ASTM B569-98

(Specification)Standard Specification for Brass Strip in Narrow Widths and Light Gage for Heat-Exchanger Tubing

Standard Specification for Brass Strip in Narrow Widths and Light Gage for Heat-Exchanger Tubing

SCOPE

1.1 This specification establishes requirements for brass strip (Copper Alloy UNS Nos. C23000, C26000, and C26130 ) in widths 3 in. (76.2 mm) and under and thickness less than 0.018 in. (0.457 mm), for the manufacture of thin-walled tubes for water passages in heat exchangers for internal combustion engines and other closed-system heat sources.

1.2 The values stated in inch-pound units are the standard, except for grain size, which is always specified in millimetres. Values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 569 – 98

Standard Specification for

Brass Strip in Narrow Widths and Light Gage for Heat-

Exchanger Tubing

This standard is issued under the fixed designation B 569; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * 3.2.1 capable of—the test need not be performed by the

producer of the product; however, should subsequent testing by

1.1 This specification establishes the requirements for brass

the purchaser establish that the product does not meet these

strip in narrow widths and light gages produced from Copper

requirements, the product shall be subject to rejection.

Alloys Nos. C23000, C26000, and C26130.

NOTE 1—This product is commonly used for the manufacture of 4. Ordering Information

thin-wall tubes for water passages in heat exchangers for internal

4.1 Orders for products should include the following infor-

combustion engines and other closed system heat sources.

mation:

1.2 Values given in inch-pound units are the standard except

4.1.1 ASTM designation and year of issue (for example,

for grain size, which are given in SI units. Values given in

B 569–XX),

parentheses are for information only.

4.1.2 Copper Alloy UNS No. designation (for example,

C26000),

2. Referenced Documents

4.1.3 Temper (Section 7),

2.1 ASTM Standards:

4.1.4 Dimensions: thickness, width, length, and so forth

B 248 Specification for General Requirements for Wrought

(Section 11), and

Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled

4.1.5 Quantity: total weight each form, temper, and size.

Bar

4.2 The following options are available and should be

B 601 Practice for Temper Designations for Copper and

specified at the time of placing an order when required:

Copper Alloys—Wrought and Cast

4.2.1 Heat identification or traceability details,

B 846 Terminology for Copper and Copper Alloys

4.2.2 Certification, and

E 3 Methods of Preparation of Metallographic Specimens

4.2.3 Mill test report.

E 8 Test Methods for Tension Testing of Metallic Materials

5. Materials and Manufacture

E 29 Practice for Using Significant Digits in Test Data to

Determine Conformance With Specifications

5.1 Material:

E 112 Test Methods for Determining Average Grain Size

5.1.1 The material of manufacture shall be cast bar, cake, or

E 478 Test Methods for Chemical Analysis of Copper

slab of Copper Alloy UNS No. C23000, C26000, or C26130 of

Alloys

such purity and soundness as to be suitable for processing into

the products prescribed herein.

3. Terminology

5.1.2 In the event heat identification or traceability is

3.1 Definitions—For definitions of terms used in this speci-

required, the purchaser shall specify the details desired.

fication, refer to Terminology B 846.

NOTE 2—Because of the discontinuous nature of the processing of

3.2 Definitions of Terms Specific to This Standard:

castings into wrought products, it is not always practical to identify a

specific casting analysis with a specific quantity of finished material.

This specification is under the jurisdiction of ASTM Committee B-5 on Copper 5.2 Manufacture:

and Copper Alloys and is the direct responsibility of Subcommittee B05.01 on Plate,

5.2.1 The product width shall be 3 in. (76.2 mm) and under,

Sheet, and Strip.

and thickness shall be less than 0.018 in. (0.457 mm).

Current edition approved May 10, 1998. Published March 1999. Originally

5.2.2 The product shall be manufactured by such hot-

published as B 569 – 72. Last previous edition B 569 – 93.

Annual Book of ASTM Standards, Vol 02.01.

working, cold-working, and annealing processes as to produce

Annual Book of ASTM Standards, Vol 03.01.

a uniform wrought structure in the finished product.

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 03.06.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B569–98

5.2.2.1 The product shall be hot- or cold-worked to the 10. Dimensions, Mass, and Permissible Variations

finished size, and subsequently annealed, when required, to

10.1 Unless closer tolerances are specified in the contract or

meet the temper properties specified.

purchase order, the product furnished shall conform to the

following thickness and width tolerances:

6. Chemical Composition

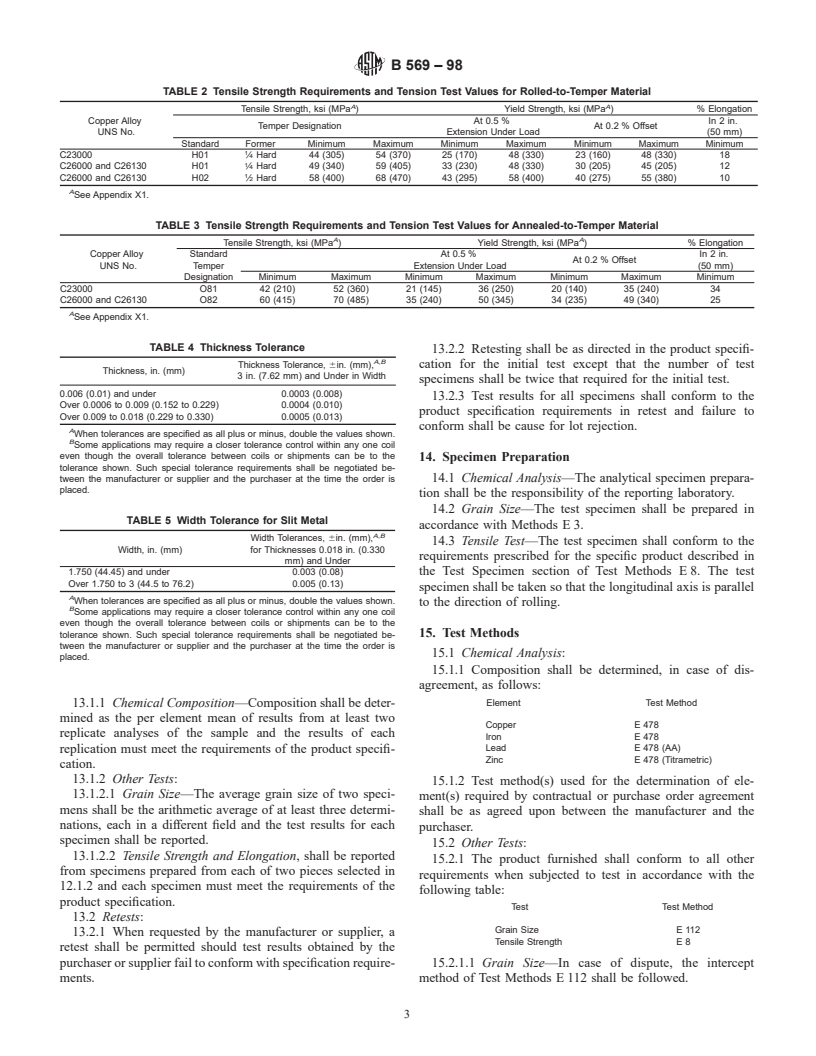

10.1.1 Thickness Tolerances—Table 4.

10.1.2 Width Tolerances—Table 5.

6.1 The material shall conform to the chemical composi-

10.2 Straightness Tolerances—The maximum edgewise

tional requirements in Table 1 for Copper Alloy UNS No.

curvature (depth of arc) in any 72-in. (1830-mm) continuous

designation specified in the ordering information.

length shall not exceed ⁄8in. (3.18 mm).

6.1.1 These composition limits do not preclude the presence

of other elements. Limits may be established and analysis

11. Workmanship, Finish and Appearance

required for unnamed elements by agreement between the

manufacturer and the purchaser. 11.1 The strip shall be free of defects, but blemishes of a

nature that do not interfere with normal commercial operations

6.2 Zinc, specified as the “Remainder,” may be taken as the

difference between the sum of results for all elements deter- are acceptable. It shall be well-cleaned and free of dirt. A

superficial film of residual light lubricant may be present and is

mined and 100 %.

acceptable unless otherwise specified.

6.2.1 When zinc is determined, however, copper may be

11.2 The surface finish and appearance shall be the normal

taken by difference, and when so taken, the results must

commercial quality for the alloy, thickness, and temper or-

conform with the requirements of Table 1 for copper.

dered. When application information is provided with the

6.3 When all elements listed in Table 1 are determined for

purchase order, the surface shall be that commercially produc-

C26000 and C26130 the sum of results shall be 99.7 % min and

ible for the application. Superficial films of discoloration, or

for C23000 the sum of results shall be 99.8 % min.

lubricants, or tarnish inhibitors are permissible unless other-

wise specified.

7. Temper

7.1 Products shall be produced in tempers H01 ( ⁄4 hard),

12. Sampling

1 1

H02 ( ⁄2 hard), O81 (Annealed-to-Temper— ⁄4 hard), and O82

12.1 Sampling—The lot size, portion size, and selection of

(Annealed-to-Temper— ⁄2 hard) as defined in Practice B 601.

sample pieces shall be as follows:

NOTE 3—The purchaser should confer with the manufacturer or sup-

12.1.1 Lot Size—An inspection lot shall be 10 000 lb (4550

plier for the availability of product in a specific temper.

kg) or less of material of the same mill form, alloy, temper, and

nominal dimensions, subject to inspection at one time or shall

8. Grain Size of Annealed Tempers

be the product of one cast bar from a single melt charge, whose

8.1 Annealed-to-Temper (O81 and O82) strip shall have an

weight shall not exceed 25 000 lb (11 350 kg), that has been

average grain size of 0.015 mm max as determined by Test

processed continuously and subject to inspection at one time.

Methods E 112.

12.1.2 Portion Size—A portion shall be four or more pieces

selected to be representative of each lot. If the lot consists of

9. Mechanical Property Requirement less than four pieces, representative samples shall be taken

from each piece.

9.1 Tensile Strength Requirement—The product furnished

12.1.2.1 Chemical Analysis—The sample for chemical

shall conform to the requirements prescribed in Tables 2 and 3

analysis shall be taken in accordance with Practice E 255 for

for the temper specified in the ordering information when

product in its final form. Unless otherwise required by the

tested in accordance with Test Methods E 8.

purchaser, at the time the order is placed the manufacturer shall

9.2 Yield Strength Requirement—The product furnished

have the option of determining conformance to chemical

shall be capable of conforming to the requirements prescribed

composition by analyzing samples taken at the time the

in Tables 2 and 3 for the temper specified in the ordering

castings are poured or samples taken from the semifinished

information when tested in accordance with Test Methods E 8.

product if heat identity can be maintained throughout all

9.3 Elongation Test Requirement—The product furnished

operations. If the manufacturer determines the chemical com-

shall conform to the requirements prescribed in Tables 2 and 3

position during manufacture, he shall not be required to sample

for the temper specified in the ordering information when

and analyze the finished product. The minimum weight of the

tested in accordance with Test Methods E 8.

composite sample in accordance with Practice E 255 shall be

150 g.

12.1.2.2 Samples for All Other Tests—Samples for all other

TABLE 1 Chemical Requirements

tests shall be taken from the sample portion in 12.1.2 and be of

Copper Composition, %

a convenient size to accommodate the test and comply with the

Alloy UNS Lead, Iron,

Copper Arsenic Zinc

requirements of the appropriate ASTM product standards and

No. max max

A

C23000 84.0–86.0 0.05 0.05 . . . Remainder

test methods.

B

C26000 68.5–71.5 0.07 0.05 . . . Remainder

B

C26130 68.5–71.5 0.05 0.05 0.02–0.08 Remainder

13. Number of Tests and Retests

A

Cu + Sum of Named Elements = 99.8 %.

B

Cu + Sum of Named Elements = 99.7 %. 13.1 Tests:

B569–98

TABLE 2 Tensile Strength Requirements and Tension Test Values for Rolled-to-Temper Material

A A

Tensile Strength, ksi (MPa ) Yield Strength, ksi (MPa ) % Elongation

Copper Alloy At 0.5 % In 2 in.

Temper Designation At 0.2 % Offset

UNS No. Extension Under Load (50 mm)

Standard Former Minimum Maximum Minimum Maximum Minimum Maximum Minimum

C23000 H01 ⁄4 Hard 44 (305) 54 (370) 25 (170) 48 (330) 23 (160) 48 (330) 18

C26000 and C26130 H01 ⁄4 Hard 49 (340) 59 (405) 33 (230) 48 (330) 30 (205) 45 (205) 12

C26000 and C26130 H02 ⁄2 Hard 58 (400) 68 (470) 43 (295) 58 (400) 40 (2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.