ASTM C1848-17a(2023)

(Practice)Standard Practice for Installation of High-Pressure Spray Polyurethane Foam Insulation for the Building Enclosure

Standard Practice for Installation of High-Pressure Spray Polyurethane Foam Insulation for the Building Enclosure

SIGNIFICANCE AND USE

5.1 This practice outlines general procedures that are recommended for correct installation of spray polyurethane foam (SPF) as an insulation in the building enclosure including; walls, ceilings, attics, floors, crawl spaces, attics and foundations.

Note 2: SPF roofing installations are not covered by this document. Users may wish to consult Guide D5469 and Specification D7425.

5.2 This practice is not all-inclusive; this practice is intended only to supplement detailed instructions from manufacturers, SPF industry best practices and safety requirements as may be established by law.

SCOPE

1.1 This practice covers the installation of high-pressure spray polyurethane foam (SPF) as an insulation for building enclosure assemblies including: walls, ceilings, attics, floors, and crawl spaces. This practice does not apply to SPF used strictly as a component for an air barrier system or for SPF used in roofing applications.

1.2 Building design criteria and selection of SPF are beyond the scope of this practice.

1.3 The use of SPF insulation covered by this practice is typically regulated by building codes or other agencies that address fire performance. Where required the fire performance of the material shall be addressed through standard fire test methods established by the appropriate governing documents.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1848 − 17a (Reapproved 2023)

Standard Practice for

Installation of High-Pressure Spray Polyurethane Foam

Insulation for the Building Enclosure

This standard is issued under the fixed designation C1848; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4263 Test Method for Indicating Moisture in Concrete by

the Plastic Sheet Method

1.1 This practice covers the installation of high-pressure

D4449 Test Method for Visual Evaluation of Gloss Differ-

spray polyurethane foam (SPF) as an insulation for building

ences Between Surfaces of Similar Appearance

enclosure assemblies including: walls, ceilings, attics, floors,

D4541 Test Method for Pull-Off Strength of Coatings Using

and crawl spaces. This practice does not apply to SPF used

Portable Adhesion Testers

strictly as a component for an air barrier system or for SPF

D5469 Guide for Application of New Spray Applied Poly-

used in roofing applications.

urethane Foam and Coated Roofing Systems

1.2 Building design criteria and selection of SPF are beyond

D6226 Test Method for Open Cell Content of Rigid Cellular

the scope of this practice.

Plastics

1.3 The use of SPF insulation covered by this practice is D7425 Specification for Spray Polyurethane Foam Used for

Roofing Applications

typically regulated by building codes or other agencies that

address fire performance. Where required the fire performance 2.2 European Standard:

of the material shall be addressed through standard fire test EN 14315-2:2013 Thermal insulating products for buildings

methods established by the appropriate governing documents. - In-situ formed sprayed rigid polyurethane (PUR) and

polyisocyanurate (PIR) foam products - Part 2: Specifica-

1.4 The values stated in SI units are to be regarded as the

tion for the installed insulation products

standard. The values given in parentheses are for information

2.3 Society for Protective Coatings (SSPC):

only.

SSPC SP 1 Society for Protective Coatings: Solvent Clean-

1.5 This standard does not purport to address all of the

ing

safety concerns, if any, associated with its use. It is the

SSPC SP 6 Society for Protective Coatings: Commercial

responsibility of the user of this standard to establish appro-

Blast Cleaning

priate safety, health, and environmental practices and deter-

2.4 Spray Polyurethane Foam Alliance (SPFA):

mine the applicability of regulatory limitations prior to use.

SPFA-119 Glossary of Terms

1.6 This international standard was developed in accor-

SPFA-137 Spray Polyurethane Equipment Guidelines

dance with internationally recognized principles on standard-

SPFA-143 Primers: Why, When and How to Use Them

ization established in the Decision on Principles for the

SPFA-148 Spray Polyurethane Foam Insulation Installation

Development of International Standards, Guides and Recom-

Certificate

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

3. Terminology

3.1 Definitions are in accordance with Terminology C168.

2. Referenced Documents

3.2 Definitions:

2.1 ASTM Standards:

3.2.1 Specific Definitions per SPFA-119:

C168 Terminology Relating to Thermal Insulation

3.2.2 lift, n—the sprayed polyurethane foam resulting from

passes of foam in a specific area, as defined by its thickness and

This practice is under the jurisdiction of ASTM Committee C16 on Thermal

the area.

Insulation and is the direct responsibility of Subcommittee C16.40 on Insulation

Systems.

Current edition approved March 1, 2023. Published April 2023. Originally

approved in 2017. Last previous edition approved in 2017 as C1848 – 17a. DOI: Available from European Committee for Standardization (CEN), Avenue

10.1520/C1848-17AR23. Marnix 17, B-1000, Brussels, Belgium, http://www.cen.eu.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Society for Protective Coatings (SSPC), 800 Trumbull Dr.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Pittsburgh, PA 15205, http://www.sspc.org.

Standards volume information, refer to the standard’s Document Summary page on Available from Spray Polyurethane Foam Alliance (SPFA), 3927 Old Lee Hwy.

the ASTM website. #101B, Fairfax, VA 22030, http://www.sprayfoam.org/.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1848 − 17a (2023)

3.2.3 pass, n—the amount of coating or polyurethane foam 6.2.2 Grease, oil or other contaminants should be removed

applied by moving the gun from side to side and moving away with suitable cleaning solutions. An example of a specification

from fresh material, delineated by its width, length, and for solvent cleaning of metal surfaces is provided by SSPC SP

thickness. 1.

6.2.3 Fine condensation on some metal substrates may be

4. Classifications

difficult to visually detect. Consider using moisture-detection

paper (cobalt-chloride strips) to check for condensation when

4.1 Low-Pressure Spray Polyurethane Foam—Spray poly-

metal substrate temperatures are close to the atmospheric dew

urethane foam where the plural components (A- and B- side)

point temperature.

are delivered a pressure of less than 1.72 MPa (250 psi), at a

rate up to 6.4 kg/min (10 lb/min) wherein the liquid compo- 6.2.4 Thick metal substrates, such as structural steel and

walls of pressure vessels can act as a heat sink. In these cases,

nents are mechanically mixed using a static mixing nozzle.

Components are typically delivered in pressurized tanks. consult manufacturer installation instructions (MII) or contact

the SPF manufacturer.

4.2 High-Pressure Spray Polyurethane Foam—Spray poly-

6.2.5 If the cleaned metal substrate does not allow for

urethane foam where the where the plural components (A- and

adequate adhesion of the SPF, primers may be needed and

B-side) are delivered at a pressure between 3.45 and 8.96 MPa

installed in accordance with the primer and the SPFMII.

(500 and 1300 psi), at a rate up to 13.6 kg/min (30 lb/min)

Guidance for primer selection can be found in SPFA-143.

wherein the liquid components are aerosolized and impinge-

6.2.5.1 Ferrous Metal—Sandblasting is recommended for

ment mixed outside of the spray gun.

iron and steel surfaces that are not shop primed, painted, or

NOTE 1—Both classes of plural components spray polyurethane foam

otherwise protected. Remove loose rust and unsound primer

are defined in this standard to identify their differences. This standard only

from shop-primed iron and steel surfaces. The sandblasted area

applies to installation of high-pressure spray polyurethane foam.

should be primed the same day using an SPF-compatible

primer. An example of a specification for abrasive blast

5. Significance and Use

cleaning procedures and condition of steel surfaces is provided

5.1 This practice outlines general procedures that are rec-

by SSPC SP 6.

ommended for correct installation of spray polyurethane foam

6.2.5.2 Non-Ferrous Metal—SPF Installer should clean and

(SPF) as an insulation in the building enclosure including;

prime all surfaces (if required) as recommended by primer or

walls, ceilings, attics, floors, crawl spaces, attics and founda-

SPF manufacturer, or both.

tions.

6.3 Concrete or Masonry:

NOTE 2—SPF roofing installations are not covered by this document.

Users may wish to consult Guide D5469 and Specification D7425. 6.3.1 SPF installer should verify the concrete or masonry

surfaces are clean, and free of contaminants that can affect

5.2 This practice is not all-inclusive; this practice is in-

adhesion. Existing concrete should be free of spalling, scaling,

tended only to supplement detailed instructions from

loose coatings, efflorescence and other conditions that affect

manufacturers, SPF industry best practices and safety require-

adhesion.

ments as may be established by law.

6.3.2 SPF Installer should verify the concrete is dry to

obtain good adhesion of the primer or SPF, or both. Consider

6. Substrate Requirements

using Test Method D4263 or other reliable method approved

6.1 General Requirements:

by the SPF and primer manufacturer to check concrete mois-

6.1.1 Installation of SPF in buildings or structures shall

ture.

conform to the requirements of the applicable construction

6.3.3 SPF installer should verify that any newly poured

codes, regulations and standards as adopted and enforced by

concrete has cured before application of SPF or primer.

the relevant authority having jurisdiction or local code official.

6.1.2 Substrate materials to receive SPF should be physi-

NOTE 5—Most new poured concrete requires a 28-day cure time unless

cally stable and resistant to movement or excessive flexure

the concrete is specifically designed for a shorter cure time.

relative to the building structure.

6.3.4 Thick concrete substrates can act as a heat sink. In

6.1.3 All substrates to receive SPF should be clean, dry and

these cases, consult MII or contact the SPF manufacturer.

free of contaminants that may cause poor adhesion of the SPF.

6.3.5 Primer (as may be required) should be applied as

NOTE 3—If in doubt of the potential adhesion, spray a section of the

recommended by the primer and SPF manufacturer.

substrate with SPF and test the adhesion in accordance with SPF industry

6.4 Wood:

guidelines. An example of a typical SPF field adhesion test procedure is

provided in Test Method D4541. To assure proper bonding of SPF to the

6.4.1 The SPF installer should verify the wood surface is

substrate, the failure surface should indicate a cohesive failure of the SPF.

clean, dry and free of contaminants that can affect adhesion.

6.2 Metal:

6.4.2 Wood substrates should typically have a surface mois-

6.2.1 Primed or coated metal substrates should be free of

ture content no greater than 18 % as measured in accordance

dirt, loose scale, rust, weathered or chalked coatings. Such

with Test Method D4449. Field measurements may be obtained

substrates should be cleaned using suitable means.

with hand held moisture meters.

6.4.3 Treated wood (for insects or water resistance) may

NOTE 4—Suitable means may include, but are not limited to, clean and

dry compressed air, vacuum equipment, and hand or power tools. provide poor adhesion and should be evaluated for adhesion. If

C1848 − 17a (2023)

a primer is required, it should be applied as recommended by 8. Installation Personnel

the primer and SPF manufacturer.

8.1 Installation of high-pressure SPF requires training and

6.5 Interior Cladding Board (gypsum board, fiberboard, experience. All SPF installers should be trained on the proper

fiber-reinforced gypsum board, etc.): operation of the equipment and installation of the SPF mate-

6.5.1 SPF installer to verify surfaces are clean, dry and free rials. Training may be provided by manufacturers, distributors

of contaminants that can affect adhesion. or third-party organizations. Certifications or licensing

6.5.2 Primer, if required, shall be applied as recommended programs, or both, may be available.

by primer or SPF manufacturer, or both.

9. Safety Requirements

7. Equipment

9.1 All handling, storage and installation safety precautions

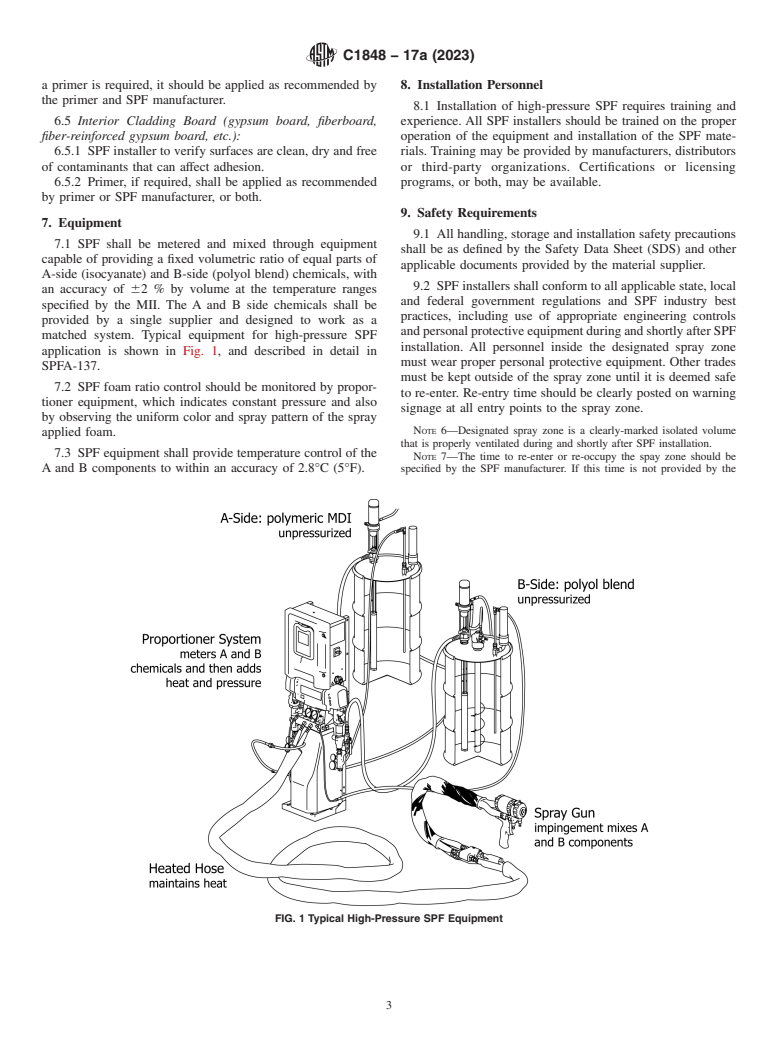

7.1 SPF shall be metered and mixed through equipment

shall be as defined by the Safety Data Sheet (SDS) and other

capable of providing a fixed volumetric ratio of equal parts of

applicable documents provided by the material supplier.

A-side (isocyanate) and B-side (polyol blend) chemicals, with

9.2 SPF installers shall conform to all applicable state, local

an accuracy of 62 % by volume at the temperature ranges

and federal government regulations and SPF industry best

specified by the MII. The A and B side chemicals shall be

practices, including use of appropriate engineering controls

provided by a single supplier and designed to work as a

and personal protective equipment during and shortly after SPF

matched system. Typical equipment for high-pressure SPF

installation. All personnel inside the designated spray zone

application is shown in Fig. 1, and described in detail in

must wear proper personal protective equipment. Other trades

SPFA-137.

must be kept outside of the spray zone until it is deemed safe

7.2 SPF foam ratio control should be monitored by propor-

to re-enter. Re-entry time should be clearly posted on warning

tioner equipment, which indicates constant pressure and also

signage at all entry points to the spray zone.

by observing the uniform color and spray pattern of the spray

NOTE 6—Designated spray zone is a clearly-marked isolated volume

applied foam.

that is properly ventilated during and shortly after SPF installation.

7.3 SPF equipment shall provide temperature control of the

NOTE 7—The time to re-enter or re-occupy the spay zone should be

A and B components to within an accuracy of 2.8°C (5°F). specified by the SPF manufacturer. If this time is not provided by the

FIG. 1 Typical High-Pressure SPF Equipment

C1848 − 17a (2023)

manufacturer, the time to re-enter or re-occupy the spray zone shall be 24

12.5 Before application of any coating or covering, the SPF

h.

shall be inspected.

9.3 Prior to installation, SPF contractor shall review all

safety requirements for SPF installation with building owner, 13. Inspection

general contractor and other trades.

13.1 Procedures for the inspection and approval of the SPF

insulation system should be determined by the owner and

10. Products

contractor prior to installation and such details should be

10.1 Spray Polyurethane Foam—The SPF contractor should

included in the contract.

procure and install the SPF products as specified in the

13.2 Inspection parameters may include:

construction documents, architectural specifications or con-

• foam surface texture

tract.

• adhesion of the SPF to the substrate

10.2 Labeling and Marking:

• cohesion of the SPF

10.2.1 The SPF contractor should record the names all

• density

products and their manufacturers used, including lot or batch

• total thickness

number, or both, and provide this information to the customer

• lift thickness

on the insulation installation certificate (see 12.3).

• SPF defects or anomalies

10.2.2 The SPF contractor should ensure all liquid compo-

• adhesion of the thermal or ignition barrier, or both, to the

nents used for the SPF application are obtained from one

SPF

manufacturer as

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.