ASTM D2463-23

(Test Method)Standard Test Method for Drop Impact Resistance of Blow-Molded Thermoplastic Containers

Standard Test Method for Drop Impact Resistance of Blow-Molded Thermoplastic Containers

SIGNIFICANCE AND USE

5.1 These procedures provide a means to assess the drop impact resistance of the group or lot of blown containers from which the test specimens were selected.

5.2 It is acceptable to use these procedures for routine inspection purposes.

5.3 These procedures will evaluate the combined effect of construction, materials, and processing conditions on the impact resistance of the blown containers.

5.4 Before proceeding with this test method, reference the specification of the material being tested. Any test specimen preparation, conditioning, dimensions, or testing parameters, or combination thereof, covered in the materials specification shall take precedence over those mentioned in this test method. If there are no material specifications, then the default conditions apply.

SCOPE

1.1 This test method provides a means to assess the drop impact resistance of water-filled, blow-molded thermoplastic containers, which is a summation of the effects of material, manufacturing conditions, container design, and perhaps other factors.

1.2 Two procedures are provided as follows:

1.2.1 Procedure A, Static Drop Height Method—This procedure is particularly useful for quality control since it is quick.

1.2.2 Procedure B, Bruceton Staircase Method—This procedure is used to determine the mean failure height and the standard deviation of the distribution.

1.3 The values stated in SI units are to be regarded as standard. The inch-pound units given in parentheses are for information only.

Note 1: There is no known ISO equivalent to this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2463 − 23

Standard Test Method for

Drop Impact Resistance of Blow-Molded Thermoplastic

1

Containers

This standard is issued under the fixed designation D2463; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D883 Terminology Relating to Plastics

E456 Terminology Relating to Quality and Statistics

1.1 This test method provides a means to assess the drop

E691 Practice for Conducting an Interlaboratory Study to

impact resistance of water-filled, blow-molded thermoplastic

Determine the Precision of a Test Method

containers, which is a summation of the effects of material,

manufacturing conditions, container design, and perhaps other

2.2 Plastics Industry Association (formerly Society of Plas-

factors.

tics Industry) Standard:

3

PBI-4 Test for Drop Impact Resistance of Plastic Bottles

1.2 Two procedures are provided as follows:

1.2.1 Procedure A, Static Drop Height Method—This pro-

3. Terminology

cedure is particularly useful for quality control since it is quick.

1.2.2 Procedure B, Bruceton Staircase Method—This pro-

3.1 Definitions:

cedure is used to determine the mean failure height and the

3.1.1 Terms used in this standard are defined in accordance

standard deviation of the distribution.

with Terminology D883, unless otherwise specified. For terms

1.3 The values stated in SI units are to be regarded as

relating to precision and bias and associated issues, the terms

standard. The inch-pound units given in parentheses are for

used in this standard are defined in accordance with Terminol-

information only.

ogy E456.

3.2 Definitions of Terms Specific to This Standard:

NOTE 1—There is no known ISO equivalent to this standard.

3.2.1 failure, n—any rupture visible to an observer with the

1.4 This standard does not purport to address all of the

unaided eye and normal eyesight is considered a failure; this

safety concerns, if any, associated with its use. It is the

includes also any evidence of contained liquid on the outside of

responsibility of the user of this standard to establish appro-

the container through any aperture other than the molded

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. opening.

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard- 4. Summary of Test Method

ization established in the Decision on Principles for the

4.1 The drop impact resistance is determined by dropping

Development of International Standards, Guides and Recom-

conditioned blow-molded containers filled with water from a

mendations issued by the World Trade Organization Technical

platform onto a prescribed surface. Data developed with a

Barriers to Trade (TBT) Committee.

water-filled container are not always representative of what

2. Referenced Documents might be expected with a carbonated liquid, an aerosol pack, a

2

product of high specific gravity, or a powder of low bulk

2.1 ASTM Standards:

density.

B177/B177M Guide for Engineering Chromium Electroplat-

4.1.1 Procedure A consists of dropping at least 20 contain-

ing

ers from a fixed height and reporting the percent failures.

1 4.1.2 Procedure B consists of dropping at least 20 test

This test method is under the jurisdiction of ASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and

containers from varying heights above and below the mean

Molded Products.

failure height of the set. A mean failure height and standard

Current edition approved Aug. 1, 2023. Published August 2023. Originally

deviation are then calculated from the data.

approved in 1965. Last previous edition approved in 2015 as D2463 - 15. DOI:

10.1520/D2463-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from the Plastics Industry Association, Inc., 1425 K Street, NW,

the ASTM website. Washington, DC 20005.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2463 − 23

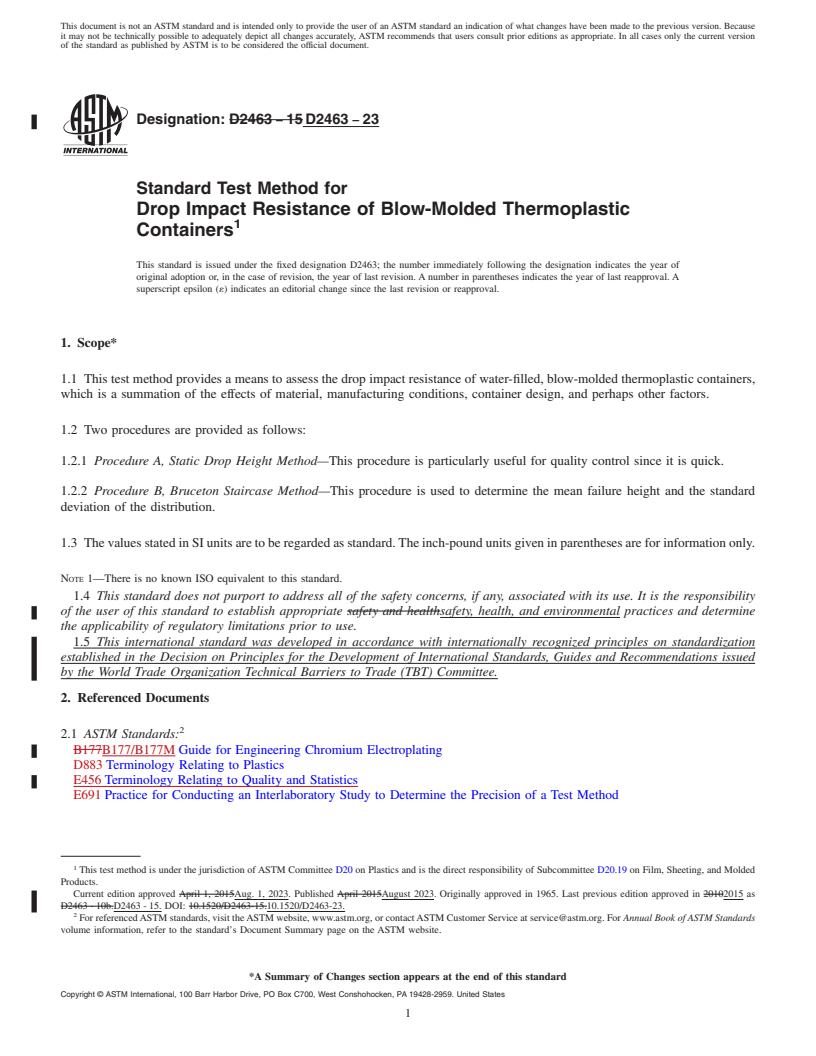

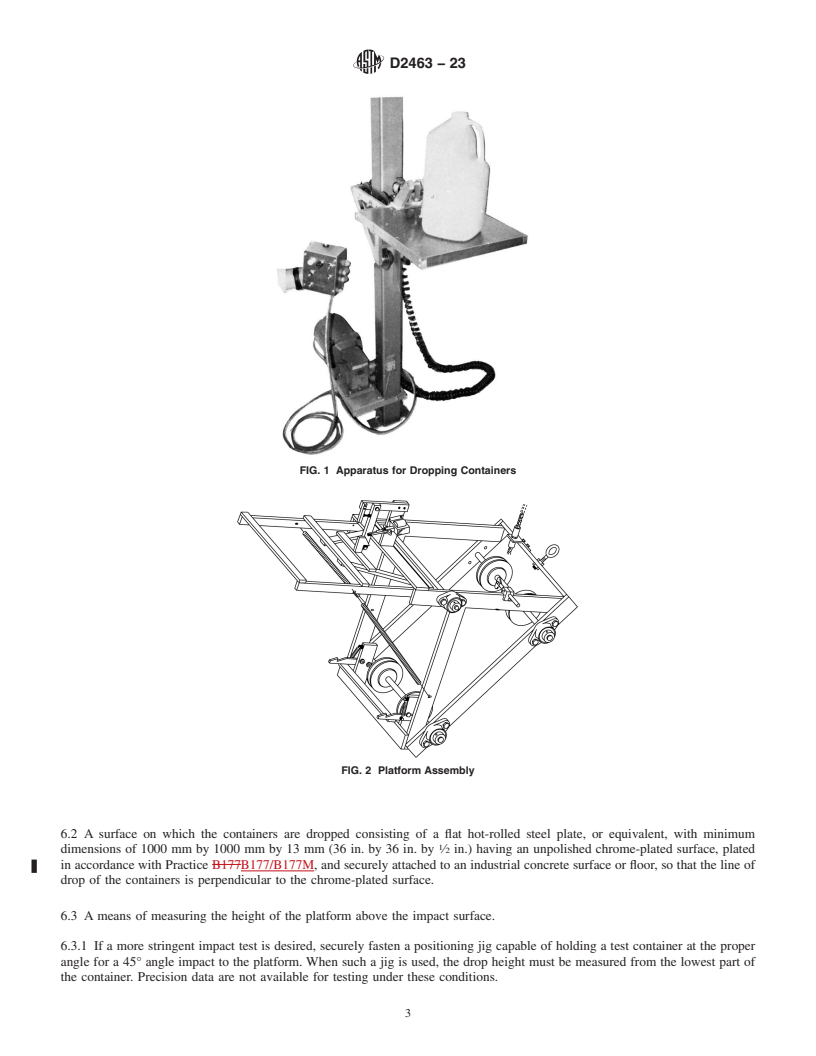

FIG. 2 Platform Assembly

6.1.4 A manually or electrically operated platform release

mechanism that

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2463 − 15 D2463 − 23

Standard Test Method for

Drop Impact Resistance of Blow-Molded Thermoplastic

1

Containers

This standard is issued under the fixed designation D2463; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method provides a means to assess the drop impact resistance of water-filled, blow-molded thermoplastic containers,

which is a summation of the effects of material, manufacturing conditions, container design, and perhaps other factors.

1.2 Two procedures are provided as follows:

1.2.1 Procedure A, Static Drop Height Method—This procedure is particularly useful for quality control since it is quick.

1.2.2 Procedure B, Bruceton Staircase Method—This procedure is used to determine the mean failure height and the standard

deviation of the distribution.

1.3 The values stated in SI units are to be regarded as standard. The inch-pound units given in parentheses are for information only.

NOTE 1—There is no known ISO equivalent to this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and determine

the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B177B177/B177M Guide for Engineering Chromium Electroplating

D883 Terminology Relating to Plastics

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and Molded

Products.

Current edition approved April 1, 2015Aug. 1, 2023. Published April 2015August 2023. Originally approved in 1965. Last previous edition approved in 20102015 as

D2463 - 10b.D2463 - 15. DOI: 10.1520/D2463-15.10.1520/D2463-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2463 − 23

2.2 Plastics Industry Association (formerly Society of Plastics IndustryIndustry) Standard:

3

PBI-4 Test for Drop Impact Resistance of Plastic Bottles

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms found in this test method refer to Terms used in this standard are defined in accordance with

Terminology D883, unless otherwise specified. For terms relating to precision and bias and associated issues, the terms used in

this standard are defined in accordance with Terminology E456.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 failure, n—any rupture visible to an observer with the unaided eye and normal eyesight is considered a failure; this includes

also any evidence of contained liquid on the outside of the container through any aperture other than the molded opening.

4. Summary of Test Method

4.1 The drop impact resistance is determined by dropping conditioned blow-molded containers filled with water from a platform

onto a prescribed surface. Data developed with a water-filled container are not always representative of what might be expected

with a carbonated liquid, an aerosol pack, a product of high specific gravity, or a powder of low bulk density.

4.1.1 Procedure A consists of dropping at least 20 containers from a fixed height and reporting the percent failures.

4.1.2 Procedure B consists of dropping at least 20 test containers from varying heights above and below the mean failure height

of the set. A mean failure height a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.