ASTM D5469-00

(Guide)Standard Guide for Application of New Spray Applied Polyurethane Foam and Coated Roofing Systems

Standard Guide for Application of New Spray Applied Polyurethane Foam and Coated Roofing Systems

SCOPE

1.1 This guide covers the application of new roofing systems consisting of spray applied polyurethane foam insulation, elastomeric protective coatings, and optional mineral granules. This guide does not apply to retrofit or remedial applications.

1.2 Design criteria associated with the installation of spray in place polyurethane foam are beyond the scope of this specification.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5469 – 00

Standard Guide for

Application of New Spray Applied Polyurethane Foam and

Coated Roofing Systems

This standard is issued under the fixed designation D 5469; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope ment of Wood and Wood-Base Materials

2.2 Other Standard:

1.1 This guide covers the application of new roofing sys-

SSPC SP-6 Steel Structures Painting Council

tems consisting of spray applied polyurethane foam insulation,

2.3 Other Documents:

elastomeric protective coatings, and optional mineral granules.

Underwriters Laboratories, Roofing Materials and Systems

This guide does not apply to retrofit or remedial applications.

Directory

1.2 Design criteria associated with the installation of spray

Factory Mutual Research Corporation, Loss Prevention

in place polyurethane foam are beyond the scope of this

Data Sheets 1–28

specification.

Alliance for the Polyurethane IndustryAX119 Guide for the

1.3 The values stated in SI units are to be regarded as the

Safe Handling and Use of Polyurethane and Polyisocya-

standard. The values given in parentheses are for information

nurate Foam Systems

only.

Spray Polyurethane Foam Alliance Documents:

1.4 This standard does not purport to address all of the

AY-102 Guide for Selection of Protective Coatings Over

safety concerns, if any, associated with its use. It is the

Spray Polyurethane Foam Roofing Systems

responsibility of the user of this standard to establish appro-

AY-104 Spray Polyurethane Foam Roofing Systems for

priate safety and health practices and determine the applica-

New and Remedial Roofing

bility of regulatory limitations prior to use.

AY-118 Moisture Vapor Transmission

2. Referenced Documents NRCA Roofing and Waterproofing Manual, Spray Polyure-

thane Foam-Based Roofing Manual

2.1 ASTM Standards:

NRCA/SPFAQuality Control Guidelines for theApplication

C 1029 Specification for Spray-Applied Rigid Cellular

of Spray Polyurethane Foam Roofing

Polyurethane Thermal Insulation

NRCA/SPFA Manual for Inspection and Maintenance of

D 451 Test Method for Sieve Analysis of Granular Mineral

Spray Polyurethane Foam-Based Roof Systems, AGuide

Surfacing for Asphalt Roofing Products

for Building Owners

D 1079 Terminology Relating to Roofing, Waterproofing,

and Bituminous Materials

NOTE 1—Details: Numerous details are found in the referenced docu-

D 1621 Test Method of Compressive Properties of Rigid

ments, in foam and coating manufacturers literature and from other

sources. These details are to be considered general in nature. They should

Cellular Plastics

not be used without modification to allow for movement between the

D 1622 Test Method forApparent Density of Rigid Cellular

4 building, roofing, roof top equipment, and roof drainage systems.

Plastics

D 2856 Test Method for Open-Cell Content of Rigid Cel-

3. Terminology

lular Plastics by the Air Pycnometer

3.1 Definitions—Definitions are in accordance with Termi-

D 4442 TestMethodsforDirectMoistureContentMeasure-

nology D 1079.

1 6

This guide is under the jurisdiction of ASTM Committee D08 on Roofing, Annual Book of ASTM Standards, Vol 04.10.

Waterproofing, and Bituminous Materials and is the direct responsibility of AvailablefromSteelStructuresPaintingCouncil,44005thAve.,Pittsburgh,PA

Subcommittee D08.06 on Spray Polyurethane Foam Roof Systems. 15213.

Current edition approved July 10, 2000. Published September 2000. Originally Available from Underwriters Laboratories Inc., 333 Pfingsten Rd., Northbrook,

published as D 5469 – 93. Last previous edition D 5469 – 93. IL 60062.

2 9

Annual Book of ASTM Standards, Vol 04.06. AvailablefromFactoryMutualResearchCorporation,1151Boston-Providence

Annual Book of ASTM Standards, Vol 04.04.

Tpke., Norwood, MA 02062.

Annual Book of ASTM Standards, Vol 08.01. Available from Spray Polyurethane Foam Alliance, 1300 Wilson Boulevard,

Annual Book of ASTM Standards, Vol 08.02. Suite 800, Arlington, VA 22209.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5469–00

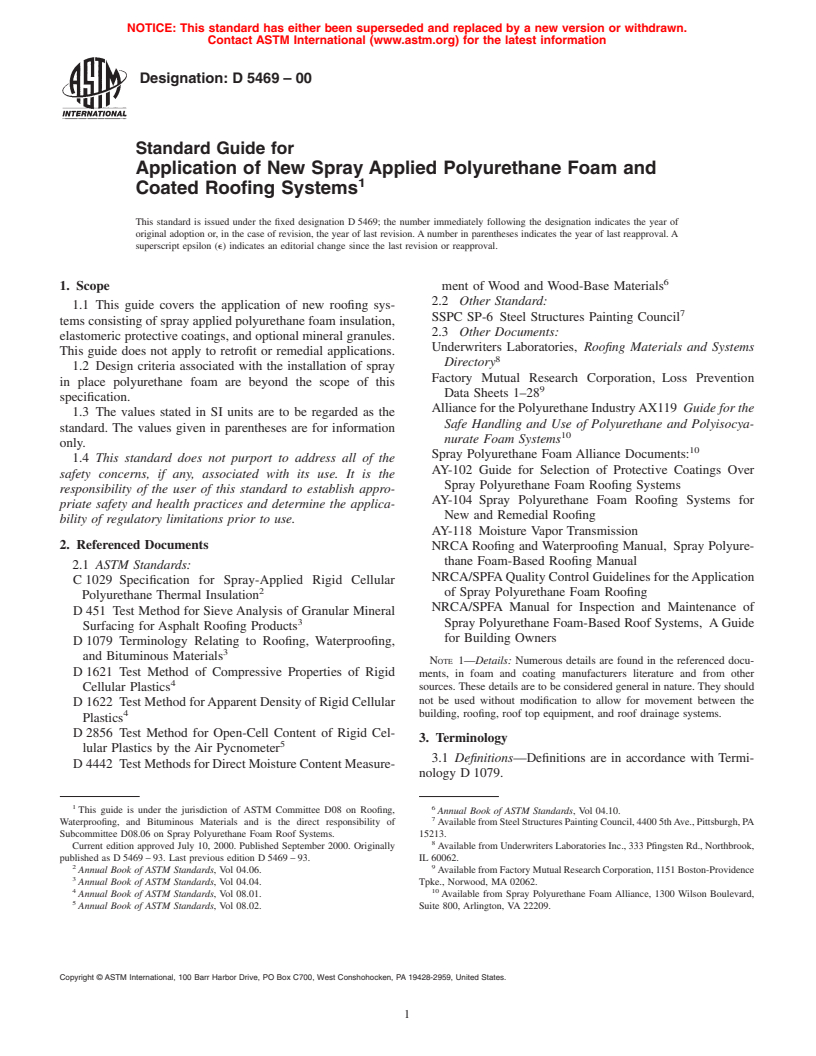

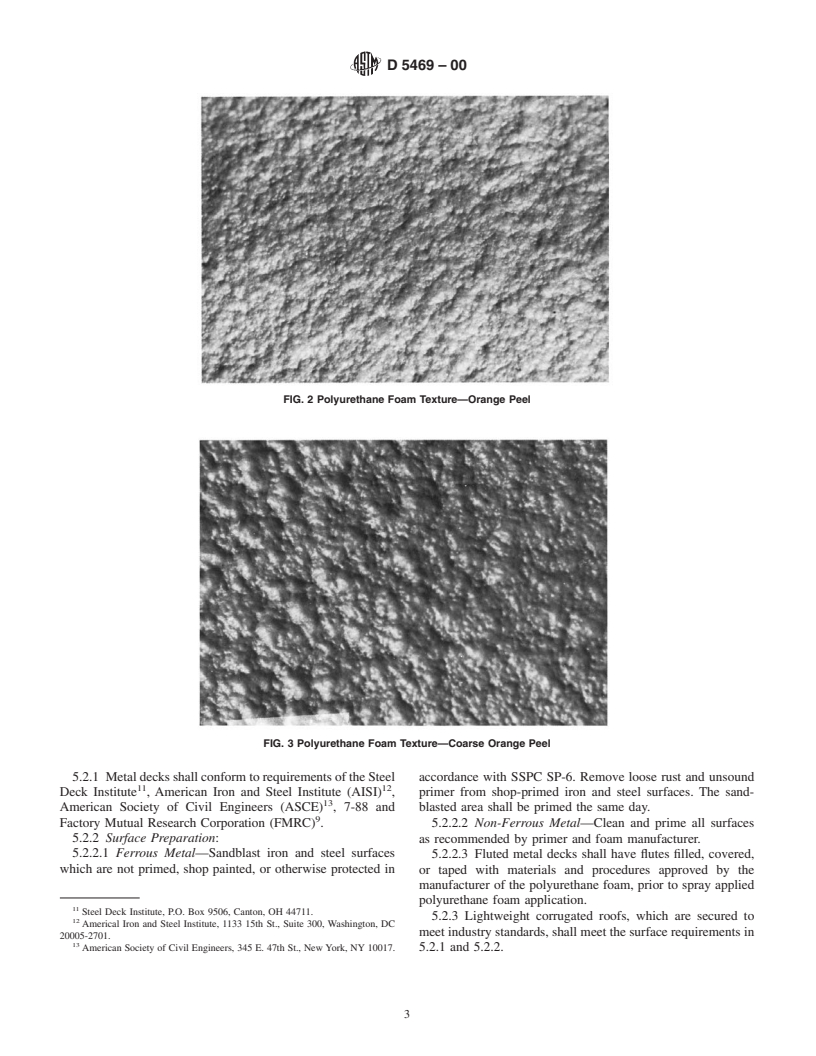

3.2 Definitions of Terms Specific to This Standard: Figs. 1-6 4. Significance and Use

show the various types of polyurethane foam surfaces.

4.1 This guide outlines general procedures and precautions

3.2.1 coarse orange peel surface—a surface of spray ap-

necessary for correct and safe application of spray applied

plied polyurethane foam that is slightly rough, having irregu-

polyurethane foam roofing systems.

larities that form obtuse angles with the plane of the surface.

4.2 This guide is not all-inclusive; this guide is intended

3.2.2 core samples—cylindrical sections of approximately

only to supplement detailed instructions from manufacturers

50 to 75 mm (2 to 3 in.) diameter. They shall be cut using a

and safety requirements established by law.

roundmetaltemplateorcoringtool,andtheyshallextendfrom

4.3 Refer to Polyurethane Foam Contractors Alliance AY-

surface down to substrate.

104 and NRCA Spray Polyurethane Foam-Based Manual for

3.2.3 lift—a single application of spray applied polyure-

industry guidelines.

thane foam.

3.2.4 lightweight or insulating concrete fill—concrete made

5. Substrate Requirements

with or without aggregate additions to portland cement, water,

5.1 General Requirements:

and air to form a hardened material which, when oven dried,

3 3 5.1.1 Application shall conform to codes having jurisdic-

will have a unit weight of 800 kg/m (50 lb/ft ) or less.

tion.

3.2.5 orange peel surface—a surface of spray applied poly-

5.1.2 Allsubstratesshallbecleanandfreeofmoisture,dust,

urethane foam that is relatively smooth, but has a slightly

oil, grease, and release agents or other contaminants.

rippled or dimpled appearance.

5.1.3 If a vapor retarder is specified, it should be installed in

3.2.6 popcorn surface—a surface of spray applied polyure-

accordance with instructions of the vapor retarder manufac-

thane foam that is extremely rough, having irregularities that

turer and be compatible with the spray applied polyurethane

form angles which are perpendicular to the plane of the

foam and substrate being covered. Refer to SPI/PFCD docu-

surface.

ment AY-118.

3.2.7 verge of popcorn surface—a surface of spray applied

5.1.4 If a primer is specified or required, it shall be installed

polyurethane foam that is moderately rough, but does not

toacleansurfaceinaccordancewiththeprimermanufacturer’s

exhibit sharp angles perpendicular to the plane of the surface.

instructions. The primer must be suitable for the substrate, be

3.2.8 slit samples—crescent-shaped samples approximately

1 able to meet service temperature requirements, be compatible

25 mm (1 in.) long and 12.5 mm ( ⁄2 in.) in depth. They are

with the spray applied polyurethane foam, and acceptable to

used to check coating surface quality and coating adhesion and

the foam manufacturer.

thickness.

5.2 Metal:

3.2.9 smooth surface—a surface of spray applied polyure-

thane foam that is relatively smooth.

3.2.10 tree bark surface—a surface of spray applied poly-

urethane foam that is extremely rough and irregular, having

undercuts (upper surface of foam overhangs a lower surface)

and usually accompanied by pinholes.

FIG. 1 Polyurethane Foam Texture—Smooth

D5469–00

FIG. 2 Polyurethane Foam Texture—Orange Peel

FIG. 3 Polyurethane Foam Texture—Coarse Orange Peel

5.2.1 MetaldecksshallconformtorequirementsoftheSteel accordance with SSPC SP-6. Remove loose rust and unsound

11 12

Deck Institute , American Iron and Steel Institute (AISI) , primer from shop-primed iron and steel surfaces. The sand-

American Society of Civil Engineers (ASCE) , 7-88 and blasted area shall be primed the same day.

Factory Mutual Research Corporation (FMRC) . 5.2.2.2 Non-Ferrous Metal—Clean and prime all surfaces

5.2.2 Surface Preparation: as recommended by primer and foam manufacturer.

5.2.2.1 Ferrous Metal—Sandblast iron and steel surfaces

5.2.2.3 Fluted metal decks shall have flutes filled, covered,

which are not primed, shop painted, or otherwise protected in

or taped with materials and procedures approved by the

manufacturer of the polyurethane foam, prior to spray applied

polyurethane foam application.

Steel Deck Institute, P.O. Box 9506, Canton, OH 44711.

5.2.3 Lightweight corrugated roofs, which are secured to

Americal Iron and Steel Institute, 1133 15th St., Suite 300, Washington, DC

meet industry standards, shall meet the surface requirements in

20005-2701.

American Society of Civil Engineers, 345 E. 47th St., New York, NY 10017. 5.2.1 and 5.2.2.

D5469–00

FIG. 4 Polyurethane Foam Texture—Rippling Verge of Popcorn

FIG. 5 Polyurethane Foam Texture—Popcorn

5.3 Concrete: 5.4.2 Wood surfaces shall be primed with exterior grade

5.3.1 Alljointsandcracksthatexceed6mm( ⁄4in.)shallbe primer as recommended by the primer and polyurethane foam

filled, covered, or taped with materials and procedures ap- manufacturers.

proved by the manufacturer of the polyurethane foam, prior to 5.4.3 Wood joints in excess of 6 mm ( ⁄4 in.) shall be taped

application of spray applied polyurethane foam. or filled with materials and procedures approved by the

5.3.2 Primer, if required, shall be as recommended by the manufacturer of the polyurethane foam.

primer or polyurethane foam manufacturer. 5.4.4 Wood plank must be overlaid with a material, ap-

5.3.3 Sprayed polyurethane foam is not recommended di- proved by the polyurethane foam manufacturer and secured by

rectly over lightweight nonstructural concretes. methods proven to meet the wind resistance requirements of

5.4 Wood: FMRC, Underwriters Laboratory (UL), and local building

5.4.1 Wood shall contain no more than 18 % moisture, as codes.

measured in accordance with Test Methods D 4442. 5.5 Gypsum Board:

D5469–00

FIG. 6 Polyurethane Foam Texture—Tree Bark

5.5.1 Boards shall be firmly butted together and mechani- 9. Polyurethane Foam Material and Application

cally fastened. Joints exceeding 6 mm ( ⁄4 in.) shall be filled or Requirements

taped with materials and procedures approved by the manu-

9.1 The spray applied polyurethane foam shall meet the

facturer of the polyurethane foam.

physical requirements of Specification C 1029 Type III.

5.5.2 Wet gypsum is not acceptable (see 9.10).

9.2 The spray applied polyurethane foam lifts must be

5.5.3 Cleaning by power brooming is not permitted. applied in a thickness of 12.5 mm ( ⁄2 in.) or greater. The foam

manufacturer must be consulted if the foam is to be applied in

6. Slope lifts greater than 37 mm (1 ⁄2 in.).

9.3 The total spray applied polyurethane foam thickness

6.1 The finished roofing system shall be sloped a minimum

shall be a minimum of one in. (or more if specified). The total

of 6 mm/m ( ⁄4 in./ft) to minimize ponding.

thickness of the spray applied polyurethane foam shall be as

specified+6mm( ⁄4 – 0 in.), except where variations are

7. Equipment

required to ensure drainage or to complete a tapered edge.

7.1 The spray applied polyurethane foam shall be metered

9.4 Areastobebuiltupinordertopreventpondingaretobe

and mixed through equipment capable of providing a ratio of

filled in with spray applied polyurethane foam before the

equal parts of “A” (isocyanate) component and “B” (polyol)

specified thickness is applied to the entire roof surface.

component, by volume to within an accuracy of 62%.

9.5 At parapet walls, building junctions, and penetrations,

7.2 Spray applied polyurethane foam ratio control shall be the spray applied polyurethane foam shall be terminated a

monitored by equipment pressure gages, which indicate con- minimum of 100 mm (4 in.) above the roof line. The coating

stant pressure, and by uniform color of the spray applied system shall be carried an additional 100 mm (4 in.) above the

polyurethane foam.

foam.Foamedinplacecantsshallbesmoothandcontinuousto

allow positive drainage.

7.3 Spray applied polyurethane foam equipment shall pro-

9.6 The final configuration of the spray applied polyure-

vide temperature control of the “A” component and “B”

thane foam surface shall not be excessively rough. “Verge of

component to within an accuracy of 2.8°C (65°F).

popcorn” spray polyurethane foam surfaces are acceptable if

7.4 Spray equipment used to apply coating shall be in

sufficient additional coats are applied to ensure a uniform

accordance with the coating manufacturer’s recommendations.

coating at the dry film thickness specified.“ Popcorn” or “tree

bark”surfacesarenotacceptable.Theseareasshallberemoved

8. Safety Requirements

and refoamed to an acceptable surface.

8.1 All handling, storage, applications, and end use safety

9.7 Any damage or defects to the spray applied polyure-

precautions shall be as outlined by the material manufacturers

thane foam surface shall be repaired prior to the protective

and SPI Polyurethane Division Technical Bulletin AX119.

coating application.

8.2 Refer to appropriate Material Safety Data Sheets

9.8 Spray applied polyurethane foam shall not be applied

(MSDS) for additional safety information.

when the roof deck surface temperature is below 10°C (50°F),

8.3 Conform to local codes and ordinances. as measured by a surface pyrometer, unless low temperature

D5469–00

sensitive materials are provided by the foam material supplier. less than two hours or more than 24 h elapse between

Spray applied polyurethane foam shall not be applied under application of the spray applied polyurethane foam and the

humid conditions exceeding manufacturer’s recommendations

base coat. If, due to weather conditions, or any other circum-

or when the roof deck surface temperature, as measured by a stances, the application of coating cannot be made within 24 h

psychrometer is less than 15°C (5°F ) above the dew point, as

then the surfaces shall be evaluated as to the suitability for

determined at the job site.

coating (see 10.4). The owner, or the coating manufacturer, or

9.9 Spray applied polyurethane foam shall only be applied

both, shall be informed and a course of action mutually agreed

to a previously prepared roof deck surface that is free of loose

upon.

dirt, dust, oil, grease, and other contaminants that will interfere

10.9 Thebasecoatshallbesmoothlyappliedatthespecified

with proper adhesion.

thickness with the rate of application being governed by the

9.10 All accessory sheet metal shall b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.