ASTM B820-23

(Test Method)Standard Test Method for Bend Test for Determining the Formability of Copper and Copper Alloy Strip

Standard Test Method for Bend Test for Determining the Formability of Copper and Copper Alloy Strip

SIGNIFICANCE AND USE

5.1 This bend test provides information as to the formability or the ability of copper and copper alloy strip to resist cracking when being formed.

5.2 This test method can be used as a quality control tool to determine if material will form to a given radius.

5.3 This test method is also useful in research and development to provide data for use in selecting a spring material that will safely form to the geometry of a given part.

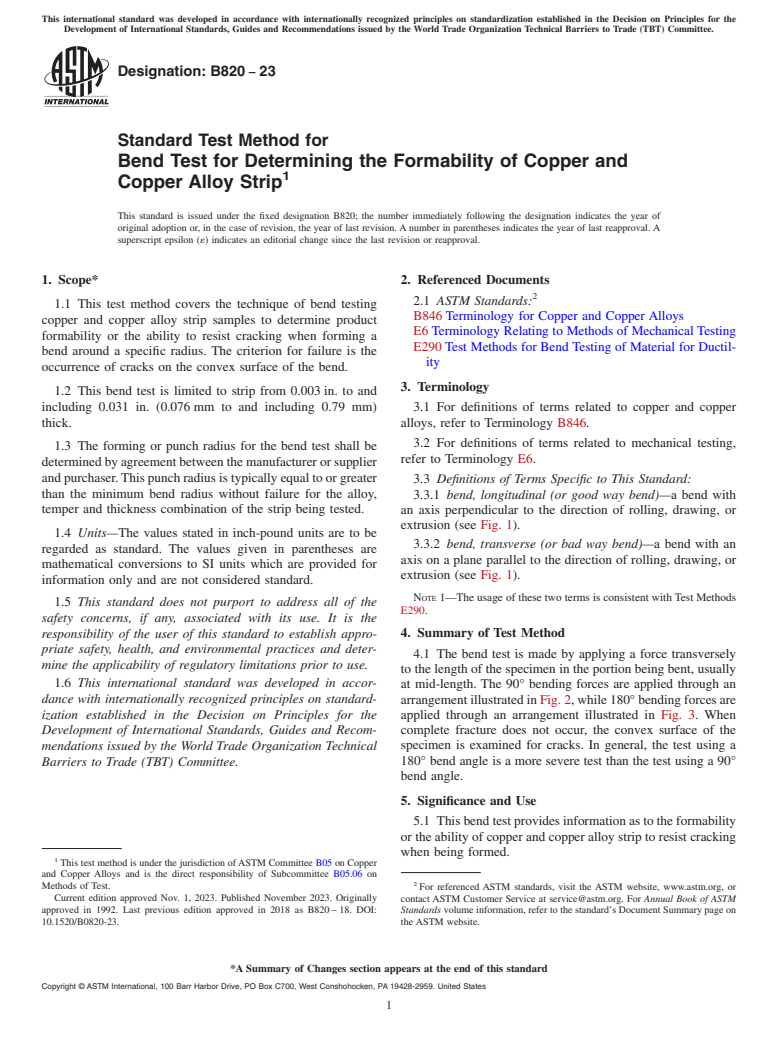

5.3.1 The forming characteristic of interest is the smallest bend radius that can be formed without cracks or otherwise unacceptable surface conditions (8.4). This radius, R, is the radius of curvature of the nose of the punch used in the test.

5.3.2 In addition, the difference between the angle of the bend after testing and 90° provides a measure of post-forming springback.

5.4 The results are suitable for direct application in design and manufacturing, only when all factors such as the geometry of the part, punch and die design, lubrication, stamping speed, and other material properties are known.

SCOPE

1.1 This test method covers the technique of bend testing copper and copper alloy strip samples to determine product formability or the ability to resist cracking when forming a bend around a specific radius. The criterion for failure is the occurrence of cracks on the convex surface of the bend.

1.2 This bend test is limited to strip from 0.003 in. to and including 0.031 in. (0.076 mm to and including 0.79 mm) thick.

1.3 The forming or punch radius for the bend test shall be determined by agreement between the manufacturer or supplier and purchaser. This punch radius is typically equal to or greater than the minimum bend radius without failure for the alloy, temper and thickness combination of the strip being tested.

1.4 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units which are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B820 − 23

Standard Test Method for

Bend Test for Determining the Formability of Copper and

1

Copper Alloy Strip

This standard is issued under the fixed designation B820; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method covers the technique of bend testing

B846 Terminology for Copper and Copper Alloys

copper and copper alloy strip samples to determine product

E6 Terminology Relating to Methods of Mechanical Testing

formability or the ability to resist cracking when forming a

E290 Test Methods for Bend Testing of Material for Ductil-

bend around a specific radius. The criterion for failure is the

ity

occurrence of cracks on the convex surface of the bend.

3. Terminology

1.2 This bend test is limited to strip from 0.003 in. to and

including 0.031 in. (0.076 mm to and including 0.79 mm)

3.1 For definitions of terms related to copper and copper

thick. alloys, refer to Terminology B846.

3.2 For definitions of terms related to mechanical testing,

1.3 The forming or punch radius for the bend test shall be

refer to Terminology E6.

determined by agreement between the manufacturer or supplier

and purchaser. This punch radius is typically equal to or greater

3.3 Definitions of Terms Specific to This Standard:

than the minimum bend radius without failure for the alloy,

3.3.1 bend, longitudinal (or good way bend)—a bend with

temper and thickness combination of the strip being tested. an axis perpendicular to the direction of rolling, drawing, or

extrusion (see Fig. 1).

1.4 Units—The values stated in inch-pound units are to be

3.3.2 bend, transverse (or bad way bend)—a bend with an

regarded as standard. The values given in parentheses are

axis on a plane parallel to the direction of rolling, drawing, or

mathematical conversions to SI units which are provided for

extrusion (see Fig. 1).

information only and are not considered standard.

NOTE 1—The usage of these two terms is consistent with Test Methods

1.5 This standard does not purport to address all of the

E290.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 4. Summary of Test Method

priate safety, health, and environmental practices and deter-

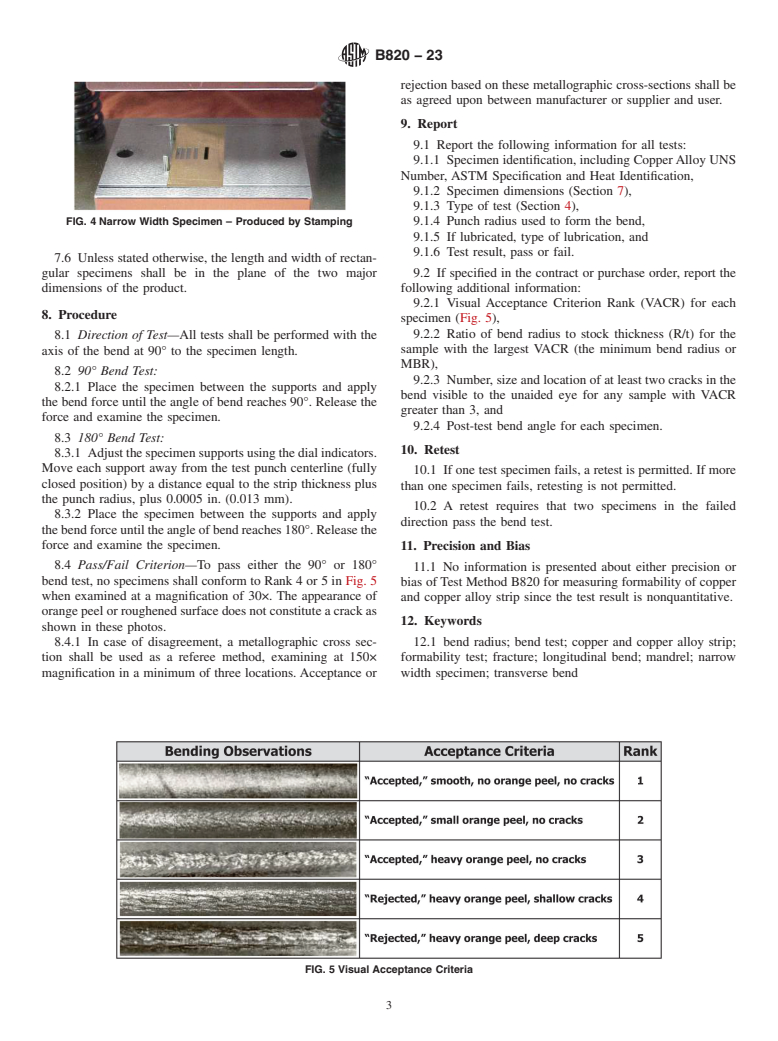

4.1 The bend test is made by applying a force transversely

mine the applicability of regulatory limitations prior to use.

to the length of the specimen in the portion being bent, usually

1.6 This international standard was developed in accor- at mid-length. The 90° bending forces are applied through an

dance with internationally recognized principles on standard-

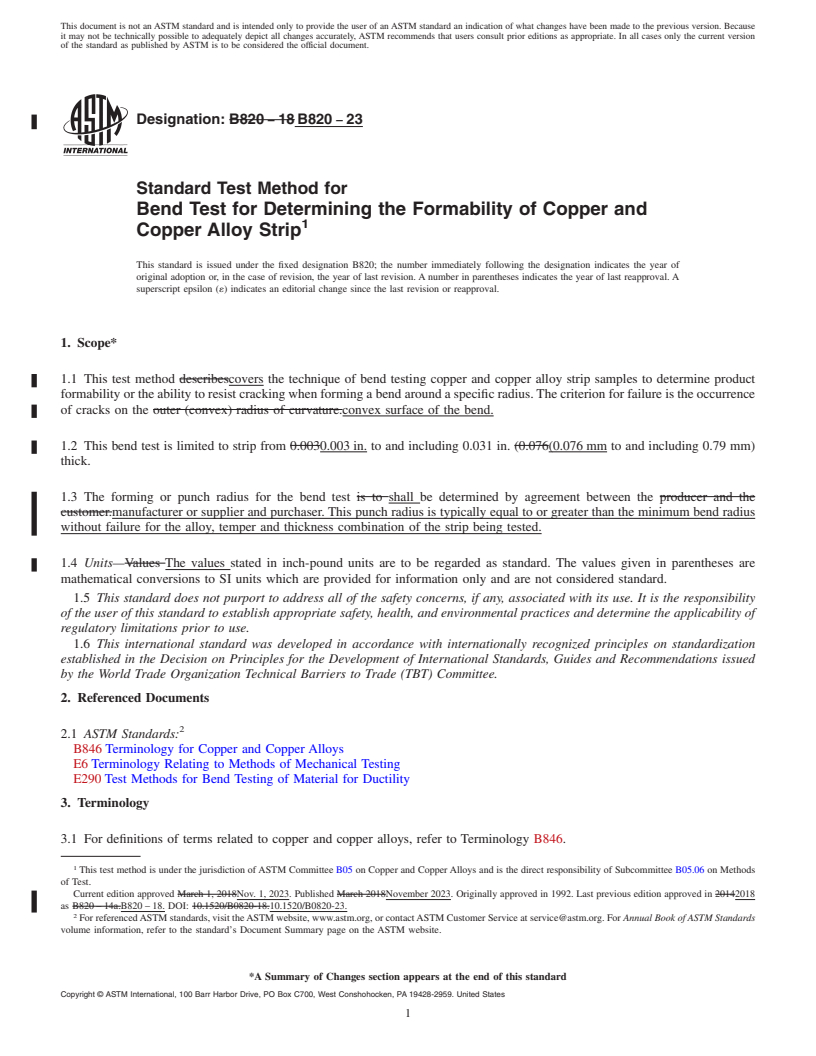

arrangement illustrated in Fig. 2, while 180° bending forces are

ization established in the Decision on Principles for the applied through an arrangement illustrated in Fig. 3. When

Development of International Standards, Guides and Recom- complete fracture does not occur, the convex surface of the

specimen is examined for cracks. In general, the test using a

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. 180° bend angle is a more severe test than the test using a 90°

bend angle.

5. Significance and Use

5.1 This bend test provides information as to the formability

or the ability of copper and copper alloy strip to resist cracking

when being formed.

1

This test method is under the jurisdiction of ASTM Committee B05 on Copper

and Copper Alloys and is the direct responsibility of Subcommittee B05.06 on

2

Methods of Test. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2023. Published November 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1992. Last previous edition approved in 2018 as B820 – 18. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/B0820-23. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B820 − 23

die. A punch of a given bend radius applies the bending force

at the specimen mid-length.

6.1.2 180° Bend Test Fixture—An illustration of this test

fixture is shown in Fig. 3. A specimen rests on a pair of pins,

rollers, or radiused flat sup

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B820 − 18 B820 − 23

Standard Test Method for

Bend Test for Determining the Formability of Copper and

1

Copper Alloy Strip

This standard is issued under the fixed designation B820; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method describescovers the technique of bend testing copper and copper alloy strip samples to determine product

formability or the ability to resist cracking when forming a bend around a specific radius. The criterion for failure is the occurrence

of cracks on the outer (convex) radius of curvature.convex surface of the bend.

1.2 This bend test is limited to strip from 0.0030.003 in. to and including 0.031 in. (0.076(0.076 mm to and including 0.79 mm)

thick.

1.3 The forming or punch radius for the bend test is to shall be determined by agreement between the producer and the

customer.manufacturer or supplier and purchaser. This punch radius is typically equal to or greater than the minimum bend radius

without failure for the alloy, temper and thickness combination of the strip being tested.

1.4 Units—Values The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units which are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B846 Terminology for Copper and Copper Alloys

E6 Terminology Relating to Methods of Mechanical Testing

E290 Test Methods for Bend Testing of Material for Ductility

3. Terminology

3.1 For definitions of terms related to copper and copper alloys, refer to Terminology B846.

1

This test method is under the jurisdiction of ASTM Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.06 on Methods

of Test.

Current edition approved March 1, 2018Nov. 1, 2023. Published March 2018November 2023. Originally approved in 1992. Last previous edition approved in 20142018

as B820 – 14a.B820 – 18. DOI: 10.1520/B0820-18.10.1520/B0820-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B820 − 23

3.2 For definitions of terms related to mechanical testing, refer to Terminology E6.

3.3 Definitions of Terms Specific to This Standard:

3.3.1 bend, longitudinal (or good way bend)—a bend with an axis perpendicular to the direction of rolling, drawing, or extrusion

(see Fig. 1).

3.3.2 bend, transverse (or bad way bend)—a bend with an axis on a plane parallel to the direction of rolling, drawing, or extrusion

(see Fig. 1).

NOTE 1—The usage of these two terms is consistent with Test Methods E290.

4. Summary of Test Method

4.1 The bend test is made by applying a force transversely to the length of the specimen in the portion being bent, usually at

mid-length. The 90° bending forces are applied through an arrangement illustrated in Fig. 2, while 180° bending forces are applied

through an arrangement illustrated in Fig. 3. When complete fracture does not occur, the convex surface of the specimen is

examined for cracks. In general, the test using a 180° bend angle is a more severe test than the test using a 90° bend angle.

5. Significance and Use

5.1 This bend test provides information as to the formability or the ability of copper and copper alloy strip to resis

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.