ASTM G142-98

(Test Method)Standard Test Method for Determination of Susceptibility of Metals to Embrittlement in Hydrogen Containing Environments at High Pressure, High Temperature, or Both

Standard Test Method for Determination of Susceptibility of Metals to Embrittlement in Hydrogen Containing Environments at High Pressure, High Temperature, or Both

SCOPE

1.1 This test method covers a procedure for determination of tensile properties of metals in high pressure or high temperature, or both, gaseous hydrogen-containing environments. It includes accommodations for the testing of either smooth or notched specimens.

1.2 This applies to all materials and product forms including, but not restricted to, wrought and cast materials.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See 6.1 for additional information.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G 142 – 98

Standard Test Method for

Determination of Susceptibility of Metals to Embrittlement in

Hydrogen Containing Environments at High Pressure, High

Temperature, or Both

This standard is issued under the fixed designation G 142; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope MIL-P-27201B Propellant, Hydrogen

1.1 This test method covers a procedure for determination

3. Terminology

of tensile properties of metals in high pressure or high

3.1 Definitions:

temperature, or both, gaseous hydrogen-containing environ-

3.1.1 control test, n—a mechanical test conducted in an

ments. It includes accommodations for the testing of either

environment that does not produce embrittlement of a test

smooth or notched specimens.

material.

1.2 This applies to all materials and product forms includ-

3.1.2 hydrogen embrittlement, n—hydrogen induced crack-

ing, but not restricted to, wrought and cast materials.

ing or severe loss of ductility caused by the presence of

1.3 The values stated in SI units are to be regarded as the

hydrogen in the metal.

standard.

3.1.3 Other definitions and terminology related to testing

1.4 This standard does not purport to address all of the

can be found in Terminology G 15.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

4.1 Specimens of selected materials are exposed to a gas-

bility of regulatory limitations prior to use. See 6.1 for

eous hydrogen containing environment at high pressure or high

additional information.

temperature, or both, while being pulled to failure in uniaxial

tension. The susceptibility to hydrogen embrittlement is evalu-

2. Referenced Documents

ated through the determination of standard mechanical prop-

2.1 ASTM Standards:

2 erties in tension (that is, yield strength, ultimate tensile

D 1193 Specification for Reagent Water

3 strength, notched tensile strength, reduction in area or elonga-

E 4 Practices for Force Verification of Testing Machines

3 tion, or both). Comparison of these mechanical properties

E 8 Test Methods for Tension Testing of Metallic Materials

determined in a hydrogen-containing environment to those

E 691 Practice for Conducting an Interlaboratory Study to

4 determined in a non-embrittling environment (control test)

Determine the Precision of a Test Method

provides a general index of susceptibility to cracking versus the

G 15 Terminology Relating to Corrosion and Corrosion

5 material’s normal mechanical behavior.

Testing

G 111 Guide for Corrosion Tests in High Temperature or

5. Significance and Use

High Pressure Environment, or Both

5.1 This test method provides a reliable prediction of the

G 129 Practice for Slow Strain Rate Testing to Evaluate the

resistance or susceptibility, or both, to loss of material strength

Susceptibility of Metallic Materials to Environmentally

5 and ductility as a result of exposure to hydrogen-containing

Assisted Cracking

gaseous environments. This test method is applicable over a

2.2 Military Standard:

broad range of pressures, temperatures, and gaseous environ-

ments. The results from this test method can be used to

This test method is under the jurisdiction of ASTM Committee G-1 on evaluate the effects of material composition, processing, and

Corrosion of Metals and is the direct responsibility of Subcommittee G01.06 on

heat treatment as well as the effects of changes in environment

Stress Corrosion Cracking and Corrosion Fatigue.

composition, temperature, and pressure. These results may or

Current edition approved April 10, 1998. Published September 1998.

Originally published as G 142–96. Last previous edition G 142–96.

Annual Book of ASTM Standards, Vol 11.01.

Annual Book of ASTM Standards, Vol 03.01.

4 6

Annual Book of ASTM Standards, Vol 14.02. Available from Standardization Documents, Order Desk, Bldg. 4 Section D,

Annual Book of ASTM Standards, Vol 03.02. 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G 142

may not correlate with service experience for particular appli- environment) should be used. Materials with low values of this

cations. Furthermore, this test method may not be suitable for parameter should be avoided.

the evaluation of high temperature hydrogen attack in steels

6.2.2 Closure and Seal—To facilitate operation of the test

unless suitable exposure time at the test conditions has taken

cell and tension testing, the closure should provide for rapid

place prior to the initiation of tensile testing to allow for the

opening and closing of the test cell and reliable sealing

development of internal blistering, decarburization or cracking,

capabilities for hydrogen. This can include either metallic or

or both.

non-metallic materials with high resistance to hydrogen em-

brittlement and degradation.

6. Apparatus

6.2.3 Gas Port(s)—The gas port should be designed to

6.1 Since this test method is intended to be conducted at

promote flow and circulation of the gaseous test environments,

high pressures and may also involve high temperatures, the

inert gas purging and evacuation as required to produce the

apparatus must be constructed to safely contain the test

intended test environment. Usually two ports are used so that

environment while being resistant to the embrittling effects of

flow-through capabilities are attained to facilitate these func-

hydrogen. Secondly, the test apparatus must be capable of

tions.

allowing introduction of the test gas, removal of air from the

6.2.4 Electrical Feed-Throughs—If very high temperature

test cell, and accurate performance of the tension test on the

conditions are required it may be advantageous to utilize an

test specimen. In cases where the tests are conducted at

internal heater to heat the test specimen and the gaseous

elevated temperatures, the apparatus must provide for heating

environment in the immediate vicinity of the specimen. There-

of the specimen and the test environment in direct contact with

the specimen. fore, a feed-through would be needed to reach an internal

resistance or induction heater. These feed-throughs must also

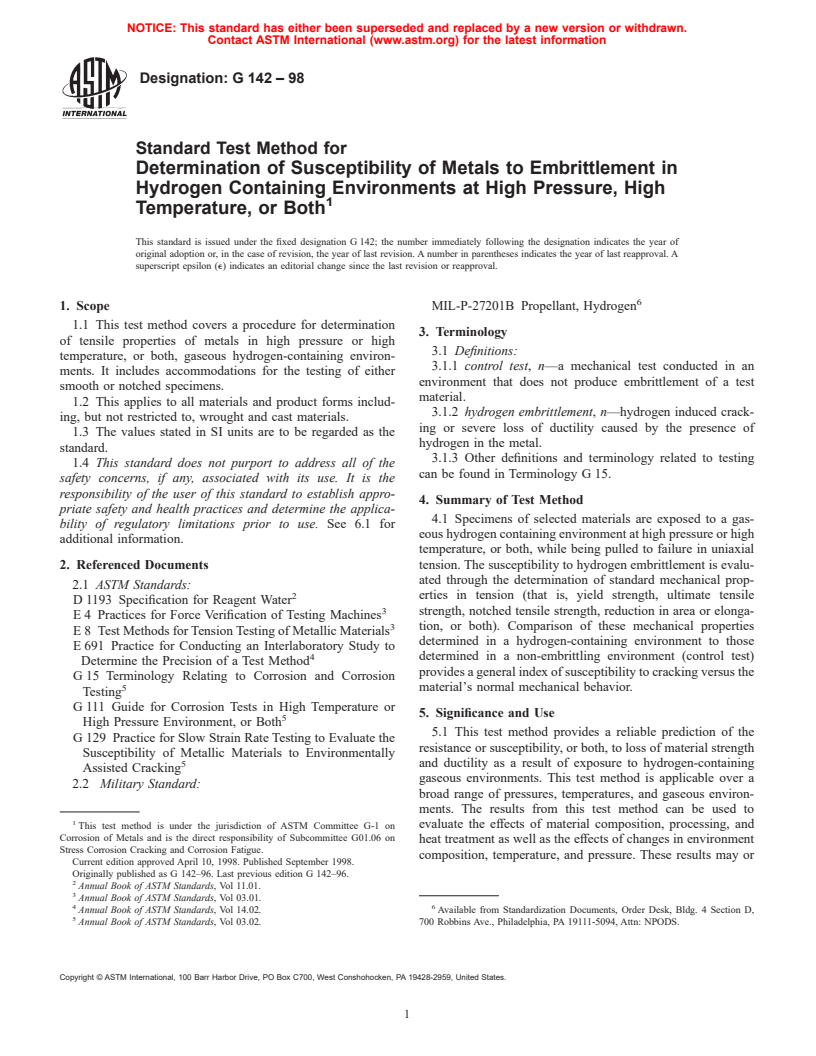

6.2 Fig. 1 shows a schematic representation of a typical test

cell designed to conduct HP/HT gaseous hydrogen embrittle- provide electrical isolation from the test cell and internal

ment experiments. The typical components include: fixtures, and maintain a seal to prevent leakage of the test

6.2.1 Metal Test Cell—The test cell should be constructed

environment. If external heaters are used, no electric feed-

from materials that have proven to have high resistance to

throughs would be required for testing.

hydrogen embrittlement under the conditions. A list of poten-

6.2.5 Tensile Feed-Through(s)—To apply tensile loading to

tial materials of construction is shown in Fig. 2. Materials

the test specimen it is necessary to have feed-through(s) which

with high values of tensile ratios (environment versus a control

provide linear motion and transmission of loads from an

external source. Care must be taken to design such feed-

throughs to have low friction to minimize errors due to friction

losses when using externally applied loads. These are usually

R. D. Kane, “High Temperature and High Pressure”, Corrosion Tests and

Standards, Ed. Robert Baboian, ASTM, West Conshohocken, PA.

designed to incorporate thermoplastic or elastomeric materials,

Metals Handbook, Vol 9, Corrosion, 9th Edition, ASM International, Metals

or both. If elevated temperature tests are being conducted, then

Park, OH, 1987, p. 1104.

FIG. 2 Notched Tensile Strength (NTS) Ratio for Various Alloys in 35 to 69 MPa Gaseous Hydrogen versus Air Tested at Room

Temperature

G 142

6.2.7.2 Internal load cells which are either attached to the

pull rod or grip assembly inside of the autoclave or are

integrated into the pull rod. When using external load cells it is

important to correct load cell readings for frictional forces in

the pressure seal. Additionally, if non-pressure balanced pull

rods are used, compensation for pressure loading of the

specimen must be also performed.

6.2.8 Electric Resistance or Induction Heater(s)—Either

internal or external heaters can be used to obtain elevated

temperature. For lower temperatures and when using test

environments containing reactive constituents in addition to

hydrogen, external heating of the test cell is typically more

convenient. At high temperatures when using non-reactive or

hydrogen gas environments, an internal heater can be used to

heat only the test specimen and the gaseous environment in the

vicinity of the test specimen to limit power requirements and

problems with high temperature sealing and pressure contain-

ment.

6.2.9 Grips—Grips shall provide for efficient and accurate

transfer of load from the pull rods to the test specimen. Grips

should be designed to minimize compliance in the loading

system under the anticipated loads to pull the test specimen.

6.2.10 Loading Fixture—A fixture is used to react the load

used to pull the specimen. An internal fixture is shown

schematically in Fig. 1.

6.2.11 Testing Machines—Tension testing machines used

for conducting tests according to this test method shall conform

to the requirements of Practices E 4. The loads used in tests

shall be within the calibrated load ranges of the testing

machines in accordance with Practices E 4.

7. Reagents

7.1 Purity of Reagents—Reagent grade chemicals and ultra

low oxygen gases (<1 ppm) shall be used in all tests unless the

test environment is derived from a field or plant environment.

If the test is to be conducted for aerospace propulsion appli-

FIG. 1 Hydrogen Tensions Test Autoclave for Various Alloys in

cations, the environment shall consist of hydrogen gas per

Hydrogen versus Air

MIL-P-27201B.

7.2 If water is to be added to any test environment, distilled

or deionized water conforming to Specification D 1193 Type

extreme care must be used in the selection of these materials to

IV shall be used.

also resist deterioration and loss of mechanical properties at the

test temperature.

8. Test Environment

6.2.6 Pull Rod—The pull rod works in combination with the

8.1 Test environments can consist of either field or plant

tensile feed-through to provide for loading of the test speci-

samples or be prepared in the laboratory from chemicals and

men. It is usually attached to a tensile testing machine on one

gases as indicated in Section 7.

end and the tension specimen on the other. It should be

8.2 When testing in hydrogen containing environments,

designed to have adequate cross-sectional area to minimize

susceptibility to hydrogen embrittlement typically increases

compliance in the loading system under the anticipated loads to

with decreasing oxygen content of the test environment.

be used. Also, to minimize frictional forces in the seal and

Therefore, strict procedures for deaeration shall be followed

promote sealing, it should be made with a highly polished

and periodically qualified for oxygen content as discussed in

surfaces [<0.25 μm (10 μin.) RMS]. It is possible to obtain pull

Sections 9 and 11.

rod systems that are pressure balanced so specimen loading

from the internal pressure in the test cell can be minimized. 8.3 For purposes of standardization, suggested standardized

6.2.7 Load Cell—Load cells for conducting high pressure pressures for hydrogen gas testing shall be 7 MPa, 35 MPa, and

tensile tests may be two configurations: 69 MPa. However, for materials evaluation for specific appli-

6.2.7.1 External load cells which are attached to the pull rod cations, the test pressure should be equal to or greater than that

outside of the test cell, and which represents the service conditions.

G 142

9. Sampling

9.1 The procedure for sampling mill products is typically

covered in product or other specifications and is outside the

scope of this document.

9.2 Sampling of the test environment is recommended to

confirm that the test environment is in conformance with this

test method and attains the intended test conditions. Such

sampling shall be conducted immediately prior to and after

testing. The frequency of environmental sampling shall be as

required to cover applicable product, purchase or in-house

testing specifications, or both. As a minimum requirement to be

in compliance with this test method, however, sampling of the

test environment shall be conducted at the start of testing and

again when any element of the test procedure or test system has

been changed or modified.

10. Test Specimens

10.1 Tension specimens shall be used for evaluation of

hydrogen embrittlement. These specimens shall conform to the

dimensions and guidelines provided in Test Methods E 8.

However, in some cases, the material size, configuration and

form or the confines of various test cells may limit the actual

dimensions of the test specimen. In such cases, the specimen

geometry and dimensions shall be fully described. Take care to

only compare the results obtained from similar specimens.

10.2 For purposes of standardizing the evaluation of mate-

rials according to this test method, two standard test specimens

FIG. 3 Standard Tension Specimens (a) Smooth and (b) Notched

shall be used: standard smooth tension specimen, and standard

notched tensile specimen. The dimensions of these specimens

12. Test Procedure

are given in Fig. 3a and Fig. 3 b.

12.1 Follow the basic guidelines for high pressure/high

10.3 Specimens shall be machined to have a minimal

temperature corrosion testing in Guide G 111 where applicable.

amount of cold work on the gage or notch surfaces. Total metal

12.2 Measure the initial specimen dimensions. For smooth

removed in the last two passes shall be limited to a total of 0.05

tensile specimens, the dimensions measured are gage length

mm and have a surface finish of 0.25 μm (10 μin.) or better. The

and diameter. For notched specimens, the dimensions are gage

method of final machining of the gage section should be by

and notch diameter.

grinding (not turning) to avoid localized grooves and cold

12.3 Degrease and clean the specimen. Once cleaned the

worked areas.

specimen shall not be handled with bare hands.

12.4 Mount the specimen in the test cell using suitable grips

11. Standardi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.