ASTM D304-05

(Specification)Standard Specification for n-Butyl Alcohol (Butanol)

Standard Specification for <i>n</i>-Butyl Alcohol (Butanol)

ABSTRACT

This specification covers n-butyl alcohol (butanol). The apparent specific gravity, color, distillation range, non-volatile matter, water properties, and acidity shall be tested to meet the requirements prescribed.

SCOPE

1.1 This specification covers n-butyl alcohol (butanol).

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are to be included in this standard.

1.3 The following applies to all specified limits in this standard; for purposes of determining conformance with this standard, an observed value or a calculated value shall be rounded off "to the nearest unit" in the last right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E 29.

1.4 For hazard information and guidance, see the supplier's Material Safety Data Sheets.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D304 – 05

Standard Specification for

1

n-Butyl Alcohol (Butanol)

This standard is issued under the fixed designation D304; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* Chemical Intermediates Used in Paint, Varnish, Lacquer,

and Related Products

1.1 This specification covers n-butyl alcohol (butanol).

D4052 Test Method for Density, Relative Density, and API

1.2 The values stated in SI units are to be regarded as

Gravity of Liquids by Digital Density Meter

standard. No other units of measurement are included in this

D5386 Test Method for Color of Liquids Using Tristimulus

standard.

Colorimetry

1.3 The following applies to all specified limits in this

E1 Specification for ASTM Liquid-in-Glass Thermometers

standard; for purposes of determining conformance with this

E29 Practice for Using Significant Digits in Test Data to

standard, an observed value or a calculated value shall be

Determine Conformance with Specifications

rounded off “to the nearest unit” in the last right-hand digit

E300 Practice for Sampling Industrial Chemicals

used in expressing the specification limit, in accordance with

2.2 U.S. Federal Specification:

the rounding-off method of Practice E29.

PPP-C-2020 Chemicals, Liquid, Dry, and Paste: Packaging

1.4 For hazard information and guidance, see the supplier’s

3

of

Material Safety Data Sheets.

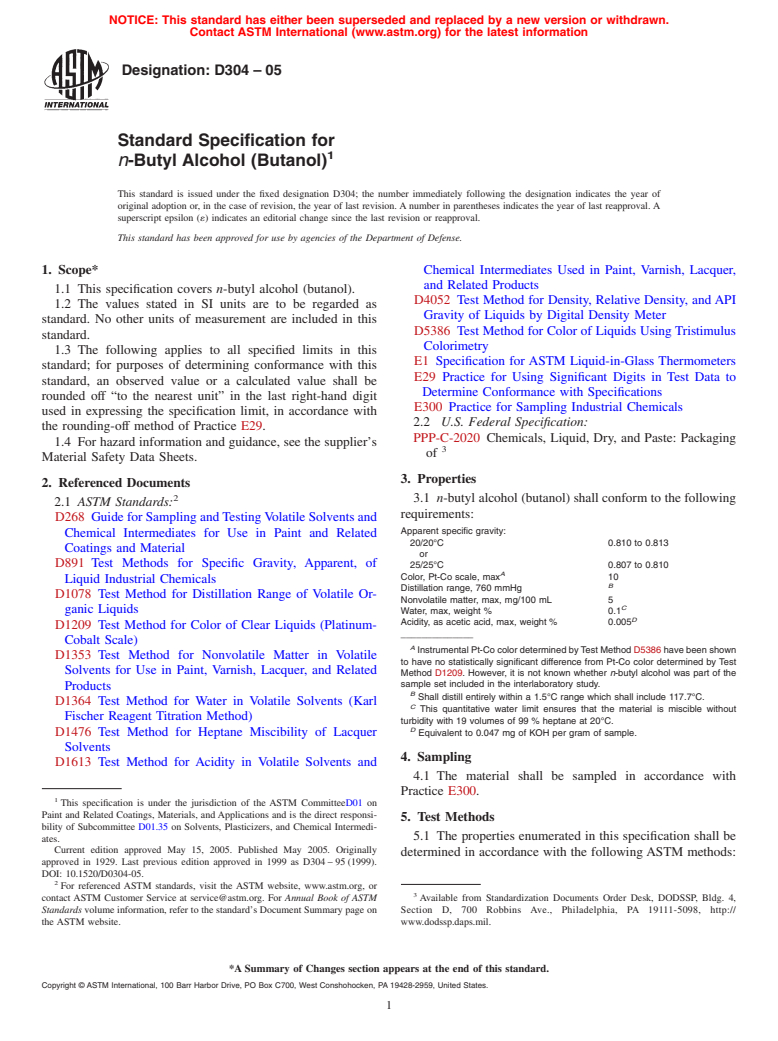

3. Properties

2. Referenced Documents

2

3.1 n-butyl alcohol (butanol) shall conform to the following

2.1 ASTM Standards:

requirements:

D268 Guide for Sampling andTestingVolatile Solvents and

Apparent specific gravity:

Chemical Intermediates for Use in Paint and Related

20/20°C 0.810 to 0.813

Coatings and Material

or

D891 Test Methods for Specific Gravity, Apparent, of 25/25°C 0.807 to 0.810

A

Color, Pt-Co scale, max 10

Liquid Industrial Chemicals

B

Distillation range, 760 mmHg

D1078 Test Method for Distillation Range of Volatile Or-

Nonvolatile matter, max, mg/100 mL 5

C

ganic Liquids

Water, max, weight % 0.1

D

Acidity, as acetic acid, max, weight % 0.005

D1209 Test Method for Color of Clear Liquids (Platinum-

______________

Cobalt Scale)

A

Instrumental Pt-Co color determined byTest Method D5386 have been shown

D1353 Test Method for Nonvolatile Matter in Volatile

to have no statistically significant difference from Pt-Co color determined by Test

Solvents for Use in Paint, Varnish, Lacquer, and Related

Method D1209. However, it is not known whether n-butyl alcohol was part of the

sample set included in the interlaboratory study.

Products

B

Shall distill entirely within a 1.5°C range which shall include 117.7°C.

D1364 Test Method for Water in Volatile Solvents (Karl

C

This quantitative water limit ensures that the material is miscible without

Fischer Reagent Titration Method)

turbidity with 19 volumes of 99 % heptane at 20°C.

D

D1476 Test Method for Heptane Miscibility of Lacquer Equivalent to 0.047 mg of KOH per gram of sample.

Solvents

4. Sampling

D1613 Test Method for Acidity in Volatile Solvents and

4.1 The material shall be sampled in accordance with

Practice E300.

1

This specification is under the jurisdiction of the ASTM CommitteeD01 on

Paint and Related Coatings, Materials, and Applications and is the direct responsi-

5. Test Methods

bility of Subcommittee D01.35 on Solvents, Plasticizers, and Chemical Intermedi-

5.1 The properties enumerated in this specification shall be

ates.

Current edition approved May 15, 2005. Published May 2005. Originally

determined in accordance with the following ASTM methods:

approved in 1929. Last previous edition approved in 1999 as D304 – 95 (1999).

DOI: 10.1520/D0304-05.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standards volume information, refer to the standard’s Document Summary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. www.dodssp.daps.mil.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D304 – 05

5.1.1 Apparent Specific Gravity—Determine the apparent 5.1.6 Acidity—Test Method D1613.

specific gravity at 20 or 25°C by a convenient method that is

6. Packaging and Package Marking

accurate to the third decimal place. See Guide D268 or Test

Methods D891

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.