ASTM D3364-99(2011)

(Test Method)Standard Test Method for Flow Rates for Poly(Vinyl Chloride) with Molecular Structural Implications

Standard Test Method for Flow Rates for Poly(Vinyl Chloride) with Molecular Structural Implications

SIGNIFICANCE AND USE

This test method is useful for quality-control tests on PVC compounds having a wide range of melt viscosities. Measurements are made at shear rates close to 1 s−1.

In addition to the properties mentioned in Test Method D1238, this technique is sensitive to plasticizer content, polymer molecular weight, polymer stability (both thermally and rheologically), shear instability, and general composition. The sensitivity of the material to temperature necessitates slightly tighter controls than those stated in Test Method D1238.

The sensitivity of this test method makes it useful for correlating with processing conditions and as an aid in predicting changes in processing. However, as a one-point measure of flow relative to shear rate, its one drawback is that the same PVC melt flow values can be obtained for materials having different processibility; the chance of this happening is minimized, however, if the compounds are similar in composition.

Correlations with a wide range of processing conditions have supported the conclusions that little or no change in composition occurs during the test. Thus, this test is able to detect and follow profound changes which occur during extrusion, injection molding, milling, or mixing. These changes are due to three types of measured instability in polymers:

Thermal instability due to temperature effect.

Shear instability due to breaking of polymer bonds.

Rheological instability due to nonuniform distributions of widely different viscosity or molecular weight elements.

Thus, implications with respect to PVC molecular structural changes can be detected and predicted.

SCOPE

1.1 This test method is an extension of Test Method D1238 specific to the measurement of flow rates of poly(vinyl chloride) (PVC) compounds while detecting and controlling various polymer instabilities associated with the flow rate.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no known ISO equivalent to this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3364 − 99 (Reapproved 2011)

Standard Test Method for

Flow Rates for Poly(Vinyl Chloride) with Molecular

Structural Implications

This standard is issued under the fixed designation D3364; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 See Test Method D3835, Sections 5.1, 5.2, and 5.3.

3.2.2 Flow is the reciprocal of the viscosity; therefore, the

1.1 This test method is an extension of Test Method D1238

flow is defined as the volumetric displacement through a

specific to the measurement of flow rates of poly(vinyl

controlled orifice and is expressed as shear rate over shear

chloride) (PVC) compounds while detecting and controlling

stress.

various polymer instabilities associated with the flow rate.

1.2 The values stated in SI units are to be regarded as NOTE 2—Since PVC obeys the power law function, the above relation-

ship can be expressed as follows:

standard. The values given in parentheses are mathematical

1−N

(Viscosity) (Shear Rate) =(shear stress) in which the shear rate is

conversions to inch-pound units that are provided for informa-

expressed as 4Q/πR and depends on the power law exponent N.

tion only and are not considered standard.

Since Qisthevolumetricflowrateintermsofcubicmillimetres/second

and R is the radius of the die, it follows that the flow rate varies much

1.3 This standard does not purport to address all of the

faster than the viscosity as a result of N.This means that the flow is much

safety concerns, if any, associated with its use. It is the

more sensitive to change than the viscosity. For PVC, N varies from 0.1

responsibility of the user of this standard to establish appro-

to 0.33.

priate safety and health practices and determine the applica-

3.2.3 Flow rate by this test method is the rate in milligrams/

bility of regulatory limitations prior to use.

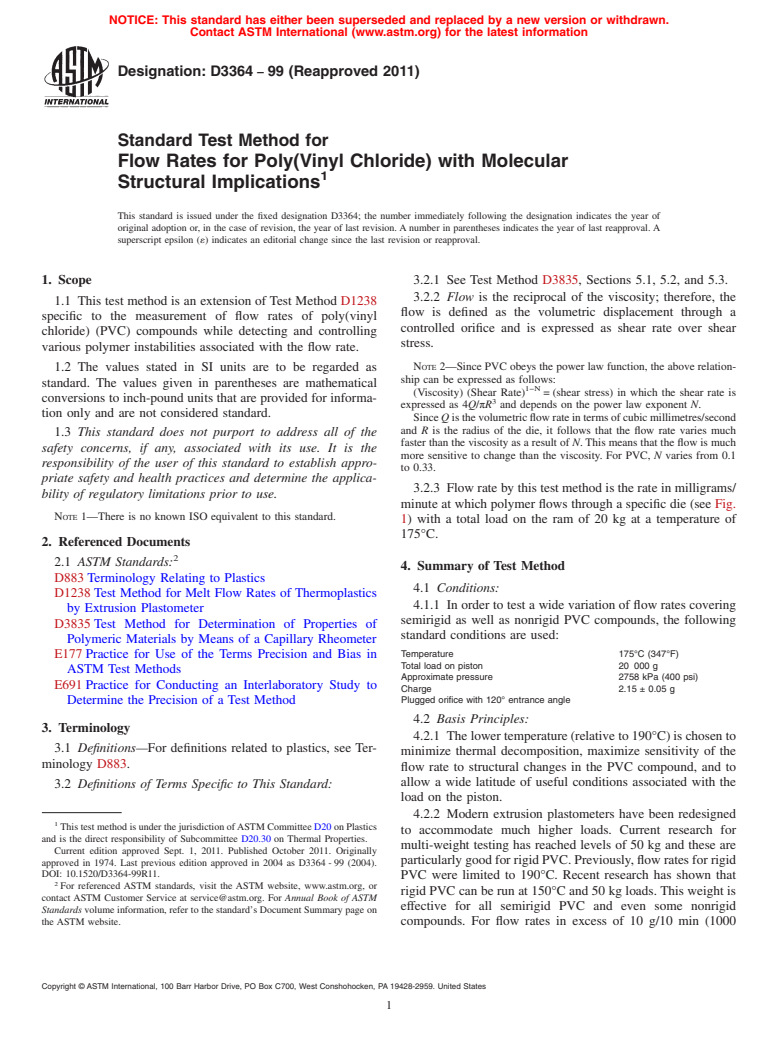

minute at which polymer flows through a specific die (see Fig.

NOTE 1—There is no known ISO equivalent to this standard.

1) with a total load on the ram of 20 kg at a temperature of

175°C.

2. Referenced Documents

2.1 ASTM Standards:

4. Summary of Test Method

D883Terminology Relating to Plastics

4.1 Conditions:

D1238Test Method for Melt Flow Rates of Thermoplastics

4.1.1 In order to test a wide variation of flow rates covering

by Extrusion Plastometer

semirigid as well as nonrigid PVC compounds, the following

D3835Test Method for Determination of Properties of

standard conditions are used:

Polymeric Materials by Means of a Capillary Rheometer

Temperature 175°C (347°F)

E177Practice for Use of the Terms Precision and Bias in

Total load on piston 20 000 g

ASTM Test Methods

Approximate pressure 2758 kPa (400 psi)

E691Practice for Conducting an Interlaboratory Study to

Charge 2.15 ± 0.05 g

Plugged orifice with 120° entrance angle

Determine the Precision of a Test Method

4.2 Basis Principles:

3. Terminology

4.2.1 Thelowertemperature(relativeto190°C)ischosento

3.1 Definitions—For definitions related to plastics, see Ter-

minimize thermal decomposition, maximize sensitivity of the

minology D883.

flow rate to structural changes in the PVC compound, and to

allow a wide latitude of useful conditions associated with the

3.2 Definitions of Terms Specific to This Standard:

load on the piston.

4.2.2 Modern extrusion plastometers have been redesigned

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

to accommodate much higher loads. Current research for

and is the direct responsibility of Subcommittee D20.30 on Thermal Properties.

multi-weight testing has reached levels of 50 kg and these are

Current edition approved Sept. 1, 2011. Published October 2011. Originally

particularlygoodforrigidPVC.Previously,flowratesforrigid

approved in 1974. Last previous edition approved in 2004 as D3364-99 (2004).

DOI: 10.1520/D3364-99R11.

PVC were limited to 190°C. Recent research has shown that

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

rigid PVC can be run at 150°C and 50 kg loads.This weight is

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

effective for all semirigid PVC and even some nonrigid

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. compounds. For flow rates in excess of 10 g/10 min (1000

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3364 − 99 (2011)

NOTE 1—Specify material when ordering.

FIG. 1 Die Used for Test Method D3364

mg/min), lower weights are used, for example, color concen- 5.4 Correlations with a wide range of processing conditions

trates used in PVC extrusion may have flow rates in excess of have supported the conclusions that little or no change in

100g/10min(10 000mg/min)andwillrequirea5-kgloadon composition occurs during the test. Thus, this test is able to

the piston. detect and follow profound changes which occur during

4.2.3 When the flow rates become very small as in the case extrusion, injection molding, milling, or mixing. These

of the stiffest semirigid containing 25 parts of plasticizer (flow changes are due to three types of measured instability in

rates below 15 mg/min), it may be desirable to use the die (flat polymers:

entry 8 mm (0.315 in.) long) in Test Method D1238. The flow 5.4.1 Thermal instability due to temperature effect.

is so slow that little rheological instability exists. By changing 5.4.2 Shear instability due to breaking of polymer bonds.

the die, approximately a tenfold increase in flow is achieved. 5.4.3 Rheological instability due to nonuniform distribu-

4.2.4 The charge size is important. Many PVC compounds tions of widely different viscosity or molecular weight ele-

are elastic in nature, causing a severe loss in pressure from the ments.

bottom of the piston through the material to the orifice of the 5.4.4 Thus, implications with respect to PVC molecular

die. Evidence indicates that the force to extrude may be structural changes can be detected and predicted.

reduced by as much as 67% using a 9-g charge and 4.14 MPa

(600 psi) on the piston. 6. Apparatus

4.2.5 The plugged orifice should be used in all PVC

6.1 Plastometer—The apparatus is identical to that used in

compound work since the amount of charge is limited and

Test Method D1238 except for the die.An alternative thermo-

since the plugging for various times has been observed to give

regulator is suggested for improved temperature control.

significant variations in the flow rate.

6.2 Die:

6.2.1 Thedieisapproximatelythreetimesaslongastheone

5. Significance and Use

used in Test Method D1238, a major factor in controlling any

5.1 This test method is useful for quality-control tests on

rheological instability in the polymer. If instability still occurs,

PVC compounds having a wide range of melt viscosities.

particularly at high flow rates, dies 2 in. or longer can be used

−1

Measurements are made at shear rates close to 1 s .

toimprovethe L/Dratio.Thedimensionsoftheregulardieare

5.2 In addition to the properties mentioned in Test Method

shown in Fig. 1.

D1238, this technique is sensitive to plasticizer content,

6.3 Thermoregulator—Although a thermoregulator identi-

polymer molecular weight, polymer stability (both thermally

cal to that used in Test Method D1238 may be used (provided

and rheologically), shear instability, and general composition.

it regulates to 175 6 0.1°C), a unit coupled with a 90° angle

The sensitivity of the material to temperature necessitates

thermometer, divided into 0.1°C is suggested for improved

slightly tighter controls than those stated in Test Method

reproducibility. Most regulators designed for Test Method

D1238.

D1238 cannot control better than 60.2°C. The sensitivity of

5.3 The sensitivity of this test method makes it useful for

this test method is illustrated by the fact that a 19% change in

correlating with processing conditions and as an aid in predict-

flow rate is observed on a typical PVC compound with a 1°C

ingchangesinprocessing.However,asaone-pointmeasureof

change in temperatures.

flow relative to shear rate, its one drawback is that the same

PVC melt flow values can be obtained for materials having

different processibility; the chance of this happening is

The “Thermo Watch” unit, manufactured by Instruments for Research and

minimized, however, if the compounds are similar in compo-

Industry, 103 FranklinAve., Cheltenham, PA19012, has been found satisfactory for

sition. this purpose.

D3364 − 99 (2011)

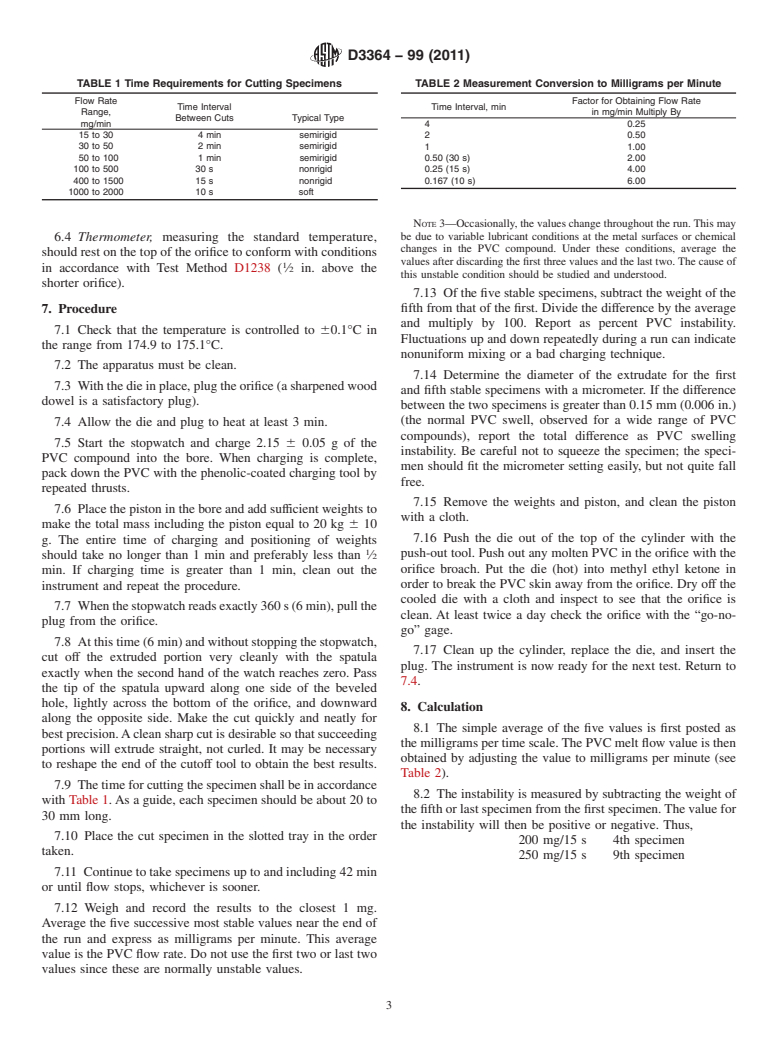

TABLE 1 Time Requirements for Cutting Specimens TABLE 2 Measurement Conversion to Milligrams per Minute

Flow Rate Factor for Obtaining Flow Rate

Time Interval Time Interval, min

Range, in mg/min Multiply By

Between Cuts Typical Type

mg/min 4 0.25

15 to 30 4 min semirigid 2 0.50

30 to 50 2 min semirigid 1 1.00

50 to 100 1 min semirigid

0.50 (30 s) 2.00

100 to 500 30 s nonrigid 0.25 (15 s) 4.00

400 to 1500 15 s nonrigid 0.167 (10 s) 6.00

1000 to 2000 10 s soft

NOTE3—Occasionally,thevalueschangethroughouttherun.Thismay

be due to variable lubricant conditions at the metal surfaces or chemical

6.4 Thermometer, measuring the standard temperature,

changes in the PVC compound. Under these conditions, average the

should rest on the top of the orifice

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.