ASTM C1443-99(2010)

(Specification)Standard Specification for Glasses, Portlight, Circular, Fully Tempered

Standard Specification for Glasses, Portlight, Circular, Fully Tempered

ABSTRACT

This specification covers circular, fully tempered, high clarity, flat glasses prescribed for use in portlight applications. The glazing quality float glasses are classified into four types according to the type of edge and the texture of each face. All products should conform to the required values for breaking strength, surface and edge compression, clarity, and warpage and quality of finish.

SCOPE

1.1 This specification covers the requirements for circular, fully tempered, high clarity, flat glasses used for portlight applications.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazard caveat pertains only to the test method portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1443 −99(Reapproved 2010)

Standard Specification for

Glasses, Portlight, Circular, Fully Tempered

This standard is issued under the fixed designation C1443; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Classification

1.1 This specification covers the requirements for circular,

4.1 Glasses covered by this specification shall be of the

fully tempered, high clarity, flat glasses used for portlight

following types, as specified (see 5.1):

applications.

4.1.1 Type 1—Plain edges, both faces polished,

1.2 The values stated in inch-pound units are to be regarded 4.1.2 Type II—Plain edge, one face polished, opposite face

as standard. The values given in parentheses are mathematical frosted,

conversions to SI units that are provided for information only

4.1.3 Type III—Rabbeted edge, both faces polished, or

and are not considered standard.

4.1.4 Type IV—Rabbeted edge, one face polished, opposite

face frosted.

1.3 The following safety hazard caveat pertains only to the

test method portion, Section 11, of this specification:This

standard does not purport to address all of the safety concerns, 5. Ordering Information

if any, associated with its use. It is the responsibility of the user

5.1 Purchasers should select the preferred options permitted

of this standard to establish appropriate safety and health

in this specification, and include the following information in

practices and determine the applicability of regulatory limita-

procurement documents:

tions prior to use.

5.1.1 Title, number, and date of this specification,

2. Referenced Documents

5.1.2 Type of portlight glasses, as requested (see 4.1),

5.1.3 Dimensions of portlight glasses (see 8.1 and 9.3), and

2.1 ASTM Standards:

C162 Terminology of Glass and Glass Products

5.1.4 Type, class, and quality of glass (see Specification

C1036 Specification for Flat Glass C1036) and heat treatment (see Specification C1048).

C1048 Specification for Heat-Strengthened and Fully Tem-

5.2 Samples—If samples are to be supplied with bids, they

pered Flat Glass

should be specifically requested in the invitation for bids and

C1279 Test Method for Non-Destructive Photoelastic Mea-

the particular purpose to be served by the bid sample should be

surement of Edge and Surface Stresses in Annealed,

clearly stated.

Heat-Strengthened, and Fully Tempered Flat Glass

2.2 ANSI Standard:

6. Materials and Manufacture

ANSI Z1.4 Sampling Procedures and Tables for Inspection

by Attributes (DOD Adopted)

6.1 Material—The glass used shall be glazing quality, float

glass in accordance with the requirements for Specification

3. Terminology

C1036, Type I, Class 1, quality q or higher, if required, and

3.1 Definitions—For definitions of terms used in this

heat-treated Specification C1048, kind FT.

specification, refer to Terminology C162 and also Specifica-

6.2 Marking—Specimens shall exhibit the words “fully

tions C1036 and C1048 and Test Method C1279.

tempered” approximately ⁄2 in. (12.7 mm) from the edge by

means of etching or sand blasting. Marking shall be done

This specification is under the jurisdiction of ASTM CommitteeC14 on Glass

before heat treating.

and Glass Products and is the direct responsibility of Subcommittee C14.08 on Flat

Glass.

Current edition approved March 1, 2010. Published March 2010. Originally

7. Other Requirements

approvedin1999.Lastpreviouseditionapprovedin2005asC1443–99(2005).DOI:

10.1520/C1443-99R10.

7.1 Breaking Strength—Glasses shall exhibit satisfactory

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

resistance to breakage (see 11.1.2.1).

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

7.2 Surface and Edge Compression —Type I and III glasses

the ASTM website.

3 shall have a surface compression of not less than 10 000 psi or

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. an edge compression of not less than 9700 psi (see 11.1.1.2).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1443−99 (2010)

TABLE 2 Sampling for Surface and Edge Stress Examination and

7.3 Clarity—When glasses are tested (see 11.1.2.3), black

Tests

and white lines of the clarity target shall be definitely distin-

Allowable Number of Allowable Number of

guishable for all parts of the critical area.

Sample Failures for Surface and Failures for Tests (Load,

Lot Size Size Edge Stress Examination Clarity, Warpage)

7.4 Warpage—Glasses shall not exhibit more than ⁄32 in.

(0.8 mm) warpage along any line on either face (see 11.1.2.3). 1-6 all none none

A

7-50 6 load

8. Dimensions B

clarity: none

... ... none

C

warpage: none

51-100 14

8.1 The dimensions of the specimens shall be as specified in

5.1. The thickness of a circular glass specimen shall not vary A

load

B

101-1000 10 none clarity: none

more than ⁄32 in. (0.8 mm) between any two points on its

C

warpage: none

periphery. Dimensional tolerances for circular cut glasses shall

A

See 11.1.2.1.

not exceed values specified in Table 1 and Specification B

Supplier may, at his option, test all remaining glasses in the lot for clarity in

C1036.

accordancewith11.1.2.2andallglassesthatpassshallbeconsideredacceptable.

C

Supplier may, at his option, test all remaining glasses in the lot for warpage in

accordancewith11.1.2.3andallglassesthatpassshallbeconsideredacceptable.

9. Finish and Appearance

9.1 Finish—Glasses shall be finished by grinding to the

tolerances specified in 8.1. Edges shall be ground, with corners

10.1.3 Sampling for Test—Sampling for all tests to be

chamfered ⁄16 in. (1.6 mm).

performed on specimens shall be in accordance with 10.1.2.

9.2 Types II and IV—The designated faces of the glasses

shall be uniformly frosted by sand blasting or etching.

11. Inspection, Acceptance and Rejection

9.3 Types III and IV—The edges of the glasses shall be

11.1 Responsibility—The supplier is responsible for inspec-

rabbeted. The depth of the rabbet in the horizontal direction

tion of cut specimens unless otherwise specified in the contract

and in the vertical direction shall be specified by the purchaser

or purchase order. Two forms of inspection are required:

(see 5.1.3). Depth dimensions for the rabbet shall be accurate

examination and test.

to within in. (0.8 mm) when measured from the edge and from

11.1.1 Examination—Inspection by examination shall con-

the face of the glass. One edge of the rabbet shall be

sist of determining compliance with visual and dimensional

perpendicular to the face of the glass and the other edge of the

requirements.

rabbet shall be perpendicular to the edge of the glass such that

11.1.1.1 Visual and Dimensional Examinations—All speci-

the angle formed by the faces of the rabbet is 90 6 2°.

mens of a sample size selected in accordance with 10.1.1 shall

be examined to verify conformance to all of the requirements

10. Sampling

which do not involve tests or polariscopic examination.The lot

10.1 Inspection Lot—For purposes of inspection, a lot shall

shall be accepted if all of the specimens in the sample (see

consist of not more than 1000 specimens which shall be of a

10.1.1) conform to visual requirements of Section 6.2 and

single thickness, produced in a single plant and offered for

Section 9 and dimensional requirements of Section 8. The lot

delivery at one time.

shall be rejected if any of the specimens in the sample fail to

10.1.1 Sampling for Visual and Dimensional

conformtotheserequirements.Ifthelotisrejectedonthebasis

Examinations—Samples shall be selected in accordance with

of visual and dimensional examination, the supplier may at his

the procedures of ANSI Z1.4 at inspection Level II for

option examine all remaining specimens of the lot to determine

examination in accordance with 11.1.1.1.

conformance with visual and dimensional requirements. Any

10.1.2 Sampling for Surface and Edge Stress—Samples

of the specimens of the lot that comply with the visual and

shall be selected at random in accordance with Table 2 for

dimensional requirements shall be considered acceptable, sub-

examination in accordance with 11.1.1.2. When a lot contains

ject to conformance with polariscopic examination require-

fewer than seven glasses, or when a special use (see 5.1)

ments and test requirements.

requires protection against defects, the sample shall consist of

11.1.1.2 Surface and Edge Stresses, (Type I and Type III

all specimens in the lot. Where the lot consists of between 7

Glasses)—All specimens of a sample size selected in accor-

and 50 glasses, the sample shall consist of 6 specimens. Where

dance with 10.1.2 shall be subjected to surface or edge stress

the lot consists of between 51 and 100 glasses, the sample shall

examination (see 7.2) to determine if they are fully tempered.

consistof14specimens.Lotscontainingmorethan100glasses

It is suggested that Type III glasses be tested for surface stress.

shall be evaluated by means of a sample of 10 specimens.

Test Method C1279 is recommended for testing edge and

Samples from lots consisting of more than 6 glasses shall

surface stresses. If any glass specimen from a sample under-

contain a representative variety of types and diameters.

going surface and edge stress examination does not meet the

requiredvalues(see7.2),thelotshallberejectedinaccordance

with criteria given in Table 2.

TABLE 1 Permitted Tolerances

11.1.2 Test Acceptance or Rejection—Inspection by test

Dimension Tolerance, ± in. (± mm)

shall consist of load, clarity, and warpage tests.

Diameter ⁄16 (1.6)

11.1.2.1 Load Test—All specimens of a sample size selected

Depth of rabbet ⁄32 (0.8)

in accordance with 10.1.3 shall be tested under a load applied

C1443−99 (2010)

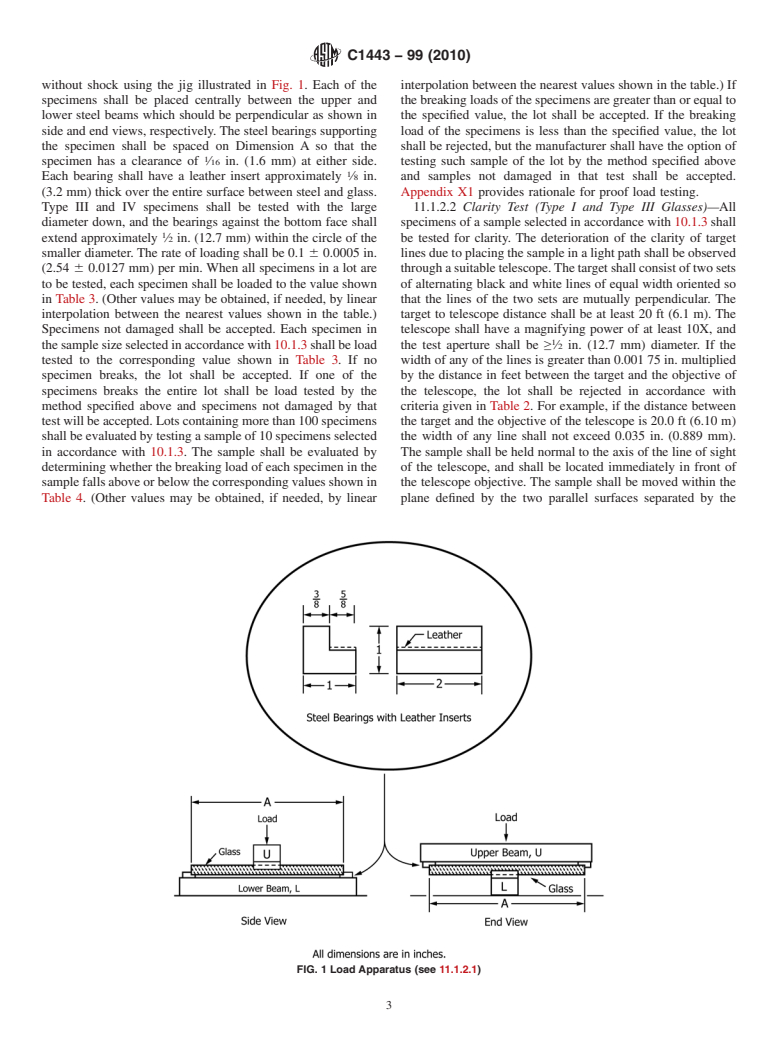

without shock using the jig illustrated in Fig. 1. Each of the interpolation between the nearest values shown in the table.) If

specimens shal

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.