ASTM F2522-05

(Test Method)Standard Test Method for Determining the Protective Performance of a Shield Attached on Live Line Tools or on Racking Rods for Electric Arc Hazards

Standard Test Method for Determining the Protective Performance of a Shield Attached on Live Line Tools or on Racking Rods for Electric Arc Hazards

SCOPE

1.1 This test method is used to determine the heat attenuation factor (HAF), the effective heat attenuation factor (EHAF), and the shields mechanical strength (SMS) of a shield attached on live line tools or racking rods intended for protection of workers exposed to electric arcs.

1.2 The materials used in this test method of worker protection are in the form of a shield attached on live line tools or on the racking rods.

1.3 The protective shield described in this test method shall be transparent and shall be easily attached and removed from live line tools or from racking rods.

1.4 The protective shield described in this test method has 24-in. (0.61-m) diameter and can be used for most applications, however for special cases, the shield can have different sizes to suit the protective requirements of the application.

1.5 This standard shall be used to measure and describe the properties of materials, products, or assemblies in response to incident energies (thermal-convective, and radiant and pressure wave) generated by an electric arc under controlled laboratory conditions and does not purport to predict damage from light, resultant pressure impact other than the pressure and thermal aspects measured.

1.6 UnitsThe values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.7 This standard shall not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire assessment, which takes into account all of the factors, which are pertinent to an assessment of the fire hazard of a particular end use.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautions, see Section .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2522–05

Standard Test Method for

Determining the Protective Performance of a Shield

Attached on Live Line Tools or on Racking Rods for Electric

Arc Hazards

This standard is issued under the fixed designation F2522; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific

1.1 This test method is used to determine the heat attenua-

precautions, see Section 7.

tionfactor(HAF),theeffectiveheatattenuationfactor(EHAF),

and the shields mechanical strength (SMS) of a shield attached

2. Referenced Documents

on live line tools or racking rods intended for protection of

2.1 ASTM Standards:

workers exposed to electric arcs.

D4391 Terminology Relating to The Burning Behavior of

1.2 The materials used in this test method of worker

Textiles

protection are in the form of a shield attached on live line tools

F1959/F1959M Test Method for Determining the Arc Rat-

or on the racking rods.

ing of Materials for Clothing

1.3 The protective shield described in this test method shall

be transparent and shall be easily attached and removed from

3. Terminology

live line tools or from racking rods.

3.1 Definitions:

1.4 The protective shield described in this test method has

3.1.1 arc, n—conductive path in air for the electric current

24-in.(0.61-m)diameterandcanbeusedformostapplications,

caused by ionization of air between two electrodes.

however for special cases, the shield can have different sizes to

3.1.2 arc duration, n—time duration of the arc, s.

suit the protective requirements of the application.

3.1.3 arc energy, vi dt, n—sum of the instantaneous arc

1.5 This standard shall be used to measure and describe the

voltage values multiplied by the instantaneous arc current

properties of materials, products, or assemblies in response to

values multiplied by the incremental time values during the

incidentenergies(thermal-convective,andradiantandpressure

arc, J.

wave) generated by an electric arc under controlled laboratory

3.1.4 arc gap, n—distance between the arc electrodes.

conditions and does not purport to predict damage from light,

3.1.5 arc voltage, n—voltage across the gap caused by the

resultant pressure impact other than the pressure and thermal

current flowing through the resistance created by the arc gap,

aspects measured.

V. See also Terminology D4391.

1.6 Units—The values stated in inch-pound units are to be

3.1.6 asymmetrical arc current, n—the total arc current

regarded as standard. The values given in parentheses are

produced during closure; it includes a direct component and a

mathematical conversions to SI units that are provided for

symmetrical component, A.

information only and are not considered standard.

3.1.7 blowout, n—the extinguishing of the arc caused by a

1.7 This standard shall not be used to describe or appraise

magnetic field.

the fire hazard or fire risk of materials, products, or assemblies

3.1.8 closure, n—point on supply current wave form where

under actual fire conditions. However, results of this test may

arc is initiated.

be used as elements of a fire assessment, which takes into

3.1.9 delta peak temperature, n—difference between the

account all of the factors, which are pertinent to an assessment

maximum temperature and the initial temperature of the sensor

of the fire hazard of a particular end use.

during the test, °C.

1.8 This standard does not purport to address all of the

3.1.10 effective heat attenuation (EHAF)/cone of protection

safety concerns, if any, associated with its use. It is the

(COP) factor, n—the percentage of the incident heat energy

responsibility of the user of this standard to establish appro-

that is attenuated by the shield at the location of the worker.

This test method is under the jurisdiction of ASTM Committee F18 on

Electrical Protective Equipment for Workers and is the direct responsibility of For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Subcommittee F18.35 on Tools and Equipment. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Oct. 1, 2005. Published November 2005. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2522-05. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2522–05

3.1.11 fragmentation, n—molten metal fragments or other procedure, the amount of heat energy reduced (blocked) by the

fragments emitted from an electric arc. shield is measured during exposure to an electric arc.

4.3 The heat energy of the arc exposure is measured with

3.1.12 heat attenuation factor (HAF), n—the percentage of

the incident heat energy that is blocked by the safety shield calorimeters. The rate at which the temperature of the calorim-

eters increases is a direct measure of the heat energy received.

material.

4.4 Theshieldprotectiveperformanceforthistestmethodis

3.1.13 heat flux, n—the thermal intensity indicated by the

determined from the heat attenuation factor (in percent) at the

amount of energy transmitted divided by area and time

2 2

W/m [cal/cm s]. shield location, and from the effective heat attenuation factor at

the worker location. The effective heat attenuation factor in

3.1.14 i t, n—sum of the instantaneous arc current values

percentisthedifferenceintheincidentenergygeneratedbythe

squared multiplied by the incremental time values during the

arc flash before and after the shield was used.

arc, A /s.

4.5 Heat transfer data can be used to predict the onset of

3.1.15 ignitability, n (ignitable, adj)—in electric arc expo-

second degree burn using the Stoll curve.

sure, the property of a material involving ignition accompanied

4.6 This procedure incorporates incident heat energy moni-

by heat and light, and continued burning resulting in consump-

toring sensors.

tion of at least 25 % of the exposed area of the test specimen.

4.7 Further description of the shield reduction of the electric

3.1.16 ignition, n—the initiation of combustion.

arc exposure on the worker is presented in Sections 12 and 13.

3.1.17 incident energy (E), n—the amount of energy (total

i

heat, cal/cm ) received at a surface as a direct result of an

5. Significance and Use

electrical arc discharge as measured by temperature rise on

5.1 This test method is intended for determining the heat

copper calorimeters.

attenuation factor (HAF) of a shield material and the effective

3.1.18 peak arc current, n—maximum value of the AC arc

heat attenuation factor (EHAF) at the location of the worker.

current, A.

This can be obtained by measuring the reduction of the arc

3.1.19 pressure wave, n—a certain force over an area

incident energy levels caused by a shield attached on a live line

created by air movement caused by an electric arc.

tool (hot stick) or on a racking rod and designed for protection

3.1.20 RMS arc current, n—root mean square of theAC arc

for workers exposed to electric arcs. The shield mechanical

current, A.

strength(SMS)canbeobtainedfromvisualobservationsofthe

3.1.21 sensors, n—copper calorimeter, instrumented with a

high speed video recordings of each shot during HAF tests.

thermocouple contained in a dielectric, heat protective housing

5.1.1 Because of the variability of the arc exposure, differ-

for use in measuring energy.

ent heat transmission values and pressure may result for

3.1.22 shield mechanical strength value (SMS) factor,

individual sensors. The results of each sensor are evaluated in

n—themechanicalabilityoftheshieldtowithstandtheelectric

accordance with Section 12.

arc pressure wave and fragmentation.

5.2 This test method maintains the shield and the heat

3.1.23 time to delta peak temperature, n—the time from

sensors in a static, vertical position and does not involve

beginning of the initiation of the arc to the time the delta peak

movement except that resulting from the exposure.

temperature is reached, s.

5.3 This test method specifies a standard set of exposure

3.1.24 X/R ratio, n—the ratio of system inductive reactance

conditions. Different exposure conditions may produce differ-

toresistance.ItisproportionaltotheL/Rratiooftimeconstant,

ent results.

and is, therefore, indicative of the rate of decay of any DC

NOTE 1—In addition to the standard set of exposure conditions, other

offset. A large X/R ratio corresponds to a large time constant

conditions representative of the expected hazard may be used and shall be

and a slow rate of decay.

reported should this data be cited.

4. Summary of Test Method

6. Apparatus

4.1 This test method determines the heat attenuation factor 6.1 GeneralArrangement for Determining HeatAttenuation

(HAF) of the shield material, the effective heat attenuation

Factor (HAF) of the Shield—Thetestapparatusshallconsistof

factor (EHAF) at the location where the worker may be while

supply bus, arc controller, recorder, arc electrodes, the shield,

holding the hot stick or racking rod to which the shield is and incident energy monitoring sensors. The arc exposure in

attached, and the shield mechanical strength (SMS). The

the form of heat attenuation factor at the shield location shall

copper calorimeters (incident energy monitoring sensors) are be monitored with two incident energy monitoring sensors.

placed for the HAF at the shield (front and back), and for the

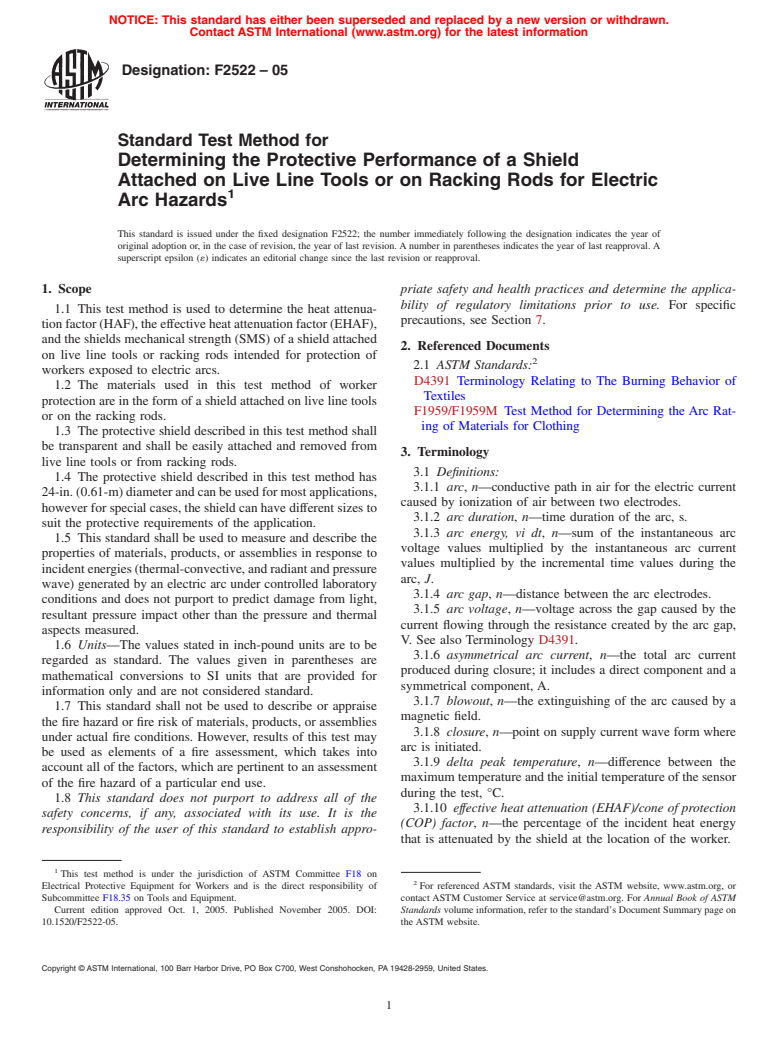

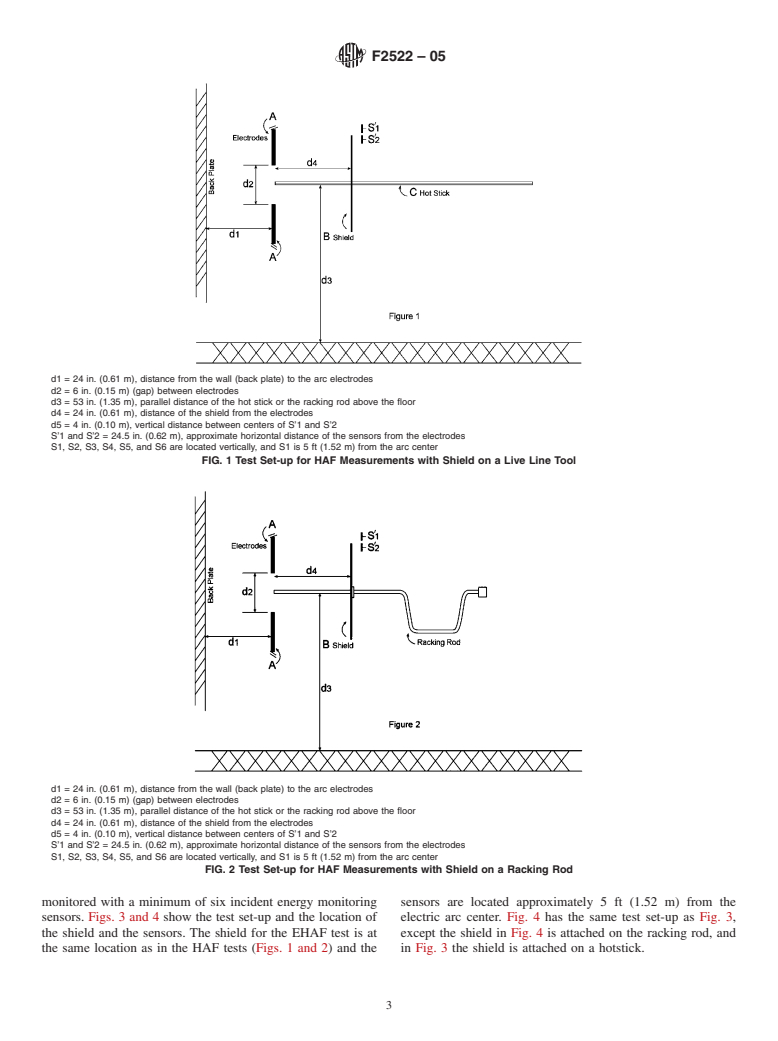

Figs. 1 and 2 show the test set-up and the location of the shield

EHAF test at the probable location of the worker’s hand, head, on the hot stick and on the racking rod and the location of

side of the face, chest, and legs when exposed to the heat

sensors. Fig. 2 has the same test set-up as Fig. 1, except the

energy from a controlled electric arc. The SMS value of the shield is attached on the racking rod.

shield is obtained from visual observations of the HAF test for

6.2 General Arrangement for Determining Effective Heat

the ability of the shield to absorb and deflect the fragmentation Attenuation Factor (EHAF) at the Location of the Worker—

shrapnel, not break or ignite, not to move from its attachment,

The test apparatus shall consist of supply bus, arc controller,

and not to bend more then 20 degrees. recorder, arc electrodes, a shield, and incident energy monitor-

4.2 During HAF and EHAF tests, the center of the shield is ing sensors. The arc exposure in the form of effective heat

aligned with the mid point of the arc gap. During this attenuation factor at the location of the worker shall be

F2522–05

d1 = 24 in. (0.61 m), distance from the wall (back plate) to the arc electrodes

d2=6in.(0.15m)(gap) between electrodes

d3 = 53 in. (1.35 m), parallel distance of the hot stick or the racking rod above the floor

d4 = 24 in. (0.61 m), distance of the shield from the electrodes

d5=4in.(0.10m),vertical distance between centers of S’1 and S’2

S’1 and S’2 = 24.5 in. (0.62 m), approximate horizontal distance of the sensors from the electrodes

S1, S2, S3, S4, S5, and S6 are located vertically, and S1 is 5 ft (1.52 m) from the arc center

FIG. 1 Test Set-up for HAF Measurements with Shield on a Live Line Tool

d1 = 24 in. (0.61 m), distance from the wall (back plate) to the arc electrodes

d2=6in.(0.15m)(gap) between electrodes

d3 = 53 in. (1.35 m), parallel distance of the hot stick or the racking rod above the floor

d4 = 24 in. (0.61 m), distance of the shield from the electrodes

d5=4in.(0.10m),vertical distance between centers of S’1 and S’2

S’1 and S’2 = 24.5 in. (0.62 m), approximate horizontal distance of the sensors from the electrodes

S1, S2, S3, S4, S5, and S6 are located vertically, and S1 is 5 ft (1.52 m) from the arc center

FIG. 2 Test Set-up for HAF Measurements with Shield on a Racking Rod

monitored with a minimum of six incident energy monitoring sensors are located approximately 5 ft (1.52 m) from the

sensors. Figs. 3 and 4 show the test set-up and the location of electric arc center. Fig. 4 has the same test set-up as Fig. 3,

the shield and the sensors. The shield for the EHAF test is at except the shield in Fig. 4 is attached on the racking rod, and

the same location as in the HAF tests (Figs. 1 and 2) and the in Fig. 3 the shield is attached on a hotstick.

F2522–05

d1 = 24 in. (0.61 m), distance from the wall (back plate) to the arc electrodes

d2=6in.(0.15m)(gap) between electrodes

d3 = 53 in. (1.35 m), parallel distance of the hot stick or the racking rod above the floor

d4 = 24 in. (0.61 m), distance of the shield from the electrodes

d5=4in.(0.10m),vertical distance between centers of S’1 and S’2

S’1 and S’2 = 24.5 in. (0.62 m), approximate horizontal distance of the sensors from the electrodes

S1, S2, S3, S4, S5, and S6 are located vertically, and S1 is 5 ft (1.52 m) from the arc center

FIG. 3 Test Set-up for EHAF Measurement with Shield on a Live Line Tool

d1 = 24 in. (0.61 m), distance from the wall (back plate) to the arc electrodes

d2=6in.(0.15m)(gap) between electrodes

d3 = 53 in. (1.35 m), parallel distance of the hot stick or the racking rod above the floor

d4 = 24 in. (0.61 m), distance of the shield from the electrodes

d5=4in.(0.10m),vertical distance between centers of S’1 and S’2

S’1 and S’2 = 24.5 in. (0.62 m), approximate horizontal distance of the sensors from the electrodes

S1, S2, S3, S4, S5, and S6 are located vertically, and S1 is 5 ft (1.52 m) from the arc center

FIG. 4 Test Set-up for EHAF Measurement with Shield on a Racking Rod

6.3 General Arrangement for Determining Shield’s Me- mined by observing the HAF tests for the ability of the shield

chanical Strength (SMS)—The evaluation of shield’s mechani- to absorb and deflect the fragmentation shrapnel, not break or

cal strength value (SMS) is based on visual observations of the ignite, not to move from its attachment, and not to bend more

high speed video recordings of the arc tests made in 6.1 (HAF then 20 degrees.

tests). The purpose of the SMS test is to determine the 6.4 Electrodes—Atypical arrangement of the arc electrodes

mechanical ability of the shield to withstand the electric arc is shown in Fig. 1. The arc shall be in a vertical position as

pressure wave and fragmentation. The SMS value is deter- shown.

F2522–05

6.5 Electrodes—Make the electrodes from electrical grade 7.2 The test apparatus, electrodes and calorimeter assem-

copper (allo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.