ASTM A767/A767M-09

(Specification)Standard Specification for Zinc-Coated (Galvanized) Steel Bars for Concrete Reinforcement

Standard Specification for Zinc-Coated (Galvanized) Steel Bars for Concrete Reinforcement

ABSTRACT

This specification covers steel reinforcing bars with protective zinc coatings applied by dipping the properly prepared reinforcing bars into a molten bath of zinc. Galvanization shall be used to prepare reinforcing bars. The galvanizer shall be permitted to subject the newly coated steel reinforcing bars to air or steam wiping to remove excess zinc from the bars. The mass of zinc coating shall conform to specified requirements. The mass of the coating shall be determined by magnetic thickness gage measurements. Stripping method, weighing before and after galvanizing, and microscopy method shall be used to referee the results obtained by magnetic thickness measurements. A retest shall be provided if the average zinc coating mass fails to meet the requirements. The galvanized coating shall be chromate treated.

SCOPE

1.1 This specification covers steel reinforcing bars with protective zinc coatings applied by dipping the properly prepared reinforcing bars into a molten bath of zinc.

1.2 This specification is applicable for orders in either inch-pound units (as Specification A 767) or SI units (as Specification A 767M).

1.3 The values stated in either SI or inch-pound units are to be regarded as standard. Within the text, the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents. Therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this specification.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A767/A767M −09

StandardSpecification for

Zinc-Coated (Galvanized) Steel Bars for Concrete

1

Reinforcement

This standard is issued under the fixed designationA767/A767M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* E376 Practice for Measuring Coating Thickness by

Magnetic-Field or Eddy-Current (Electromagnetic) Test-

1.1 This specification covers steel reinforcing bars with

ing Methods

protective zinc coatings applied by dipping the properly

3

2.2 ACI Specification:

prepared reinforcing bars into a molten bath of zinc.

ACI 301 Specifications for Structural Concrete

1.2 This specification is applicable for orders in either

inch-pound units (as Specification A767) or SI units (as

3. Ordering Information

Specification A767M).

3.1 It shall be the responsibility of the purchaser to specify

1.3 The values stated in either SI or inch-pound units are to

all requirements that are necessary for material ordered to this

be regarded as standard. Within the text, the inch-pound units

specification. Such requirements shall include, but are not

are shown in brackets.The values stated in each system are not

limited to, the following:

exact equivalents. Therefore, each system must be used inde-

3.1.1 Quantity of bars,

pendentlyoftheother.Combiningvaluesfromthetwosystems

3.1.2 Size of bars,

may result in nonconformance with this specification.

3.1.3 Reinforcing bar specification (ASTM designation and

year of issue) and grade,

2. Referenced Documents

3.1.4 Class of coating,

2

3.1.5 Galvanization before or after fabrication, and

2.1 ASTM Standards:

A90/A90M Test Method for Weight [Mass] of Coating on

NOTE 1—Atypical ordering description is as follows: Deformed Grade

Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

420 bars to ASTM A615M-____; 1600 m, No. 19, 8 m long in secured

A615/A615M SpecificationforDeformedandPlainCarbon- lifts; zinc-coated (galvanized) to ASTM A767M-____; including Class 1

coating, and galvanization after fabrication.

Steel Bars for Concrete Reinforcement

[Deformed Grade 60 bars to ASTM A615-____; 4000 linear ft, No. 6,

A706/A706M Specification for Low-Alloy Steel Deformed

20 ft, 0 in. long in secured lifts; zinc-coated (galvanized) to ASTM

and Plain Bars for Concrete Reinforcement

A767-____, including Class 1 coating, and galvanization after fabrica-

A780/A780M PracticeforRepairofDamagedandUncoated

tion.]

Areas of Hot-Dip Galvanized Coatings

4. Galvanizing

A996/A996M Specification for Rail-Steel and Axle-Steel

Deformed Bars for Concrete Reinforcement

4.1 Handling:

B6 Specification for Zinc

4.1.1 The galvanizer shall be permitted to subject the newly

B487 Test Method for Measurement of Metal and Oxide

coated steel reinforcing bars to air or steam wiping to remove

Coating Thickness by Microscopical Examination of

excess zinc from the bars. After the wiping, the coated steel

Cross Section

reinforcing bars shall meet the minimum coating mass

[weight].

NOTE 2—During the wiping process, care should be taken to maintain

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

a uniformly thick coating around the perimeter of the bar.

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.05 on Steel Reinforcement. 4.1.2 It shall be the responsibility of the galvanizer to

Current edition approved July 1, 2009. Published August 2009. Originally

maintain identity of the reinforcing bars throughout the galva-

approved in 1979. Last previous edition approved in 2005 as A767/A767M – 05.

nizing process and to the point of shipment.

DOI: 10.1520/A0767_A0767M-09.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican Concrete Institute (ACI), P.O. Box 9094, Farmington

the ASTM website. Hills, MI 48333-9094, http://www.concrete.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A767/A767M − 09

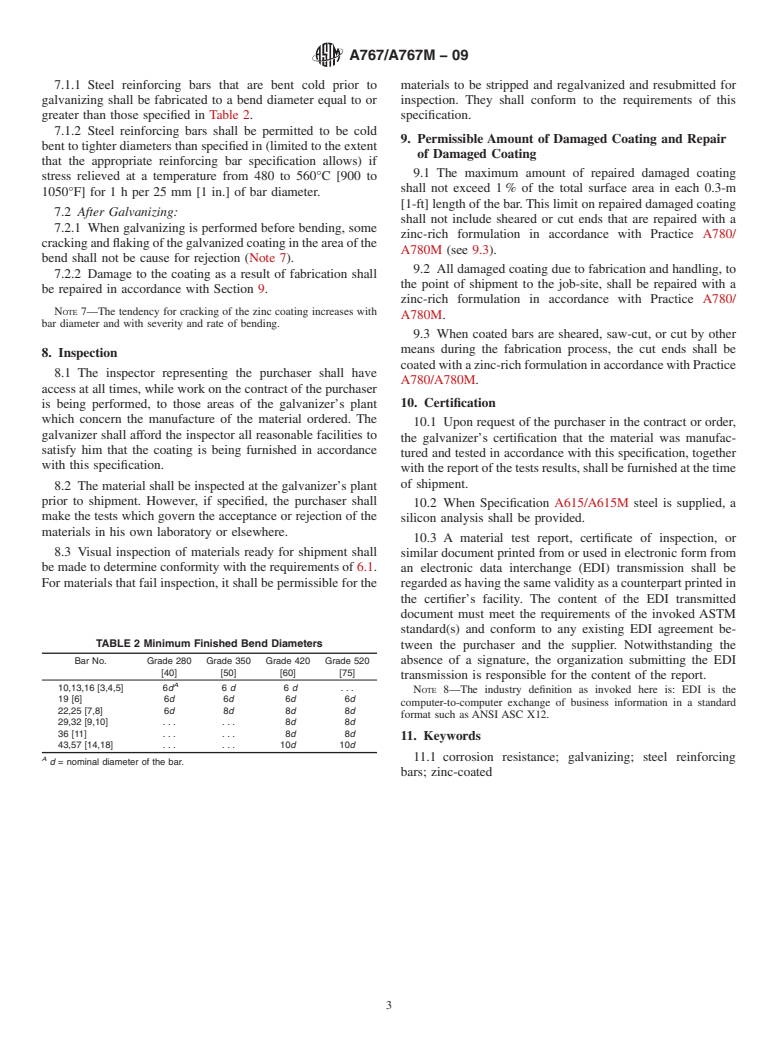

4.2 Mass [Weight] of Coating and Test: averaged to obtain the coating thickness. For the stripping

4.2.1 This specification includes two classes of coating method and the weighing method, three samples per lot shall

mass [weight]. The mass [weight] of zinc coating based on be measured

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A 767/A 767M–05 Designation: A767/A767M – 09

Standard Specification for

Zinc-Coated (Galvanized) Steel Bars for Concrete

1

Reinforcement

This standard is issued under the fixed designationA767/A767M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers steel reinforcing bars with protective zinc coatings applied by dipping the properly prepared

reinforcing bars into a molten bath of zinc.

1.2 This specification is applicable for orders in either inch-pound units (as Specification A767) or SI units (as Specification

A767M).

1.3 The values stated in either SI or inch-pound units are to be regarded as standard. Within the text, the inch-pound units are

shown in brackets.The values stated in each system are not exact equivalents.Therefore, each system must be used independently

of the other. Combining values from the two systems may result in nonconformance with this specification.

2. Referenced Documents

2

2.1 ASTM Standards:

A90/A90M Test Method for Weight [Mass] of Coating Iron With Zinc or Zinc-Alloy Coating Test Method for Weight [Mass]

of Coating on Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

A615/A615M Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement A706/A 706M

A706/A706M Specification for Low-Alloy Steel Deformed and Plain Bars for Concrete Reinforcement

A780/A780M Practice for Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized Coatings A 996/A 996M

A996/A996M Specification for Rail-Steel and Axle-Steel Deformed Bars for Concrete Reinforcement

B6 Specification for Zinc

B487 Test Method for Measurement of Metal and Oxide Coating Thickness by Microscopical Examination of Cross Section

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel,Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.05 on Steel Reinforcement.

Current edition approved March 1, 2005. Published March 2005. Originally approved in 1979. Last previous edition approved in 2000 as A 767/A 767M–00b.

Current edition approved July 1, 2009. Published August 2009. Originally approved in 1979. Last previous edition approved in 2005 as A767/A767M – 05. DOI:

10.1520/A0767_A0767M-09.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A767/A767M – 09

E376 Practice for Measuring Coating Thickness by Magnetic-Field or Eddy-Current (Electromagnetic) ExaminationTesting

Methods

3

2.2 American Concrete Institute Specification:ACI Specification:

ACI 301 Specifications for Structural Concrete

3. Ordering Information

3.1 It shall be the responsibility of the purchaser to specify all requirements that are necessary for material ordered to this

specification. Such requirements shall include, but are not limited to, the following:

3.1.1 Quantity of bars,

3.1.2 Size of bars,

3.1.3 Reinforcing bar specification (ASTM designation and year of issue) and grade,

3.1.4 Class of coating,

3.1.5 Galvanization before or after fabrication, and

NOTE 1—A typical ordering description is as follows: Deformed Grade 420 bars to ASTM A615M-____; 1600 m, No. 19, 8 m long in secured lifts;

zinc-coated (galvanized) to ASTM A767M-____; including Class 1 coating, and galvanization after fabrication.

[Deformed Grade 60 bars toASTMA615-____; 4000 linear ft, No. 6, 20 ft, 0 in. long in secured lifts; zinc-coated (galvanized) toASTMA767-____,

including Class 1 coating, and galvanization after fabrication.]

4. Galvanizing

4.1 Handling:

4.1.1 The galvanizer shall be permitted to subject the newly coated steel reinforcing bars to air or steam wiping to remove

excess zinc from the bars. After the wiping, the coated steel reinforcing bars shall meet the minimum coating mass [weight].

NOTE 2—During the wiping process, care should be taken to maintain a uniform

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A 767/A767M–05 Designation: A 767/A 767M – 09

Standard Specification for

Zinc-Coated (Galvanized) Steel Bars for Concrete

1

Reinforcement

This standard is issued under the fixed designationA 767/A 767M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers steel reinforcing bars with protective zinc coatings applied by dipping the properly prepared

reinforcing bars into a molten bath of zinc.

1.2 This specification is applicable for orders in either inch-pound units (as Specification A 767) or SI units (as Specification

A 767M).

1.3 The values stated in either SI or inch-pound units are to be regarded as standard. Within the text, the inch-pound units are

shown in brackets.The values stated in each system are not exact equivalents.Therefore, each system must be used independently

of the other. Combining values from the two systems may result in nonconformance with this specification.

2. Referenced Documents

2

2.1 ASTM Standards:

A 90/A 90M Test Method for Weight [Mass] of Coating Iron With Zinc or Zinc-Alloy Coating Test Method for Weight [Mass]

of Coating on Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

A 615/A 615M Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement

A 706/A 706M Specification for Low-Alloy Steel Deformed and Plain Bars for Concrete Reinforcement

A 780/A 780M Practice for Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized Coatings

A 996/A 996M Specification for Rail-Steel and Axle-Steel Deformed Bars for Concrete Reinforcement

B6 Specification for Zinc

B 487 Test Method for Measurement of Metal and Oxide Coating Thickness by Microscopical Examination of Cross Section

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel,Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.05 on Steel Reinforcement.

Current edition approved MarchJuly 1, 2005.2009. Published March 2005.August 2009. Originally approved in 1979. Last previous edition approved in 20002005 as

A 767/A 767M – 00b5.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 767/A 767M – 09

E 376 Practice for Measuring Coating Thickness by Magnetic-Field or Eddy-Current (Electromagnetic) Examination Methods

3

2.2 American Concrete Institute Specification:ACI Specification:

ACI 301 Specifications for Structural Concrete

3. Ordering Information

3.1 It shall be the responsibility of the purchaser to specify all requirements that are necessary for material ordered to this

specification. Such requirements shall include, but are not limited to, the following:

3.1.1 Quantity of bars,

3.1.2 Size of bars,

3.1.3 Reinforcing bar specification (ASTM designation and year of issue) and grade,

3.1.4 Class of coating,

3.1.5 Galvanization before or after fabrication, and

NOTE 1—A typical ordering description is as follows: Deformed Grade 420 bars to ASTM A 615M-____; 1600 m, No. 19, 8 m long in secured lifts;

zinc-coated (galvanized) to ASTM A 767M-____; including Class 1 coating, and galvanization after fabrication.

[Deformed Grade 60 bars toASTMA 615-____; 4000 linear ft, No. 6, 20 ft, 0 in. long in secured lifts; zinc-coated (galvanized) toASTMA 767-____,

including Class 1 coating, and galvanization after fabrication.]

4. Galvanizing

4.1 Handling:

4.1.1 The galvanizer shall be permitted to subject the newly coated steel reinforcing bars to air or steam wiping to remove

excess zinc from the bars. After the wiping, the coated steel reinforcing bars shall meet the minimum coating mass [weight].

NOTE 2—During the wiping process, care should be taken to maintain a uniformly thick coating around the perimeter of the bar.

4.1.2 It shall be the responsibility of the galvanizer to maintain identity of the reinforcing bars throughout

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.