ASTM D6918-03(2007)

(Test Method)Standard Test Method for Testing Vertical Strip Drains in the Crimped Condition

Standard Test Method for Testing Vertical Strip Drains in the Crimped Condition

SIGNIFICANCE AND USE

This test method is considered satisfactory for the acceptance of commercial shipments of vertical strip drains.

5.1.1 In case of dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is any statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens that as homogenous as possible, and that are from a lot of material of the type in question. The test specimens should be randomly assigned in numbers to each laboratory for testing. The average results from the two laboratories should be compared using Student’t-test for unpaired data and an acceptable probability level chosen by the two parties before the start of testing. If a bias is found, either its cause must be found and corrected, or the purchaser and the supplier must agree to interpret future test results in light of the known bias.

Vertical strip drains are installed in areas where it is desired to increase the rate of soil consolidation. It has been shown that as the soil around the vertical strip drain consolidates, a crimp may form in the vertical strip drain due to the movement of the drain in the area of soil consolidation.

This test method can be used to evaluate if there is any reduction in flow rate of water through the drain due to the crimping, and what effect, if any, this crimping may have on the rate of consolidation of the soil.

SCOPE

1.1 This test method is a performance test, which measures the effect crimping, has on the ability of vertical strip drains to transmit water parallel to the plane of the drain.

1.2 This test method is applicable to all vertical strip drains.

1.3 The values stated in SI units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D6918–03 (Reapproved 2007)

Standard Test Method for

Testing Vertical Strip Drains in the Crimped Condition

This standard is issued under the fixed designation D6918; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.4 vertical strip drain, n—ageocompositeconsistingofa

geotextile cover and drainage core installed vertically into soil

1.1 This test method is a performance test, which measures

to provide drainage for accelerated consolidation of soils.

the effect crimping, has on the ability of vertical strip drains to

transmit water parallel to the plane of the drain.

4. Summary of Test Method

1.2 This test method is applicable to all vertical strip drains.

4.1 This test method describes procedures for determining

1.3 The values stated in SI units are to be regarded as the

the effect of a crimp forming in the vertical strip drain due the

standard.

consolidation of soils around it in the field.

1.4 This standard does not purport to address all of the

4.1.1 Avertical strip drain is sealed in a cover of heat shrink

safety concerns, if any, associated with its use. It is the

plastic to prevent any water from escaping out through the

responsibility of the user of this standard to establish appro-

geotextile during the test.

priate safety and health practices and determine the applica-

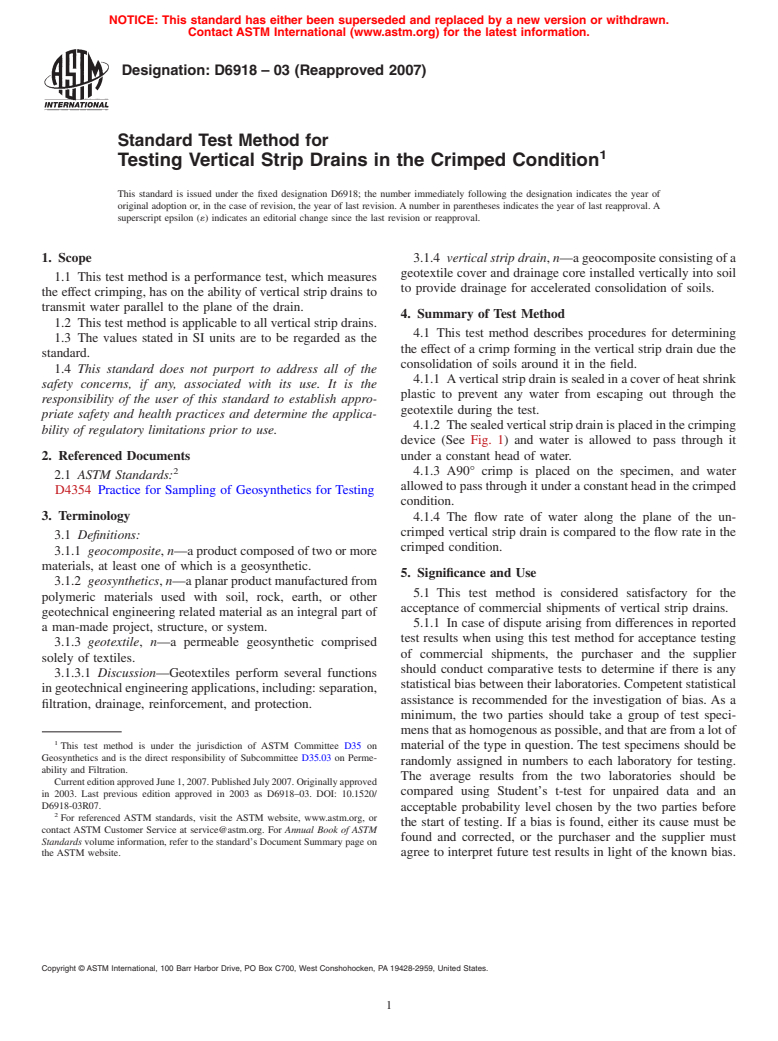

4.1.2 Thesealedverticalstripdrainisplacedinthecrimping

bility of regulatory limitations prior to use.

device (See Fig. 1) and water is allowed to pass through it

2. Referenced Documents under a constant head of water.

4.1.3 A90° crimp is placed on the specimen, and water

2.1 ASTM Standards:

allowed to pass through it under a constant head in the crimped

D4354 Practice for Sampling of Geosynthetics for Testing

condition.

3. Terminology

4.1.4 The flow rate of water along the plane of the un-

crimped vertical strip drain is compared to the flow rate in the

3.1 Definitions:

crimped condition.

3.1.1 geocomposite, n—a product composed of two or more

materials, at least one of which is a geosynthetic.

5. Significance and Use

3.1.2 geosynthetics, n—aplanarproductmanufacturedfrom

5.1 This test method is considered satisfactory for the

polymeric materials used with soil, rock, earth, or other

acceptance of commercial shipments of vertical strip drains.

geotechnical engineering related material as an integral part of

5.1.1 In case of dispute arising from differences in reported

a man-made project, structure, or system.

test results when using this test method for acceptance testing

3.1.3 geotextile, n—a permeable geosynthetic comprised

of commercial shipments, the purchaser and the supplier

solely of textiles.

should conduct comparative tests to determine if there is any

3.1.3.1 Discussion—Geotextiles perform several functions

statistical bias between their laboratories. Competent statistical

ingeotechnicalengineeringapplications,including:separation,

assistance is recommended for the investigation of bias. As a

filtration, drainage, reinforcement, and protection.

minimum, the two parties should take a group of test speci-

mens that as homogenous as possible, and that are from a lot of

This test method is under the jurisdiction of ASTM Committee D35 on material of the type in question. The test specimens should be

Geosynthetics and is the direct responsibility of Subcommittee D35.03 on Perme-

randomly assigned in numbers to each laboratory for testing.

ability and Filtration.

The average results from the two laboratories should be

CurrenteditionapprovedJune1,2007.PublishedJuly2007.Originallyapproved

compared using Student’s t-test for unpaired data and an

in 2003. Last previous edition approved in 2003 as D6918–03. DOI: 10.1520/

D6918-03R07.

acceptable probability level chosen by the two parties before

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the start of testing. If a bias is found, either its cause must be

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

found and corrected, or the purchaser and the supplier must

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. agree to interpret future test results in light of the known bias.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6918–03 (2007)

FIG. 1 Crimping Wedge

5.2 Vertical strip drains are installed in areas where it is

desired to increase the rate of soil consolidation. It has been

FIG. 2 Complete Crimp Test Apparatus

shown that as the soil around the vertical strip drain consoli-

dates, a crimp may form in the vertical strip drain due to the

movement of the drain in the area of soil consolidation.

9. Sampling, Test Specimens, and Test Units

5.3 This test method can be used to evaluate if there is any

reduction in flow rate of water through the drain due to the 9.1 Division into Lots and Lot Samples—Divide the mate-

crimping, and what effect, if any, this crimping may have on rial into lots and take a lot sample as directed in Practice

the rate of consolidation of the soil.

D4354. Rolls of prefabricated vertical strip drains are the

primary sampling unit.

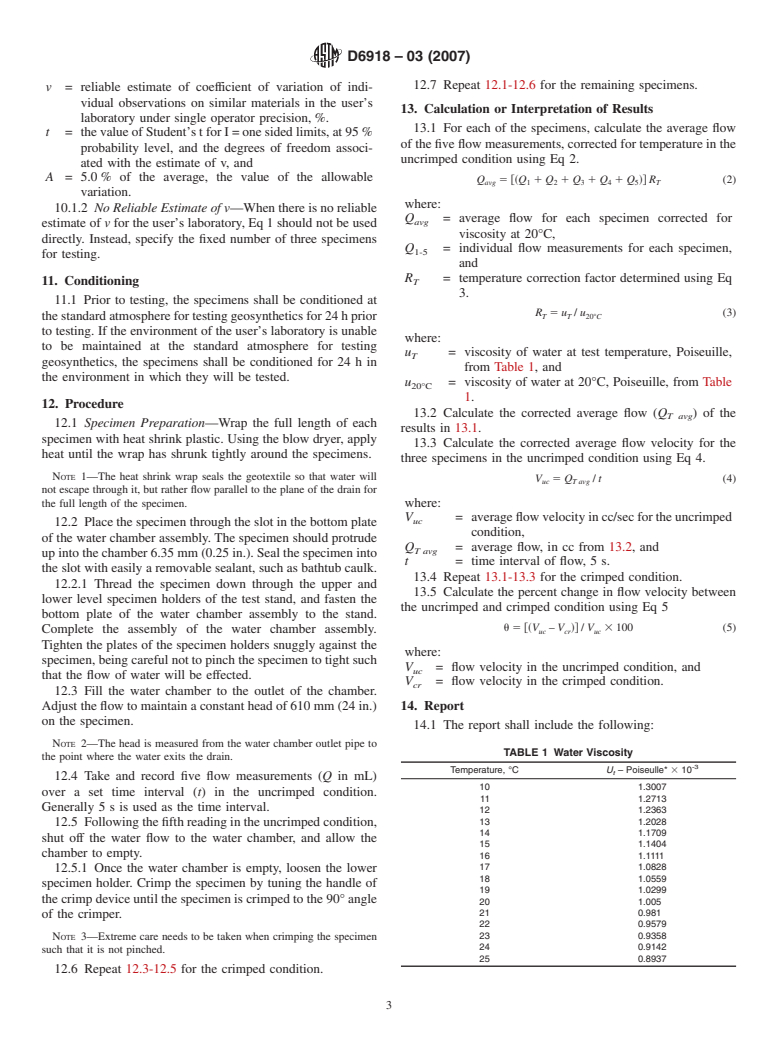

6. Apparatus

9.2 Laboratory Sample—Remove the outer wrap of drain

6.1 The test device must be capable of maintaining a

material from the roll to avoid sampling and testing any

constant head of water on the vertical strip drain being tested.

material, which may have been damaged during storage. Take

The apparatus consists of a water chamber assembly, a speci-

for the laboratory sample a 1830 mm (6 ft) length of the drain

men holder, and a crimping wedge, all of which are attached to

material.

a holding stand. See Fig. 2.

9.3 Test Specimens—From the laboratory sample taken

6.2 Container, for collecting the water as it flows through

from each lot, cut test specimens as directed in 10. Each test

the vertical strip drain.

specimen shall be 610 mm (2 ft) long.

6.3 Stopwatch or Electronic Timing Device, connected to

the collection container, for timing the flow of water through

10. Number of Specimens

the vertical strip drain.

6.4 Blow Dryer, used for applying heat to the heat shrink-

10.1 Unless otherwise agreed upon, as when provided in an

wrap that is placed around the test specimen prior to testing.

applicable material specification, take a number of test speci-

mens per laboratory sample such that the user may expect the

7. Materials

95 % probability level that the test result is no more than 5 %

7.1 Heat Shrink Plastic Wrap—The heat shrink plastic

above the average for each laboratory sample.

wrap, of the type used in homes for sealing windows from

10.1.1 Reliable Estimate of v—When there is a reliable

wind drafts, is used to seal the vertical strip drain so that water

estimate of v based upon extensive test records for similar

does not flow out through the geotextile wrap on the core. The

materials in the user’s laboratory as directed in the method,

water is to flow in a parallel plan to the fabric, along the core

calculate the required num

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.