ASTM B905-00(2010)

(Test Method)Standard Test Methods for Assessing the Adhesion of Metallic and Inorganic Coatings by the Mechanized Tape Test

Standard Test Methods for Assessing the Adhesion of Metallic and Inorganic Coatings by the Mechanized Tape Test

SIGNIFICANCE AND USE

If a coating is to fulfill its function of protecting or imparting unique properties to the surface of a substrate, it must adhere to the substrate for the expected service life. Because surface preparation (or lack of it) has a drastic effect on adhesion of coatings, a test method for evaluating adhesion to different surface treatments or of different coatings to the same treatment is of considerable use to the industry.

The limitations of all adhesion methods, and the specific limitation of this test method to lower levels of adhesion (see 1.3) should be recognized before using it. These test methods are mechanized adaptations of Test Methods D3359; therefore, the intra- and interlaboratory precision of these test methods are similar to Test Methods D3359 and to other widely-accepted tests for coated substrates, for example, Test Method D2370, but this is partly the result of it being insensitive to all but large differences in adhesion. The pass-fail scale of 0 to 5 for Method B1 and B2 was selected deliberately to avoid a false impression of being sensitive.

SCOPE

1.1 These test methods describe procedures for assessing the adhesion of metallic and inorganic coatings and other thin films to metallic and nonmetallic substrates. Assessment is made by applying pressure-sensitive tape to a coated surface and then utilizing a mechanical device to remove the tape at a regulated, uniform rate and constant angle while simultaneously recording the removal force.

1.2 Four methods are described. Methods A1 and A2 are intended primarily for use on parts. Methods B1 and B2 are intended primarily for use in laboratory evaluations. Methods B1 and B2 are not recommended for testing coatings and films on polymer substrates.

1.3 These test methods may be used to establish whether the adhesion of a coating to a substrate is within a required range (between a quantified low and a quantified high level). Determination of actual adhesive forces requires more sophisticated methods of measurement. In multilayer systems adhesion failure may occur between intermediate coating layers so that the adhesion of the total coating system to the substrate may not necessarily be determined.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B905 − 00(Reapproved 2010)

Standard Test Methods for

Assessing the Adhesion of Metallic and Inorganic Coatings

by the Mechanized Tape Test

This standard is issued under the fixed designation B905; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 These test methods describe procedures for assessing

B183 Practice for Preparation of Low-Carbon Steel for

the adhesion of metallic and inorganic coatings and other thin

Electroplating

films to metallic and nonmetallic substrates. Assessment is

B242 Guide for Preparation of High-Carbon Steel for Elec-

made by applying pressure-sensitive tape to a coated surface

troplating

and then utilizing a mechanical device to remove the tape at a

B252 Guide for Preparation of Zinc Alloy Die Castings for

regulated, uniform rate and constant angle while simultane-

Electroplating and Conversion Coatings

ously recording the removal force.

B253 Guide for Preparation of Aluminum Alloys for Elec-

1.2 Four methods are described. Methods A1 and A2 are troplating

intended primarily for use on parts. Methods B1 and B2 are B254 Practice for Preparation of and Electroplating on

Stainless Steel

intended primarily for use in laboratory evaluations. Methods

B281 Practice for Preparation of Copper and Copper-Base

B1 and B2 are not recommended for testing coatings and films

Alloys for Electroplating and Conversion Coatings

on polymer substrates.

B320 Practice for Preparation of Iron Castings for Electro-

1.3 Thesetestmethodsmaybeusedtoestablishwhetherthe

plating

adhesion of a coating to a substrate is within a required range

B343 Practice for Preparation of Nickel for Electroplating

(between a quantified low and a quantified high level). Deter-

with Nickel

mination of actual adhesive forces requires more sophisticated

B480 Guide for Preparation of Magnesium and Magnesium

methods of measurement. In multilayer systems adhesion

Alloys for Electroplating

failure may occur between intermediate coating layers so that

B481 Practice for Preparation of Titanium and Titanium

the adhesion of the total coating system to the substrate may

Alloys for Electroplating

not necessarily be determined. B482 Practice for Preparation of Tungsten and Tungsten

Alloys for Electroplating

1.4 The values stated in SI units are to be regarded as

B537 Practice for Rating of Electroplated Panels Subjected

standard. No other units of measurement are included in this

to Atmospheric Exposure

standard.

B538 Method of FACT (Ford Anodized Aluminum Corro-

1.5 This standard does not purport to address all of the sion Test) (Withdrawn 1986)

B629 Practice for Preparation of Molybdenum and Molyb-

safety concerns, if any, associated with its use. It is the

denum Alloys for Electroplating

responsibility of the user of this standard to establish appro-

B630 Practice for Preparation of Chromium for Electroplat-

priate safety and health practices and determine the applica-

ing with Chromium

bility of regulatory limitations prior to use.

B727 Practice for Preparation of Plastics Materials for Elec-

troplating

D1730 Practices for Preparation of Aluminum and

Aluminum-Alloy Surfaces for Painting

1 2

These test methods are under the jurisdiction of ASTM Committee B08 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Metallic and Inorganic Coatingsand are the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

B08.10 onTest Methods. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2010. Published June 2010. Originally the ASTM website.

approved in 2000. Last previous edition approved in 2005 as B905 – 00 (2005). The last approved version of this historical standard is referenced on

DOI: 10.1520/B0905-00R10. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B905 − 00 (2010)

D1731 Practices for Preparation of Hot-DipAluminum Sur- 5. Apparatus and Materials

faces for Painting

5.1 PeelTestFixture—Thefixtureshallconsistofaframeto

D1732 Practices for Preparation of Magnesium Alloy Sur-

which the specimen is rigidly clamped, and a moveable beam

faces for Painting

by which the tape is pulled off under a constant peel angle of

D2370 Test Method for Tensile Properties of Organic Coat-

90 (MethodA1 and B1) or 180° (MethodA2 and B2).The peel

ings

rate should be controllable between 20 mm/s and 200 mm/s for

D3330/D3330M TestMethodforPeelAdhesionofPressure-

Method A1 and B1 and between 14 mm/s and 140 mm/s for

Sensitive Tape

Methods A2 and B2. A recording force gage is fitted between

D3359 Test Methods for Measuring Adhesion by Tape Test

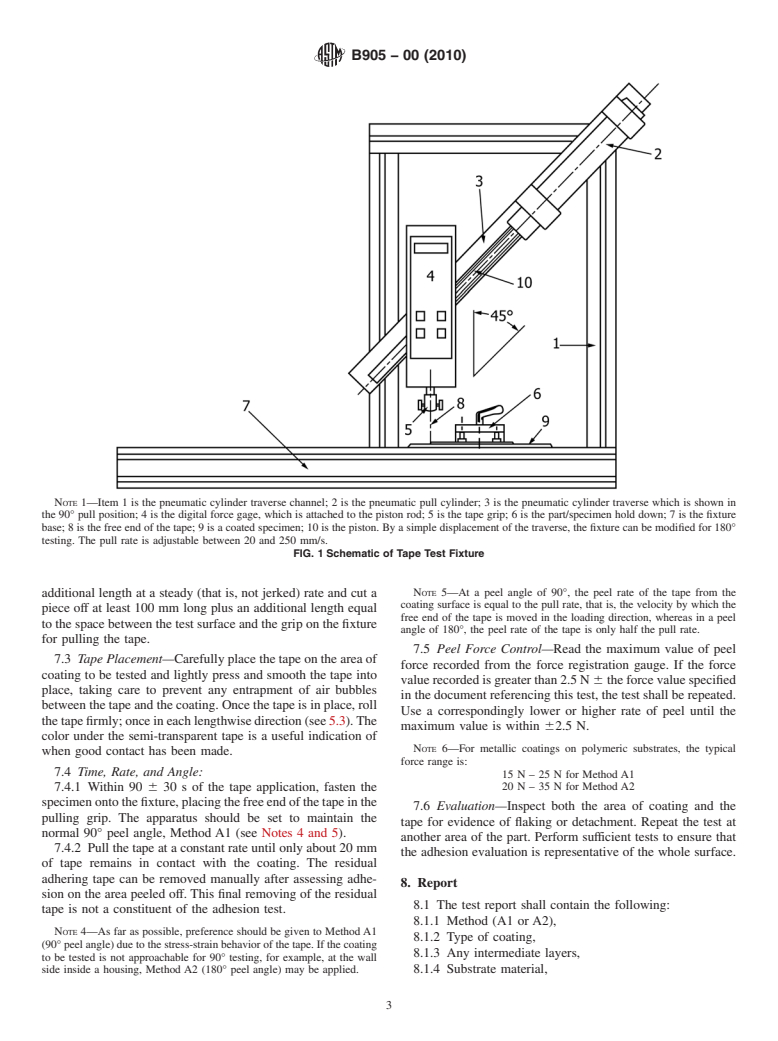

the tape grip and the movable beam (see Fig. 1).

5.2 Pressure-Sensitive Tape—Unless otherwise specified in

3. Summary of Test Method

the document referencing this test, the tape shall be 25 mm

3.1 Pressure-sensitive tape is adhered to the surface of the

wide,semitransparent,pressure-sensitivetapewithanadhesion

coating and then removed utilizing a motorized mechanical

strength of 43 6 5.6 g/mm or N/100 mm width when tested in

device that peels the tape at a constantly maintained angle and

accordance with D3330/D3330M. The adhesion shall not

controlled rate of peel.Adigital recording force gage is used to

change by more than + 6.5 % of its mean value within 12

record the maximum peel force.

months.Thebackingofthetapemayconsistoffiber-reinforced

cellulose acetate, unplasticized poly (vinyl chloride), or poly-

NOTE 1—All due care must be taken to ensure that test specimens are

ester film. When results obtained in different laboratories do

handled and stored such that they are not subjected to conditions that will

notagreeitisrecommendedthatthetestberepeatedusingtape

cause deleterious effects. These conditions include but are not limited to

handling without the use of gloves, storing in areas that accumulate dust,

from the same batch.

areas of high humidity or where the sample may be subjected to fumes or

5.3 Roller—The roller, which is hand operated, consists of

vapors that might condense on the sample.

a steel roller 85 6 2.5 mm in diameter and 45 6 1.5 mm in

3.2 Methods A1 and A2:

width, covered with rubber approximately 6 mm in thickness,

3.2.1 In these methods, which are nondestructive, the mea-

having a Shore scale A durometer hardness of 80 6 5. The

surement area used is the unbroken coating surface with peel

surfaceoftherollershallbeatruecylindervoidofanyconcave

angles of 90 and 180° respectively.

orconvexdeviations.Themassoftherollershallbe2040 645

3.2.2 Adhesion is assessed in terms of “passed,” if the

g.

coating does not detach, or “failed,” if the coating detaches

NOTE 2—A standardized roller is used in place of the pencil eraser of

within the specified range of peel forces as recorded during the

Test Methods D3359 because of the variety of rubber and abrasives

test.

formulations used to make pencil erasers.Afurther consideration was the

extended range of localized pressures that could be exerted by the pencil

3.3 Methods B1 and B2:

and eraser.

3.3.1 In these methods, which are destructive, the measure-

ment area used is a broken coating surface created by scoring

TEST METHOD A

alatticepatternthroughthecoatingtothesubstrateandpeeling

NONDESTRUCTIVE, PARTS TAPE TEST

at angles of 90 and 180°, respectively.

3.3.2 Adhesion is assessed qualitatively on the 0 to 5 scale.

6. Test Specimen

6.1 Parts—This test normally is performed on parts. Any

4. Significance and Use

requirements for test specimens will be found in the document

4.1 If a coating is to fulfill its function of protecting or specifying their use.

imparting unique properties to the surface of a substrate, it

NOTE 3—When specified by the document referencing this test, the

must adhere to the substrate for the expected service life.

coated parts shall be subjected to a preliminary exposure, such as water

Because surface preparation (or lack of it) has a drastic effect immersion, salt spray, or humidity, before conducting the tape test.

on adhesion of coatings, a test method for evaluating adhesion

7. Procedure

to different surface treatments or of different coatings to the

7.1 Test Area—Select a flat area, on a significant surface,

same treatment is of considerable use to the industry.

free of blemishes and minor surface imperfections. Ensure that

4.2 The limitations of all adhesion methods, and the specific

the surface is clean and dry. Extremes in temperature or

limitation of this test method to lower levels of adhesion (see

relative humidity may affect the adhesion of the tape or the

1.3) should be recognized before using it. These test methods

coating.

are mechanized adaptations of Test Methods D3359; therefore,

7.2 Tape Section—Remove two complete laps of the

the intra- and interlaboratory precision of these test methods

pressure-sensitive tape from the roll and discard. Remove an

are similar to Test Methods D3359 and to other widely-

accepted tests for coated substrates, for example, Test Method

The sole source of supply of the apparatus known to the committee at this time

D2370, but this is partly the result of it being insensitive to all

is Pressure-Sensitive Tape Council (PSTC), 104 Wilmot Rd., Suite 201, Deerfield,

but large differences in adhesion. The pass-fail scale of 0 to 5

IL 60015. If you are aware of alternative suppliers, please provide this information

for Method B1 and B2 was selected deliberately to avoid a

to ASTM International Headquarters. Your comments will receive careful consid-

false impression of being sensitive. eration at a meeting of the responsible technical committee, which you may attend.

B905 − 00 (2010)

NOTE 1—Item 1 is the pneumatic cylinder traverse channel; 2 is the pneumatic pull cylinder; 3 is the pneumatic cylinder traverse which is shown in

the 90° pull position; 4 is the digital force gage, which is attached to the piston rod; 5 is the tape grip; 6 is the part/specimen hold down; 7 is the fixture

base; 8 is the free end of the tape; 9 is a coated specimen; 10 is the piston. By a simple displacement of the traverse, the fixture can be modified for 180°

testing. The pull rate is adjustable between 20 and 250 mm/s.

FIG. 1 Schematic of Tape Test Fixture

NOTE 5—At a peel angle of 90°, the peel rate of the tape from the

additional length at a steady (that is, not jerked) rate and cut a

coating surface is equal to the pull rate, that is, the velocity by which the

piece off at least 100 mm long plus an additional length equal

free end of the tape is moved in the loading direction, whereas in a pe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.