ASTM D5936-96

(Specification)Specification for Multipurpose Test Specimens (Withdrawn 1998)

Specification for Multipurpose Test Specimens (Withdrawn 1998)

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5936 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

1

Multipurpose Test Specimens Used for Testing Plastics

This standard is issued under the fixed designation D 5936; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

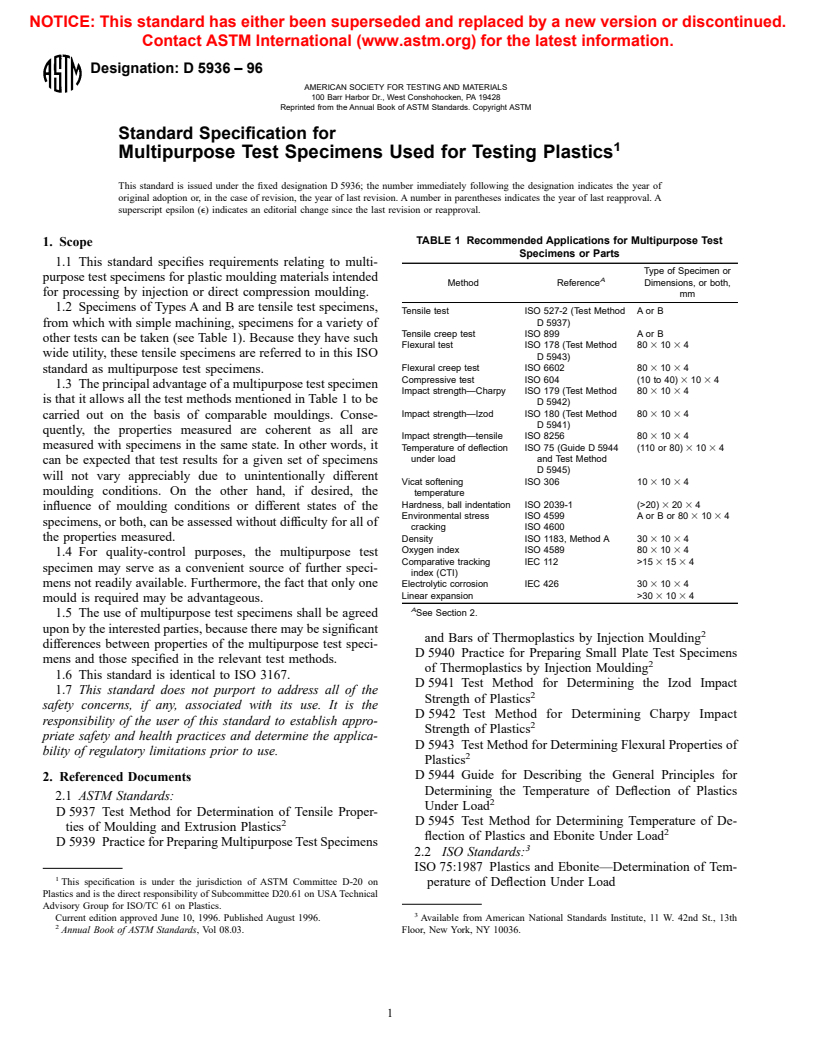

TABLE 1 Recommended Applications for Multipurpose Test

1. Scope

Specimens or Parts

1.1 This standard specifies requirements relating to multi-

Type of Specimen or

purpose test specimens for plastic moulding materials intended

A

Method Reference Dimensions, or both,

for processing by injection or direct compression moulding. mm

1.2 Specimens of Types A and B are tensile test specimens,

Tensile test ISO 527-2 (Test Method Aor B

D 5937)

from which with simple machining, specimens for a variety of

Tensile creep test ISO 899 A or B

other tests can be taken (see Table 1). Because they have such

Flexural test ISO 178 (Test Method 80 3 10 3 4

wide utility, these tensile specimens are referred to in this ISO

D 5943)

Flexural creep test ISO 6602 80 3 10 3 4

standard as multipurpose test specimens.

Compressive test ISO 604 (10 to 40) 3 10 3 4

1.3 The principal advantage of a multipurpose test specimen

Impact strength—Charpy ISO 179 (Test Method 80 3 10 3 4

is that it allows all the test methods mentioned in Table 1 to be

D 5942)

Impact strength—Izod ISO 180 (Test Method 80 3 10 3 4

carried out on the basis of comparable mouldings. Conse-

D 5941)

quently, the properties measured are coherent as all are

Impact strength—tensile ISO 8256 80 3 10 3 4

measured with specimens in the same state. In other words, it

Temperature of deflection ISO 75 (Guide D 5944 (110 or 80) 3 10 3 4

under load and Test Method

can be expected that test results for a given set of specimens

D 5945)

will not vary appreciably due to unintentionally different

Vicat softening ISO 306 10 3 10 3 4

moulding conditions. On the other hand, if desired, the

temperature

Hardness, ball indentation ISO 2039-1 (>20) 3 20 3 4

influence of moulding conditions or different states of the

Environmental stress ISO 4599 AorBor80 3 10 3 4

specimens, or both, can be assessed without difficulty for all of

cracking ISO 4600

the properties measured.

Density ISO 1183, Method A 30 3 10 3 4

Oxygen index ISO 4589 80 3 10 3 4

1.4 For quality-control purposes, the multipurpose test

Comparative tracking IEC 112 >15 3 15 3 4

specimen may serve as a convenient source of further speci-

index (CTI)

mens not readily available. Furthermore, the fact that only one Electrolytic corrosion IEC 426 30 3 10 3 4

Linear expansion >30 3 10 3 4

mould is required may be advantageous.

A

See Section 2.

1.5 The use of multipurpose test specimens shall be agreed

upon by the interested parties, because there may be significant

2

and Bars of Thermoplastics by Injection Moulding

differences between properties of the multipurpose test speci-

D 5940 Practice for Preparing Small Plate Test Specimens

mens and those specified in the relevant test methods.

2

of Thermoplastics by Injection Moulding

1.6 This standard is identical to ISO 3167.

D 5941 Test Method for Determining the Izod Impact

1.7 This standard does not purport to address all of the

2

Strength of Plastics

safety concerns, if any, associated with its use. It is the

D 5942 Test Method for Determining Charpy Impact

responsibility of the user of this standard to establish appro-

2

Strength of Plastics

priate safety and health practices and determine the applica-

D 5943 Test Method for Determining Flexural Properties of

bility of regulatory limitations prior to use.

2

Plastics

D 5944 Guide for Describing the General Principles for

2. Referenced Documents

Determining the Temperature of Deflection of Plastics

2.1 ASTM Standards:

2

Under Load

D 5937 Test Method for Determination of Tensile Proper-

D 5945 Test Method for Determining Temperature of De-

2

ties of Moulding and Extrusion Plastics

2

flection of Plastics and Ebonite Under Load

D 5939 Practice for Preparing Multipurpose Test Specimens

3

2.2 ISO Standards:

ISO 75:1987 Plastics and Ebonite—Determination of Tem-

1

This specification is under the jurisdiction of ASTM Committee D-20 on

perature of Deflection Under Load

Plastics and is the direct responsibility of Subcommittee D20.61 on USA Technical

Advisory Group for ISO/TC 61 on Plastics.

3

Current edition approved June 10, 1996. Published August 1996. Available from American National Standards Institute, 11 W. 42nd St., 13th

2

Annual Book of ASTM Standards, Vol 08.03. Floor, New

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.