ASTM F392/F392M-23

(Practice)Standard Practice for Conditioning Flexible Barrier Materials for Flex Durability

Standard Practice for Conditioning Flexible Barrier Materials for Flex Durability

SIGNIFICANCE AND USE

5.1 This practice is valuable in determining the resistance of flexible packaging materials to flex-formed pinholes. Conditioning levels A, B, or C are typically used. Reference Practice E171 and Guide F2097.

5.2 Conditions D and E are typically used for determining the effect of flexing on barrier properties and transmission rates related to gas and/or moisture.

5.3 This practice does not measure or condition materials for abrasion related to flex failure.

5.4 Failures in the integrity of one or more of the plies of a multi-ply structure may require alternative testing. Supplementary permeation testing using gas or water vapor can be used in conjunction with the flex conditioning to measure the loss of ply integrity. Other test methods may be used after flexing for assessment of presence of pinholes. For a list of test methods, refer to Guide F2097.

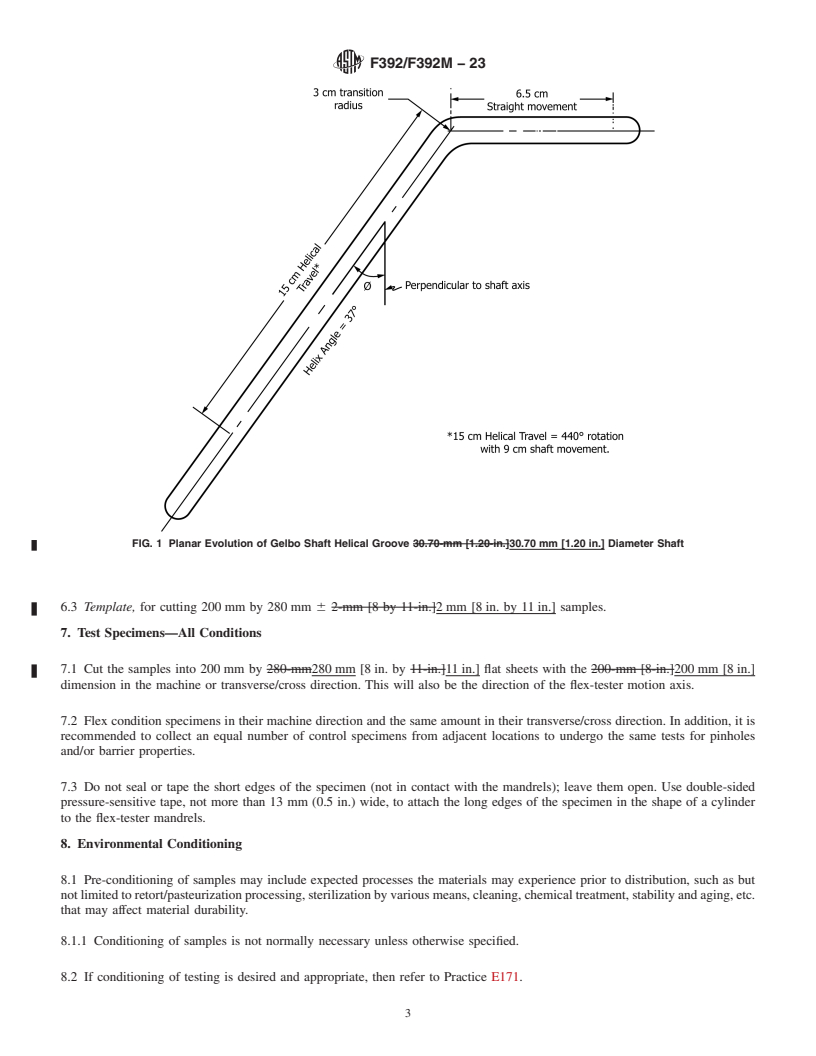

FIG. 1 Planar Evolution of Gelbo Shaft Helical Groove 30.70 mm [1.20 in.] Diameter Shaft

5.4.1 The various conditions described in this practice are to prevent evaluating a material structure with an outcome of too many holes to effectively count (normally greater than 50), or too few to be significant (normally less than five per sample). Material structure, testing basis, and a mutual agreement with specified objectives are to be considered in the selection of conditioning level for testing.

SCOPE

1.1 This practice covers conditioning of flexible barrier materials for the determination of flex resistance. Subsequent testing can be performed to determine the effects of flexing on material properties. These tests are beyond the scope of this practice.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F392/F392M − 23

Standard Practice for

1

Conditioning Flexible Barrier Materials for Flex Durability

This standard is issued under the fixed designation F392/F392M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

1.1 This practice covers conditioning of flexible barrier 3.1 pinhole, n—a small opening of non-specific shape or

materials for the determination of flex resistance. Subsequent

dimension that passes completely through all layers of a

testing can be performed to determine the effects of flexing on

flexible material.

material properties. These tests are beyond the scope of this

3.1.1 Discussion—The use of the term “pin” provides the

practice.

relative size reference as in a small hole made with or as if with

a pin.

1.2 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

4. Summary of Practice

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining

4.1 Specimens of flexible materials are flexed at standard

values from the two systems may result in non-conformance

atmospheric conditions defined in Practice E171, unless other-

with the standard.

wise specified. Flexing conditions, number of cycles, and

1.3 This standard does not purport to address all of the

severity of flexing strokes vary with the type of material

safety concerns, if any, associated with its use. It is the

structure being tested. Except for condition E, the flexing

responsibility of the user of this standard to establish appro-

condition consists of a twisting motion followed, in conditions

priate safety, health, and environmental practices and deter-

A to D, by a horizontal motion, thus, repeatedly twisting and

mine the applicability of regulatory limitations prior to use.

crushing the film. The frequency is at a rate of 45 cycles per

1.4 This international standard was developed in accor-

minute (cpm).

dance with internationally recognized principles on standard-

4.2 The effect of flexing on a material is determined by

ization established in the Decision on Principles for the

measuring the effect of the flex conditioning on the barrier

Development of International Standards, Guides and Recom-

and/or mechanical performance of the structure. The property

mendations issued by the World Trade Organization Technical

to be evaluated determines the appropriate conditioning level.

Barriers to Trade (TBT) Committee.

4.3 The various flex conditioning levels are summarized as

2. Referenced Documents

follows:

2

2.1 ASTM Standards: 4.3.1 Condition A—Full flex for 1 h (that is, 2700 cycles).

E171 Practice for Conditioning and Testing Flexible Barrier

4.3.2 Condition B—Full flex for 20 min (that is, 900 cycles).

Packaging

4.3.3 Condition C—Full flex for 6 min (that is, 270 cycles).

F1249 Test Method for Water Vapor Transmission Rate

4.3.4 Condition D—Full flex for 20 cycles.

Through Plastic Film and Sheeting Using a Modulated

4.3.5 Condition E—Partial flex for 20 cycles.

Infrared Sensor

F2097 Guide for Design and Evaluation of Primary Flexible

5. Significance and Use

Packaging for Medical Products

5.1 This practice is valuable in determining the resistance of

flexible packaging materials to flex-formed pinholes. Condi-

1

This practice is under the jurisdiction of ASTM Committee F02 on Primary

tioning levels A, B, or C are typically used. Reference Practice

Barrier Packaging and is the direct responsibility of Subcommittee F02.50 on

E171 and Guide F2097.

Package Design and Development.

Current edition approved Oct. 1, 2023. Published November 2023. Originally

5.2 Conditions D and E are typically used for determining

approved in 1974. Last previous edition approved in 2021 as F392/F392M – 21.

the effect of flexing on barrier properties and transmission rates

DOI: 10.1520F0392_F0392M-23.

2

related to gas and/or moisture.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.3 This practice does not measure or condition materials

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. for abrasion related to flex failure.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

----------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F392/F392M − 21 F392/F392M − 23

Standard Practice for

1

Conditioning Flexible Barrier Materials for Flex Durability

This standard is issued under the fixed designation F392/F392M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This practice covers conditioning of flexible barrier materials for the determination of flex resistance. Subsequent testing can

be performed to determine the effects of flexing on material properties. These tests are beyond the scope of this practice.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E171 Practice for Conditioning and Testing Flexible Barrier Packaging

F1249 Test Method for Water Vapor Transmission Rate Through Plastic Film and Sheeting Using a Modulated Infrared Sensor

F2097 Guide for Design and Evaluation of Primary Flexible Packaging for Medical Products

3. Terminology

3.1 pinhole, n—a small opening of non-specific shape or dimension that passes completely through all layers of a flexible material.

3.1.1 Discussion—

The use of the term “pin” provides the relative size reference as in a small hole made with or as if with a pin.

4. Summary of Practice

4.1 Specimens of flexible materials are flexed at standard atmospheric conditions defined in Practice E171, unless otherwise

specified. Flexing conditions, number of cycles, and severity of flexing strokes vary with the type of material structure being tested.

1

This practice is under the jurisdiction of ASTM Committee F02 on Primary Barrier Packaging and is the direct responsibility of Subcommittee F02.50 on Package Design

and Development.

Current edition approved May 1, 2021Oct. 1, 2023. Published April 2022November 2023. Originally approved in 1974. Last previous edition approved in 20152021 as

F392/F392M – 11 (2015).F392/F392M – 21. DOI: 10.1520F0392_F0392M-21.10.1520F0392_F0392M-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F392/F392M − 23

Except for condition E, the flexing condition consists of a twisting motion followed, in conditions A to D, by a horizontal motion,

thus, repeatedly twisting and crushing the film. The frequency is at a rate of 45 cycles per minute (cpm).

4.2 Flex failure The effect of flexing on a material is determined by measuring the effect of the tested flex conditioning on the

barrier and/or mechanical performance of the structure. The property to be evaluated determines the appropriate conditioning level.

4.3 The various flex conditioning levels are summarized as follows:

4.3.1 Condition A—Full flex for 1 h (that is, 2700 cycles).

4.3.2 Condition B—Full flex for 20 min (that is, 900 cycles).

4.3.3 Condition C—Full flex for 6 min (that is, 270 cycles).

4.3.4 Condition D—Full flex for 20 cycles.

4.3.5 Condition E—Partial flex for 20 cycles.

5. Significance and Use

5.1 This practice is valuable in determining the resistance of flexible packaging materials to flex-formed pinhole failures. pinholes.

Conditioning levels A, B, or C are typical

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.