ASTM D2152-95(2010)

(Test Method)Standard Test Method for Adequacy of Fusion of Extruded Poly(Vinyl Chloride) (PVC) Pipe and Molded Fittings by Acetone Immersion

Standard Test Method for Adequacy of Fusion of Extruded Poly(Vinyl Chloride) (PVC) Pipe and Molded Fittings by Acetone Immersion

SIGNIFICANCE AND USE

This test method is applicable only for distinguishing between inadequately fused and adequately fused PVC. The difference between thermally degraded and adequately fused PVC cannot be detected by this test method. Acetone immersion is not a substitute for burst, impact, or other physical or chemical tests on PVC pipe or fittings and it, therefore, shall not be used as the only test specification for purchasing of PVC pipe and fittings. This test only detects inadequate fusion and does not determine the over-all quality of the PVC pipe or fittings.

This test method is useful in determining whether inadequate fusion contributed to failure of PVC pipe or fittings in other physical or chemical tests, or in service.

This test method is useful in evaluating the adequacy of PVC fusion obtained in process or materials trials.

This test method determines adequacy of fusion on a single, relatively small specimen. This test method requires the use of a hazardous reagent which must be properly handled and disposed. Therefore, this test method may not be cost-effective to employ as a routine quality control test.

SCOPE

1.1 This test method covers the determination of the adequacy of fusion of extruded rigid poly(vinyl chloride) (PVC) pipe and molded fittings as indicated by reaction to immersion in anhydrous acetone.

1.2 The values stated in inch-pound units are to be regarded as the standard except where instruments are calibrated in SI units.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards statements are given in Annex A1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2152 − 95(Reapproved 2010) An American National Standard

Standard Test Method for

Adequacy of Fusion of Extruded Poly(Vinyl Chloride) (PVC)

Pipe and Molded Fittings by Acetone Immersion

This standard is issued under the fixed designation D2152; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.2 This test method is useful in determining whether

inadequatefusioncontributedtofailureofPVCpipeorfittings

1.1 This test method covers the determination of the ad-

in other physical or chemical tests, or in service.

equacy of fusion of extruded rigid poly(vinyl chloride) (PVC)

pipe and molded fittings as indicated by reaction to immersion 3.3 This test method is useful in evaluating the adequacy of

in anhydrous acetone. PVC fusion obtained in process or materials trials.

1.2 The values stated in inch-pound units are to be regarded 3.4 This test method determines adequacy of fusion on a

as the standard except where instruments are calibrated in SI single,relativelysmallspecimen.Thistestmethodrequiresthe

units. useofahazardousreagentwhichmustbeproperlyhandledand

disposed.Therefore, this test method may not be cost-effective

1.3 This standard does not purport to address all of the

to employ as a routine quality control test.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Apparatus

priate safety and health practices and determine the applica-

4.1 Container—Either individual, sealable containers for

bility of regulatory limitations prior to use. Specific hazards

each specimen or one large, airtight container capable of

statements are given in Annex A1.

holding several specimens without touching one another.

2. Referenced Documents

4.2 Hydrometer and Cylinder—Precision hydrometer,

graduated in thousandths, with a minimum range of 0.780 to

2.1 ASTM Standards:

0.790 g/mL and a cylinder large enough to immerse the

D618Practice for Conditioning Plastics for Testing

hydrometer.

3. Significance and Use

4.3 Thermometer—ASTM 12C total immersion

thermometer,rangefrom−20°Cto102°Caccurateto0.2°C,or

3.1 This test method is applicable only for distinguishing

equivalent.

between inadequately fused and adequately fused PVC. The

difference between thermally degraded and adequately fused

5. Reagent

PVC cannot be detected by this test method. Acetone immer-

5.1 Acetone—American Chemical Society Reagent Grade,

sion is not a substitute for burst, impact, or other physical or

having a maximum density of 0.7857 g/mL at 25°C.

chemical tests on PVC pipe or fittings and it, therefore, shall

notbeusedastheonlytestspecificationforpurchasingofPVC

NOTE1—SeeAnnexA1forthesafetyandhealthprecautionstobeused

pipe and fittings. This test only detects inadequate fusion and

with acetone.

does not determine the over-all quality of the PVC pipe or

5.2 Prior to conducting the test, check the density of the

fittings.

acetone with a precision hydrometer to determine its dryness.

If the density of the acetone is greater than 0.7890 g/mL at

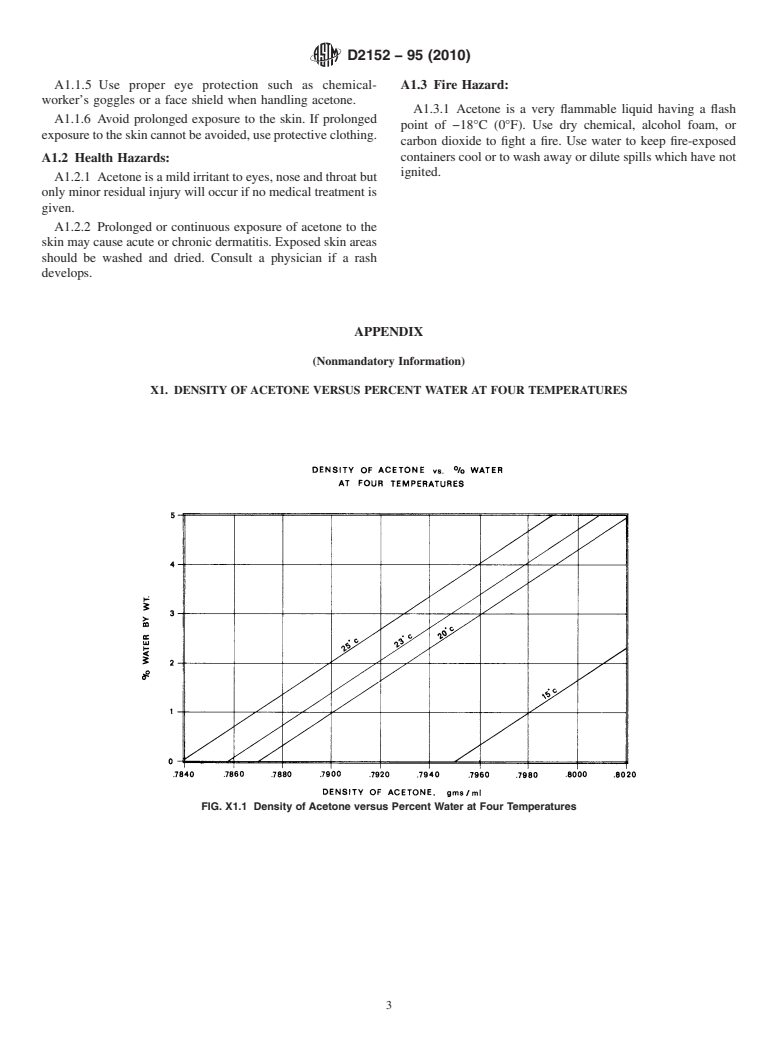

23°C,(correspondingtoapproximately1%waterbymass(see

This test method is under the jurisdiction ofASTM Committee F17 on Plastic

Fig. X1.1)), use fresh acetone or dry the wet acetone with a

Piping Systems and is the direct responsibility of Subcommittee F17.25 on Vinyl

drying agent. Recheck the density of the fresh or dried acetone

Based Pipe.

Current edition approved April 1, 2010. Published May 2010. Originally before using.

approved in 1963T. Last previous edition approved in 2003 as D2152–95(2003).

NOTE 2—Wet acetone can be dried by thoroughly agitating it with at

DOI: 10.1520/D2152-95R10.

least 15 g of anhydrous calcium sulfate (CaSO ) for each gram of water

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

present.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on NOTE 3—The presence of water in the acetone reduces its sensitivity to

the ASTM website. differences in the degree of fusion of rigid poly(vinyl chloride) (PVC). It

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2152 − 95 (2010)

is important to dry the acetone properly and conduct the test in a sealed

effect water has on the acetone. For referee purposes condi-

container, because acetone rapidly absorbs moisture from the atmosphere.

tioning shall be in accordance with Procedure A of Practice

NOTE 4—Round-robin testing between four laboratories showed that

D618.

test results are not significantly altered with up to 2% water by weight in

the acetone.

9. Procedure

9.1 Conduct the tests in a Standard LaboratoryAtmosphere

6. Sampling

of 23 6 2°C unless otherwise specified.

6.1 Specimens shall be taken from individual pipe sections,

9.2 Place sufficient dried acetone into the container to

fittings,orremnantportionsofpipeorfittings.Specimensshall

ensure complete immersion of the specimen.

betakenfromlocationswhicharetobeevaluatedforadequacy

9.3 Place the test specimen in the acetone, seal the con-

of fusion, or immediately adjacent to them.

tainer, and do not agitate. Allow speci

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D2152–95 (Reapproved 2003) Designation:D2152–95 (Reapproved 2010)

Standard Test Method for

Adequacy of Fusion of Extruded Poly(Vinyl Chloride) (PVC)

Pipe and Molded Fittings by Acetone Immersion

This standard is issued under the fixed designation D2152; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method covers the determination of the adequacy of fusion of extruded rigid poly(vinyl chloride) (PVC) pipe and

molded fittings as indicated by reaction to immersion in anhydrous acetone.

1.2 Thevaluesstatedininch-poundunitsaretoberegardedasthestandardexceptwhereinstrumentsarecalibratedinSIunits.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific hazards statements are given in Annex A1.

2. Referenced Documents

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

3. Significance and Use

3.1 ThistestmethodisapplicableonlyfordistinguishingbetweeninadequatelyfusedandadequatelyfusedPVC.Thedifference

between thermally degraded and adequately fused PVC cannot be detected by this test method. Acetone immersion is not a

substitute for burst, impact, or other physical or chemical tests on PVC pipe or fittings and it, therefore, shall not be used as the

onlytestspecificationforpurchasingofPVCpipeandfittings.Thistestonlydetectsinadequatefusionanddoesnotdeterminethe

over-all quality of the PVC pipe or fittings.

3.2 This test method is useful in determining whether inadequate fusion contributed to failure of PVC pipe or fittings in other

physical or chemical tests, or in service.

3.3 This test method is useful in evaluating the adequacy of PVC fusion obtained in process or materials trials.

3.4 This test method determines adequacy of fusion on a single, relatively small specimen. This test method requires the use

of a hazardous reagent which must be properly handled and disposed. Therefore, this test method may not be cost-effective to

employ as a routine quality control test.

4. Apparatus

4.1 Container—Either individual, sealable containers for each specimen or one large, airtight container capable of holding

several specimens without touching one another.

4.2 Hydrometer and Cylinder—Precisionhydrometer,graduatedinthousandths,withaminimumrangeof0.780to0.790g/mL

and a cylinder large enough to immerse the hydrometer.

4.3 Thermometer—ASTM 12C total immersion thermometer, range from −20°C to 102°C accurate to 0.2°C, or equivalent.

5. Reagent

5.1 Acetone—American Chemical Society Reagent Grade, having a maximum density of 0.7857 g/mL at 25°C.

NOTE 1—See Annex A1 for the safety and health precautions to be used with acetone.

This test method is under the jurisdiction ofASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.25 on Vinyl Based

Pipe.

´1

Current edition approved March 15, 1995. Published May 1995. Originally published as D2152–63T. Last previous edition D2152–80(1986) . DOI: 10.1520/D2152-

95R03.

Current edition approved April 1, 2010. Published May 2010. Originally approved in 1963T. Last previous edition approved in 2003 as D2152–95(2003). DOI:

10.1520/D2152-95R10.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2152–95 (2010)

5.2 Prior to conducting the test, check the density of the acetone with a precision hydrometer to determine its dryness. If the

density of the acetone is greater than 0.7890 g/mLat 23°C, (corresponding to approximately 1% water by mass (see Fig. X1.1)),

use fresh acetone or dry the wet acetone with a drying agent. Recheck the density of the fresh or dried acetone before using.

NOTE 2—Wet acetone can be dried by thoroughly agitating it with at least 15 g of anhydrous calcium sulfate (CaSO ) for each gram of water present.

NOTE 3—The presence of water in the acetone reduces its sensitivity to differences in the degree of fusion of rigid poly(vinyl chloride) (PVC). It is

important to dry the acetone properly and conduct the test in a sealed container, because acetone rapidly absorbs moisture from the atmosphere.

NOTE 4—Round-robin testing between four laboratories showed that test results are not significantly altered with up to 2% water by weight in the

acetone.

6. Sampling

6.1 Specimens shall be taken from individual pipe sections, fittings, or remnant portions of pipe or fittings. Specimens shall be

taken from locations which are to be evaluated for adequacy of fusion, or immediately adjacent to them.

6.2 The number of individual specimens to be tested and their locations shall be chosen to be representative of the pipe or

fittings being evaluated for adequacy of fusion.

7. Test Specimens

7.1 Size of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.