ASTM D5607-08

(Test Method)Standard Test Method for Performing Laboratory Direct Shear Strength Tests of Rock Specimens Under Constant Normal Force

Standard Test Method for Performing Laboratory Direct Shear Strength Tests of Rock Specimens Under Constant Normal Force

SIGNIFICANCE AND USE

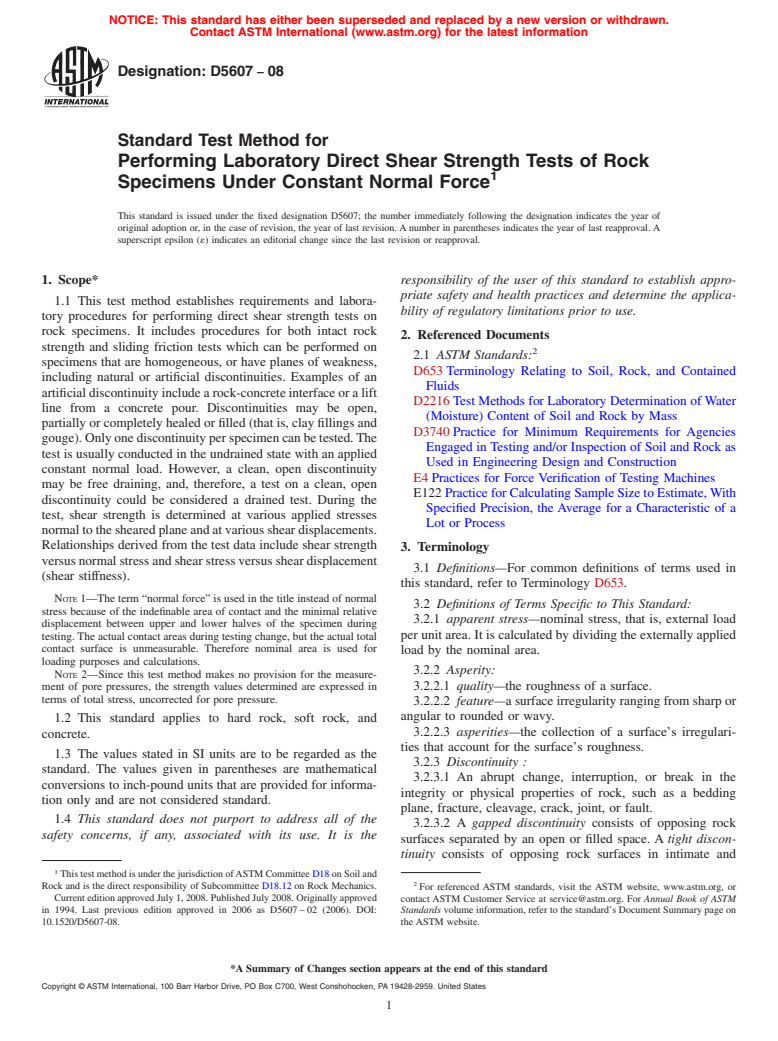

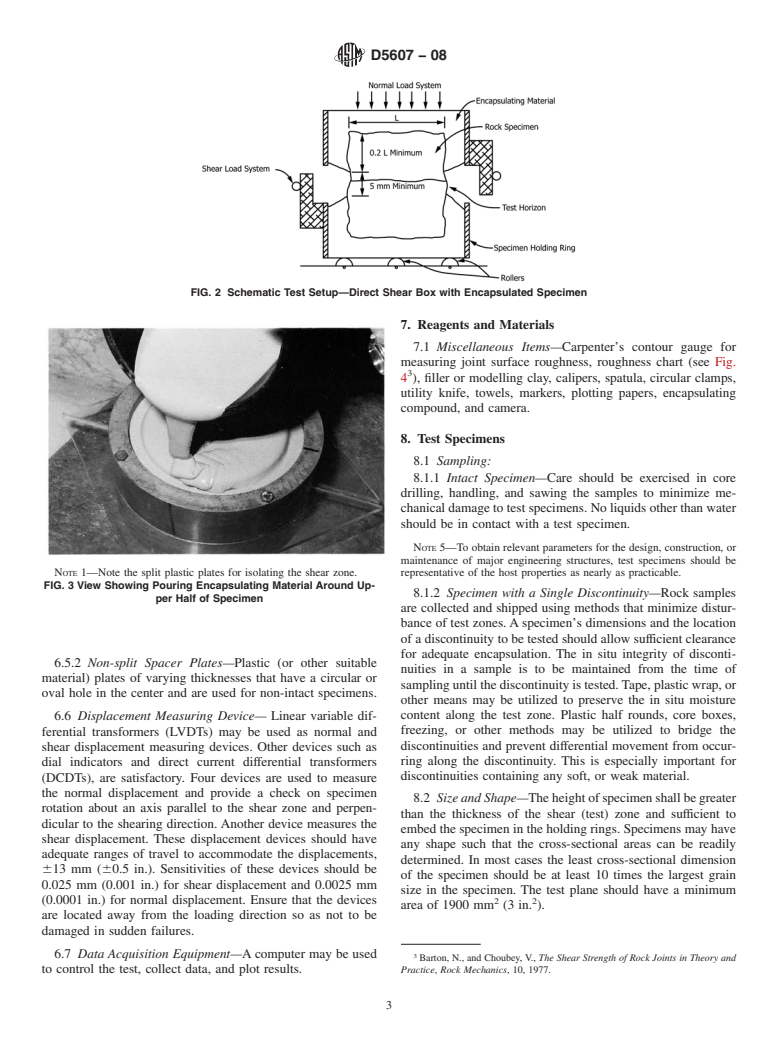

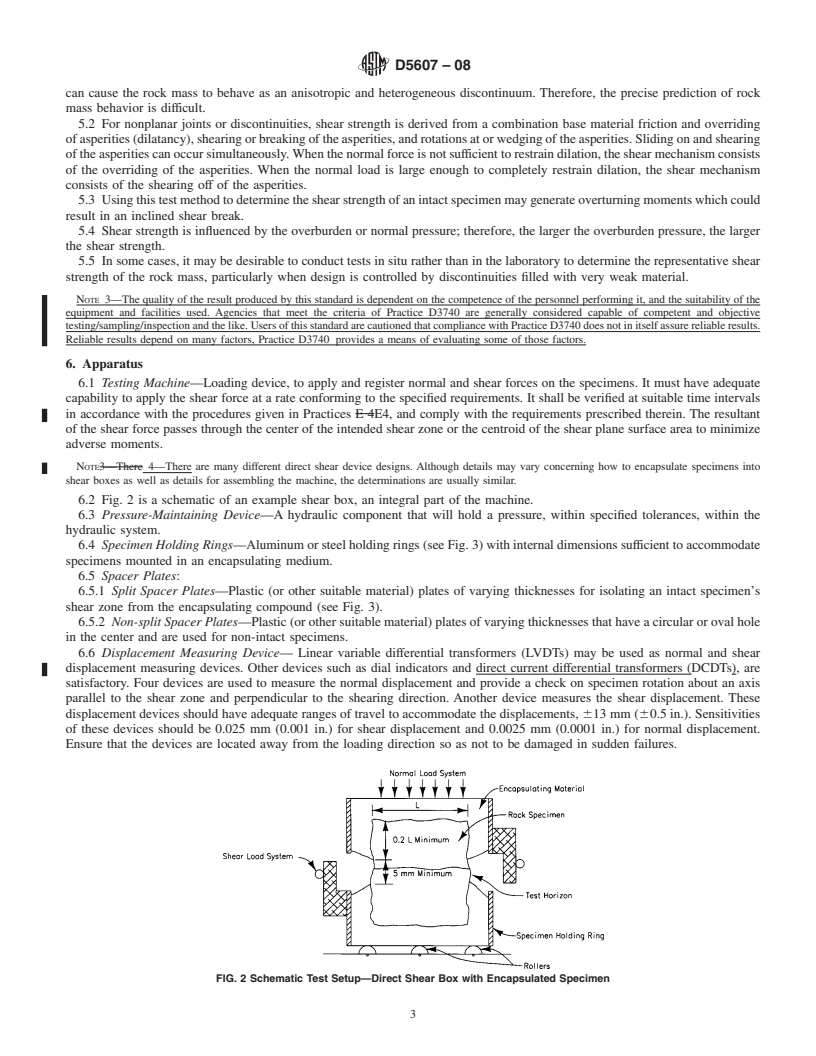

Determination of shear strength of a rock specimen is an important aspect in the design of structures such as rock slopes, dam foundations, tunnels, shafts, waste repositories, caverns for storage, and other purposes. Pervasive discontinuities (joints, bedding planes, shear zones, fault zones, schistosity) in a rock mass, and genesis, crystallography, texture, fabric, and other factors can cause the rock mass to behave as an anisotropic and heterogeneous discontinuum. Therefore, the precise prediction of rock mass behavior is difficult.

For nonplanar joints or discontinuities, shear strength is derived from a combination base material friction and overriding of asperities (dilatancy), shearing or breaking of the asperities, and rotations at or wedging of the asperities. Sliding on and shearing of the asperities can occur simultaneously. When the normal force is not sufficient to restrain dilation, the shear mechanism consists of the overriding of the asperities. When the normal load is large enough to completely restrain dilation, the shear mechanism consists of the shearing off of the asperities.

Using this test method to determine the shear strength of an intact specimen may generate overturning moments which could result in an inclined shear break.

Shear strength is influenced by the overburden or normal pressure; therefore, the larger the overburden pressure, the larger the shear strength.

In some cases, it may be desirable to conduct tests in situ rather than in the laboratory to determine the representative shear strength of the rock mass, particularly when design is controlled by discontinuities filled with very weak material.

Note 3—The quality of the result produced by this standard is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D 3740 are generally considered capable of competent and objective testing/sampling/inspection and the ...

SCOPE

1.1 This test method establishes requirements and laboratory procedures for performing direct shear strength tests on rock specimens. It includes procedures for both intact rock strength and sliding friction tests which can be performed on specimens that are homogeneous, or have planes of weakness, including natural or artificial discontinuities. Examples of an artificial discontinuity include a rock-concrete interface or a lift line from a concrete pour. Discontinuities may be open, partially or completely healed or filled (that is, clay fillings and gouge). Only one discontinuity per specimen can be tested. The test is usually conducted in the undrained state with an applied constant normal load. However, a clean, open discontinuity may be free draining, and, therefore, a test on a clean, open discontinuity could be considered a drained test. During the test, shear strength is determined at various applied stresses normal to the sheared plane and at various shear displacements. Relationships derived from the test data include shear strength versus normal stress and shear stress versus shear displacement (shear stiffness).

Note 1—The term “normal force” is used in the title instead of normal stress because of the indefinable area of contact and the minimal relative displacement between upper and lower halves of the specimen during testing. The actual contact areas during testing change, but the actual total contact surface is unmeasurable. Therefore nominal area is used for loading purposes and calculations.

Note 2—Since this test method makes no provision for the measurement of pore pressures, the strength values determined are expressed in terms of total stress, uncorrected for pore pressure.

1.2 This standard applies to hard rock, soft rock, and concrete.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are mathematical conversions to inch-pound units t...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5607 − 08

Standard Test Method for

Performing Laboratory Direct Shear Strength Tests of Rock

1

Specimens Under Constant Normal Force

This standard is issued under the fixed designation D5607; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 This test method establishes requirements and labora-

bility of regulatory limitations prior to use.

tory procedures for performing direct shear strength tests on

rock specimens. It includes procedures for both intact rock

2. Referenced Documents

strength and sliding friction tests which can be performed on

2

2.1 ASTM Standards:

specimens that are homogeneous, or have planes of weakness,

D653 Terminology Relating to Soil, Rock, and Contained

including natural or artificial discontinuities. Examples of an

Fluids

artificialdiscontinuityincludearock-concreteinterfaceoralift

D2216 Test Methods for Laboratory Determination of Water

line from a concrete pour. Discontinuities may be open,

(Moisture) Content of Soil and Rock by Mass

partially or completely healed or filled (that is, clay fillings and

D3740 Practice for Minimum Requirements for Agencies

gouge).Onlyonediscontinuityperspecimencanbetested.The

Engaged in Testing and/or Inspection of Soil and Rock as

test is usually conducted in the undrained state with an applied

Used in Engineering Design and Construction

constant normal load. However, a clean, open discontinuity

E4 Practices for Force Verification of Testing Machines

may be free draining, and, therefore, a test on a clean, open

E122 Practice for Calculating Sample Size to Estimate,With

discontinuity could be considered a drained test. During the

Specified Precision, the Average for a Characteristic of a

test, shear strength is determined at various applied stresses

Lot or Process

normaltotheshearedplaneandatvarioussheardisplacements.

Relationships derived from the test data include shear strength

3. Terminology

versusnormalstressandshearstressversussheardisplacement

3.1 Definitions—For common definitions of terms used in

(shear stiffness).

this standard, refer to Terminology D653.

NOTE 1—The term “normal force” is used in the title instead of normal

3.2 Definitions of Terms Specific to This Standard:

stress because of the indefinable area of contact and the minimal relative

3.2.1 apparent stress—nominal stress, that is, external load

displacement between upper and lower halves of the specimen during

per unit area. It is calculated by dividing the externally applied

testing. The actual contact areas during testing change, but the actual total

contact surface is unmeasurable. Therefore nominal area is used for

load by the nominal area.

loading purposes and calculations.

3.2.2 Asperity:

NOTE 2—Since this test method makes no provision for the measure-

3.2.2.1 quality—the roughness of a surface.

ment of pore pressures, the strength values determined are expressed in

terms of total stress, uncorrected for pore pressure.

3.2.2.2 feature—a surface irregularity ranging from sharp or

angular to rounded or wavy.

1.2 This standard applies to hard rock, soft rock, and

3.2.2.3 asperities—the collection of a surface’s irregulari-

concrete.

ties that account for the surface’s roughness.

1.3 The values stated in SI units are to be regarded as the

3.2.3 Discontinuity :

standard. The values given in parentheses are mathematical

3.2.3.1 An abrupt change, interruption, or break in the

conversions to inch-pound units that are provided for informa-

integrity or physical properties of rock, such as a bedding

tion only and are not considered standard.

plane, fracture, cleavage, crack, joint, or fault.

1.4 This standard does not purport to address all of the

3.2.3.2 A gapped discontinuity consists of opposing rock

safety concerns, if any, associated with its use. It is the

surfaces separated by an open or filled space. A tight discon-

tinuity consists of opposing rock surfaces in intimate and

1

This test method is under the jurisdiction ofASTM Committee D18 on Soil and

2

Rock and is the direct responsibility of Subcommittee D18.12 on Rock Mechanics. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2008. Published July 2008. Originally approved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 1994. Last previous edition approved in 2006 as D5607 – 02 (2006). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D5607-08. t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D 5607–95 Designation: D5607 – 08

Standard Test Method for

Performing Laboratory Direct Shear Strength Tests of Rock

1

Specimens Under Constant Normal Force

This standard is issued under the fixed designation D5607; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method establishes requirements and laboratory procedures for performing direct shear strength tests on rock

specimens. It includes procedures for both intact rock strength and sliding friction tests which can be performed on specimens that

are homogeneous, or have planes of weakness, including natural or artificial discontinuities. Examples of an artificial discontinuity

include a rock-concrete interface or a lift line from a concrete pour. Discontinuities may be open, partially or completely healed

or filled (that is, clay fillings and gouge). Only one discontinuity per specimen can be tested. The test is usually conducted in the

undrained state with an applied constant normal load. However, a clean, open discontinuity may be free draining, and, therefore,

a test on a clean, open discontinuity could be considered a drained test. During the test, shear strength is determined at various

applied stresses normal to the sheared plane and at various shear displacements. Relationships derived from the test data include

shear strength versus normal stress and shear stress versus shear displacement (shear stiffness).

NOTE 1—The term “normal force” is used in the title instead of normal stress because of the indefinable area of contact and the minimal relative

displacement between upper and lower halves of the specimen during testing. The actual contact areas during testing change, but the actual total contact

surface is unmeasurable. Therefore nominal area is used for loading purposes and calculations.

NOTE 2—Since this test method makes no provision for the measurement of pore pressures, the strength values determined are expressed in terms of

total stress, uncorrected for pore pressure.

1.2 This standard applies to hard rock, soft rock, and concrete.

1.3

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are mathematical

conversions to inch-pound units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D653 Terminology Relating to Soil, Rock, and Contained Fluids

D2216 Test Methods for Laboratory Determination of Water (Moisture) Content of Soil and Rock by Mass

D3740 Practice for Minimum Requirements for Agencies Engaged in Testing and/or Inspection of Soil and Rock as Used in

Engineering Design and Construction

E4 Practices for LoadForce Verification of Testing Machines

E122Practice for Choice of Sample Size to Estimate the Average Quality of a Lot or Process

D2216Test Method for Laboratory Determination of Water (Moisture) Content of Soil and Rock 122 Practice for Calculating

Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or Process

3. Terminology

3.1

3.1 Definitions: For common definitions of terms used in this standard, refer to Terminology D653.

3.2 Definitions of Terms Specific to This Standard:

1

This test method is under the jurisdiction ofASTM Committee D-18D18 on Soil and Rock and is the direct responsibility of Subcommittee D18.12 on Rock Mechanics.

Current edition approved Dec. 10, 1995. Published April 1996. Originally published as D 5607–94. Last previous edition D 5607–94.

Current edition approved July 1, 2008. Published July 2008. Originally approved in 1994. Last previous edition approved in 2006 as D5607 – 02 (2006). DOI:

10.1520/D5607-08.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 03.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.