ASTM B476-01(2006)

(Specification)Standard Specification for General Requirements for Wrought Precious Metal Electrical Contact Materials

Standard Specification for General Requirements for Wrought Precious Metal Electrical Contact Materials

ABSTRACT

This specification covers general requirements common to wrought precious metal electrical contact alloy products in the form of sheet, strip, wire, and rod. The raw material shall be of such quality and purity that the finished product shall have the properties and characteristics prescribed in the applicable product specification. The product shall be produced by a combination of hot or cold working operations, it shall be finished, unless otherwise specified, by cold working, annealing, or heat treatment as may be necessary to meet the specified properties. Surfaces of all material furnished to this specification shall be smooth, clean, and free from scratches, stains, rough spots, slivers, laps, scale, pits, and any other injurious defects. Test methods such as chemical analysis and physical tests shall be performed accordingly.

SCOPE

1.1 This specification covers general requirements common to wrought precious metal electrical contact alloy products in the form of sheet, strip, wire, and rod. Unless otherwise specified in the purchase order or in an individual specification, these general requirements shall apply to wrought electrical contact materials where indicated in the applicable product specifications issued by ASTM.

1.2 In case of conflict, the requirements on the purchase order, the individual specification, and this general specification shall prevail in the sequence named.

1.3 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units may be approximate.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B476 – 01 (Reapproved 2006)

Standard Specification for

General Requirements for Wrought Precious Metal Electrical

Contact Materials

This standard is issued under the fixed designation B476; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope B772 Guide for Specifying the Chemical Compositions for

Electrical Contact Materials (Arcing and Nonarcing)

1.1 This specification covers general requirements common

E3 Guide for Preparation of Metallographic Specimens

to wrought precious metal electrical contact alloy products in

E8 Test Methods for Tension Testing of Metallic Materials

the form of sheet, strip, wire, and rod. Unless otherwise

E29 Practice for Using Significant Digits in Test Data to

specifiedinthepurchaseorderorinanindividualspecification,

Determine Conformance with Specifications

these general requirements shall apply to wrought electrical

E55 Practice for Sampling Wrought Nonferrous Metals and

contact materials where indicated in the applicable product

Alloys for Determination of Chemical Composition

specifications issued by ASTM.

E112 Test Methods for Determining Average Grain Size

1.2 In case of conflict, the requirements on the purchase

E384 Test Method for Microindentation Hardness of Mate-

order, the individual specification, and this general specifica-

rials

tion shall prevail in the sequence named.

1.3 The values stated in inch-pound units are to be regarded

3. Terminology

as standard. The values given in parentheses are mathematical

3.1 Definition:

conversions to SI units that are provided for information only

3.1.1 lot, n—the quantity of material of the same type, size,

and are not considered standard.

and finish produced at one time from the same cast or heat, and

1.4 This standard does not purport to address all of the

heat treated in the same heat-treatment cycle.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to become familiar

4. Ordering Information

with all hazards including those identified in the appropriate

4.1 Orders for material to this specification shall include the

Material Safety Data Sheet (MSDS) for this product/material

following information:

as provided by the manufacturer, to establish appropriate

4.1.1 Designation and revision date of this specification.

safety and health practices, and determine the applicability of

4.1.1.1 Ifarevisiondateisnotdesignated,thelatestrevision

regulatory limitations prior to use.

should be used.

4.1.2 Designation and revision date of the applicable prod-

2. Referenced Documents

uct specification.

The following documents of the issue in effect, on the date

4.1.2.1 Ifarevisiondateisnotdesignated,thelatestrevision

of material purchase, form a part of this specification to the

of the product specification should be used.

extent referenced herein:

2 4.1.3 Description of material form,

2.1 ASTM Standards:

4.1.4 Dimensions of the material,

B63 Test Method for Resistivity of Metallically Conducting

4.1.5 Total quantity of each size,

Resistance and Contact Materials

4.1.6 Temper of the material (annealed, cold worked, etc.),

4.1.7 Temper test (hardness or tensile) (Section 10),

This specification is under the jurisdiction of ASTM Committee B02 on

4.1.8 Special requirements (if any), and

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

4.1.9 Certification (Section 14).

B02.05 on Precious Metals and Electrical Contact Materials.

4.2 Specify the following, if required:

Current edition approved June 1, 2006. Published June 2006. Originally

approved in 1968. Last previous edition approved in 2001 as B476 – 01. DOI: 4.2.1 Certificate of compliance of physical and chemical

10.1520/B0476-01R06.

requirement.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.2.2 Test Data—Specifytestsandanalysestobeperformed

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and reported.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

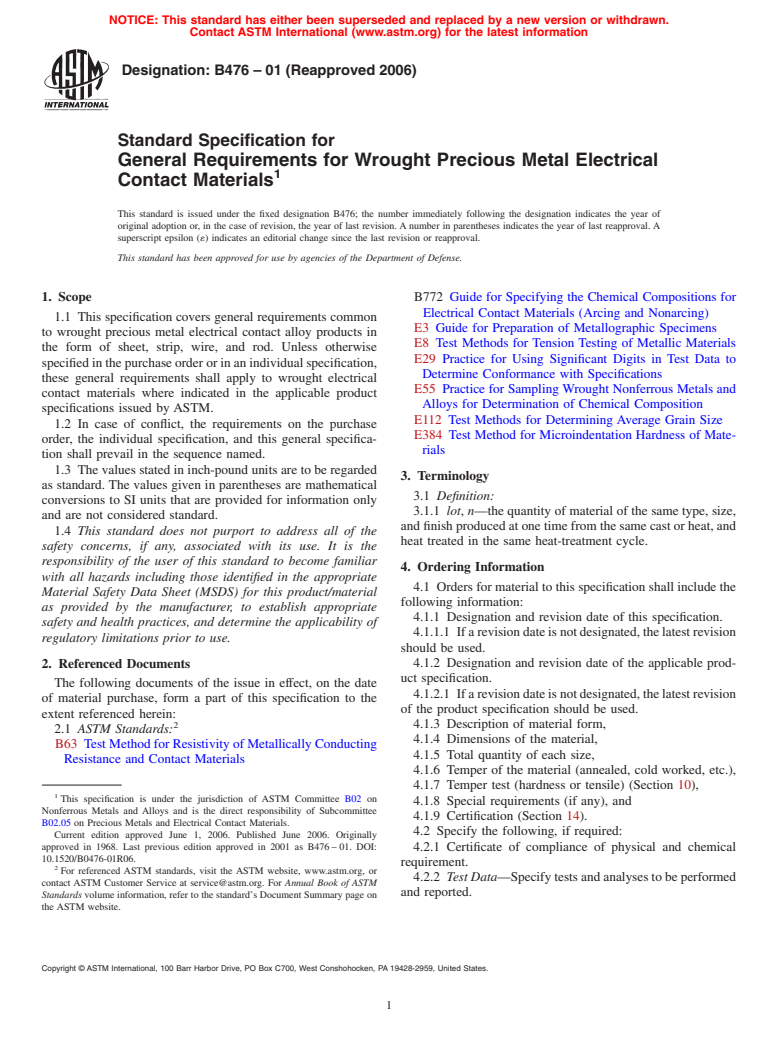

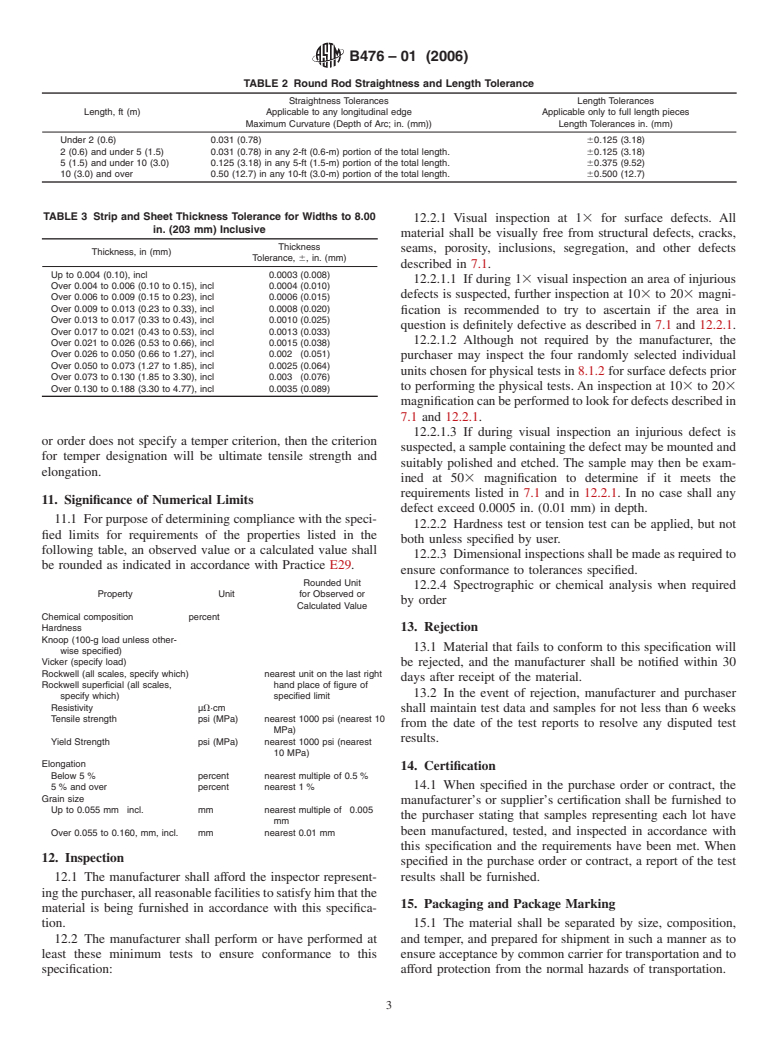

B476 – 01 (2006)

4.2.3 Special packaging, if required. discuss flatness requirements. It is not a requirement of this

specification, unless agreed upon and made part of the pur-

5. Materials and Manufacture

chase order or request for quotation. The flatness of a flat form

shall be that the maximum deviation from the flat surface shall

5.1 The raw material shall be of such quality and purity that

be less than 1 % of the measurement distance specified for the

the finished product shall have the properties and characteris-

product, such as diameter for circles, length or width of blanks,

tics prescribed in the applicable product specification issued by

or any specific measurement length; that is, maximum of 0.20

ASTM.

in. (5.08 mm) deviation in any 20 in. (508 mm) length in any

5.2 The product shall be produced by a combination of hot

direction.

or cold working operations. it shall be finished, unless other-

wise specified, by such cold working, annealing, or heat

treatment as may be necessary to meet the specified properties. 7. Workmanship

7.1 Surfaces of all material furnished to this specification

6. Dimensions and Permissible Variations

shall be smooth, clean, and free from scratches, stains, rough

6.1 General—For the purpose of determining conformance

spots, slivers, laps, scale, pits, and any other injurious defects

with the dimensional requirements prescribed in this specifi-

within limits consistent with the best possible practice.

cation, any measured value outside the specified limiting

values for any dimension may be cause for rejection.

8. Sampling

6.2 Tolerance tables to cover all forms of products can

8.1 Sampling—The portion size and selection of pieces

become quite voluminous. For this reason, it is recommended

shall be as follows:

that tolerances be established and agreed upon between the

8.1.1 Chemical Analysis—Samples for chemical analysis

producer and user at the time of placing an order or an inquiry

shall be taken and prepared in accordance with Practice E55.

for quotation of price and delivery. Refer to Section 16

The minimum weight of the composite sample that is to be

(Supplementary Requirements). Details of form and tolerances

divided into three equal parts shall be 6 g.

for products not covered by this specification, such as, the

8.1.2 Physical Tests—For physical tests, a test specimen

types of materials listed below, and means of measurement,

shall be taken from each of four randomly selected individual

should be established between producer and user.

units of finished product from a lot. If the lot consists of less

6.2.1 Sawed products,

thanfourunits,apieceshallbetakenfromeachindividualunit.

6.2.2 Square sheared products,

6.2.3 Flat wire, thickness, width and edge radius tolerances,

9. Number of Tests and Retests

6.2.4 Edge rolled flat wire, thickness, width and corner

radius tolerances. 9.1 If any specimen tested shows a defective test method or

6.3 Wire and Rod: extraneous flaws, it may be discarded and another specimen

6.3.1 The standard tolerances applied to the diameter of substituted.

wire and rod shall be as prescribed in Table 1.

9.2 If the chemical analysis fails to conform to the specified

6.3.2 The rod straightness and length tolerance shall be limits, analysis shall be made on a new composite sample,

those prescribed in Table 2.

prepared from samples selected in accordance with Practice

6.4 Strip and Sheet—Supplied in the form of coils, flat E55 or 8.1.2 after the physical tests have been performed. The

lengths or on spools.

results of this retest shall comply with the specified require-

6.4.1 The thickness tolerances shall be those prescribed in ments.

Table 3.

9.3 The required physical tests shall be performed on 2 of 4

6.4.2 The width standard tolerance for slit products shall be

of the pieces selected in accordance with 8.1.2.

those prescribed in Table 4.

9.3.1 If one of the two tests made to determine any of the

6.4.3 The straightness (camber or edgewise curvature) tol-

physical properties fails to meet a specified limit, this test shall

erance for slit strip is prescribed in Table 4 also.

be repeated on each of the two remaining pieces selected in

6.5 Flatness—The flatness of blanks, shims, circles, or

accordancewith8.1.2andtheresultsofbothofthesetestsshall

other forms should be negotiated between the manufacturer

comply with the specified requirements.

and the purchaser. The following suggestion is to be used for

9.4 In the case of micro hardness, the number of readings

guidance only when the manufacturer and the purchaser

shall not be less than 5 on each test specimen.

10. Test Methods

TA

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.