ASTM D4897-01

(Specification)Standard Specification for Asphalt-Coated Glass-Fiber Venting Base Sheet Used in Roofing

Standard Specification for Asphalt-Coated Glass-Fiber Venting Base Sheet Used in Roofing

ABSTRACT

This specification covers the manufacture and requirements of Type II heavy-duty asphalt-impregnated and coated glass-fiber venting base sheet with mineral surfacing on the top side and coarse mineral granules on the bottom side for use as the first ply of a roofing membrane. The mat shall be a thin porous sheet of uniformly distributed glass fibers, with or without the addition of reinforcing strands, or glass yarns, which are bonded with a water-resistant resinous binder, and shall be permitted to contain holes designated for attachment with mopping asphalt. The material shall conform to physical (longitudinal and transverse breaking strength, and diameter and center-to-center spacing of spot-mopping holes, pliability, loss and behavior on heating, ash content, and moisture) and dimensional (mass, width, and area) property requirements. The finished product shall not crack nor be so sticky as to cause tearing or other damage upon being unrolled at given temperatures.

SCOPE

1.1 This specification covers asphalt-impregnated and coated glass-fiber base sheet with fine mineral surfacing on the top side and coarse mineral granules on the bottom side for use as the first ply of a roofing membrane. These base sheets provide for the lateral release of pressure in roofing systems because they are not solidly attached and the coarse granular surface provides an open, porous channel in the horizontal plane beneath the membrane. The base sheets may be with or without perforations or embossings.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4897 – 01

Standard Specification for

Asphalt-Coated Glass-Fiber Venting Base Sheet Used in

1

Roofing

This standard is issued under the fixed designation D 4897; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

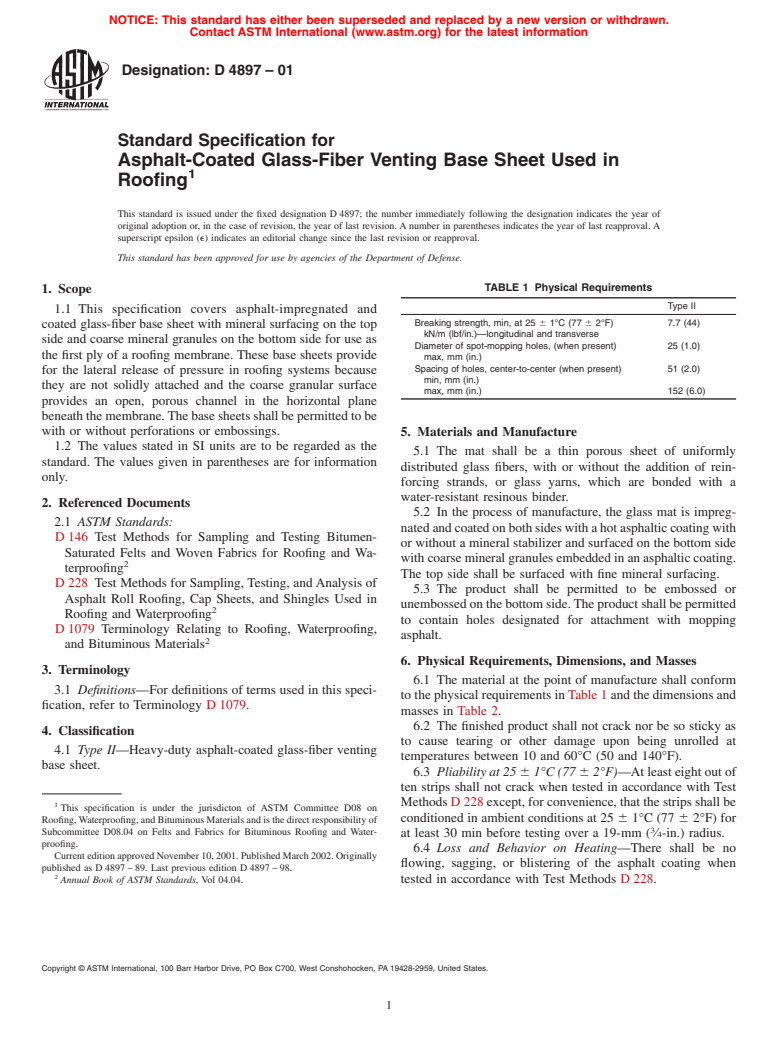

TABLE 1 Physical Requirements

1. Scope

Type II

1.1 This specification covers asphalt-impregnated and

Breaking strength, min, at 25 6 1°C (77 6 2°F) 7.7 (44)

coated glass-fiber base sheet with mineral surfacing on the top

kN/m (lbf/in.)—longitudinal and transverse

side and coarse mineral granules on the bottom side for use as

Diameter of spot-mopping holes, (when present) 25 (1.0)

the first ply of a roofing membrane. These base sheets provide

max, mm (in.)

Spacing of holes, center-to-center (when present) 51 (2.0)

for the lateral release of pressure in roofing systems because

min, mm (in.)

they are not solidly attached and the coarse granular surface

max, mm (in.) 152 (6.0)

provides an open, porous channel in the horizontal plane

beneaththemembrane.Thebasesheetsshallbepermittedtobe

with or without perforations or embossings.

5. Materials and Manufacture

1.2 The values stated in SI units are to be regarded as the

5.1 The mat shall be a thin porous sheet of uniformly

standard. The values given in parentheses are for information

distributed glass fibers, with or without the addition of rein-

only.

forcing strands, or glass yarns, which are bonded with a

water-resistant resinous binder.

2. Referenced Documents

5.2 In the process of manufacture, the glass mat is impreg-

2.1 ASTM Standards:

natedandcoatedonbothsideswithahotasphalticcoatingwith

D 146 Test Methods for Sampling and Testing Bitumen-

or without a mineral stabilizer and surfaced on the bottom side

Saturated Felts and Woven Fabrics for Roofing and Wa-

withcoarsemineralgranulesembeddedinanasphalticcoating.

2

terproofing

The top side shall be surfaced with fine mineral surfacing.

D 228 Test Methods for Sampling, Testing, andAnalysis of

5.3 The product shall be permitted to be embossed or

Asphalt Roll Roofing, Cap Sheets, and Shingles Used in

unembossedonthebottomside.Theproductshallbepermitted

2

Roofing and Waterproofing

to contain holes designated for attachment with mopping

D 1079 Terminology Relating to Roofing, Waterproofing,

asphalt.

2

and Bituminous Materials

6. Physical Requirements, Dimensions, and Masses

3. Terminology

6.1 The material at the point of manufacture shall conform

3.1 Definitions—For definitions of terms used in this speci-

to the physical requirements inTable 1 and the dimensions and

fication, refer to Terminology D 1079.

masses in Table 2.

6.2 The finished product shall not crack nor be so sticky as

4. Classification

to cause tearing or other damage upon being unrolled at

4.1 Type II—Heavy-duty asphalt-coated glass-fiber venting

temperatures between 10 and 60°C (50 and 140°F).

base sheet.

6.3 Pliability at 25 6 1°C (77 6 2°F)—At least eight out of

ten strips shall not crack when tested in accordance with Test

1 Methods D 228 except, for convenience, that the strips shall be

This specification is under the jurisdicton of ASTM Committee D08 on

conditioned in ambient conditions at 25 6 1°C (77 6 2°F) for

Roofing,Waterproofing, and Bituminous Materials and is the direct responsibility of

3

Subcommittee D08.04 on Felts and Fabrics for Bituminous Roofing and Water-

at least 30 min before testing over a 19-mm ( ⁄4-in.) radius.

proofing.

6.4 Loss and Behavior on Heating—There shall be no

Current edition approved November 10, 2001. Published March 2002. Originally

flowing, sagging, or blistering of the asphalt coating when

published as D 4897 – 89. Last previous edition D 4897 – 98.

2

Annual Book of ASTM Standards, Vol 04.04. tested in accordance with Test Methods D 228.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4897–01

A

TABLE 2 Dimensions and Masses

Type II

Width of roll, mm (in.) 36 (914) 6 0.7 %

2 2

Area of roll, min, m (ft ) 9.64 (104)

2 2

Mass of any roofing in shipment min, g/m (lb/100 ft ) 2685 (55)

2 2

Mass of desaturated glass mat min, g/m (lb/100 ft ) 83 (1.7)

2 2

Mass of asphalt, min, gm/m (lb/100 ft ) 586 (12)

2 2

Mass of total unstabilized coating, filler and top surfacing min, g/m (lb/100 ft ) 1075 (22.0)

2 2

Mass of mineral granules retained on a 212-µm (No. 70) sieve min, g/m (lb/100 ft ) 391 (8.0)

Mass of mineral matter passing a 212-µm (No. 70) sieve on basis of total mass of mineral stabilized coating 60

and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.