ASTM B507-14(2021)

(Practice)Standard Practice for Design of Articles to Be Electroplated on Racks

Standard Practice for Design of Articles to Be Electroplated on Racks

SIGNIFICANCE AND USE

2.1 When an article is to be electroplated, it is necessary to consider not only the characteristics of the electroplating process, but also the design of the part to minimize electroplating and finishing costs and solution dragout as well as to improve appearance and functionality. It is often possible during the design and engineering stages to make small adjustments in shape that will result in considerable benefit toward a better quality part at a lower cost.

2.2 The specific property of an electroplating process that would require some attention to the details of optional designs, is the throwing power of the electroplating solution. This term describes the properties of the solution as it relates to the solution electrical resistance and solution capacitance at the cathode and overall efficiency of the electrolyte system. Throwing power is defined as the improvement of the coating distribution over the primary current distribution on an electrode (usually cathode) in a given solution, under specified conditions.

SCOPE

1.1 This practice covers design information for parts to be electroplated on racks. The recommendations contained herein are not mandatory, but are intended to give guidance toward good practice.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B507 −14 (Reapproved 2021)

Standard Practice for

Design of Articles to Be Electroplated on Racks

This standard is issued under the fixed designation B507; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope distribution over the primary current distribution on an elec-

trode (usually cathode) in a given solution, under specified

1.1 This practice covers design information for parts to be

conditions.

electroplated on racks. The recommendations contained herein

are not mandatory, but are intended to give guidance toward

3. Current Distribution and Throwing Power

good practice.

3.1 The apparent current during practical electroplating is

1.2 The values stated in SI units are to be regarded as

never uniform over the surface of the product. Even parallel

standard. No other units of measurement are included in this

plates have a nonuniform distribution of current when freely

standard.

suspended in a bath as shown in Fig. 1. In this example, the

1.3 This standard does not purport to address all of the

current lines tend to concentrate as corners, and edges (high-

safety concerns, if any, associated with its use. It is the

current density) of the part. Consequently more metal is

responsibility of the user of this standard to establish appro-

deposited at the high-current density areas than at the low-

priate safety, health, and environmental practices and deter-

current density areas.

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

4. Relative Throwing Powers of Different Electrolytes

dance with internationally recognized principles on standard-

4.1 Throwing power is not the same for all metals and all

ization established in the Decision on Principles for the

electroplating baths. Table 1 lists the commonly used electro-

Development of International Standards, Guides and Recom-

plating processes. They are arranged according to decreasing

mendations issued by the World Trade Organization Technical

throwing power.

Barriers to Trade (TBT) Committee.

4.2 A Rochelle-type copper electroplating solution has ex-

2. Significance and Use

cellent throwing power compared to the poor throwing power

2.1 When an article is to be electroplated, it is necessary to

of a chromic acid solution used to deposit chromium. The

consider not only the characteristics of the electroplating widely used Watts-type nickel bath has fair throwing power.

process, but also the design of the part to minimize electro-

plating and finishing costs and solution dragout as well as to 5. Geometric Factors Determining Deposit Distribution

improve appearance and functionality. It is often possible

5.1 Since a metal deposits preferentially at protuberances,

during the design and engineering stages to make small

such as sharp corners, edges, fins, and ribs, these should be

adjustments in shape that will result in considerable benefit

rounded to a radius of at least 0.4 and preferably 0.8 mm to

toward a better quality part at a lower cost.

avoid excessive buildup. Contouring a base corner in a

2.2 The specific property of an electroplating process that

depression is also recommended to avoid thickness deficiency

would require some attention to the details of optional designs, at the location.

is the throwing power of the electroplating solution. This term

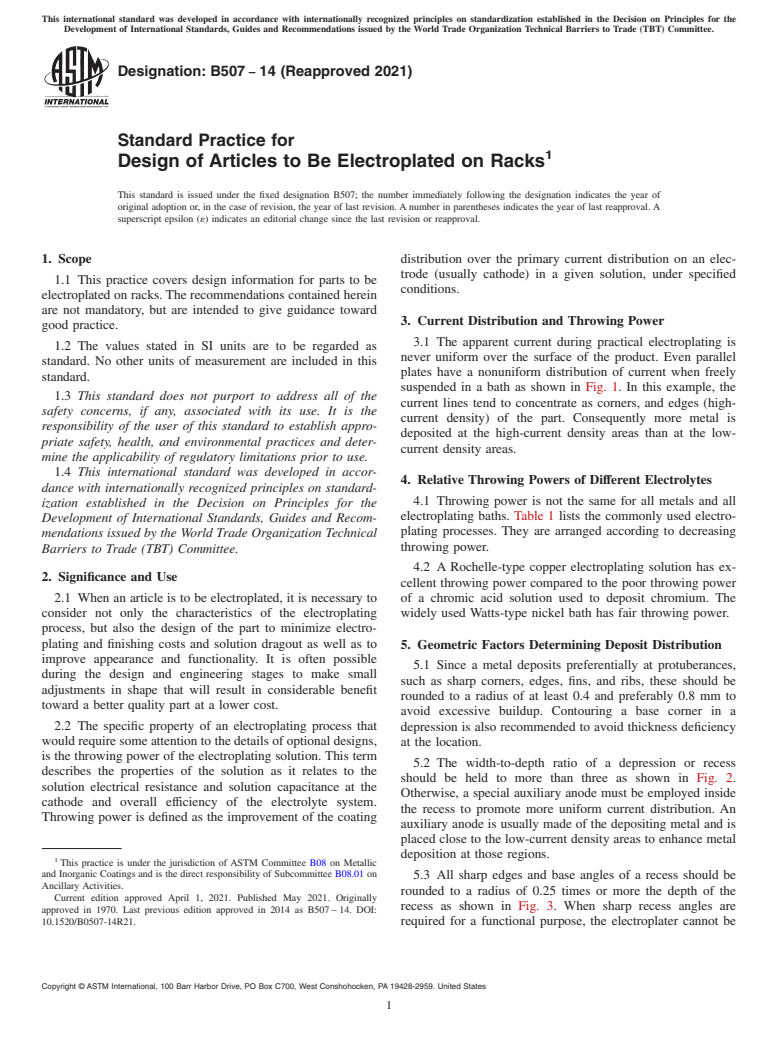

5.2 The width-to-depth ratio of a depression or recess

describes the properties of the solution as it relates to the

should be held to more than three as shown in Fig. 2.

solution electrical resistance and solution capacitance at the

Otherwise, a special auxiliary anode must be employed inside

cathode and overall efficiency of the electrolyte system.

the recess to promote more uniform current distribution. An

Throwing power is defined as the improvement of the coating

auxiliary anode is usually made of the depositing metal and is

placed close to the low-current density areas to enhance metal

deposition at those regions.

This practice is under the jurisdiction of ASTM Committee B08 on Metallic

and Inorganic Coatings and is the direct responsibility of Subcommittee B08.01 on

5.3 All sharp edges and base angles of a recess should be

Ancillary Activities.

rounded to a radius of 0.25 times or more the depth of the

Current edition approved April 1, 2021. Published May 2021. Originally

recess as shown in Fig. 3. When sharp recess angles are

approved in 1970. Last previous edition approved in 2014 as B507 – 14. DOI:

10.1520/B0507-14R21. required for a functional purpose, the electroplater cannot be

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B507−14 (2021)

FIG. 1 Current Density Distribution and Typical Electrodeposit (filled area)

TABLE 1 Relative Throwing Powers of Common Electroplating

6. Examples of Distribution of Electrodeposited Nickel

Baths

on Various Shapes

Bath/Metal Ranking

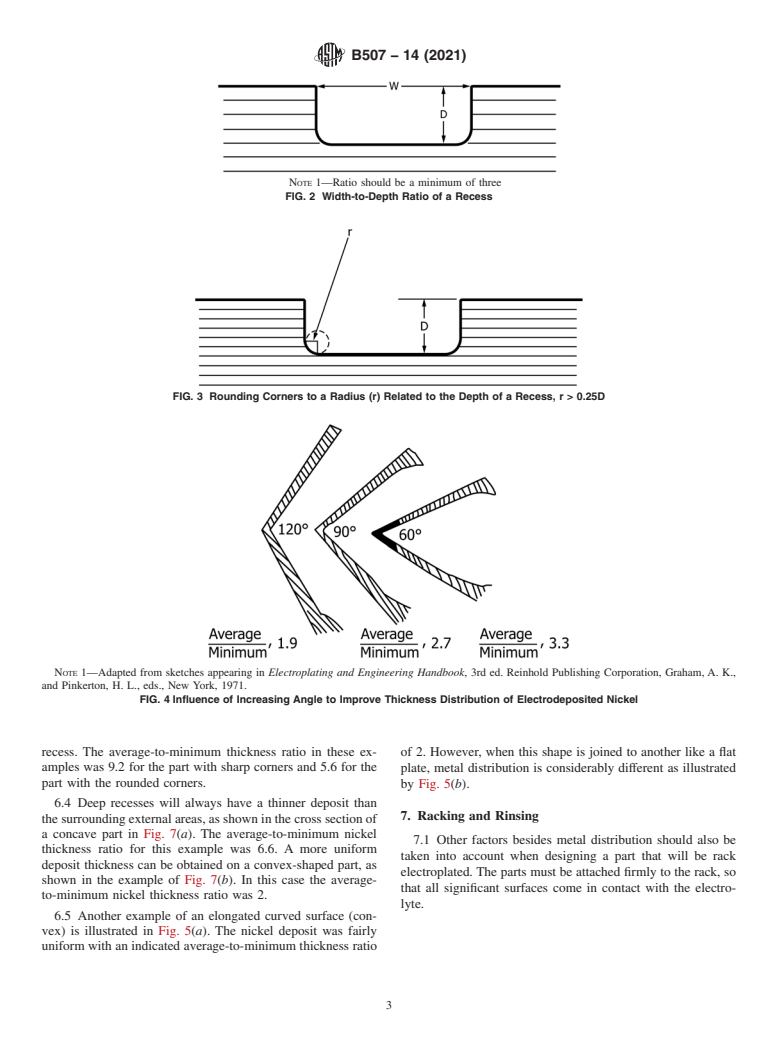

6.1 Fig. 4 through Fig. 5 show the kind of nickel distribu-

Rochell copper (cyanide based) Excellent

tion that was obtained on several different cathode configura-

Cyanide cadmium Excellent

Cyanide gold Good tions as deposited from a Watts-type bath at normal operating

Cyanide silver Good

current densities.The thicknesses illustrated are exaggerated to

Alkaline tin Good

emphasize the variations that were obtained. The data are

Cyanide zinc Good

Alkaline non cyanide zinc Good

measurements taken from metallographic cross sections. Ref-

Fluoborate lead Good

erence to the figures enables similar conclusions to be drawn

All chloride nickel Fair

with most other metals, excluding chromium. The ranges will

Tin nickel Fair

Sulfamate nickel Fair

be smaller for metals above nickel in Table 1 and larger for

A

Watts nickel Fair

metals below nickel.

Bright nickel Fair

Acid chloride zinc Fair

6.2 Improvement in nickel distribution can be gained inside

Nickel-iron Fair

an angle by increasing the angle size, as shown in Fig. 4.Two

C

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.