ASTM B476-01

(Specification)Standard Specification for General Requirements for Wrought Precious Metal Electrical Contact Materials

Standard Specification for General Requirements for Wrought Precious Metal Electrical Contact Materials

SCOPE

1.1 This specification covers general requirements common to wrought precious metal electrical contact alloy products in the form of sheet, strip, wire, and rod. Unless otherwise specified in the purchase order or in an individual specification, these general requirements shall apply to wrought electrical contact materials where indicated in the applicable product specifications issued by ASTM.

1.2 In case of conflict, the requirements on the purchase order, the individual specification, and this general specification shall prevail in the sequence named.

1.3 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units may be approximate.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 It is the responsibility of the user to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet for this product/material as provided by the manufacturer.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 476 – 01

Standard Specification for

General Requirements for Wrought Precious Metal

1

Electrical Contact Materials

This standard is issued under the fixed designation B 476; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

4

1. Scope E 3 Methods of Preparation of Metallographic Specimens

4

E 8 Test Methods of Tension Testing of Metallic Materials

1.1 This specification covers general requirements common

E 29 Practice for Using Significant Digits in Test Data to

to wrought precious metal electrical contact alloy products in

5

Determine Conformance with Specifications

the form of sheet, strip, wire, and rod. Unless otherwise

E 55 PracticeforSamplingWroughtNonferrousMetalsand

specifiedinthepurchaseorderorinanindividualspecification,

6

Alloys for Determination of Chemical Composition

these general requirements shall apply to wrought electrical

4

E 112 Test Methods for Determining Average Grain Size

contact materials where indicated in the applicable product

4

E 384 Test Method for Microhardness of Materials

specifications issued by ASTM.

1.2 In case of conflict, the requirements on the purchase

3. Terminology

order, the individual specification, and this general specifica-

3.1 Definition:

tion shall prevail in the sequence named.

3.1.1 lot—the quantity of material of the same type, size,

1.3 The values stated in inch-pound units are to be regarded

and finish produced at one time from the same cast or heat, and

as the standard. The metric equivalents of inch-pound units

heat treated in the same heat-treatment cycle.

may be approximate.

1.4 This standard does not purport to address all of the

4. Ordering Information

safety concerns, if any, associated with its use. It is the

4.1 Orders for material to this specification shall include the

responsibility of the user of this standard to establish appro-

following information:

priate safety and health practices and determine the applica-

4.1.1 Designation and revision date of this specification.

bility of regulatory limitations prior to use.

4.1.1.1 Ifarevisiondateisnotdesignated,thelatestrevision

1.5 It is the responsibility of the user to become familiar

should be used.

with all hazards including those identified in the appropriate

4.1.2 Designation and revision date of the applicable prod-

Material Safety Data Sheet for this product/material as pro-

uct specification.

vided by the manufacturer.

4.1.2.1 Ifarevisiondateisnotdesignated,thelatestrevision

of the product specification should be used.

2. Referenced Documents

4.1.3 Description of material form,

The following documents of the issue in effect, on the date

4.1.4 Dimensions of the material,

of material purchase, form a part of this specification to the

4.1.5 Total quantity of each size,

extent referenced herein:

4.1.6 Temper of the material (annealed, cold worked, etc.),

2.1 ASTM Standards:

4.1.7 Temper test (hardness or tensile) (Section 10),

B 63 Test Method for Resistivity of Metallically Conduct-

2 4.1.8 Special requirements (if any), and

ing Resistance and Contact Materials

4.1.9 Certification (Section 14).

B 772 Guide for Specifying the Chemical Compositions for

3 4.2 Specify the following, if required:

Electrical Contact Materials (Arcing and Nonarcing)

4.2.1 Certificate of compliance of physical and chemical

requirement.

4.2.2 Test Data—Specifytestsandanalysestobeperformed

1

This test method is under the jurisdiction of ASTM Committee B02 on

and reported.

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

4.2.3 Special packaging, if required.

B02.05 on Precious Metals.

Current edition approved May 10, 2001. Published July 2001. Originally

e1

published as B476 –68. Last previous edition B476 – 90 (1995) .

2 4

Annual Book of ASTM Standards, Vol 03.04. Annual Book of ASTM Standards, Vol 03.01.

3 5

Annual Book of ASTM Standards, Vol 02.04. Annual Book of ASTM Standards, Vol 14.02.

6

Annual Book of ASTM Standards, Vol 03.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

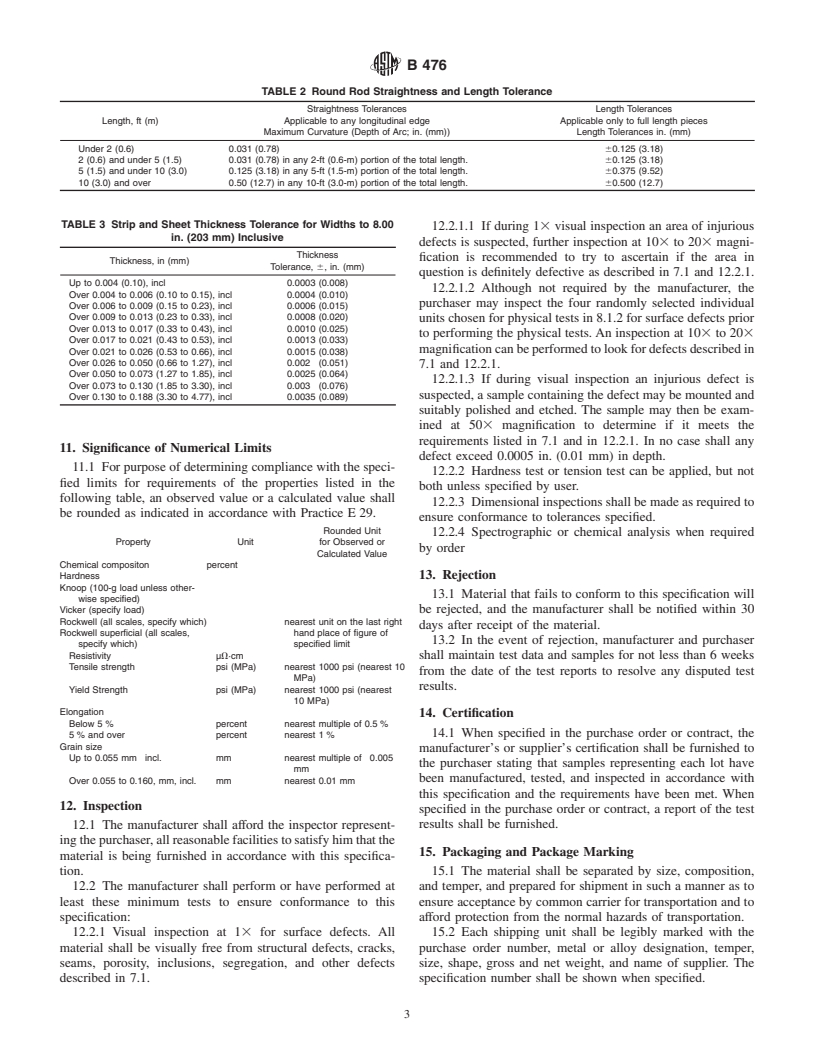

B 476

5. Materials and Manufacture chase order or request for quotation. The flatness of a flat form

shall be that the maximum deviation from the flat surface shall

5.1 The raw material shall be of such quality and purity that

be less than 1 % of the measurement distance specified for the

the finished product shall have the properties and characteris-

product, such as diameter for circles, length or width o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.