ASTM B407-08a(2014)

(Specification)Standard Specification for Nickel-Iron-Chromium Alloy Seamless Pipe and Tube

Standard Specification for Nickel-Iron-Chromium Alloy Seamless Pipe and Tube

ABSTRACT

This specification covers the standard requirements for nickel-iron-chromium alloy which include UNS N08120, UNS N08800, UNS N08801, UNS N08810, UNS N08811, UNS N08890, and UNS N06811 in the form of cold-worked and hot-finished annealed seamless pipe and tube. The materials shall be heat treated at certain annealing temperatures and shall conform to the chemical composition limits for nickel, chromium, iron, manganese, carbon, copper, silicon, sulfur, aluminum, titanium, columbium, molybdenum, niobium, tantalum, phosphorus, tungsten, cobalt, nitrogen, and boron. Planimetric method of measurement and tension test shall be conducted in full tubular size, longitudinal strip, or round specimens in the direction of fabrication to determine the grain size and mechanical properties, respectively. These materials shall conform to the specified grain size, yield strength, tensile strength, and elongation requirements. Each pipe or tube shall be subjected to hydrostatic or nondestructive eddy-current tests to determine the allowable fiber stress and to detect significant discontinuities such as drilled hole and transverse tangential notch. The cold-drawn material shall be commercially straight, uniform in quality and temper, smooth, and free of bends, kinks, and other injurious imperfections.

SCOPE

1.1 This specification2 covers UNS N08120, UNS N08800, UNS N08801, UNS N08810, UNS N08811, UNS N08890, and UNS N06811 in the form of cold-worked and hot-finished annealed seamless pipe and tube. Alloys UNS N08800 and UNS N06811 are normally employed in service temperatures up to and including 1100°F (593°C). Alloys UNS N08120, UNS N08810, UNS N08811, and UNS N08890 are normally employed in service temperatures above 1100°F (593°C) where resistance to creep and rupture is required, and they are annealed to develop controlled grain size for optimum properties in this temperature range.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 7, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B407 −08a (Reapproved 2014)

Standard Specification for

Nickel-Iron-Chromium Alloy Seamless Pipe and Tube

This standard is issued under the fixed designation B407; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E140 Hardness Conversion Tables for Metals Relationship

Among Brinell Hardness, Vickers Hardness, Rockwell

1.1 This specification covers UNS N08120, UNS N08800,

Hardness, Superficial Hardness, Knoop Hardness, Sclero-

UNS N08801, UNS N08810, UNS N08811, UNS N08890, and

scope Hardness, and Leeb Hardness

UNS N06811 in the form of cold-worked and hot-finished

annealed seamless pipe and tube. Alloys UNS N08800 and

3. General Requirements

UNS N06811 are normally employed in service temperatures

3.1 Material furnished under this specification shall con-

up to and including 1100°F (593°C). Alloys UNS N08120,

form to the applicable requirements of Specification B829

UNS N08810, UNS N08811, and UNS N08890 are normally

unless otherwise specified herein.

employed in service temperatures above 1100°F (593°C)

where resistance to creep and rupture is required, and they are

4. Ordering Information

annealed to develop controlled grain size for optimum proper-

4.1 Orders for material to this specification should include

ties in this temperature range.

information with respect to the following:

1.2 The values stated in inch-pound units are to be regarded

4.1.1 Alloy (Table 1).

as standard. The values given in parentheses are mathematical

4.1.2 Condition Temper (Table 2 and Table X3.1, and

conversions to SI units that are provided for information only

Appendix X2 and Appendix X3).

and are not considered standard.

4.1.3 Finish (Table X1.1 and Table X3.2).

4.1.4 Dimensions:

1.3 The following safety hazards caveat pertains only to the

4.1.4.1 Tube—May be specified in two dimensions only

test method portion, Section 7, of this specification.This

(length excepted) as follows: Outside diameter and average or

standard does not purport to address all of the safety concerns,

minimum wall, inside diameter and average wall, or outside

if any, associated with its use. It is the responsibility of the user

diameter and inside diameter.

of this standard to become familiar with all hazards including

those identified in the appropriate Material Safety Data Sheet

NOTE1—Tubeproducedtooutsidediameterandminimumwallmaybe

(MSDS) for this product/material as provided by the

furnished upon agreement between the manufacturer and the purchaser.

manufacturer, to establish appropriate safety and health

4.1.4.2 Pipe—Standardpipesizeandschedule(TableX3.1).

practices, and determine the applicability of regulatory limi-

4.1.5 Fabrication Details—Not mandatory but helpful to

tations.

the manufacturer:

4.1.5.1 Cold Bending or Coiling.

2. Referenced Documents

4.1.5.2 Hot Forming.

2.1 ASTM Standards: 4.1.5.3 Welding or Brazing—Process to be employed.

B829 Specification for General Requirements for Nickel and 4.1.5.4 Pressure Requirements—Test pressure if other than

Nickel Alloys Seamless Pipe and Tube required by 7.3.

4.1.5.5 Machining—Indicate finished size and length in

which to be machined and whether to be chucked to outside

diameter or inside diameter.

This specification is under the jurisdiction of ASTM Committee B02 on

4.1.5.6 Ends—Plain ends cut and deburred will be fur-

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.07 on Refined Nickel and Cobalt and Their Alloys.

nished. If threaded ends or ends beveled for welding are

Current edition approved Oct. 1, 2014. Published October 2014. Originally

desired, give details.

approved in 1957. Last previous edition approved in 2008 as B407 – 08a. DOI:

4.1.6 Certification—State if certification or a report of test

10.1520/B0407-08AR14.

results is required.

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

cation SB-407 in Section II of that Code.

4.1.7 Samples for Product (Check) Analysis—State whether

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

samples for product (check) analysis should be furnished (6.2).

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1.8 Purchaser Inspection—If the purchaser wishes to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. witness tests or inspection of material at place of manufacture,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B407−08a (2014)

TABLE 1 Chemical Requirements

Composition Limits, %

UNS N08800, UNS

Element

UNS N08120 N08810, and UNS UNS N08801 UNS N08890 UNS N06811

N08811

Nickel 35.0 min 30.0 min 30.0 min 40.0 min 38.0 min

39.0 max 35.0 max 34.0 max 45.0 max 46.0 max

Chromium 23.0 min 19.0 min 19.0 min 23.5 min 27.0 min

27.0 max 23.0 max 22.0 max 28.5 max 31.0 max

A A

Iron remainder 39.5 min 39.5 min remainder remainder

Manganese, max 1.5 1.5 1.5 1.5 2.0

B

Carbon 0.02 min 0.10 max 0.06 min 0.03 max

0.10 max . . 0.14 max .

Copper, max 0.5 0.75 0.5 0.75 .

Silicon 1.0 1.0 1.0 1.0 min 0.60 max

... ... ... 2.0 max ...

Sulfur, max 0.03 0.015 0.015 0.015 0.010

C

Aluminum 0.40 max 0.15 min . 0.05 min .

... 0.60 max ... 0.60 max ...

C

Titanium 0.20 max 0.15 min 0.75 min 0.15 min .

... 0.60 max 1.50 max 0.60 max ...

Columbium 0.4 min . . . .

0.9 max . . . .

Molybdenum 2.50 max . . 1.0 min 0.50 min

... ... ... 2.0 max 1.50 max

Niobium . . . 0.2 min .

... ... ... 1.0 max ...

Tantalum . . . 0.10 min .

... ... ... 0.60 max ...

Phosphorus 0.040 max . . . 0.030 max

Tungsten 2.50 max . . . .

Cobalt, max 3.0 . . . .

Nitrogen 0.15 min . . . 0.10 min

0.30 max . . . 0.20 max

Boron 0.010 max . . . .

A

Iron shall be determined arithmetically by difference.

B

Alloy UNS N08800: 0.10 max. Alloy UNS N08810: 0.05–0.10. Alloy UNS N08811: 0.06–0.10.

C

Alloy UNS N08811: Al + Ti, 0.85–1.20.

A

TABLE 2 Mechanical Properties of Pipe and Tube

Elongation in

Yield Strength,

Tensile Strength, 2 in. or 50

Alloy Condition (Temper) (0.2 % offset), min,

min, psi (MPa) mm (or 4D),

psi (MPa)

min,%

UNS N08120 hot-finished annealed or cold-worked annealed 90 000 (621) 40 000 (276) 30

UNS N08800 cold-worked annealed 75 000 (520) 30 000 (205) 30

UNS N08800 hot-finished annealed or hot-finished 65 000 (450) 25 000 (170) 30

UNS N08810 and UNS N08811 hot-finished annealed or cold-worked annealed 65 000 (450) 25 000 (170) 30

UNS N08801 hot-finished annealed or cold-worked annealed 65 000 (450) 25 000 (170) 30

UNS N08890 hot-finished annealed or cold-worked annealed 75 000 (520) 30 000 (205) 35

UNS N06811 hot-finished annealed or cold-worked annealed 85 000 (585) 35 000 (240) 30

A

For properties of small-diameter and light-wall tubing, see Table X3.1.

the purchase order must so state indicating which tests or 2050°F (1121°C) minimum, UNS N08811, UNS N08890,

inspections are to be witnessed. 2100°F (1149°C) minimum, and UNS N06811, 1920°F

4.1.9 Small-Diameter and Light-Wall Tube—(Converter (1050°C) minimum.

Sizes) (Table X3.2).

6. Chemical Composition

4.1.10 Optional Requirement—Hydrostatic or Nondestruc-

6.1 The material shall conform to the composition limits

tive Electric Test (see 7.3).

specified in Table 1.

5. Materials and Manufacture

6.2 If a product (check) analysis is performed by the

5.1 Heat Treatment—The final heat treatment of UNS purchaser, the material shall conform to the product (check)

N08120 shall be 2150°F (1177°C) minimum, UNS N08810, analysis variations in Specification B829.

B407−08a (2014)

7. Mechanical Properties and Other Requirements 8.1.1 The permissible variations in the outside and inside

diameter and wall thickness of pipe and tube shall not exceed

7.1 Mechanical Properties—The material shall conform to

those prescribed in Table 3 and Table X3.2, as applicable.

the mechanical properties specified in Table 2.

8.1.2 PermissiblevariationsgiveninTable3andTableX3.2

7.2 Grain Size—Annealed UNS Alloys N08120, N08810,

are applicable only to two dimensions. Thus, if outside

N08811, and UNS N08890 shall conform to an average grain

diameter and wall are specified, the inside diameter may not

size of ASTM No. 5 or coarser.

conform to the permissible variations shown. Similarly, if

7.3 Hydrostatic Test or Nondestructive Electric Test—Each outside diameter and inside diameter are specified, the wall

may not conform to the permissible variations shown.

pipe or tube shall be subjected to either the hydrostatic test or

thenondestructiveelectrictest.Thetypeoftesttobeusedshall

8.2 Length—When pipe or tube is ordered cut-to-length, the

be at the option of the manufacturer, unless otherwise specified

length shall not be less than that specified, but a variation of

in the purchase order.

+ ⁄8 in. (3.2 mm) will be permitted for cold-worked material

and + ⁄16 in. (4.8 mm) for hot-finished tube, except that for

7.4 Annealing Temperature—Alloy UNS N08120 shall be

lengths over 30 ft (9.1 m), a variation of + ⁄4 in. (6.4 mm) will

annealed at 2150°F (1177°C) minimum, and UNS N08810 at

2050°F (1120°C) minimum. be permitted. For small-diameter and light-wall tube, material

shall conform to the applicable requirements of Table X3.2.

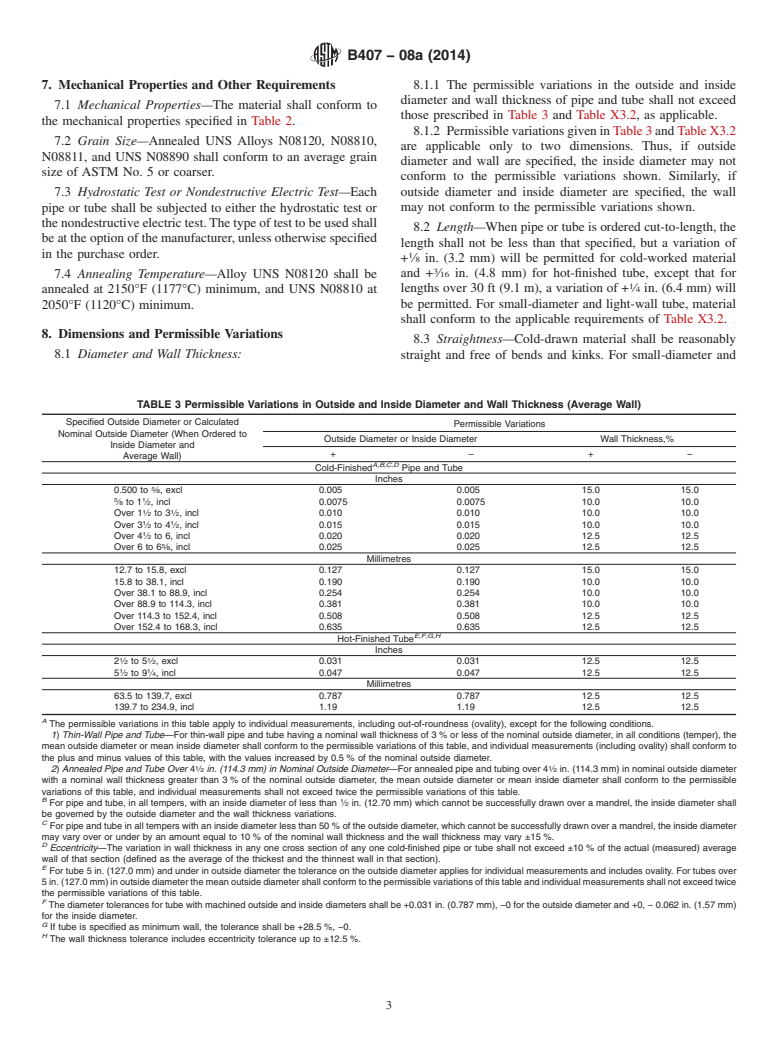

8. Dimensions and Permissible Variations

8.3 Straightness—Cold-drawn material shall be reasonably

8.1 Diameter and Wall Thickness: straight and free of bends and kinks. For small-diameter and

TABLE 3 Permissible Variations in Outside and Inside Diameter and Wall Thickness (Average Wall)

Specified Outside Diameter or Calculated

Permissible Variations

Nominal Outside Diameter (When Ordered to

Outside Diameter or Inside Diameter Wall Thickness,%

Inside Diameter and

+− + −

Average Wall)

A,B,C,D

Cold-Finished Pipe and Tube

Inches

0.500 to ⁄8, excl 0.005 0.005 15.0 15.0

5 1

⁄8 to 1 ⁄2, incl 0.0075 0.0075 10.0 10.0

1 1

Over 1 ⁄2 to 3 ⁄2, incl 0.010 0.010 10.0 10.0

1 1

Over 3 ⁄2 to 4 ⁄2, incl 0.015 0.015 10.0 10.0

Over 4 ⁄2 to 6, incl 0.020 0.020 12.5 12.5

Over 6 to 6 ⁄8, incl 0.025 0.025 12.5 12.5

Millimetres

12.7 to 15.8, excl 0.127 0.127 15.0 15.0

15.8 to 38.1, incl 0.190 0.190 10.0 10.0

Over 38.1 to 88.9, incl 0.254 0.254 10.0 10.0

Over 88.9 to 114.3, incl 0.381 0.381 10.0 10.0

Over 114.3 to 152.4, incl 0.508 0.508 12.5 12.5

Over 152.4 to 168.3, incl 0.635 0.635 12.5 12.5

E,F,G,H

Hot-Finished Tube

Inches

1 1

2 ⁄2 to 5 ⁄2, excl 0.031 0.031 12.5 12.5

1 1

5 ⁄2 to 9 ⁄4, incl 0.047 0.047 12.5 12.5

Millimetres

63.5 to 139.7, excl 0.787 0.787 12.5 12.5

139.7 to 234.9, incl 1.19 1.19 12.5 12.5

A

The permissible variations in this table apply to individual measurements, including out-of-roundness (ovality), except for the following conditions.

1) Thin-Wall Pipe and Tube—For thin-wall pipe and tube having a nominal wall thickness of 3 % or less of the nominal outside diameter, in all conditions (temper), the

mean outside diameter or mean inside diameter shall conform to the permissible variations of this table, and individual measurements (including ovality) shall conform to

the plus and minus values of this table, with the values increased by 0.5 % of the nominal outside diameter.

1 1

2) Annealed Pipe and Tube Over 4 ⁄2 in. (114.3 mm) in Nominal Outside Diameter—For annealed pipe and tubing over 4 ⁄2 in. (114.3 mm) in nominal outside diameter

with a nominal wall thickness greater than 3 % of the nominal outside diameter, the mean outside diameter or mean inside diameter shall conform to the permissible

variations of this table, and individual measurements shall not exceed twice the permissible variations of this table.

B

For pipe and tube, in all tempers, with an inside diameter of less than ⁄2 in. (12.70 mm) which cannot be successfully drawn over a mandrel, the inside diameter shall

be governed by the outside diameter and the wall thickness variations.

C

For pipe and tube in all tempers with an inside diameter less than 50 % of the outside diameter, which cannot be successfully drawn over a mandrel, the inside diameter

may vary over or under by an amount equal to 10 % of the nominal wall thickness and the wall thickness may vary ±15 %.

D

Eccentricity—The variation in wall thickness in any one cross section of any one cold-finished pipe or tube shall not exceed ±10 % of the actual (measured) average

wall of that section (defined as the average of the thickest and the thinnest wall in that section).

E

For tube 5 in. (127.0 mm) and under in outside diameter the tolerance on the outside diameter applies for individual measurements and includes ovality. For tubes over

5 in. (127.0 mm) in outside diameter the mean outside diameter shall conform to the permissible variations of this table and individual measurements shall not exceed twice

the permissible variations of this table.

F

The diameter tolerances for tube with machined outside and inside diameters shall be +0.031 in. (0.787 mm), −0 for the outside diameter and +0, − 0.062 in. (1.57 mm)

for the inside diameter.

G

If tube is specified as minimum wall, the tolerance shall be +28.5 %, −0.

H

The wall thickness tolerance includes eccentricity tolerance up to ±12.5 %.

B407−08a (2014)

light-wall tube, material shall conform to the applicable re- 9.3 Grain Size—One test per lot.

quirements of Table X3.2. The camber (depth of chord) of

9.4 Hydrostatic or Nondestructive Electric Test—Eachpiece

hot-finished tube 5 in. (127 mm) in outside diameter and under

per lot.

shall not exceed 0.01 in./ft (0.8 mm/m). For sizes over 5 in. in

outside diameter, the camber shall not exceed 0.015 in./ft (1.4

10. Keywords

mm/m).

10.1 seamless pipe; seamless tube; UNS N08120; UNS

9. Number of Tests

N08800; UNS N08801; UNS N08810; UNS N08811; UNS

9.1 Chemical Analysis—One test per lot.

N08890; UNS N06811

9.2 Mechanical Properties—One test per lot.

APPENDIXES

(Nonmandatory Information)

X1. SCHEDULES OF COLD-DRAWN, SEAMLESS NICKEL-IRON-CHROMIUM ALLOY PIPE

X1.1 The schedules of cold-worked, seamless nickel-iron-

chromium alloy pipe as given in Table X1.1 are regularly

available. Other schedules may be furnished, and the manu-

facturer should be consulted. Table X1.1 is published for

information only.

A

TABLE X1.1 Pipe Schedules

Nominal Wall Thickness

Nominal Pipe Outside

Size Diameter

Schedule No. 5 Schedule No. 10 Schedule No. 40 Schedule No. 80

Inches

⁄4 0.540 . 0.065 0.088 .

⁄8 0.675 . 0.065 0.091 0.126

⁄2 0.840 0.065 0.083 0.109 0.147

⁄4 1.050 0.065 0.08

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B407 − 08a B407 − 08a (Reapproved 2014)

Standard Specification for

Nickel-Iron-Chromium Alloy Seamless Pipe and Tube

This standard is issued under the fixed designation B407; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*Scope

1.1 This specification covers UNS N08120, UNS N08800, UNS N08801, UNS N08810, UNS N08811, UNS N08890, and

UNS N06811 in the form of cold-worked and hot-finished annealed seamless pipe and tube. Alloys UNS N08800 and UNS N06811

are normally employed in service temperatures up to and including 1100°F (593°C). Alloys UNS N08120, UNS N08810, UNS

N08811, and UNS N08890 are normally employed in service temperatures above 1100°F (593°C) where resistance to creep and

rupture is required, and they are annealed to develop controlled grain size for optimum properties in this temperature range.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 7, of this specification.This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for

this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the

applicability of regulatory limitations.

2. Referenced Documents

2.1 ASTM Standards:

B829 Specification for General Requirements for Nickel and Nickel Alloys Seamless Pipe and Tube

E140 Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness,

Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and Leeb Hardness

3. General Requirements

3.1 Material furnished under this specification shall conform to the applicable requirements of Specification B829 unless

otherwise specified herein.

4. Ordering Information

4.1 Orders for material to this specification should include information with respect to the following:

4.1.1 Alloy (Table 1).

4.1.2 Condition Temper (Table 2 and Table X3.1, and Appendix X2 and Appendix X3).

4.1.3 Finish (Table X1.1 and Table X3.2).

4.1.4 Dimensions:

4.1.4.1 Tube—May be specified in two dimensions only (length excepted) as follows: Outside diameter and average or

minimum wall, inside diameter and average wall, or outside diameter and inside diameter.

NOTE 1—Tube produced to outside diameter and minimum wall may be furnished upon agreement between the manufacturer and the purchaser.

4.1.4.2 Pipe—Standard pipe size and schedule (Table X3.1).

4.1.5 Fabrication Details—Not mandatory but helpful to the manufacturer:

4.1.5.1 Cold Bending or Coiling.

This specification is under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.07 on Refined

Nickel and Cobalt and Their Alloys.

Current edition approved Nov. 1, 2008Oct. 1, 2014. Published December 2008October 2014. Originally approved in 1957. Last previous edition approved in 2008 as

B407 – 08.B407 – 08a. DOI: 10.1520/B0407-08A.10.1520/B0407-08AR14.

For ASME Boiler and Pressure Vessel Code applications see related Specification SB-407 in Section II of that Code.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B407 − 08a (2014)

TABLE 1 Chemical Requirements

Composition Limits, %

UNS N08800, UNS

Element

UNS N08120 N08810, and UNS UNS N08801 UNS N08890 UNS N06811

N08811

Nickel 35.0 min 30.0 min 30.0 min 40.0 min 38.0 min

39.0 max 35.0 max 34.0 max 45.0 max 46.0 max

Chromium 23.0 min 19.0 min 19.0 min 23.5 min 27.0 min

27.0 max 23.0 max 22.0 max 28.5 max 31.0 max

A A

Iron remainder 39.5 min 39.5 min remainder remainder

Manganese, max 1.5 1.5 1.5 1.5 2.0

B

Carbon 0.02 min 0.10 max 0.06 min 0.03 max

0.10 max . . 0.14 max .

Copper, max 0.5 0.75 0.5 0.75 .

Silicon 1.0 1.0 1.0 1.0 min 0.60 max

... ... ... 2.0 max ...

Sulfur, max 0.03 0.015 0.015 0.015 0.010

C

Aluminum 0.40 max 0.15 min . 0.05 min .

... 0.60 max ... 0.60 max ...

C

Titanium 0.20 max 0.15 min 0.75 min 0.15 min .

... 0.60 max 1.50 max 0.60 max ...

Columbium 0.4 min . . . .

0.9 max . . . .

Molybdenum 2.50 max . . 1.0 min 0.50 min

... ... ... 2.0 max 1.50 max

Niobium . . . 0.2 min .

... ... ... 1.0 max ...

Tantalum . . . 0.10 min .

... ... ... 0.60 max ...

Phosphorus 0.040 max . . . 0.030 max

Tungsten 2.50 max . . . .

Cobalt, max 3.0 . . . .

Nitrogen 0.15 min . . . 0.10 min

0.30 max . . . 0.20 max

Boron 0.010 max . . . .

A

Iron shall be determined arithmetically by difference.

B

Alloy UNS N08800: 0.10 max. Alloy UNS N08810: 0.05–0.10. Alloy UNS N08811: 0.06–0.10.

C

Alloy UNS N08811: Al + Ti, 0.85–1.20.

A

TABLE 2 Mechanical Properties of Pipe and Tube

Elongation in

Yield Strength,

Tensile Strength, 2 in. or 50

Alloy Condition (Temper) (0.2 % offset), min,

min, psi (MPa) mm (or 4D),

psi (MPa)

min,%

UNS N08120 hot-finished annealed or cold-worked annealed 90 000 (621) 40 000 (276) 30

UNS N08800 cold-worked annealed 75 000 (520) 30 000 (205) 30

UNS N08800 hot-finished annealed or hot-finished 65 000 (450) 25 000 (170) 30

UNS N08810 and UNS N08811 hot-finished annealed or cold-worked annealed 65 000 (450) 25 000 (170) 30

UNS N08801 hot-finished annealed or cold-worked annealed 65 000 (450) 25 000 (170) 30

UNS N08890 hot-finished annealed or cold-worked annealed 75 000 (520) 30 000 (205) 35

UNS N06811 hot-finished annealed or cold-worked annealed 85 000 (585) 35 000 (240) 30

A

For properties of small-diameter and light-wall tubing, see Table X3.1.

4.1.5.2 Hot Forming.

4.1.5.3 Welding or Brazing—Process to be employed.

4.1.5.4 Pressure Requirements—Test pressure if other than required by 7.3.

4.1.5.5 Machining—Indicate finished size and length in which to be machined and whether to be chucked to outside diameter

or inside diameter.

4.1.5.6 Ends—Plain ends cut and deburred will be furnished. If threaded ends or ends beveled for welding are desired, give

details.

4.1.6 Certification—State if certification or a report of test results is required.

4.1.7 Samples for Product (Check) Analysis—State whether samples for product (check) analysis should be furnished (6.2).

4.1.8 Purchaser Inspection—If the purchaser wishes to witness tests or inspection of material at place of manufacture, the

purchase order must so state indicating which tests or inspections are to be witnessed.

4.1.9 Small-Diameter and Light-Wall Tube—(Converter Sizes) (Table X3.2).

4.1.10 Optional Requirement—Hydrostatic or Nondestructive Electric Test (see 7.3).

B407 − 08a (2014)

5. Materials and Manufacture

5.1 Heat Treatment—The final heat treatment of UNS N08120 shall be 2150°F (1177°C) minimum, UNS N08810, 2050°F

(1121°C) minimum, UNS N08811, UNS N08890, 2100°F (1149°C) minimum, and UNS N06811, 1920°F (1050°C) minimum.

6. Chemical Composition

6.1 The material shall conform to the composition limits specified in Table 1.

6.2 If a product (check) analysis is performed by the purchaser, the material shall conform to the product (check) analysis

variations in Specification B829.

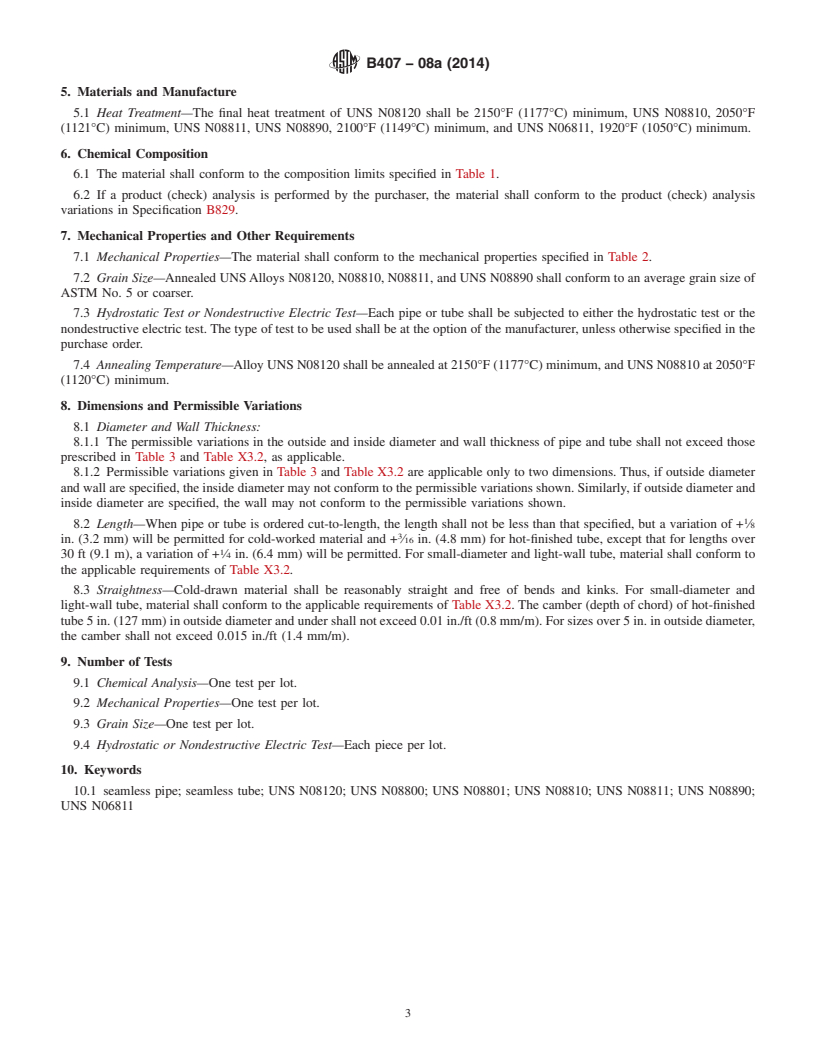

7. Mechanical Properties and Other Requirements

7.1 Mechanical Properties—The material shall conform to the mechanical properties specified in Table 2.

7.2 Grain Size—Annealed UNS Alloys N08120, N08810, N08811, and UNS N08890 shall conform to an average grain size of

ASTM No. 5 or coarser.

7.3 Hydrostatic Test or Nondestructive Electric Test—Each pipe or tube shall be subjected to either the hydrostatic test or the

nondestructive electric test. The type of test to be used shall be at the option of the manufacturer, unless otherwise specified in the

purchase order.

7.4 Annealing Temperature—Alloy UNS N08120 shall be annealed at 2150°F (1177°C) minimum, and UNS N08810 at 2050°F

(1120°C) minimum.

8. Dimensions and Permissible Variations

8.1 Diameter and Wall Thickness:

8.1.1 The permissible variations in the outside and inside diameter and wall thickness of pipe and tube shall not exceed those

prescribed in Table 3 and Table X3.2, as applicable.

8.1.2 Permissible variations given in Table 3 and Table X3.2 are applicable only to two dimensions. Thus, if outside diameter

and wall are specified, the inside diameter may not conform to the permissible variations shown. Similarly, if outside diameter and

inside diameter are specified, the wall may not conform to the permissible variations shown.

8.2 Length—When pipe or tube is ordered cut-to-length, the length shall not be less than that specified, but a variation of + ⁄8

in. (3.2 mm) will be permitted for cold-worked material and + ⁄16 in. (4.8 mm) for hot-finished tube, except that for lengths over

30 ft (9.1 m), a variation of + ⁄4 in. (6.4 mm) will be permitted. For small-diameter and light-wall tube, material shall conform to

the applicable requirements of Table X3.2.

8.3 Straightness—Cold-drawn material shall be reasonably straight and free of bends and kinks. For small-diameter and

light-wall tube, material shall conform to the applicable requirements of Table X3.2. The camber (depth of chord) of hot-finished

tube 5 in. (127 mm) in outside diameter and under shall not exceed 0.01 in./ft (0.8 mm/m). For sizes over 5 in. in outside diameter,

the camber shall not exceed 0.015 in./ft (1.4 mm/m).

9. Number of Tests

9.1 Chemical Analysis—One test per lot.

9.2 Mechanical Properties—One test per lot.

9.3 Grain Size—One test per lot.

9.4 Hydrostatic or Nondestructive Electric Test—Each piece per lot.

10. Keywords

10.1 seamless pipe; seamless tube; UNS N08120; UNS N08800; UNS N08801; UNS N08810; UNS N08811; UNS N08890;

UNS N06811

B407 − 08a (2014)

TABLE 3 Permissible Variations in Outside and Inside Diameter and Wall Thickness (Average Wall)

Specified Outside Diameter or Calculated

Permissible Variations

Nominal Outside Diameter (When Ordered to

Outside Diameter or Inside Diameter Wall Thickness,%

Inside Diameter and

+ − + −

Average Wall)

A,B,C,D

Cold-Finished Pipe and Tube

Inches

0.500 to ⁄8, excl 0.005 0.005 15.0 15.0

5 1

⁄8 to 1 ⁄2, incl 0.0075 0.0075 10.0 10.0

1 1

Over 1 ⁄2 to 3 ⁄2, incl 0.010 0.010 10.0 10.0

1 1

Over 3 ⁄2 to 4 ⁄2, incl 0.015 0.015 10.0 10.0

Over 4 ⁄2 to 6, incl 0.020 0.020 12.5 12.5

Over 6 to 6 ⁄8, incl 0.025 0.025 12.5 12.5

Millimetres

12.7 to 15.8, excl 0.127 0.127 15.0 15.0

15.8 to 38.1, incl 0.190 0.190 10.0 10.0

Over 38.1 to 88.9, incl 0.254 0.254 10.0 10.0

Over 88.9 to 114.3, incl 0.381 0.381 10.0 10.0

Over 114.3 to 152.4, incl 0.508 0.508 12.5 12.5

Over 152.4 to 168.3, incl 0.635 0.635 12.5 12.5

E,F,G,H

Hot-Finished Tube

Inches

1 1

2 ⁄2 to 5 ⁄2, excl 0.031 0.031 12.5 12.5

1 1

5 ⁄2 to 9 ⁄4, incl 0.047 0.047 12.5 12.5

Millimetres

63.5 to 139.7, excl 0.787 0.787 12.5 12.5

139.7 to 234.9, incl 1.19 1.19 12.5 12.5

A

The permissible variations in this table apply to individual measurements, including out-of-roundness (ovality), except for the following conditions.

1) Thin-Wall Pipe and Tube—For thin-wall pipe and tube having a nominal wall thickness of 3 % or less of the nominal outside diameter, in all conditions (temper), the

mean outside diameter or mean inside diameter shall conform to the permissible variations of this table, and individual measurements (including ovality) shall conform to

the plus and minus values of this table, with the values increased by 0.5 % of the nominal outside diameter.

1 1

2) Annealed Pipe and Tube Over 4 ⁄2 in. (114.3 mm) in Nominal Outside Diameter—For annealed pipe and tubing over 4 ⁄2 in. (114.3 mm) in nominal outside diameter

with a nominal wall thickness greater than 3 % of the nominal outside diameter, the mean outside diameter or mean inside diameter shall conform to the permissible

variations of this table, and individual measurements shall not exceed twice the permissible variations of this table.

B

For pipe and tube, in all tempers, with an inside diameter of less than ⁄2 in. (12.70 mm) which cannot be successfully drawn over a mandrel, the inside diameter shall

be governed by the outside diameter and the wall thickness variations.

C

For pipe and tube in all tempers with an inside diameter less than 50 % of the outside diameter, which cannot be successfully drawn over a mandrel, the inside diameter

may vary over or under by an amount equal to 10 % of the nominal wall thickness and the wall thickness may vary ±15 %.

D

Eccentricity—The variation in wall thickness in any one cross section of any one cold-finished pipe or tube shall not exceed ±10 % of the actual (measured) average

wall of that section (defined as the average of the thickest and the thinnest wall in that section).

E

For tube 5 in. (127.0 mm) and under in outside diameter the tolerance on the outside diameter applies for individual measurements and includes ovality. For tubes over

5 in. (127.0 mm) in outside diameter the mean outside diameter shall conform to the permissible variations of this table and individual measurements shall not exceed twice

the permissible variations of this table.

F

The diameter tolerances for tube with machined outside and inside diameters shall be +0.031 in. (0.787 mm), −0 for the outside diameter and +0, − 0.062 in. (1.57 mm)

for the inside diameter.

G

If tube is specified as minimum wall, the tolerance shall be +28.5 %, −0.

H

The wall thickness tolerance includes eccentricity tolerance up to ±12.5 %.

APPENDIXES

(Nonmandatory Information)

X1. SCHEDULES OF COLD-DRAWN, SEAMLESS NICKEL-IRON-CHROMIUM ALLOY PIPE

X1.1 The schedules of cold-worked, seamless nickel-iron-chromium alloy

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.