ASTM C1492-01

(Specification)Standard Specification for Concrete Roof Tile

Standard Specification for Concrete Roof Tile

SCOPE

1.1 This specification covers concrete tiles intended for the use as roof covering where durability and appearance are required to provide a weather-resistant surface of specified design.

1.2 Tiles are manufactured from portland cement, water, and mineral aggregates with or without the inclusion of other materials.

1.3 Tiles are shaped during manufacturing by molding, pressing, or extrusion. The shaping method can be used to describe the tile.

1.4 Other constituents, such as chemical and mineral admixtures established as suitable for use in concrete, shall conform to ASTM standard specifications where applicable, or shall be shown by tests or experience not to be detrimental to the durability of concrete.

1.5 Tiles are generally planar or undulating rectangular shapes available in a variety of cross-sectional areas profiles, shapes, sizes, surface textures, and colors.

Note 1--Concrete roof tiles covered by this specification are made from lightweight or normal weight aggregates, or both.

Note 2--When particular features are desired, such as color, surface texture for appearance, or other special features, such properties should be specified by the purchaser. However. the local sellers should be consulted as to the availability of concrete roof tile having a desired feature.

1.6 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1492 – 01

Standard Specification for

Concrete Roof Tile

This standard is issued under the fixed designation C 1492; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C 150 Specification for Portland Cement

C 260 Specification for Air-Entraining Admixtures for Con-

1.1 This specification covers concrete tiles intended for the

crete

use as roof covering where durability and appearance are

C 331 Specification for Lightweight Aggregates for Con-

required to provide a weather-resistant surface of specified

crete Masonry Units

design.

C 494/C 494M Specification for Chemical Admixtures for

1.2 Tiles are manufactured from portland cement, water,

Concrete

and mineral aggregates with or without the inclusion of other

C 595 Specification for Blended Hydraulic Cements

materials.

C 618 Specification for Coal Fly Ash and Raw or Calcined

1.3 Tiles are shaped during manufacturing by molding,

Natural Pozzolan for Use as a Mineral Admixture in

pressing, or extrusion. The shaping method can be used to

Concrete

describe the tile.

C 979 Specification for Pigments for Integrally Colored

1.4 Other constituents, such as chemical and mineral admix-

Concrete

tures established as suitable for use in concrete, shall conform

C 989 Specification for Ground Granulated Blast-Furnace

to ASTM standard specifications where applicable, or shall be

Slag for Use in Concrete and Mortars

shown by tests or experience not to be detrimental to the

C 1157 Performance Specification for Hydraulic Cement

durability of concrete.

1.5 Tiles are generally planar or undulating rectangular

3. Terminology

shapes available in a variety of cross-sectional areas profiles,

3.1 Definitions—The following terms are used in connec-

shapes, sizes, surface textures, and colors.

tion with concrete roof tiles:

NOTE 1—Concrete roof tiles covered by this specification are made

3.2 batten lugs—protrusions on the underside of the tile

from lightweight or normal weight aggregates, or both.

designed to engage over the upper edge of tiling battens.

NOTE 2—When particular features are desired, such as color, surface

3.3 head lap—distance of overlap measured from the up-

texture for appearance, or other special features, such properties should be

permost course to the point that it laps over the undermost

specified by the purchaser. However. the local sellers should be consulted

course.

as to the availability of concrete roof tile having a desired feature.

3.4 high profile tile—tile with a rise to width ratio greater

1.6 The values stated in inch-pound units are to be regarded

than 1:5.

as the standard.

3.5 interlocking tile—tiles with a system of ribs or grooves

enabling the lateral joining of adjacent tiles in the same

2. Referenced Documents

horizontal row, with the overlapping lock covering the under-

2.1 ASTM Standards:

lapping lock.

C 33 Specification for Concrete Aggregates

3.6 length—maximum overall dimension of the tile mea-

C 67 Test Methods for Sampling and Testing Brick and

sured parallel to the water course.

Structural Clay Tile

3.7 low profile tile—tile with a rise equal to or less than ⁄2

C 90 Specification for Loadbearing Concrete Masonry

in.

Units

3.8 medium profile tile—tile with a rise greater than ⁄2 in.

C 140 Test Methods for Sampling and Testing Concrete

and a rise-to-width ratio of less than or equal to 1:5.

Masonry Units and Related Units

3.9 nail hole—small opening passing partially or totally

through the tile to allow the penetration of a nail or screw for

the purpose of fastening the tile to a support.

3.10 non-interlocking tile—tiles that butt at the sides with-

This specification is under the jurisdiction of ASTM Committee C15 on

out lapping adjacent tiles.

Manufactured Masonry Units and is the direct responsibility of Subcommittee

C15.06 on Roofing Tile.

3.11 nose lugs—protrusion on the underside of the nose of

Current edition approved Jan. 10, 2001. Published March 2001.

Annual Book of ASTM Standards, Vol 04.02.

3 4

Annual Book of ASTM Standards, Vol 04.05. Annual Book of ASTM Standards, Vol 04.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1492

TABLE 1 Physical Testing Criteria

each tile, contoured to fit into the main water courses of the tile

immediately below, inhibiting the entry of wind-driven rain.

NOTE—Number of tile to be sampled and tested for determining

3.12 profile—contour of the top surface of the tile when

compliance with this specification (see 6.2).

viewed from the nose end.

Job – Production Verification

3.13 rise—vertical distance from the underside of the batten

Quality Third

Up to Over

lug to the highest point of the surface profile.

Test Dispute Party

250 000 Tile 250 000 Tile

Resolution Certification

3.14 side lap—continuous longitudinal overlap of a tile on

its neighbor. Dimensional 5 5 5 5

Transverse 3 5 3 5

3.15 thickness—any vertical measurement of the cross sec-

Permeability 3 3 3 5

tion of the tiles excluding the lapping area, nose lugs, and

Water Absorption 3 3 3 5

weather checks. Freeze Thaw 5 5 Annual Test Annual Test

3.16 weather checks—protrusions below the tile designed to

restrict the flow of water between two consecutive courses of

with Table 1 must pass the specified test.

tiles.

6.2.1 In the event of a failure in any of the specified tests

3.17 width—maximum overall dimension of the tile mea-

indicated in Table 1, a second set of specimens shall be taken

sured perpendicular to the length or water channel

and tested in accordance with the criteria listed in Table 2.

3.18 water course—valley portion of a profiled tile along

6.2.2 Provided that the number of failures in the re-test

which water drains.

sample are less than the maximum allowed in Table 2, the lot

4. Classification

shall be rated as being in compliance with this specification.

6.3 Sampling Procedure—Buyer and seller shall agree on

4.1 Concrete roof tiles manufactured in accordance with this

the method of sampling prior to shipment. The random

specification are of the following types:

sampling method shall be used.

4.1.1 Type I—High Profile Tile.

4.1.2 Type II—Medium Profile Tile.

7. Standard Methods of Testing Concrete Roof Tiles

4.1.3 Type III—Low Profile Tile.

7.1 The following tests are required on concrete roof tiles:

4.1.4 Type IV—Accessory Tile, shall include those tile such

7.1.1 Dimensional Tolerances.

as ridge, rake, hip, and valley tile used in conjunction with

7.1.2 Freeze Thaw (see 7.3.1).

those tile listed in 4.1.1-4.1.3.

7.1.3 Transverse Strength.

5. Materials and Manufacture 7.1.4 Permeability.

7.1.5 Water Absorption.

5.1 Cementitious materials shall conform to the following

7.2 Testing for Dimensional Tolerances and Weight:

applicable ASTM specifications.

7.2.1 Dimensions—The total variation in dimensions of

5.1.1 Portland Cement—Specification C 150.

tiles (length, width, and height), when measured in accordance

5.1.2 Modified Portland Cement—Specification C 90.

with Test Methods C 140, shall not be more than 65 % from

5.1.3 Blended Cement—Specification C 595.

the manufacturer’s designated dimensions.

5.1.4 Pozzolans—Specification C 618.

7.2.2 Weight—The total variation in weight of tiles, when

5.1.5 Ground Granulated Blast Furnace Slag—

measured in accordance with Test Methods C 140 and Table 1

Specification C 989.

of this specification, shall not be more than 65 % from the

5.1.6 Performance Specification C 1157.

nominal weight specified by the supplier.

5.2 Aggregates such as normal weight and lightweight shall

7.3 Freezing and Thawing—Tiles shall be subjected to 50

conform to the following ASTM specifications, except that

cycles of freezing and thawing of Test Methods C 67 as

grading requirements do not apply.

modified in 7.3.4.

5.2.1 Normal Weight Aggregates—Specification C 33.

7.3.1 A lot shall be rated as passing without repeating a

5.2.2 Lightweight Aggregates—Specification C 331.

freezing and thawing test provided that a previous lot made by

5.3 Admixtures—shall conform to the following applicable

specifications.

TABLE 2 Retest Criteria

5.3.1 Air-Entrained Admixtures—Specification C 260.

5.3.2 Pigments—Specification C 979. NOTE 1—Retest criteria of the specific test that failed (see 6.2.1).

NOTE 2—If 250 000 tiles were in the lot, then 32 specimens would be

5.3.3 Other Admixtures—Specification C 494/C 494M.

taken for the retest of the specific test that failed. If 3 or less of the 32

specimens failed, the lot would be rated as passing; however, if 4 or more

6. Standard Methods of Sampling Concrete Tile

of the 32 specimens failed, the lot would have failed the specific test.

6.1 Tile sampling shall be appropriate for one of the

Maximum Number of

following three purposes: Number of Tile Number of

Failures Allowed

in the Lot Specimens

6.1.1 Resolution of quality disputes.

for Acceptance

6.1.2 Third party certification.

Less than 151 3 0

6.1.3 Production or job shipment verification. 151–3200 13 1

3200–35 000 20 2

6.2 Tile sampling for the purpose listed in 6.1 shall be taken

35 001–500 000 32 3

according to Table 1. To be rated as in compliance with this

Over 500 000 50 5

standard, the indicated number of tile sampled in accordance

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1492

the supplier from similar materials, by the same production remain unbroken and no individual specimen loses more than

plant, and within the previous 12 months, passed the test, and 1 % of original dry weight.

provided also that a sample of five tiles selected from the lot 7.4 Transverse Strength:

has an average and individual minimum transverse strength not

7.4.1 Apparatus—The transverse breaking strength of tiles

less than the previously tested sample and has average and shall be determined as described in the Modulus of Rupture

individual maximum water absorption not greater than those of

(Flexural Test) in Test Methods C 67 except as modified in

the previously tested sample. 7.4.2-7.4.9.

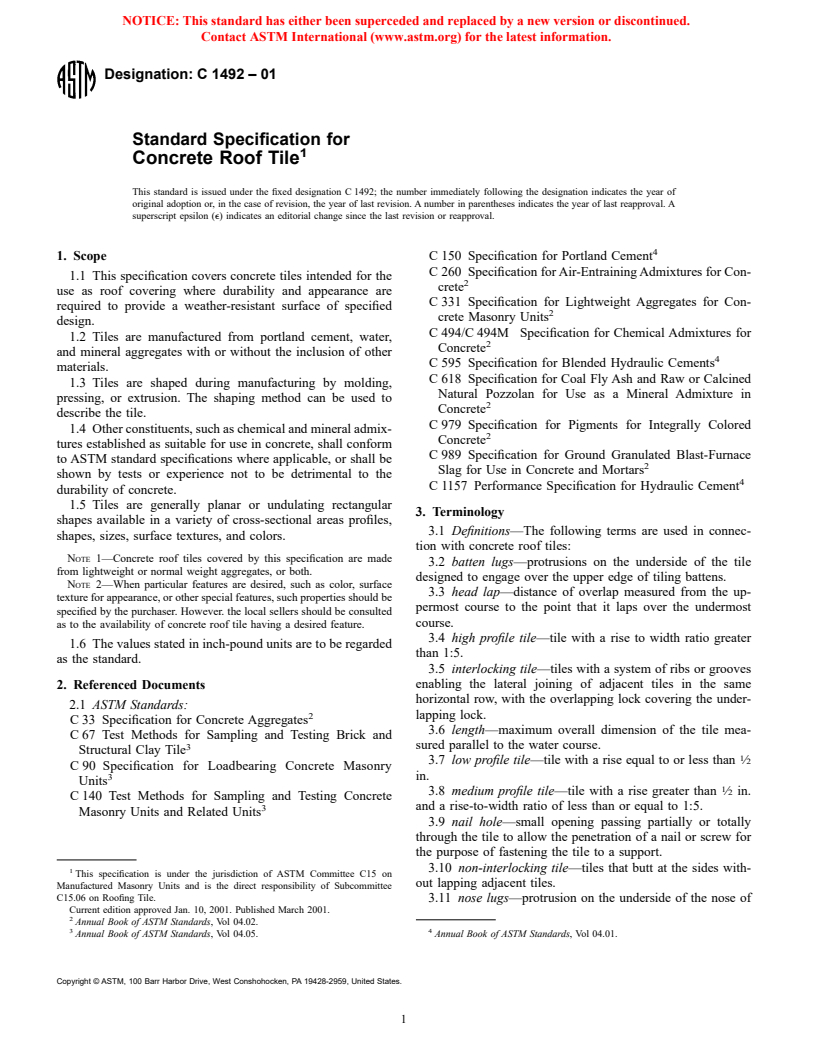

7.3.2 Only tile passing freeze-thaw testing shall be installed

7.4.2 Five tiles shall be tested wet after a 24-h submersion

in areas subjected to weathering indices of 50 or greater and lot

in water at a temperature of 75 6 10°F (24 6 6°C) or five tiles

tags or certification that the lot of tile has passed the freeze-

shall be tested dry after heating in a ventilated oven for 24 h at

thaw testing accompanies the lot. See Fig. 1 for weathering

a temperature of 230 to 239°F (100 to 115°C).

indices map.

7.4.3 Tiles shall be considered to comply with this specifi-

7.3.3 Tile not tested for freeze-thaw shall state clearly that

cation if they comply with either the wet or dry transverse

the lot has not been tested for freeze-thaw acceptance on all lot

strength required. The choice of method, wet or dry, shall be

tags or certification.

mutually agreed upon between specifier and supplier.

7.3.4 Modify Test Methods C 67 procedure for freezing and

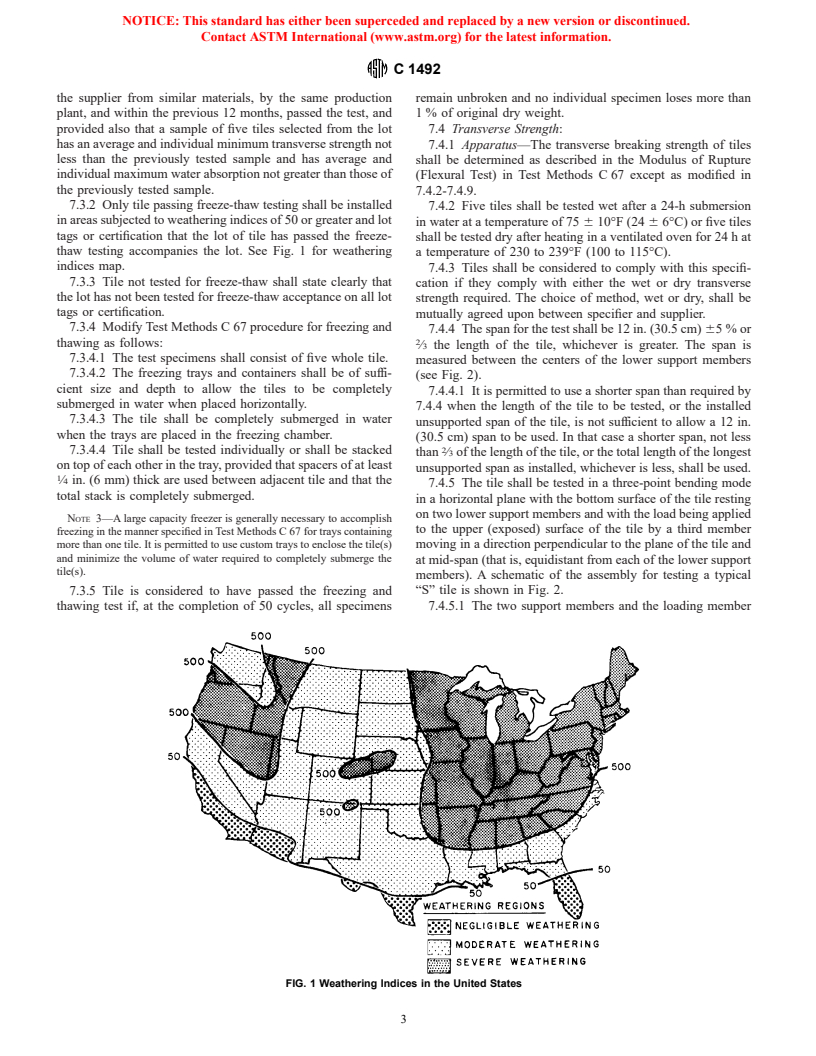

7.4.4 The span for the test shall be 12 in. (30.5 cm) 65%or

thawing as follows:

⁄3 the length of the tile, whichever is greater. The span is

7.3.4.1 The test specimens shall consist of five whole tile.

measured between the centers of the lower support members

7.3.4.2 The freezing trays and containers shall be of suffi-

(see Fig. 2).

cient size and depth to allow the tiles to be completely

7.4.4.1 It is permitted to use a shorter span than required by

submerged in water when placed horizontally.

7.4.4 when the length of the tile to be tested, or the installed

7.3.4.3 The tile shall be completely submerged in water

unsupported span of the tile, is not sufficient to allow a 12 in.

when the trays are placed in the freezing chamber.

(30.5 cm) span to be used. In that case a shorter span, not less

7.3.4.4 Tile shall be tested individually or shall be stacked

than ⁄3 of the length of the tile, or the total length of the longest

on top of each other in the tray, provided that spacers of at least

unsupported span as installed, whichever is less, shall be used.

⁄4 in. (6 mm) thick are used between adjacent tile and that the

7.4.5 The tile shall be tested in a three-point bending mode

total stack is completely submerged.

in a horizontal plane with the bottom surface of the tile resting

on two lower support members and with the load being applied

NOTE 3—A large capacity freezer is generally necessary to accomplish

to the upper (exposed) surface of the tile by a third member

freezing in the manner specified in Test Methods C 67 for trays containing

more than one tile. It is permitted to use custom trays to enclose the tile(s) moving in a direction perpendicular to the plane of the tile and

and minimize the volume of water required to completely submerge the

at mid-span (that is, equidistant from each of the lower support

tile(s).

members). A schematic of the assembly for testing a typical

“S” tile is shown in Fig. 2.

7.3.5 Tile is considered to have passed the freezing and

thawing test if, at the completion of 50 cycles, all specimens 7.4.5.1 The two support members and the loading member

FIG. 1 Weathering Indices in the United States

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1492

FIG. 2 Schematic of Assembly for Flexure Strength Testing

requirements of 7.4.4.1-7.4.5.1, and causes the load to be applied to at

shall each be of metal or hardwood with 1 in. (25 mm) 65%

least 50 % of the width of the tile and equally distributed on either side of

wide faces. The faces shall be shaped (see Note 4) to closely

the length centerline of the tile.

conform to the profile of the surface of the tile upon which they

Each wood block used that is to provide sufficient flat surface to allow

bear during the test (the profile can, therefore, be different for

loading and supporting with the flat bearing members shall have a length

each member depending on the profile and cross-sectional

of at least 25 % of the width of the tile. Such blocks shall be spaced no

shape of the tile). The total height of the support members shall

farther apart than 25 % of the width of the tile to avoid concentrated

not be more than 1 in. (25 mm) greater

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.