ASTM D1135-86(2009)

(Test Method)Standard Test Methods for Chemical Analysis of Blue Pigments

Standard Test Methods for Chemical Analysis of Blue Pigments

SIGNIFICANCE AND USE

These test methods are suitable for determining if impurities are present and establishing that the required pigments are present. These test methods may be used for manufacturing quality control.

SCOPE

1.1 These test methods cover procedures for the chemical analysis of blue pigments known commercially as iron blue, copper phthalocyanine blue, and ultramarine blue.

1.2 The analytical procedures appear in the following order:

Sections I ron Blue Pigments Identification 6 Moisture by the Brabender Moisture Tester 7 and 8 Moisture by Toluene Distillation 9 Water-Soluble Matter by Extraction10 Water-Soluble Salts by Electrical Conductivity11 Detection of Acid-Insoluble Extenders1213 Detection of Acid-Soluble Extenders14 to 17 Detection of Organic Colors and Lakes18 C opper Phthalocyanine Blue Pigments Identification19 Moisture and Other Volatile Matter20 Detection of Basic Dye Derivatives21 Detection of Other Organic Coloring Matter22 Detection of Ultramarine Blue23 Detection of Iron Blue24 U ltramarine Blue Identification25 Moisture and Other Volatile Matter26 Water-Soluble Matter27 Detection of Basic Dye Derivatives28 Detection of Other Organic Coloring Matter29

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

12.1 Acid-insoluble extenders include barium sulfate, silica, and silicates. Alumina may also be found, in part, with this group.

14.1 Acid-soluble extenders include the alkaline earth carbonates or sulfates, magnesium carbonate, and alumina hydrate.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1135 − 86 (Reapproved2009)

Standard Test Methods for

Chemical Analysis of Blue Pigments

This standard is issued under the fixed designation D1135; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 These test methods cover procedures for the chemical

2.1 ASTM Standards:

analysis of blue pigments known commercially as iron blue,

D280 Test Methods for Hygroscopic Moisture (and Other

copper phthalocyanine blue, and ultramarine blue.

Matter Volatile Under the Test Conditions) in Pigments

D1193 Specification for Reagent Water

1.2 The analytical procedures appear in the following order:

D1208 Test Methods for Common Properties of Certain

Sections

Pigments

I RON BLUE P IGMENTS

D2448 Test Method for Water-Soluble Salts in Pigments by

Measuring the Specific Resistance of the Leachate of the

Identification 6

Moisture by the Brabender Moisture Tester 7 and 8

Pigment

Moisture by Toluene Distillation 9

E11 Specification for Woven Wire Test Sieve Cloth and Test

Water-Soluble Matter by Extraction 10

Sieves

Water-Soluble Salts by Electrical Conductivity 11

Detection of Acid-Insoluble Extenders 12 and 13

Detection of Acid-Soluble Extenders 14 to 17

3. Significance and Use

Detection of Organic Colors and Lakes 18

3.1 These test methods are suitable for determining if

C OPPER PHTHALOCYANINE BLUE PIGMENTS

impurities are present and establishing that the required pig-

Identification 19

ments are present. These test methods may be used for

Moisture and Other Volatile Matter 20

manufacturing quality control.

Detection of Basic Dye Derivatives 21

Detection of Other Organic Coloring Matter 22

Detection of Ultramarine Blue 23

4. Purity of Reagents and Water

Detection of Iron Blue 24

4.1 Purity of Reagents—Unless otherwise indicated, it is

U LTRAMARINE BLUE

intended that all reagents shall conform to the specifications of

Identification 25

theCommitteeonAnalyticalReagentsoftheAmericanChemi-

Moisture and Other Volatile Matter 26

cal Society, where such specifications are available. Other

Water-Soluble Matter 27

Detection of Basic Dye Derivatives 28 grades may be used, provided it is first ascertained that the

Detection of Other Organic Coloring Matter 29

reagent is of sufficiently high purity to permit its use without

1.3 The values stated in SI units are to be regarded as

lessening the accuracy of the determination.

standard. No other units of measurement are included in this

4.2 Purity of Water—Unless otherwise indicated, references

standard.

towatershallbeunderstoodtomeanreagentwaterconforming

1.4 This standard does not purport to address the safety

to Type II of Specification D1193.

concerns associated with its use. It is the responsibility of the

user of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

tions prior to use.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1 3

These test methods are under the jurisdiction of ASTM Committee D01 on Reagent Chemicals, American Chemical Society Specifications, American

Paint and Related Coatings, Materials, and Applications and are the direct Chemical Society, Washington, DC. For suggestions on the testing of reagents not

responsibility of Subcommittee D01.31 on Pigment Specifications. listed by the American Chemical Society, see Analar Standards for Laboratory

Current edition approved June 1, 2009. Published June 2009. Originally Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

approved in 1950. Last previous edition approved in 2004 as D1135 – 86 (2004). and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

DOI: 10.1520/D1135-86R09. MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1135 − 86 (2009)

5. Preparation of Sample

5.1 Mix the sample thoroughly and take a representative

portion for analysis. Reduce any lumps or coarse particles to a

fine powder by grinding.

5.2 Grind extracted pigments to pass a No. 80 (180-µm)

sieve. Discard any skins that do not pass through the sieve.

Mix the finely ground pigment thoroughly.

Detailed requirements for this sieve are given in Specification E11.

IRON BLUE

(Prussian Blue, Chinese Blue, Milori Blue)

NOTE 2—The dried pigment is very hygroscopic. In order to obtain

IDENTIFICATION

consistentresults,thespecimenpositionmustnotbechangedandtheoven

door must not be opened.

6. Procedure

8.3 Calculation and Report—Plot time against percent loss

6.1 To approximately 0.1 g of pigment in a 50-mL beaker,

in weight on rectilinear cross-section paper. Extrapolate the

add15mLofNaOHsolution(50g/L).Heattoboiling.Inafew

linear portion of the curve to zero time. That portion beyond

minutes the blue color should be completely destroyed, giving

about 2 h will be essentially linear. Report the percent loss in

initsplacethecharacteristicreddishbrownprecipitateofferric

weight at the extrapolated zero time as the percent moisture in

hydroxide.Add HCl (1+1) until faintly acid to litmus.The iron

the pigment.

blue should be reformed, yielding again the characteristic blue

NOTE 3—The pigment undergoes a slight loss in weight due to

color.

decomposition during the heating. The method of plotting and extrapola-

tion corrects for this loss.An approximate value for moisture content may

NOTE 1—If the NaOH treatment does not completely destroy the blue

be obtained by taking the reading at the end of the first hour’s heating.An

color, the evidence is strong that a foreign pigment is present. If this

occasional pigment may decompose rapidly at the oven temperature. In

occurs, it is best to filter the alkaline solution, weakly acidify the filtrate

such cases, determine moisture by the toluene distillation method (Section

with HCl (1+1), and add approximately 2 mL of a ferric salt solution

9).

(ferric sulfate or ferric alum (20 g/L)). The formation of a blue precipitate

established the pigment as consisting, at least in part, of iron blue.

MOISTURE BY TOLUENE DISTILLATION

MOISTURE BY THE BRABENDER MOISTURE

9. Procedure

TESTER

9.1 Determine the moisture content in accordance with

7. Apparatus

Sections 7 and 8 of Test Method D1208, but using 25 g of

pigment and 200 mL of toluene and adjusting the calculation

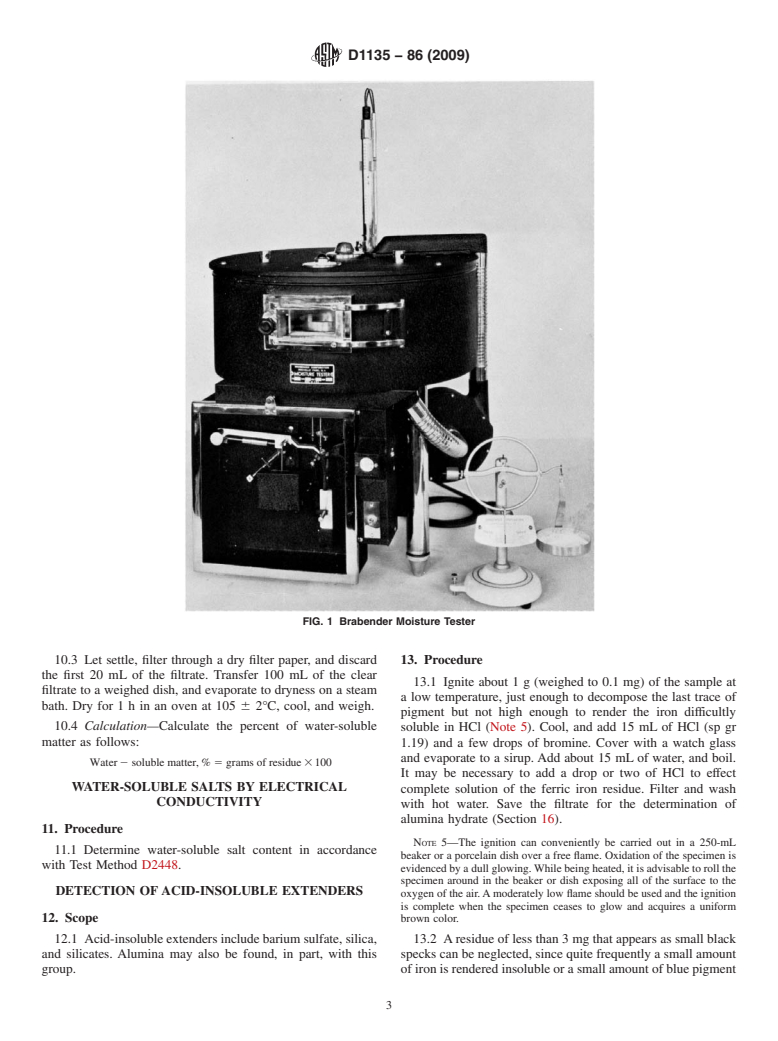

7.1 Brabender Moisture Tester—The Brabender moisture

accordingly.

tester (Fig. 1) consists of a constant-temperature oven with

weighing apparatus attached. Specimens placed in the oven

WATER-SOLUBLE MATTER BY EXTRACTION

may be weighed without opening the oven door or removing

the specimen from the oven, as the balance scale is calibrated

10. Procedure

to read directly in percent of moisture.

10.1 Determine whether or not the pigment is easily wet by

water at room temperature by adding a little to some water in

8. Procedure

a beaker. If it tends to float on top of the water with very little,

if any, tendency to sink to the bottom or disperse throughout

8.1 Set the temperature control at 160°C and allow the oven

the solution, even after agitation, it contains a hydrophobic

to reach this temperature before checking or making any

treating agent.

weighing. Check the scale by placing a sample dish containing

9.200 g standard analytical balance weights in the oven. The

10.2 Weigh to 1 mg about 2.5 g of the pigment into a

apparatus should read 8.0 % moisture. If it does not, adjust to

250-mL volumetric flask. If the pigment is hydrophobic as

a reading of 8.0 % by turning either the right hand or left hand

tested above, moisten thoroughly with a few mL of ethyl

foot screw.

alcohol (Note 4). If the pigment is easily wet with water, no

alcohol is necessary. Fill the flask about half full with water

8.2 Weigh 10.000 g of the sample into the aluminum dish

and shake to disperse the pigment thoroughly. Fill to the mark

and place in the oven. For a series of specimens, all should be

and again shake. Allow to remain at room temperature for not

placed in the oven at as nearly the same time as possible. No

less than 15 h, shaking from time to time, preferably with an

specimen should occupy the position directly in front of the

automatic shaking device.

door.Weigh the specimen at the end of each hour for 5 h.After

each weighing, return the specimen to its original place in the

NOTE 4—Ethyl alcohol denatured with acetone (Formula No. 23A) or

oven. denatured with methyl alcohol (Formula No. 3A) has been found suitable.

D1135 − 86 (2009)

FIG. 1 Brabender Moisture Tester

10.3 Let settle, filter through a dry filter paper, and discard 13. Procedure

the first 20 mL of the filtrate. Transfer 100 mL of the clear

13.1 Ignite about 1 g (weighed to 0.1 mg) of the sample at

filtrate to a weighed dish, and evaporate to dryness on a steam

a low temperature, just enough to decompose the last trace of

bath. Dry for1hinan oven at 105 6 2°C, cool, and weigh.

pigment but not high enough to render the iron difficultly

10.4 Calculation—Calculate the percent of water-soluble

soluble in HCl (Note 5). Cool, and add 15 mL of HCl (sp gr

matter as follows:

1.19) and a few drops of bromine. Cover with a watch glass

and evaporate to a sirup. Add about 15 mL of water, and boil.

Water 2 soluble matter,% 5 grams of residue 3100

It may be necessary to add a drop or two of HCl to effect

WATER-SOLUBLE SALTS BY ELECTRICAL

complete solution of the ferric iron residue. Filter and wash

CONDUCTIVITY

with hot water. Save the filtrate for the determination of

alumina hydrate (Section 16).

11. Procedure

NOTE 5—The ignition can conveniently be carried out in a 250-mL

11.1 Determine water-soluble salt content in accordance

beaker or a porcelain dish over a free flame. Oxidation of the specimen is

with Test Method D2448.

evidenced by a dull glowing.While being heated, it is advisable to roll the

specimen around in the beaker or dish exposing all of the surface to the

DETECTION OF ACID-INSOLUBLE EXTENDERS

oxygen of the air.Amoderately low flame should be used and the ignition

is complete when the specimen ceases to glow and acquires a uniform

12. Scope brown color.

12.1 Acid-insolubleextendersincludebariumsulfate,silica, 13.2 Aresidue of less than 3 mg that appears as small black

and silicates. Alumina may also be found, in part, with this specks can be neglected, since quite frequently a small amount

group. of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.