ASTM C1901-21e2

(Test Method)Standard Test Method for Measuring Optical Retardation in Flat Architectural Glass

Standard Test Method for Measuring Optical Retardation in Flat Architectural Glass

SIGNIFICANCE AND USE

5.1 Stress may be applied intentionally through a heat treatment or tempering process to increase mechanical strength and improve safety characteristics of glass sheets. The process itself makes it practically impossible to achieve a homogenous residual stress profile over a full glass panel. These variations are due to variations in type of glass (clear, tinted, coated, etc.), the fabrication, sheet geometry, heating, quenching, and cooling. Even though the level of inhomogeneity may not interfere with the global mechanical property of the glass sample, it can produce optical patterns called anisotropy (often commonly referred to as leopard spots). Today to evaluate this stress homogeneity people may use the subjective, non-standardized method of viewing through a polarized filter or employing a polariscope. The present test method provides guidelines for measuring a physical parameter, the optical retardation, directly linked to the local residual stress, at many locations on each heat-treated glass sheet.

5.2 Through this test method one can obtain in a non-destructive manner, on-line to the tempering furnace equipment, a map of the retardation value of all glasses. That information can then be used:

5.2.1 By the tempering operator to adjust the settings of the heat treatment process to optimize/tune both the levels optical retardations and its homogeneity on heat treated glass sheets.

5.2.2 To provide a standardized way to measure optical retardation values for each glass panel that can be archived and communicated when desired.

5.2.3 By customers and other stakeholders to develop/write specifications for the optical retardation values (not the visibility of the pattern) that are independently verifiable.

5.3 This test method can also be used off-line to evaluate the optical retardation level and homogeneity of any heat-treated glass, for quality assurance or other purposes.

SCOPE

1.1 This test method addresses the measurement of optical anisotropy in architectural glass.

1.2 This test method is a test method for measuring optical retardation. It is not an architectural glazing specification.

1.3 The optical retardation values may be used to calculate/predict the amount of visible pattern, commonly known as anisotropy or iridescence, present in heat-treated glass.

1.4 This test method applies to monolithic heat-treated (heat-strengthened and fully tempered) clear, tinted and coated glass.

1.5 This test method does not apply to:

1.5.1 Glass that diffuse light (that is, patterned glass, sand blasted glass, acid etched, etc.), or

1.5.2 Glass that is not optically transparent (that is, mirrors, enameled or fritted glass).

1.6 The optical measurement is integrated through the glass thickness, and therefore cannot be used to assess the level of tempering. It does not give information on the surface stress or center tension.

1.7 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´2

Designation: C1901 − 21

Standard Test Method for

Measuring Optical Retardation in Flat Architectural Glass

This standard is issued under the fixed designation C1901; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—The title of Section 9 was corrected editorially in March 2021.

1. Scope 2. Referenced Documents

1.1 This test method addresses the measurement of optical 2.1 Referencetothesedocumentsshallbethelatestrevision

anisotropy in architectural glass. unless otherwise specified by the authority applying this test

method.

1.2 This test method is a test method for measuring optical

2.2 ASTM Standards for Glass:

retardation. It is not an architectural glazing specification.

C162Terminology of Glass and Glass Products

1.3 The optical retardation values may be used to calculate/

C1036Specification for Flat Glass

predict the amount of visible pattern, commonly known as

C1048Specification for Heat-Strengthened and Fully Tem-

anisotropy or iridescence, present in heat-treated glass.

pered Flat Glass

1.4 This test method applies to monolithic heat-treated

2.3 ASTM Standards for Optical Stress and Retardation

(heat-strengthened and fully tempered) clear, tinted and coated

Measurements:

glass.

C1279Test Method for Non-Destructive Photoelastic Mea-

surement of Edge and Surface Stresses in Annealed,

1.5 This test method does not apply to:

Heat-Strengthened, and Fully Tempered Flat Glass

1.5.1 Glass that diffuse light (that is, patterned glass, sand

D4093Test Method for Photoelastic Measurements of Bire-

blasted glass, acid etched, etc.), or

fringence and Residual Strains in Transparent or Translu-

1.5.2 Glass that is not optically transparent (that is, mirrors,

cent Plastic Materials

enameled or fritted glass).

1.6 The optical measurement is integrated through the glass

3. Terminology

thickness, and therefore cannot be used to assess the level of

3.1 Definitions:

tempering. It does not give information on the surface stress or

3.1.1 For definitions of terms used in this test method, refer

center tension.

to Specifications C1036, C1048, and Terminology C162,as

1.7 The values stated in SI units are to be regarded as

appropriate.

standard. The values given in parentheses after SI units are

3.2 Definitions of Terms Specific to This Standard:

provided for information only and are not considered standard.

3.2.1 analyzer, n—a polarizing element, typically rotatable

and positioned between the specimen being evaluated and the

1.8 This standard does not purport to address all of the

observer.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.2.2 anisotropy, n—property of being directionally depen-

priate safety, health, and environmental practices and deter-

dentwherebymeasurementstakenalongdifferentaxesproduce

mine the applicability of regulatory limitations prior to use.

differences in a material’s physical or mechanical properties

1.9 This international standard was developed in accor-

(absorbance, refractive index, conductivity, etc.).

dance with internationally recognized principles on standard-

3.2.3 Babinet-Soleil compensator, n—an optical compensa-

ization established in the Decision on Principles for the

tor that can be used to measure phase shifts locally in a

Development of International Standards, Guides and Recom-

polariscope or polarimeter using shifting quartz wedges.

mendations issued by the World Trade Organization Technical

3.2.4 birefringence, n—the optical property of a material

Barriers to Trade (TBT) Committee.

having a refractive index that depends on the polarization and

propagation direction of light.

This test method is under the jurisdiction of ASTM Committee C14 on Glass

and Glass Products and is the direct responsibility of Subcommittee C14.08 on Flat For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Glass. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Jan. 1, 2021. Published February 2021. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

C1901-21E02. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´2

C1901 − 21

3.2.5 compensation methods, n—(1) Sénarmont compensa- homogeneity people may use the subjective, non-standardized

tor uses linearly polarized light incident to the specimen; it method of viewing through a polarized filter or employing a

couples a quarter wavelength plate with a 180° rotating polariscope. The present test method provides guidelines for

analyzer to provide retardation measurements; (2) Tardy com- measuring a physical parameter, the optical retardation, di-

pensator uses circularly polarized light incident to the rectly linked to the local residual stress, at many locations on

specimen,thusindependentofthespecimenorientation;italso each heat-treated glass sheet.

couples a quarter wavelength plate with a 180° rotating

5.2 Through this test method one can obtain in a non-

analyzer to provide retardation measurements.

destructive manner, on-line to the tempering furnace

3.2.6 index of refraction, n—theratioofspeedoflight(c)in

equipment, a map of the retardation value of all glasses. That

vacuum and the phase velocity of light in the medium (v).

information can then be used:

5.2.1 By the tempering operator to adjust the settings of the

3.2.7 iridescence, n—also known as quench pattern/marks,

heat treatment process to optimize/tune both the levels optical

strainpatternoranisotropy,visiblepatterninheat-treatedglass

retardations and its homogeneity on heat treated glass sheets.

that may be visible under certain polarized lighting conditions.

5.2.2 To provide a standardized way to measure optical

3.2.8 isochromatic, adj—having the same color or wave-

retardationvaluesforeachglasspanelthatcanbearchivedand

length.

communicated when desired.

3.2.9 photoelasticity, n—the property exhibited by transpar-

5.2.3 By customers and other stakeholders to develop/write

ent isotropic solids of becoming doublerefracting when sub-

specifications for the optical retardation values (not the visibil-

jected to either tensile or compressive stress.

ity of the pattern) that are independently verifiable.

3.2.10 polarizer, circular, n—an optical assembly that cre-

5.3 Thistestmethodcanalsobeusedoff-linetoevaluatethe

ates circularly polarized light for a given wavelength.

optical retardation level and homogeneity of any heat-treated

3.2.11 polarizer, linear, n—an optical assembly that trans-

glass, for quality assurance or other purposes.

mits light vibrating in a single planar direction.

3.2.12 retardation, n—the optical path difference between

6. Limitations

two perpendicular polarized light waves created in a birefrin-

6.1 A series of factors will affect the results. These factors

gent material.

should be either avoided or documented to explain how they

3.2.13 retardation standard, n—see waveplates.

affect results.

3.2.14 specular light, n—radiationemergingfromthespeci-

6.1.1 The light transmission of the specimen at the wave-

men is parallel to the beam entering.

length(s)beingusedtomeasureopticalretardationshouldbein

accordance with apparatus manufacturer specification.

3.2.15 wave retarder, n—see waveplates.

6.1.2 The deviation from flatness of the glass after the heat

3.2.16 waveplates, n—birefringent materials that retard the

treatment process might affect the measurement, as the light

polarization state or phase of light traveling through them.

may travel out of the equipment range. The glass flatness,

4. Summary of Test Method

overallbow,edgekink,rollerwavemustbeinaccordancewith

apparatus manufacturer specifications.

4.1 This test method provides an accurate non-destructive

6.1.3 The thermal stateofthespecimenwhenmeasuredwill

method of quantifying optical retardation in transparent glass

affect the results as non-uniform temperature across the thick-

using principles of photoelasticity and high-speed image pro-

ness and from one region to another on the same pane will

cessing. The result is a high-resolution retardation map in

induce stresses. Variance can occur with glass temperature.

nanometres (nm). Optionally, the apparatus can compute an

6.1.4 When measuring optical retardation using photo-

additional map of retardation axis orientation (azimuth) in

elasticdevices,attentionshouldbepaidtoexternal mechanical

degrees. This test method provides a process for monitoring

stresses applied to glass.

these variations.

6.1.5 Area around geometric features (holes, notches, open-

5. Significance and Use

ings) and edges will have high retardation values that may

exceed equipment range (see example of edge stress in Test

5.1 Stress may be applied intentionally through a heat

Method C1279). Including retardation values in these regions

treatmentortemperingprocesstoincreasemechanicalstrength

may bias calculations such as uniformity and averages. Exclu-

and improve safety characteristics of glass sheets. The process

sion zones can be setup to eliminate some regions, for

itself makes it practically impossible to achieve a homogenous

example: perimeter bands or partially enameled areas. These

residual stress profile over a full glass panel. These variations

zones should be properly identified in the report.

areduetovariationsintypeofglass(clear,tinted,coated,etc.),

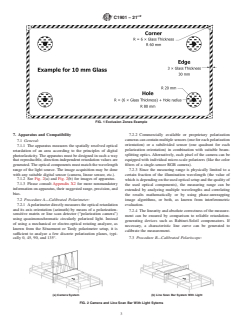

6.1.6 See Fig. 1 for example of exclusion zones.

the fabrication, sheet geometry, heating, quenching, and cool-

ing. Even though the level of inhomogeneity may not interfere 6.1.7 See Appendix X1 for further discussion about more

with the global mechanical property of the glass sample, it can complex circumstances (that is, laminates, insulated glass

produce optical patterns called anisotropy (often commonly units)thatmustbeapproachedcarefullywhenapplyingthetest

referred to as leopard spots). Today to evaluate this stress method.

´2

C1901 − 21

FIG. 1 Exclusion Zones Example

7. Apparatus and Compatibility 7.2.2 Commercially available or proprietary polarization

camerascancontainmultiplesensors(oneforeachpolarization

7.1 General:

orientation) or a subdivided sensor (one quadrant for each

7.1.1 The apparatus measures the spatially resolved optical

polarization orientation) in combination with suitable beam-

retardation of an area according to the principles of digital

splitting optics.Alternatively, each pixel of the camera can be

photoelasticity. The apparatus must be designed in such a way

equipped with individual micro-scale polarizers (like the color

that reproducible, direction-independent retardation values are

filters of a single-sensor RGB camera).

generated.Theopticalcomponentsmustmatchthewavelength

range of the light source. The image acquisition may be done

7.2.3 Since the measuring range is physically limited to a

with any suitable digital sensor (camera, linear sensor, etc.).

certain fraction of the illumination wavelength (the value of

7.1.2 See Fig. 2(a) and Fig. 2(b) for images of apparatus.

whichisdependingontheusedopticalsetupandthequalityof

7.1.3 Please consult Appendix X2 for more nonmandatory

the used optical components), the measuring range can be

informationonapparatus,theirsuggestedrange,precision,and

extended by analyzing multiple wavelengths and correlating

bias.

the results mathematically or by using phase-unwrapping

7.2 Procedure A—Calibrated Polarimeter:

image algorithms, or both, as known from interferometric

7.2.1 Apolarimeterdirectlymeasurestheopticalretardation

evaluation.

and its axis orientation (azimuth) by means of a polarization-

7.2.4 The linearity and absolute correctness of the measure-

sensitive matrix or line scan detector (“polarization camera”)

ment can be ensured by comparison to reliable retardation-

using quasimonochromatic circularly polarized light. Instead

generating devices such as Babinet-Soleil compensators. If

of using a mechanical or electro-optical rotating analyzer, as

necessary, a characteristic line curve can be generated to

known from the Sénarmont or Tardy polarimeter setup, it is

calibrate the measurement.

sufficient to analyze a few discrete polarization planes, typi-

cally 0, 45, 90, and 135°. 7.3 Procedure B—Calibrated Polariscope:

(a) Camera System (b) Line Scan Bar System With Light

FIG. 2 Camera and Line Scan Bar With Light Sytems

´2

C1901 − 21

7.3.1 By calibration, circular polariscopes can be used 9.4 This procedure can be repeated in different area in the

practically to quantify retardation based on isochromatic im- width of the scanner to verify that all light emitting, and

ages. Due to the optical configuration, the maximum optical sensing elements yield the correct values.

retardation is measured independently of the direction. There

are several approaches to correlate intensity values (RGB

10. Procedure

colors or gray values) with retardation values. One method is a

10.1 Operator should use the apparatus in accordance with

calibration using a Babinet-Soleil compensator. A correlation

manufacturer suggested practices and authorities having juris-

oftheacquiredcalibration,innm,withtheisochromaticimage

diction.

(intensity values) using an evaluation algorithm creates a new

10.2 See Appendix X3 for guidelines on operational proce-

image with retardation (nm) per pixel.

dures.

8. Hazards

11. Report

8.1 Glass is a brittle material and may result in glass

11.1 Required Information:

fracture. Glass handling safety gear should always be worn

11.1.1 Glass geometry (thickness and size, in mm).

during specimen handling, testing, evaluation, and disposal.

11.1.2 Definition of the area analyzed (base × height, in

Apparatus discussed in this test method may utilize high

mm).

intensity light sources such as a laser. Proper care and

manufacturer’s instructions must be followed by the operator. 11.1.3 Analyzed area in m .

11.1.4 Data aggregation methods definitions. Examples in-

9. Calibration and Verification clude:

11.1.4.1 Mean value of the analyzed area.

9.1 Apparatus manufacturers use proprietary methods to

11.1.4.2 Maximum value of the analyzed area.

convert their sensor output into workable retardation values.

11.1.4.3 95th percentile distribution level of the analyzed

Through self-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.