ASTM D2750-95

(Specification)Specification for Acrylonitrile- Butadiene-Sytrene (ABS) Plastics Utilities Conduit and Fittings (Withdrawn 1997)

Specification for Acrylonitrile- Butadiene-Sytrene (ABS) Plastics Utilities Conduit and Fittings (Withdrawn 1997)

General Information

Standards Content (Sample)

ASTM D2750 95 0759530 0579223 04T =

AMERICAN SOCIETY FOR TESTING AND MATERIALS

Designation: D 2750 - 95 1DD Barr Harbor Dr. West Conshohocken, PA 19428

Reprinted from ihe AnnuA Book of ASTM Standards. Copyright ASTM

ab

If not listed in the current combined index. will appear in the next edition.

Standard Specification for

Acrylonitrile-Butadiene-Styrene (ABS) Plastics Utilities

Conduit and Fittings’

This standard is issued under the fixed designation D 2750; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

Fed. Std. No. 123 Marking for Shipment (Civil agencie^)^

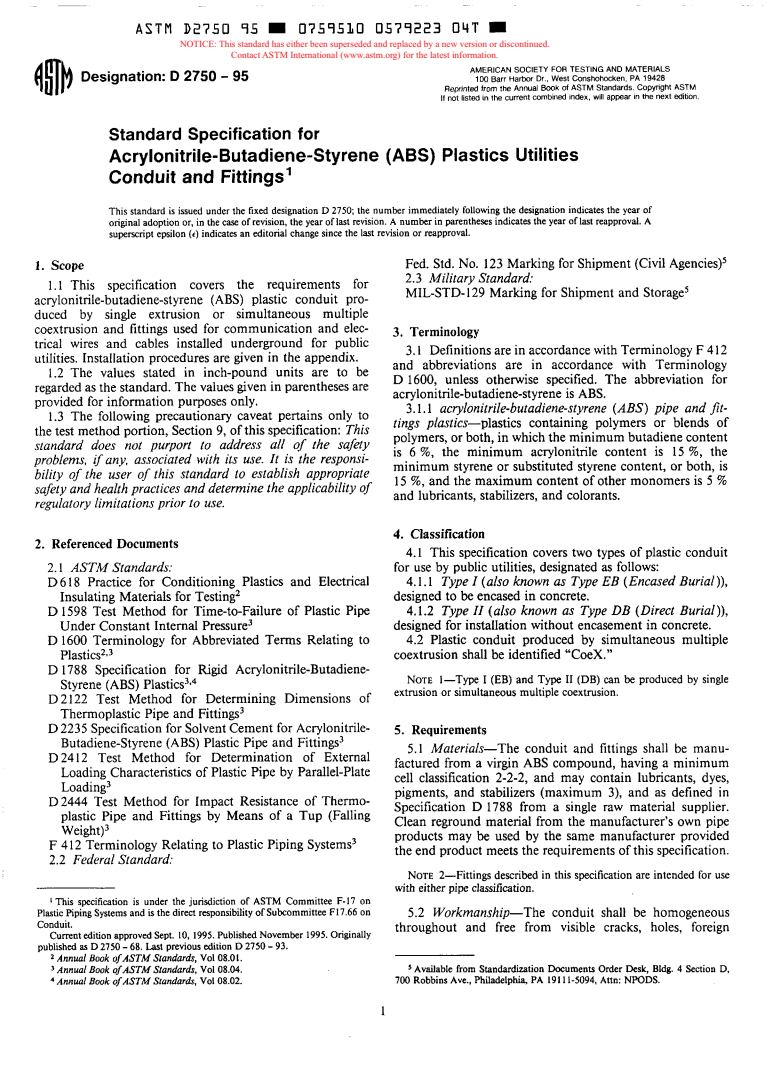

1. Scope

2.3 Military Standard:

1.1 This specification covers the requirements for

MIL-STD- 129 Marking for Shipment and Storages

acrylonitrile-butadiene-styrene (ABS) plastic conduit pro-

duced by single extrusion or simultaneous multiple

coextrusion and fittings used for communication and elec-

3. Terminology

trical wires and cables installed underground for public

3, Definitions are in accordance with Terminology 12

utilities. Installation procedures are given in the appendix.

and abbreviations are in accordance with Terminology

The

stated in inch-pound units are to be

D 1600, unless otherwise specified. The abbreviation for

regarded as the standard. The values given in parentheses are

acrylonitrile-butadiene-styrene is ABS.

provided for information purposes only.

3.1.1 acrylonitrile-butadiene-styrene (ABS) pipe and fit-

1.3 The following precautionary caveat pertains only to

tings plastics-plastics containing polymers or blends of

the test method portion, Section 9, of this specification: This

polymers, or both, in which the minimum butadiene content

standard does not purport lo ~d&es.Y all of the -%&Y

is 6 %, the minimum acrylonitrile content is 15 %, the

problems, $any, associated with its use. It is the responsi-

minimum styrene or substituted styrene content, or both, is

bility of the user of this standard to establish appropriate

15 %, and the maximum content of other is %

safety and health practices and determine the applicability of

and lubricants, stabilizers, and

regulatory limitations prior to use.

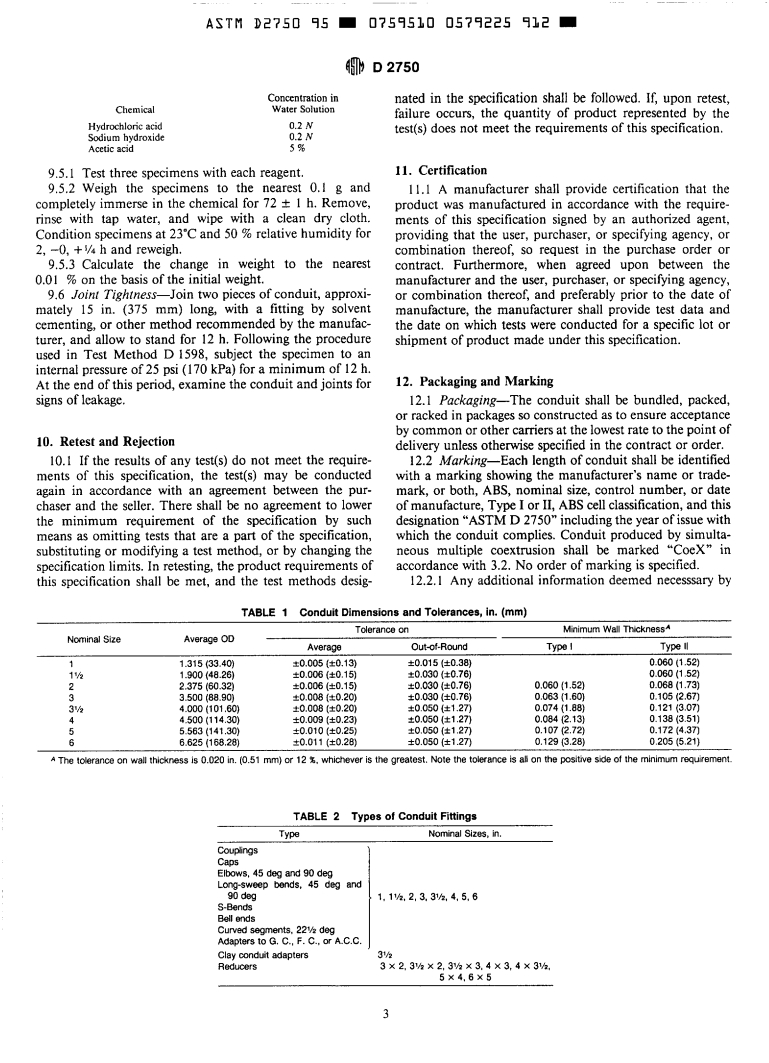

4. Classification

2. Referenced Documents

4.1 This specification covers two types of plastic conduit

for use by public utilities, designated as follows:

2.1 ASTM Standards:

4.1.1 Type I (also known as Type EB (Encased Burial )),

D 6 18 Practice for Conditioning Plastics and Electrical

designed to be encased in concrete.

Insulating Materials for Testing?

4.1.2 Type II (also known as Type DB (Direct Burial)),

D 1598 Test Method for Time-to-Failure of Plastic Pipe

designed for installation without encasement in concrete.

Under Constant Internal Pressure3

4.2 Plastic conduit produced by simultaneous multiple

D 1600 Terminology for Abbreviated Terms Relating to

plastic^^,^ coextrusion shall be identified “CoeX.”

D 1788 Specification for Rigid Acrylonitnle-Butadiene-

NOTE I-Type I (EB) and Type II (DB) can be produced by single

Styrene (ABS)

extrusion or simultaneous multiple coextrusion.

D 2 122 Test Method for Determining Dimensions of

Thermoplastic Pipe and Fittings3

D 2235 Specification for Solvent Cement for Acrylonitrile-

5. Requirements

Butadiene-Styrene (ABS) Plastic Pipe and Fittings3

5.1 Materials-The conduit and fittings shall be manu-

D2412 Test Method for Determination of External

factured from a virgin ABS compound, having a minimum

Loading Characteristics of Plastic Pipe by Parallel-Plate

cell classification 2-2-2, and may contain lubricants, dyes,

Loading3

pigments, and stabilizers (maximum 3), and as defined in

D2444 Test Method for Impact Resistance of Thermo-

Specification D 1788 from a single raw matenal supplier.

plastic Pipe and Fittings by Means of a Tup (Falling

Clean reground material from the manufacturer’s own pipe

Weight)3

products may be used by the same manufacturer provided

F 4 12 Terminology Relating to Plastic Piping Systems3

the end product meets the requirements of this specification.

2.2 Federal Standard:

NOTE 2-Fittings described in this specification are intended for use

with either pipe classification.

‘This specification is under the jurisdiction of ASTM Committee F-17 on

Plastic Piping Systems and is the direct responsibility of Subcommittee F17.66 on

5.2 Workmanship-The conduit shall be homogeneous

Conduit.

throughout and free from visible cracks, holes, foreign

Current edition approved Sept. IO, 1995. Published November 1995. Oflginally

published as D 2750 - 68. Last previous edition D 2750 - 93.

2 Annual Book of ASTM Standards, Vol 08.01.

Available from Standardization Documents Order Desk, Bldg. 4 Section D,

3 Annual Book oJASTM Standards, Vol 08.04.

Ann

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.