ASTM C1443-99(2010)

(Specification)Standard Specification for Glasses, Portlight, Circular, Fully Tempered

Standard Specification for Glasses, Portlight, Circular, Fully Tempered

ABSTRACT

This specification covers circular, fully tempered, high clarity, flat glasses prescribed for use in portlight applications. The glazing quality float glasses are classified into four types according to the type of edge and the texture of each face. All products should conform to the required values for breaking strength, surface and edge compression, clarity, and warpage and quality of finish.

SCOPE

1.1 This specification covers the requirements for circular, fully tempered, high clarity, flat glasses used for portlight applications.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazard caveat pertains only to the test method portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1443 −99(Reapproved 2010)

Standard Specification for

1

Glasses, Portlight, Circular, Fully Tempered

This standard is issued under the fixed designation C1443; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Classification

1.1 This specification covers the requirements for circular,

4.1 Glasses covered by this specification shall be of the

fully tempered, high clarity, flat glasses used for portlight

following types, as specified (see 5.1):

applications.

4.1.1 Type 1—Plain edges, both faces polished,

1.2 The values stated in inch-pound units are to be regarded 4.1.2 Type II—Plain edge, one face polished, opposite face

as standard. The values given in parentheses are mathematical frosted,

conversions to SI units that are provided for information only

4.1.3 Type III—Rabbeted edge, both faces polished, or

and are not considered standard.

4.1.4 Type IV—Rabbeted edge, one face polished, opposite

face frosted.

1.3 The following safety hazard caveat pertains only to the

test method portion, Section 11, of this specification:This

standard does not purport to address all of the safety concerns, 5. Ordering Information

if any, associated with its use. It is the responsibility of the user

5.1 Purchasers should select the preferred options permitted

of this standard to establish appropriate safety and health

in this specification, and include the following information in

practices and determine the applicability of regulatory limita-

procurement documents:

tions prior to use.

5.1.1 Title, number, and date of this specification,

2. Referenced Documents

5.1.2 Type of portlight glasses, as requested (see 4.1),

2

5.1.3 Dimensions of portlight glasses (see 8.1 and 9.3), and

2.1 ASTM Standards:

C162 Terminology of Glass and Glass Products

5.1.4 Type, class, and quality of glass (see Specification

C1036 Specification for Flat Glass C1036) and heat treatment (see Specification C1048).

C1048 Specification for Heat-Strengthened and Fully Tem-

5.2 Samples—If samples are to be supplied with bids, they

pered Flat Glass

should be specifically requested in the invitation for bids and

C1279 Test Method for Non-Destructive Photoelastic Mea-

the particular purpose to be served by the bid sample should be

surement of Edge and Surface Stresses in Annealed,

clearly stated.

Heat-Strengthened, and Fully Tempered Flat Glass

2.2 ANSI Standard:

6. Materials and Manufacture

ANSI Z1.4 Sampling Procedures and Tables for Inspection

3

by Attributes (DOD Adopted)

6.1 Material—The glass used shall be glazing quality, float

glass in accordance with the requirements for Specification

3. Terminology

3

C1036, Type I, Class 1, quality q or higher, if required, and

3.1 Definitions—For definitions of terms used in this

heat-treated Specification C1048, kind FT.

specification, refer to Terminology C162 and also Specifica-

6.2 Marking—Specimens shall exhibit the words “fully

tions C1036 and C1048 and Test Method C1279.

1

tempered” approximately ⁄2 in. (12.7 mm) from the edge by

means of etching or sand blasting. Marking shall be done

1

This specification is under the jurisdiction of ASTM CommitteeC14 on Glass

before heat treating.

and Glass Products and is the direct responsibility of Subcommittee C14.08 on Flat

Glass.

Current edition approved March 1, 2010. Published March 2010. Originally

7. Other Requirements

approvedin1999.Lastpreviouseditionapprovedin2005asC1443–99(2005).DOI:

10.1520/C1443-99R10.

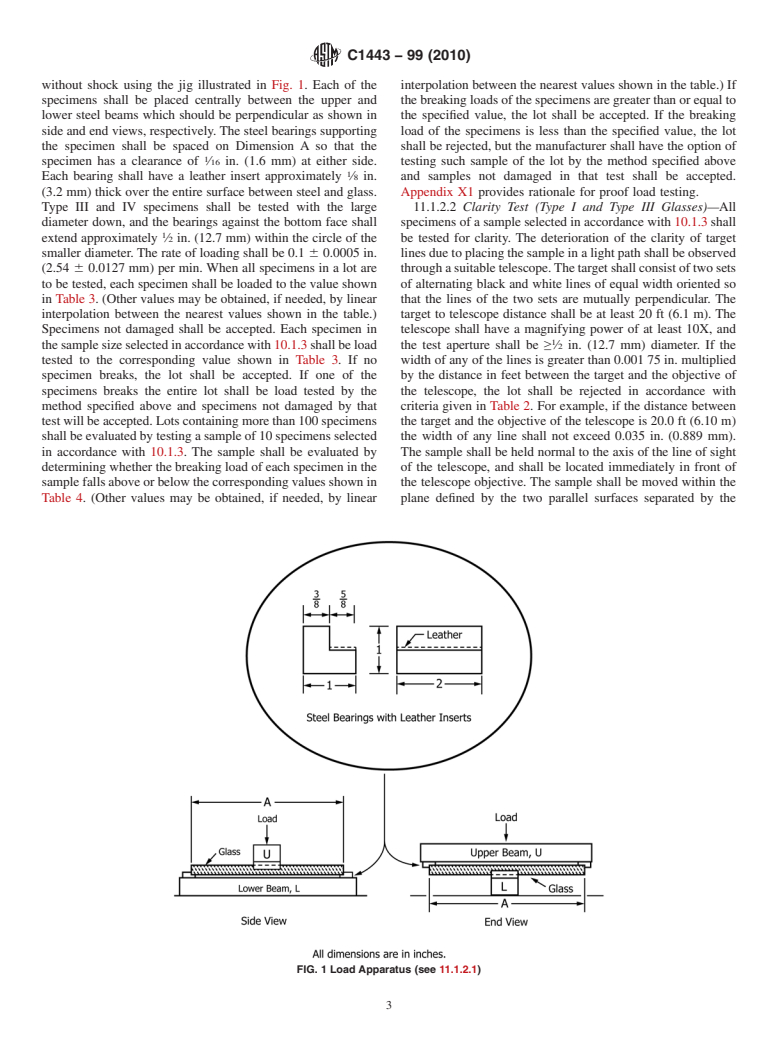

7.1 Breaking Strength—Glasses shall exhibit satisfactory

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

resistance to breakage (see 11.1.2.1).

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

7.2 Surface and Edge Compression —Type I and III glasses

the ASTM website.

3 shall have a surface compression of not less than 10 000 psi or

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. an edge compression of not less than 9700 psi (see 11.1.1.2).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1443−99 (2010)

TABLE 2 Sampling for Surface and Edge Stress Examination and

7.3 Clarity—When glasses are tested (see 11.1.2.3), black

Tests

and white lines of the clarity target shall be definitely distin-

Allowable Number of Allowable Number of

guishable for all parts of the critical area.

Sample Failures for Surface and Failures for

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.