ASTM E782-95(2007)

(Practice)Standard Practice for Exposure of Cover Materials for Solar Collectors to Natural Weathering Under Conditions Simulating Operational Mode

Standard Practice for Exposure of Cover Materials for Solar Collectors to Natural Weathering Under Conditions Simulating Operational Mode

SCOPE

1.1 This practice provides a procedure for the exposure of cover materials for flat-plate solar collectors to the natural weather environment at temperatures that are elevated to approximate operating conditions.

1.2 This practice is suitable for exposure of both glass and plastic solar collector cover materials. Provisions are made for exposure of single and double cover assemblies to accommodate the need for exposure of both inner and outer solar collector cover materials.

1.3 This practice does not apply to cover materials for evacuated collectors or photovoltaics.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E782 − 95(Reapproved 2007)

Standard Practice for

Exposure of Cover Materials for Solar Collectors to Natural

Weathering Under Conditions Simulating Operational Mode

This standard is issued under the fixed designation E782; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Significance and Use

1.1 This practice provides a procedure for the exposure of

3.1 This practice describes a weathering box test fixture and

cover materials for flat-plate solar collectors to the natural provides uniform exposure guidelines to minimize the vari-

weather environment at temperatures that are elevated to

ables encountered during outdoor exposure testing.

approximate operating conditions.

3.2 This practice may be useful in comparing the perfor-

1.2 This practice is suitable for exposure of both glass and

mance of different materials at one site or the performance of

plastic solar collector cover materials. Provisions are made for the same material at different sites, or both.

exposure of single and double cover assemblies to accommo-

3.3 Since the combination of elevated temperature and solar

date the need for exposure of both inner and outer solar

radiation may cause some solar collector cover materials to

collector cover materials.

degrade more rapidly than either alone, a weathering box that

1.3 This practice does not apply to cover materials for

elevates the temperature of the cover materials is used.

evacuated collectors or photovoltaics.

3.4 This practice is intended to assist in the evaluation of

1.4 The values stated in SI units are to be regarded as the

solar collector cover materials in the operational, not stagna-

standard.

tion mode. Insufficient data exist to obtain exact correlation

between the behavior of materials exposed according to this

1.5 This standard does not purport to address all of the

practice and actual in-service performance.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.5 Means of evaluation of effects of weathering are pro-

priate safety and health practices and determine the applica-

vided in Practice E781, and in other ASTM test methods that

bility of regulatory limitations prior to use.

evaluate material properties.

3.6 Tests of the type described in this practice may be used

2. Referenced Documents

to evaluate the stability of solar collector cover materials when

2.1 ASTM Standards:

exposed outdoors to the varied influences which comprise

E781 Practice for Evaluating Absorptive Solar Receiver

weather. Exposure conditions are complex and changeable.

Materials When Exposed to Conditions Simulating Stag-

Important factors are solar radiation, temperature, moisture,

nation in Solar Collectors With Cover Plates

time of year, presence of pollutants, etc. These factors vary

E881 Practice for Exposure of Solar Collector Cover Mate-

from site to site and should be considered in selecting locations

rials to Natural Weathering Under Conditions Simulating

for exposure. Control samples must always be used in weath-

Stagnation Mode

ering tests for comparative analysis. Outdoor exposure for at

G7 Practice for Atmospheric Environmental Exposure Test-

least two years is required to make evident changes, such as

ing of Nonmetallic Materials

surface degradation without the use of sophisticated analytical

equipment.

3.7 Temperature conditions attained with this box may not

These test methods are under the jurisdiction of ASTM Committee E44 on

exactly duplicate those that occur under operational conditions

Solar, Geothermal and Other Alternative Energy Sources and is the direct respon-

sibility of Subcommittee E44.05 on Solar Heating and Cooling Systems and with fluid flow. Dependent on environmental exposure

Materials.

conditions, the cover plate temperatures obtained with this box

Current edition approved March 1, 2007. Published April 2007. Originally

may be higher or lower than those obtained under operational

approved in 1981. Last previous edition approved in 2001 as E782 – 95 (2001).

conditions. Additional testing under stagnation conditions,

DOI: 10.1520/E0782-95R07.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

although not covered by this practice should be conducted.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on NOTE 1—Research has shown that exposure outdoors at sites having the

the ASTM website. combination of high levels of humidity, solar energy, and ambient

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E782 − 95 (2007)

temperature can cause more severe degradation of some polymeric cover

materials, (for example, microcracking and leaching of UV radiation

screening additives) than exposure in arid climates.

NOTE 2—Stagnation conditions are a normal occurrence for solar

collectors, for example, during operation when the storage is fully

charged; when the collectors are initially installed, before system start-up;

or when the system is shut down for maintenance or seasonal consider-

ations such as heating only systems in the summer.

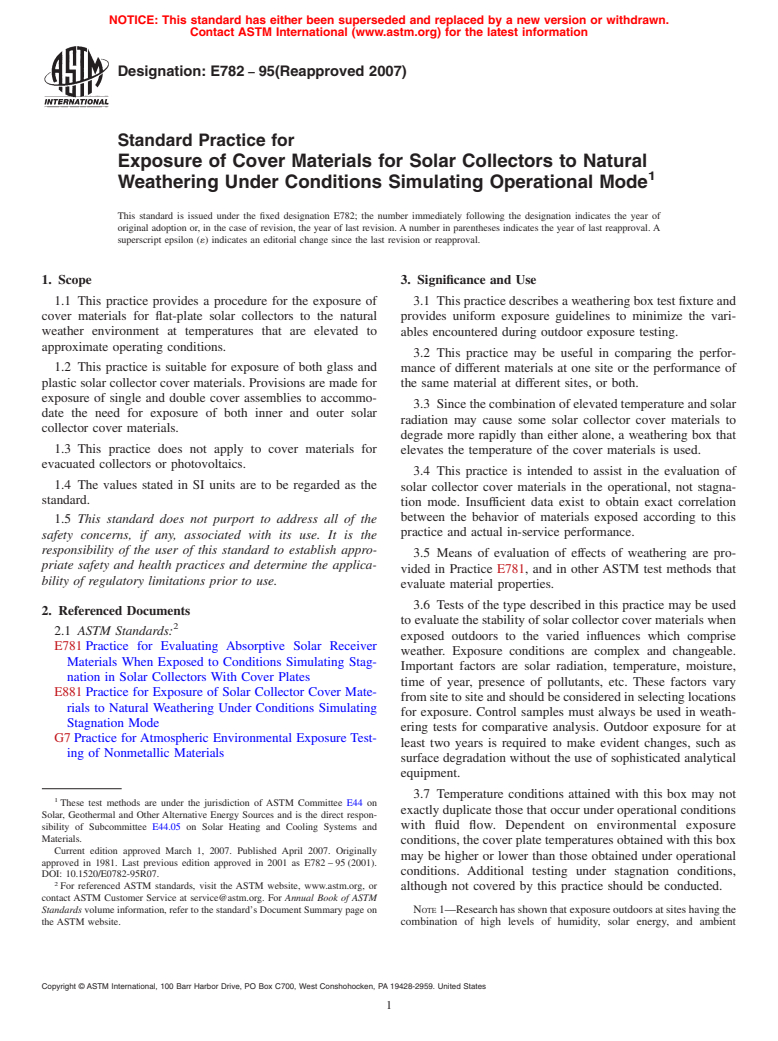

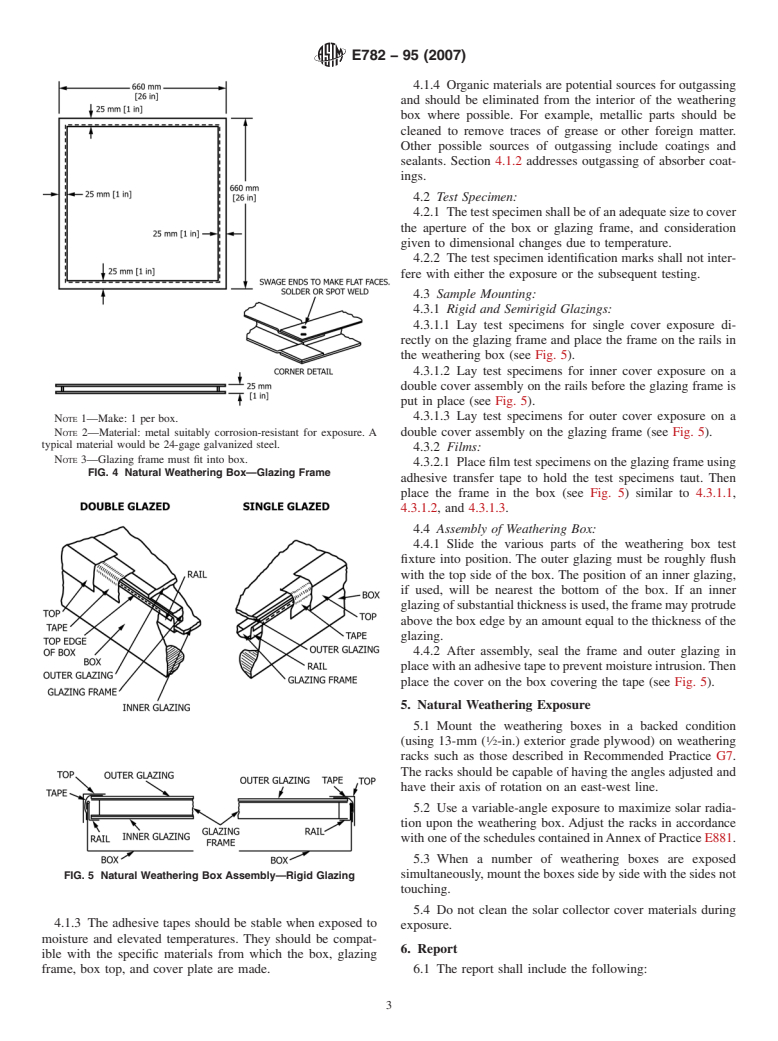

4. Weathering Box Test Fixture

4.1 Weathering Box Test Fixture, consisting of a box, rails,

a box top, a glazing frame, and adhesive tapes. The weathering

box test fixture should be constructed in accordance with Figs.

1-5.

4.1.1 The box and box top should be made in metal that is

suitably resistant to corrosion encountered in the exposure

environment.Aweep hole should be drilled at the lower end of

the bottom of the box to provide drainage and to minimize

moisture accumulation.

NOTE 3—The box top is intended to protect the edges of the test

specimen in contact with the box from reaching excessively high

temperatures, to minimize exposure of the adhesive to sunlight, and to

minimize moisture penetration into the exposure test fixture.

4.1.2 The box interior shall be a flat black nonselective

NOTE 1—Make: 4 per box.

coating having an absorptance of not less than 0.90 after

NOTE 2—Material: metal suitably corrosion-resistant for exposure. A

exposure. Organic absorber coatings should be heated in an

typical material would be 24-gage galvanized steel.

oven at 150°C (302°F) for 24 h before the test fixture is 1

NOTE 3—Dimension tolerance 61mm(6 ⁄16 in.).

asssembled. This should minimize outgassing, which results

FIG. 2 Natural Weathering Box—Rolls

NOTE 1—Make: 1 per box.

NOTE 2—Material: metal suit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.