ASTM C718-93

(Test Method)Standard Test Method for Ultraviolet (UV)-Cold Box Exposure of One-Part, Elastomeric, Solvent-Release Type Sealants (Withdrawn 2002)

Standard Test Method for Ultraviolet (UV)-Cold Box Exposure of One-Part, Elastomeric, Solvent-Release Type Sealants (Withdrawn 2002)

SCOPE

1.1 This test method provides an accelerated procedure for predicting the effects of ultraviolet (UV) exposure and cold box cycling on one-part, elastomeric, solvent-release sealing compounds, when used in channel glazing and sealing applications.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values stated in parentheses are for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

Designation: C 718 – 93

Standard Test Method for

Ultraviolet (UV)-Cold Box Exposure of One-Part,

1

Elastomeric, Solvent-Release Type Sealants

This standard is issued under the fixed designation C 718; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 6. Apparatus and Materials

3

1.1 This test method provides an accelerated procedure for 6.1 Ultraviolet Sun Lamps, two, on adjustable holders.

predicting the effects of ultraviolet (UV) exposure and cold box New sun lamps shall be lighted 24 h before using in test.

cycling on one-part, elastomeric, solvent-release sealing com- Maximum life of lamps is 500 h.

pounds, when used in channel glazing and sealing applications. 6.2 Reflective Aluminum Cabinet or Shield, having one open

1.2 The values stated in inch-pound units are to be regarded side. The shield shall be approximately 18 in. (460 mm) high

as the standard. The values stated in parentheses are for by 24 in. (600 mm) wide by 36 in. (900 mm) long, opened at

information only. the top and lined on the inside with aluminum foil.

1.3 This standard does not purport to address all of the 6.3 Aluminum Channels, for each compound to be tested,

3 3

safety problems, if any, associated with its use. It is the three 6 in. (152 mm) long by ⁄4 in. (19 mm) wide by ⁄8 in. (9

responsibility of the user of this standard to establish appro- mm) deep, inside dimensions.

priate safety and health practices and determine the applica- 6.4 Freezer Chest or Cold Box, at a controlled temperature

bility of regulatory limitations prior to use. of−10 6 5°F (−23 6 3°C).

6.5 Steel Spatula, with thin knife edge.

2. Referenced Documents

6.6 Masking Tape.

2.1 ASTM Standards: 6.7 Methyl-Ethyl-Ketone, Ethylene Dichloride, or similar

2

C 717 Terminology of Building Seals and Sealants

solvent.

3. Terminology 7. Sampling

3.1 DefinitionsùRefer to Terminology C 717 for definitions

7.1 Take the test specimens from a previously unopened

of the following terms used in this test method: compound; container as received from the sealant manufacturer.

elastomeric; sealant; solvent-release sealant.

8. Test Specimens

4. Summary of Test Method

8.1 Prepare three test specimens for each compound to be

4.1 The test compound is carefully placed in aluminum

tested as follows:

channels and all edges of the compound are struck clean. After 8.1.1 Clean the aluminum channels with solvent, allow

room temperature conditioning, specimens are subjected to ten

them to dry, then seal the open ends of the channels with

cycles of alternating exposure to UV at elevated temperature masking tape.

and conditioning at low temperature after which they are 8.1.2 Fill the channels with sealant, avoiding bubbles and

examined for deleterious effects.

air pockets, and strike off level with the spatula.

5. Significance and Use 9. Conditioning

5.1 The accelerated aging test is not intended to predict the

9.1 Condition the specimens for 48 h at 73.4 6 3.6°F (23 6

exact number of years of service life, nor the exact type of 2°C) and 50 6 5 % relative humidity before testing.

failures likely to be encountered when the compound under test

10. Procedure

is in actual use. However, the effects of this cycling procedure

will assist in judging the probable quality and overall perfor- 10.1 Mount the sun lamps side-by-side in the center of the

mance of the compound. reflective shield. Adjust the height of the sun lamps so that the

temperature at the surface of the test channel will be 140 6 5°F

(60 6 3°C). Normally, the sun lamps should be approximately

1

This test method is under the jurisdiction of ASTM Committee C-24 on

Building Seals and Sealants and is the direct responsibility of Subcommittee C24.18

on Solvent Release Sealants.

Current edition approved May 15, 1993. Published July 1993. Originally

3

published as C 718 û 72. Last previous edition C 718 û 88. General Electric sun lamps, Model RS-1, have been found satisfactory for this

2

Annual Book of ASTM Standards, Vol 04.07. purpose.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C 718

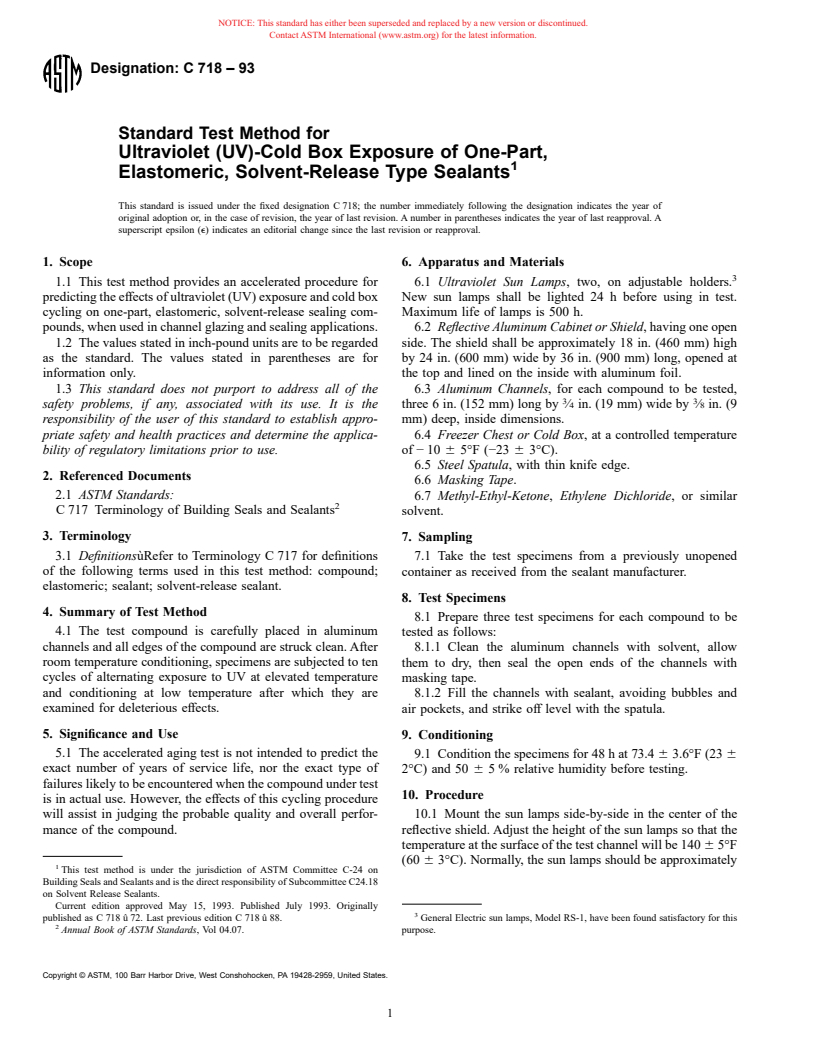

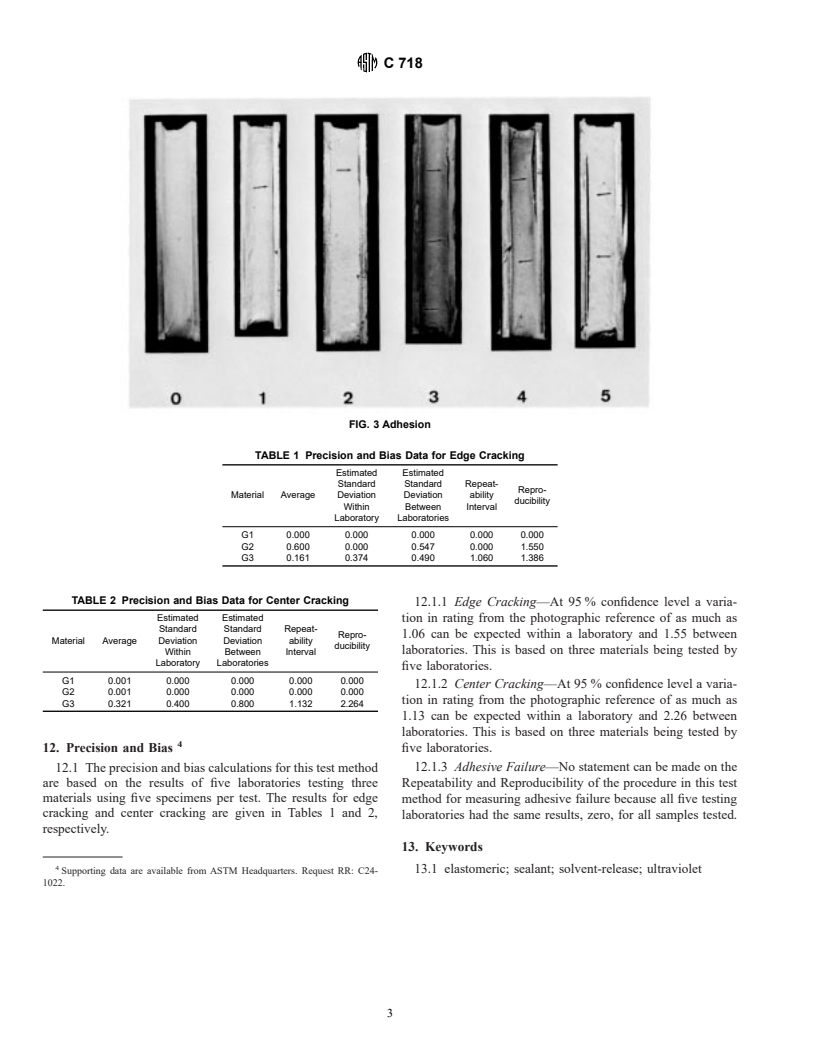

FIG. 1 Edge Cracking

FIG. 2 Center Cracking

12 to 18 in. (300 to 460 mm) from the samples to accomplish 10.5 Inspect the samples for cracking, adhesive failure, and

this. color change.

10.2 Place the test channels directly under the sun lamps for

NOTE 1—Additional cycles may be tested as specified.

a period of 8 h. At the end of this time, remove them and

11. Report

immediately place them in a freezer held at − 10 6 5°F (−23 6

3°C) for 16 h.

11.1 Using the photographic reference standards, Figs. 1-3

10.3 Repeat the exposure cycle specified in 10.2 ten times. as guidelines, examine each channel and determine

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.