ASTM B865-04(2010)

(Specification)Standard Specification for Precipitation Hardening Nickel-Copper-Aluminum Alloy (UNS N05500) Bar, Rod, Wire, Forgings, and Forging Stock

Standard Specification for Precipitation Hardening Nickel-Copper-Aluminum Alloy (UNS N05500) Bar, Rod, Wire, Forgings, and Forging Stock

ABSTRACT

This specification covers UNS N05500 nickel-copper-aluminum alloy rounds, squares, hexagons, rectangles, and forgings and forging stocks manufactured by either hot working or cold working, and cold-worked wire. The material should conform to the required mechanical properties in both aged and unaged conditions. Precipitation hardening is accomplished by holding the material at a high temperature, followed by furnace cooling and then air cooling.

SCOPE

1.1 This specification covers nickel-copper-aluminum alloy (UNS N05500) in the form of rounds, squares, hexagons, or rectangles, and forgings and forging stock, manufactured either by hot working or cold working, and cold-worked wire.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

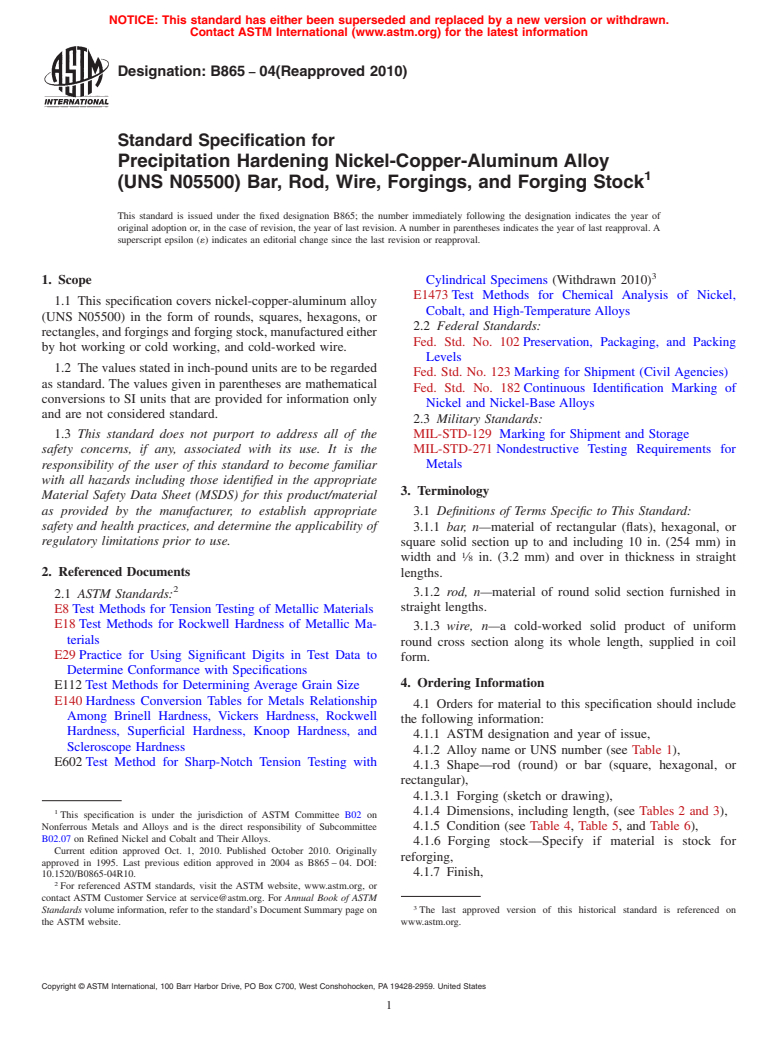

Designation:B865 −04(Reapproved 2010)

Standard Specification for

Precipitation Hardening Nickel-Copper-Aluminum Alloy

(UNS N05500) Bar, Rod, Wire, Forgings, and Forging Stock

This standard is issued under the fixed designation B865; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Cylindrical Specimens (Withdrawn 2010)

E1473 Test Methods for Chemical Analysis of Nickel,

1.1 This specification covers nickel-copper-aluminum alloy

Cobalt, and High-Temperature Alloys

(UNS N05500) in the form of rounds, squares, hexagons, or

2.2 Federal Standards:

rectangles,andforgingsandforgingstock,manufacturedeither

Fed. Std. No. 102 Preservation, Packaging, and Packing

by hot working or cold working, and cold-worked wire.

Levels

1.2 The values stated in inch-pound units are to be regarded

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

as standard. The values given in parentheses are mathematical

Fed. Std. No. 182 Continuous Identification Marking of

conversions to SI units that are provided for information only

Nickel and Nickel-Base Alloys

and are not considered standard.

2.3 Military Standards:

MIL-STD-129 Marking for Shipment and Storage

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the MIL-STD-271 Nondestructive Testing Requirements for

Metals

responsibility of the user of this standard to become familiar

with all hazards including those identified in the appropriate

3. Terminology

Material Safety Data Sheet (MSDS) for this product/material

as provided by the manufacturer, to establish appropriate

3.1 Definitions of Terms Specific to This Standard:

safety and health practices, and determine the applicability of

3.1.1 bar, n—material of rectangular (flats), hexagonal, or

regulatory limitations prior to use. square solid section up to and including 10 in. (254 mm) in

width and ⁄8 in. (3.2 mm) and over in thickness in straight

2. Referenced Documents lengths.

3.1.2 rod, n—material of round solid section furnished in

2.1 ASTM Standards:

straight lengths.

E8 Test Methods for Tension Testing of Metallic Materials

E18 Test Methods for Rockwell Hardness of Metallic Ma-

3.1.3 wire, n—a cold-worked solid product of uniform

terials

round cross section along its whole length, supplied in coil

E29 Practice for Using Significant Digits in Test Data to

form.

Determine Conformance with Specifications

4. Ordering Information

E112 Test Methods for Determining Average Grain Size

E140 Hardness Conversion Tables for Metals Relationship

4.1 Orders for material to this specification should include

Among Brinell Hardness, Vickers Hardness, Rockwell

the following information:

Hardness, Superficial Hardness, Knoop Hardness, and

4.1.1 ASTM designation and year of issue,

Scleroscope Hardness

4.1.2 Alloy name or UNS number (see Table 1),

E602 Test Method for Sharp-Notch Tension Testing with

4.1.3 Shape—rod (round) or bar (square, hexagonal, or

rectangular),

4.1.3.1 Forging (sketch or drawing),

1 4.1.4 Dimensions, including length, (see Tables 2 and 3),

This specification is under the jurisdiction of ASTM Committee B02 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

4.1.5 Condition (see Table 4, Table 5, and Table 6),

B02.07 on Refined Nickel and Cobalt and Their Alloys.

4.1.6 Forging stock—Specify if material is stock for

Current edition approved Oct. 1, 2010. Published October 2010. Originally

reforging,

approved in 1995. Last previous edition approved in 2004 as B865 – 04. DOI:

4.1.7 Finish,

10.1520/B0865-04R10.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B865−04 (2010)

TABLE 1 Chemical Requirements TABLE 3 Permissible Variations in Straightness of Precision

Straightened Cold-Worked Shafting

Product (check) analysis

variations, under min or

Permissible Variations

Element Composition Limits, %

Standard Distance

over max, of the specified

Specified Dimension, Throw In One Revolution

Between Supports,

limit of element, %

in. (mm) From Straightness,

in. (mm)

A

in. (mm)

Nickel 63.0 min 0.45

1 15

Aluminum 2.30–3.15 0.20

⁄2 (12.7) to ⁄16 (23.8), 42 (1070) 0.005 (0.13)

Carbon 0.18 max 0.01

incl

15 15

Iron 2.0 max 0.05

Over ⁄16 (23.8) to 1 ⁄16 42 (1070) 0.006 (0.15)

Manganese 1.5 max 0.04

(49.2), incl

15 1

Silicon 0.50 max 0.03 Over 1 ⁄16 (49.2) to 2 ⁄2 42 (1070) 0.007 (0.18)

Titanium 0.35–0.85 0.03 min

(63.5), incl

0.04 max Over 2 ⁄2 (63.5) to 4 42 (1070) 0.008 (0.20)

Sulfur 0.010 max 0.003

(101.6), incl

3 15

Copper 27.0–33.0 0.15 min ⁄4 (19.0) to ⁄16 (23.8), Specified lengths of 3 to 100.004 (0.10) plus 0.0025

0.20 max

incl ft (0.91 to 3.05 m) (0.064) for each foot, or

fraction thereof, in excess

A

The nickel content shall be determined arithmetically by difference.

of 3 ft (0.91 m)

Over ⁄16 (23.8) to 4 Specified lengths of 20 ft 0.005 (0.13) plus 0.0015

(101.6), incl (6.10 m) and less (0.038) for each foot, or

fraction thereof, in excess

TABLE 2 Permissible Variations in Diameter or Distance Between

A

of 3 ft (0.91 m)

Parallel Surfaces of Hot-Worked Rod and Bar

Permissible Variations from

B

Specified Dimensions, in. (mm)

Specified Dimension, in. (mm)

A

TABLE 4 Mechanical Properties—Unaged (Bar, Rod, Forgings)

Plus Minus

Hardness

Rod and bar, hot worked:

Form Condition

1 (25.4) and under 0.016 (0.41) 0.016 (0.41)

Brinell

Rockwell, max

Over 1 (25.4) to 2 (50.8), incl 0.031 (0.79) 0.016 (0.41)

3000 kg, max

Over 2 (50.8) to 4 (101.6), incl 0.047 (1.19) 0.031 (0.79)

B

Rounds, hexagons, Hot-worked 245 C23

Over 4 (101.6) 0.125 (3.18) 0.063 (1.60)

squares, rectangles, and

Rod, rough-turned or ground:

forgings

Under 1 (25.4) 0.005 (0.13) 0.005 (0.13) Hexagons Cold-worked 260 C26

1 (25.4) and over 0.031 (0.79) 0

Rounds:

Round rod, semi-smooth, machined:

⁄4 (6.4 mm) to 1 in. Cold-worked 280 C29

Over 3 ⁄2 (88.9) 0.031 (0.79) 0

(25.4 mm), incl

Round rod, smooth finished, machined:

Over 1 (25.4 mm) to 3 Cold-worked 260 C26

Over 3 ⁄2 (88.9) 0 0.005 (0.13) in. (76.2 mm), incl

Forging quality bolt stock (rounds only):

Over 3 (76.2 mm) to 4 Cold-worked 240 C22

1 5

⁄4 (6.4), ⁄16 (7.9) 0 0.0062 (0.16) in. (101.6 mm), incl

3 7 1

⁄8 (9.5), ⁄16 (11.1), ⁄2 (12.7) 0 0.0066 (0.17)

Rounds, hexagons, Hot-worked or cold- 185 B90

9 5 11 3

⁄16 (14.3), ⁄8 (7.9), ⁄16 (17.5), ⁄4 0 0.0082 (0.21) squares, rectangles, and worked and annealed

13 7

(19.1), ⁄16 (20.6), ⁄8 (22.2)

forgings

⁄16 (7.9), 1 (25.4) 0 0.0098 (0.25)

A

No tensile tests are required except as provided for in 9.2.3.

1 1 1

1 ⁄16 to 1 ⁄2 (27.0 to 38.1), in ⁄16 (1.6) 0 0.0112 (0.28)

B

Rounds over 4 ⁄4 in. (108.0 mm) in diameter shall have hardness of 260 BHN,

increments

max.

A

Not applicable to forging stock.

B

Dimensions apply to diameter of rods, to distance between parallel surfaces of

hexagons and squares, and separately to width and thickness of rectangles.

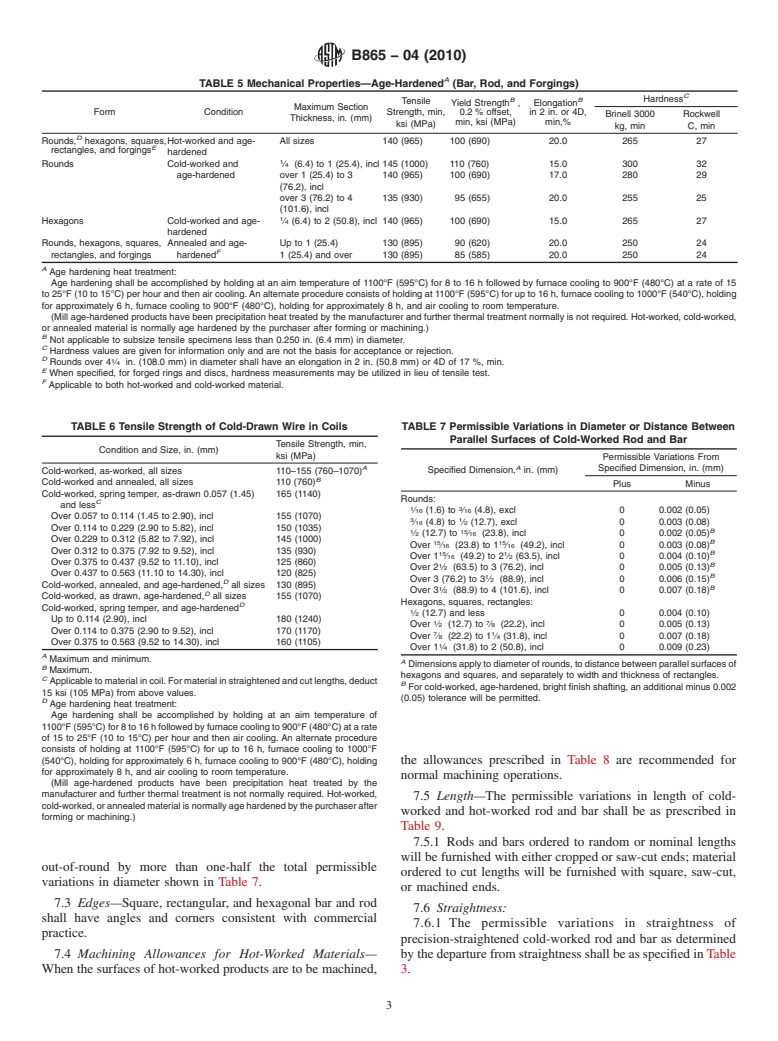

6. Mechanical Properties

6.1 Mechanical Properties—The material in the unaged

condition shall conform to the mechanical properties specified

4.1.8 Quantity—feet or number of pieces, and

in Table 4. After aging the material shall conform to the

4.1.9 Certification—State if certification or a report of test

mechanical properties specified in Table 5 and Table 6.

results is required (Section 15),

4.1.10 Samples for product (check) analysis—State whether

7. Dimensions and Permissible Variations

samples for product (check) analysis should be furnished, and

7.1 Diameter, Thickness, or Width—The permissible varia-

4.1.11 Purchaser inspection—If purchaser wishes to witness

tions from the specified dimensions as measured on the

tests or inspection of material at place of manufacture, the

diameter or between parallel surfaces of cold-worked rod and

purchase order must so state indicating which test or inspec-

barshallbeasprescribedinTable7;ofhot-workedrodandbar

tions are to be witnessed.

as prescribed in Table 2; and of wire as prescribed in Table 7.

7.2 Out-of-Round—Hot-worked rods and cold-worked rods

5. Chemical Composition

(except “forging quality”) of all sizes, in straight lengths, shall

5.1 The material shall conform to the composition limits

not be out-of-round by more than one half the total permissible

specified in Table 1.

variations in diameter shown in Table 2 and Table 7, except for

5.2 If a product (check) analysis is performed by the hot-workedrods ⁄2in.(12.7mm)indiameterandunder,which

purchaser, the material shall conform to the product (check) may be cut-of-round by the total permissible variations in

analysis variations in Table 1. diameter shown in Table 2. Cold-worked wire shall not be

B865−04 (2010)

A

TABLE 5 Mechanical Properties—Age-Hardened (Bar, Rod, and Forgings)

C

Hardness

B B

Tensile

Yield Strength , Elongation

Maximum Section

Form Condition Strength, min, 0.2 % offset, in 2 in. or 4D,

Brinell 3000 Rockwell

Thickness, in. (mm)

min, ksi (MPa) min,%

ksi (MPa)

kg, min C, min

D

Rounds, hexagons, squares,Hot-worked and age- All sizes 140 (965) 100 (690) 20.0 265 27

E

rectangles, and forgings

hardened

Rounds Cold-worked and ⁄4 (6.4) to 1 (25.4), incl 145 (1000) 110 (760) 15.0 300 32

age-hardened over 1 (25.4) to 3 140 (965) 100 (690) 17.0 280 29

(76.2), incl

over 3 (76.2) to 4 135 (930) 95 (655) 20.0 255 25

(101.6), incl

Hexagons Cold-worked and age- ⁄4 (6.4) to 2 (50.8), incl 140 (965) 100 (690) 15.0 265 27

hardened

Rounds, hexagons, squares, Annealed and age- Up to 1 (25.4) 130 (895) 90 (620) 20.0 250 24

F

rectangles, and forgings hardened 1 (25.4) and over 130 (895) 85 (585) 20.0 250 24

A

Age hardening heat treatment:

Age hardening shall be accomplished by holding at an aim temperature of 1100°F (595°C) for 8 to 16 h followed by furnace cooling to 900°F (480°C) at a rate of 15

to 25°F (10 to 15°C) per hour and then air cooling.An alternate procedure consists of holding at 1100°F (595°C) for up to 16 h, furnace cooling to 1000°F (540°C), holding

for approximately 6 h, furnace cooling to 900°F (480°C), holding for approximately 8 h, and air cooling to room temperature.

(Mill age-hardened products have been precipitation heat treated by the manufacturer and further thermal treatment normally is not required. Hot-worked, cold-worked,

or annealed material is normally age hardened by the purchaser after forming or machining.)

B

Not applicable to subsize tensile specimens less than 0.250 in. (6.4 mm) in diameter.

C

Hardness values are given for information only and are not the basis for acceptance or rejection.

D

Rounds over 4 ⁄4 in. (108.0 mm) in diameter shall have an elongation in 2 in. (50.8 mm) or 4D of 17 %, min.

E

When specified, for forged rings and discs, hardness measurements may be utilized in lieu of tensile test.

F

Applicable to both hot-worked and cold-worked material.

TABLE 6 Tensile Strength of Cold-Drawn Wire in Coils TABLE 7 Permissible Variations in Diameter or Distance Between

Parallel Surfaces of Cold-Worked Rod and Bar

Tensile Strength, min,

Condition and Size, in. (mm)

ksi (MPa)

Permissible Variations From

A

A Specified Dimension, in. (mm)

Cold-worked, as-worked, all sizes 110–155 (760–1070) Specified Dimension, in. (mm)

B

Cold-worked and annealed, all sizes 110 (760)

Plus Minus

Cold-worked, spring temper, as-drawn 0.057 (1.45) 165 (1140)

Rounds:

C

and less

1 3

⁄16 (1.6) to ⁄16 (4.8), excl 0 0.002 (0.05)

Over 0.057 to 0.114 (1.45 to 2.90), incl 155 (1070)

3 1

⁄16 (4.8) to ⁄2 (12.7), excl 0 0.003 (0.08)

Over 0.114 to 0.229 (2.90 to 5.82), incl 150 (1035)

B

1 15

⁄2 (12.7) to ⁄16 (23.8), incl 0 0.002 (0.05)

Over 0.229 to 0.312 (5.82 to 7.92), incl 145 (1000)

B

15 15

Over ⁄16 (23.8) to 1 ⁄16 (49.2), incl 0 0.003 (0.08)

Over 0.312 to 0.375 (7.92 to 9.52), incl 135 (930)

15 1 B

Over 1 ⁄16 (49.2) to 2 ⁄2 (63.5), incl 0 0.004 (0.10)

Over 0.375 to 0.437 (9.52 to 11.10), incl 125 (860)

B

Over 2 ⁄2 (63.5) to 3 (76.2), incl 0 0.005 (0.13)

Over 0.437 to 0.563 (11.10 to 14.30), incl 120 (825)

B

Over 3 (76.2) to 3 ⁄2 (88.9), incl 0 0.006 (0.15)

D

Cold-worked, annealed, and age-hardened, all sizes 130 (895)

B

Over 3 ⁄2 (88.9) to 4 (101.6), incl 0 0.007 (0.18)

D

Cold-worked, as drawn, age-hardened, all sizes 155 (1070)

Hexagons, squares, rectangles:

D

Cold-worked, spring temper, and age-hardened

⁄2 (12.7) and less 0 0.004 (0.10)

Up to 0.114 (2.90), incl 180 (1240)

1 7

Over ⁄2 (12.7) to ⁄8 (22.2), incl 0 0.005 (0.13)

Over 0.114 to 0.375 (2.90 to 9.52), incl 170 (1170)

7 1

Over ⁄8 (22.2) to 1 ⁄4 (31.8), incl 0 0.007 (0.18)

Over 0.375 to 0.563 (9.52 to 14.30), incl 160 (1105)

Over 1 ⁄4 (31.8) to 2 (50.8), incl 0 0.009 (0.23)

A

Maximum and minimum.

A

Dimensionsapplytodiameterofrounds,todistancebetweenparallelsurfacesof

B

Maximum.

hexagons and squares, and separately to width and thickness of rectangles.

C

Applicabletomaterialincoil.Formaterialinstraightenedandcutlengths,deduct

B

For cold-worked, age-hardened, bright finish shafting, an additional minus 0.002

15 ksi (105 MPa) from above values.

(0.05) tolerance will be permitted.

D

Age hardening heat treatment:

Age hardening shall be accomplished by holding at an aim temperature of

1100°F(595°C)for8to16hfollowedbyfurnacecoolingto900°F(480°C)atarate

of 15 to 25°F (10 to 15°C) per hour and then air cooling. An alternate procedure

consists of holding at 1100°F (595°C) for up to 16 h, furnace cooling to 1000°F

(540°C), holding for approximately 6 h, furnace cooling to 900°F (480°C), holding the allowances prescribed in Table 8 are recommended for

for approximately 8 h, and air cooling to room temperature.

normal machining operations.

(Mill age-hardened products have been precipitation heat treated by the

manufacturer and further thermal treatment is not normally required. Hot-worked,

7.5 Length—The permissible variations in length of cold-

cold-worked,orannealedmaterialisnormallyagehardenedbythepurchaserafter

worked and hot-worked rod and bar shall be as prescribed in

forming or machining.)

Table 9.

7.5.1 Rods and bars ordered to random or nominal lengths

will be furnished with either cropped or saw-cut ends; material

out-of-round by more than one-half the total permissible

ordered to cut lengths will be furnished with square, saw-cut,

variations in diameter shown

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.