ASTM F3300-18

(Test Method)Standard Test Method for Abrasion Resistance of Flexible Packaging Films Using a Reciprocating Weighted Stylus

Standard Test Method for Abrasion Resistance of Flexible Packaging Films Using a Reciprocating Weighted Stylus

SIGNIFICANCE AND USE

5.1 Materials such as engineered thermoplastic films are often used for flexible barrier packaging. However, handling and transportation can cause abrasion to the packaging film and possibly compromise the integrity of the contents (e.g., sterility of a medical device). This test method provides a comparative ranking of material performance that can be used as an indication of relative end-use performance.

5.2 The resistance of material surfaces to abrasion, as measured on a testing machine under laboratory conditions, is only one of several factors contributing to wear performance or durability as experienced in the actual use of the material. While abrasion resistance and durability are frequently related, the relationship varies with different end uses and different factors may be necessary in any calculation of predicted durability from specific abrasion data.

5.3 The resistance of material surfaces to abrasion may be affected by factors including test conditions of temperature and humidity, type of abradant, pressure between the specimen and abradant, mounting or tension of the specimen, and type, kind, or amount of finishing materials such as coatings or additives. Other causes of variation include local material movement during testing, material direction alignment, material characteristics, and mandrel and stylus wear. For consistency, samples to be evaluated under special environmental conditions shall be conditioned under those same conditions. It is important that the test instrument be shown to operate properly under special environmental conditions.

5.4 This test method may not be suitable for all films, including the following cases:

5.4.1 Films that stretch and generate a ripple in the abraded region during testing,

5.4.2 Films that have a thickness greater than 0.25 mm (0.010 in.), or are of such rigidity that forming over the mandrel would cause internal stresses that weaken the film, and

5.4.3 Conductive films.

SCOPE

1.1 This test method covers the determination of the abrasion resistance of flexible non-conductive films and packaging materials using a weighted stylus that wears completely through a film by oscillating or reciprocating back and forth along a linear path until an electrical circuit is completed shutting down the test.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F3300 − 18

Standard Test Method for

Abrasion Resistance of Flexible Packaging Films Using a

1

Reciprocating Weighted Stylus

This standard is issued under the fixed designation F3300; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 This test method covers the determination of the abra-

E691 Practice for Conducting an Interlaboratory Study to

sion resistance of flexible non-conductive films and packaging

Determine the Precision of a Test Method

materials using a weighted stylus that wears completely

F2251 Test Method for Thickness Measurement of Flexible

through a film by oscillating or reciprocating back and forth

Packaging Material

along a linear path until an electrical circuit is completed

shutting down the test.

3. Terminology

1.2 Units—The values stated in either SI units or inch-

3.1 Definitions:

pound units are to be regarded separately as standard. The

3.1.1 abrasion—the wearing away of any part of a material

values stated in each system may not be exact equivalents;

by rubbing against another surface.

therefore, each system shall be used independently of the other.

3.1.2 abrasion cycle—in abrasion testing, one or more

Combining values from the two systems may result in non-

movements of an abradant across a material surface, or the

conformance with the standard.

material surface across an abradant, that permits a return to its

1.3 This standard does not purport to address all of the

starting position.

safety concerns, if any, associated with its use. It is the

3.1.2.1 Discussion—In the case of the linear abrading

responsibility of the user of this standard to establish appro-

device, an abrasion cycle consists of one complete forward and

priate safety, health, and environmental practices and deter-

one complete backward stroke.

mine the applicability of regulatory limitations prior to use.

3.1.3 abrasion resistance—in abrasion testing, the ability of

1.4 This international standard was developed in accor-

a material to withstand degradation caused by the rubbing of

dance with internationally recognized principles on standard-

one material against another.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3.1.4 durability—the ability of a material to withstand

mendations issued by the World Trade Organization Technical

deterioration from the sum of all sources.

Barriers to Trade (TBT) Committee.

3.1.5 non-conductive film—any film used in this test method

that allows the stylus to completely abrade through the film,

2. Referenced Documents

making a hole, and does not prematurely stop the test before

2

2.1 ASTM Standards:

the hole is made.

D4332 Practice for Conditioning Containers, Packages, or

3.1.5.1 Discussion—The stylus (on one side of the film) and

Packaging Components for Testing

the mandrel (on the other side of the film) form part of an

D6988 Guide for Determination of Thickness of Plastic Film

electrical circuit that signals the end of the test. Wearing a hole

Test Specimens

through a non-conductive film closes the circuit and stops the

E171/E171M Practice for Conditioning and Testing Flexible

test. A conductive film would conduct electricity between the

Barrier Packaging

stylus and the mandrel before the film completely abrades

through and prematurely signal the end of the test.

1

This test method is under the jurisdiction of ASTM Committee F02 on Primary

Barrier Packaging and is the direct responsibility of Subcommittee F02.20 on

4. Summary of Test Method

Physical Properties.

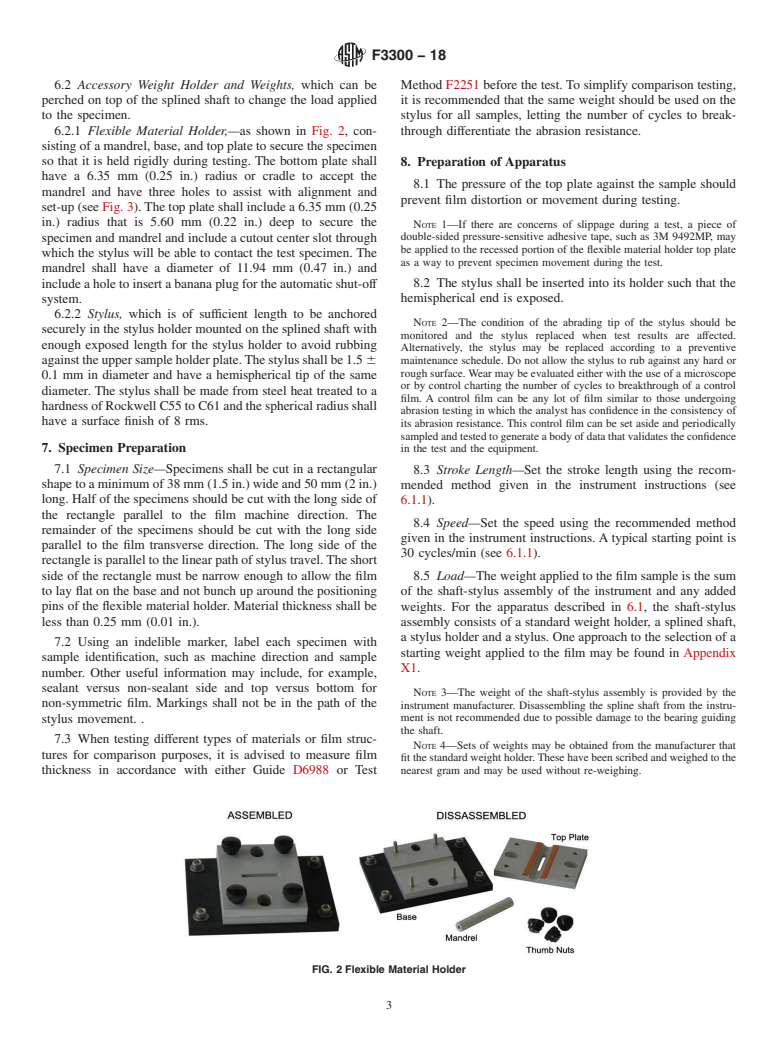

4.1 A specimen is abraded using a linear rubbing action. The

Current edition approved Feb. 15, 2018. Published March 2018. DOI: 10.1520/

F3300-18

test specimen, mounted over a mandrel and held in place by

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

two plates, is rubbed back and forth with the hemispherical tip

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

of a special stylus. The hemispherical tip rubs the specimen

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. until it abrades through and the test is automatically stopped.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3300 − 18

Resistance to abrasion in this test method is reported as the 5.4 This test method may not be suitable for all films,

number of back

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.