 1 Hotel Pan with Thermocouple Probe (not to scale)

NOTE 2—Theobjectiveofthisstepistodeterminethesmallestnumber

The thermocouple lead is long enough to allow connection to

of pans required to fill the deli case. For example, if the wells are 10 by

the monitoring device while the pans are in the deli case.

32-in. (250 by 810-mm), then each well will contain two half-size pans

and one third-size pan.

10. Procedure

10.3.2 Preheat deli case for1hatthe manufacturer’s

10.1 General:

recommended settings. If not specified by the manufacturer,

10.1.1 Record the following for each test run:

then set the controls halfway between the minimum and

10.1.1.1 Voltage while elements are energized,

maximum settings.

10.1.1.2 Ambient temperature, and

10.3.3 Prepare enough macaroni and cheese to fill the

10.1.1.3 Energy input rate during or immediately prior to

number of containers determined in 10.3.1 by following

the test.

directions on the food packages.

10.1.2 For each test run, confirm that the peak input rate is

within 65% of the rated nameplate input. If the difference is 10.3.4 Quickly transfer 9.0 6 0.01 lb (4.1 6 0.005 kg) of

macaroni and cheese to each half-size pan and 5.5 6 0.01 lb

greater than 5%, terminate testing and contact the manufac-

turer. The manufacturer may make appropriate changes or (2.5 6 0.005 kg) of macaroni and cheese to each small

(third-size)pan.Placethefilledpansintothedelicase’sheated

adjustments to the deli case.

10.2 Energy Input Rate: wells.Ifanysmallpansareused,theseshallbelocatedasclose

10.2.1 Setthetemperaturecontrolstothemaximumsetting. to the center of the wells as possible.

10.2.2 Start recording time and energy consumption when 10.3.5 Thetemperatureforeachpanofmacaroniandcheese

the elements are energized and stop recording when the

at the beginning of the test shall be 160 6 5°F (71 6 3°C).

elements commence cycling.

10.3.6 Monitor the temperature of each pan and deli case

10.2.3 Confirm that the measured input rate or power, (kW)

energy consumption for 3 h.

is within 5% of the rated nameplate input or power (it is the

10.3.7 If the lowest temperature is not 142 6 2°F (61 6

intent of the testing procedures in this test method to evaluate

1°C), then adjust the controls as appropriate and repeat 10.3.6

the performance of a deli case at its rated energy input rate). If

until the lowest pan temperature is 142 6 2°F (61 6 1°C).

thedifferenceisgreaterthan5%,terminatetestingandcontact

10.3.8 To facilitate further testing, make a mark on the dial

the manufacturer. The manufacturer may make appropriate

or a notation of this setting. Record the settings. This will be

changes or adjustments to the deli case or supply another deli

referred to as the calibrated setting.

case for testing.

10.4 Preheat Energy Consumption and Time:

10.3 Holding Temperature Calibration:

NOTE 3—The preheat test should be conducted as the first appliance

10.3.1 Determine the number of 4-in. (100 mm) deep

operation on the day of the test, starting with the appliance at room

half-size pans that will fit inside the holding wells of the deli

temperature (73 6 3°F (22 6 2°C)).

case.Ifnecessary,mixsmall(third-size)panswiththehalf-size

pans to fill the wells. Use the minimum number of small pans 10.4.1 Loadthecasewithemptypans.Ifanysmallpansare

when making this determination. Note the number of each size used, these shall be located as close to the center of the wells

of pan used. as possible.

F2472–05

10.4.2 Record ambient temperature and pan temperature at 11.1.1 Summarizethephysicalandoperatingcharacteristics

the start of the test. Both the ambient and pan temperatures of the deli case. If needed, describe other design or operating

shall be 73 6 3°F (22 6 2°C) at the start of the test. characteristics that may facilitate interpretation of the test

results.

10.4.3 Turn the unit on with controls set to the calibrated

11.2 Apparatus and Procedure:

setting determined in 10.3.8. Begin recording pan temperature

11.2.1 Confirmthatthetestingapparatusconformedtoallof

and deli case energy consumption when the unit is turned on.

the specifications in Section 6. Describe any deviations from

10.4.4 Record the empty pan temperatures over a minimum

those specifications.

of 5-s intervals during the course of preheat until the tempera-

11.2.2 Report the voltage for each test.

ture at the center of each pan stabilizes. Record the final

11.3 Energy Input Rate:

stabilization temperature for each pan.

11.3.1 Report the manufacturer’s nameplate energy input

10.4.5 Record the energy and time

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.