ASTM C1552-14a

(Practice)Standard Practice for Capping Concrete Masonry Units, Related Units and Masonry Prisms for Compression Testing

Standard Practice for Capping Concrete Masonry Units, Related Units and Masonry Prisms for Compression Testing

SIGNIFICANCE AND USE

4.1 This practice describes procedures for providing plane surfaces on the two bearing surfaces of units and prisms. The purpose of this standard is to provide consistent and standardized procedures for capping units and prisms for compression testing. The procedures are based on those contained (or previously contained) in Test Methods C140, Practice C617, and Test Method C1314.

Note 2: Specimens capped using this practice will vary significantly in size and weight. Appropriate care and handling may differ based on specimen size and weight. Provide care and handling as needed to provide for proper capping based on the physical characteristics of the specimen being capped.

SCOPE

1.1 This practice covers apparatus, materials, and procedures for capping concrete masonry units, related units, including coupons or other specimens obtained from such units, and masonry prisms for compression testing.

Note 1: The testing laboratory performing these test methods should be evaluated in accordance with Practice C1093.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1552 − 14a

StandardPractice for

Capping Concrete Masonry Units, Related Units and

Masonry Prisms for Compression Testing

This standard is issued under the fixed designation C1552; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 4. Significance and Use

1.1 This practice covers apparatus, materials, and proce- 4.1 This practice describes procedures for providing plane

dures for capping concrete masonry units, related units, includ- surfaces on the two bearing surfaces of units and prisms. The

ing coupons or other specimens obtained from such units, and purpose of this standard is to provide consistent and standard-

masonry prisms for compression testing. ized procedures for capping units and prisms for compression

NOTE 1—The testing laboratory performing these test methods should

testing. The procedures are based on those contained (or

be evaluated in accordance with Practice C1093.

previously contained) in Test Methods C140, Practice C617,

1.2 The values stated in inch-pound units are to be regarded and Test Method C1314.

NOTE2—Specimenscappedusingthispracticewillvarysignificantlyin

as standard. The values given in parentheses are mathematical

size and weight. Appropriate care and handling may differ based on

conversions to SI units that are provided for information only

specimen size and weight. Provide care and handling as needed to provide

and are not considered standard.

for proper capping based on the physical characteristics of the specimen

being capped.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Apparatus

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5.1 Capping Plate—If used, the capping plate shall be made

bility of regulatory limitations prior to use.

of steel having a thickness of not less than 1 in. (25.4 mm), or

a polished plate of granite or diabase at least 3 in. (76 mm)

2. Referenced Documents

thick. The capping surface shall be plane within 0.002 in. in

12 in. (0.05 mm in 300 mm) and shall be free of gouges,

2.1 ASTM Standards:

grooves, and indentations greater than 0.010 in. (0.25 mm)

C140 Test Methods for Sampling and Testing Concrete

2 2

deep or greater than 0.05 in. (32 mm ) in surface area. At the

Masonry Units and Related Units

time of capping, the capping surface shall be level within ⁄16

C617 Practice for Capping Cylindrical Concrete Specimens

in. (1.6 mm) over the length of the plate.

C1093 Practice for Accreditation of Testing Agencies for

5.1.1 Capping Wear Plate—If used, the capping wear plate

Masonry

shall be placed directly on top of the capping plate and shall

C1232 Terminology of Masonry

meet the requirements of 5.2.At the time of capping, the wear

C1314 Test Method for Compressive Strength of Masonry

plate surface shall be level within ⁄16 in. (1.6 mm) over the

Prisms

length of the plate. Do not use a capping wear plate with sulfur

capping materials.

3. Terminology

NOTE 3—A capping wear plate has been found to reduce the potential

3.1 Terminology defined in Terminology C1232 shall apply

of damage to the capping plate. The capping wear plate is typically more

for this practice.

resistant to scratches and can be replaced at less cost than that required to

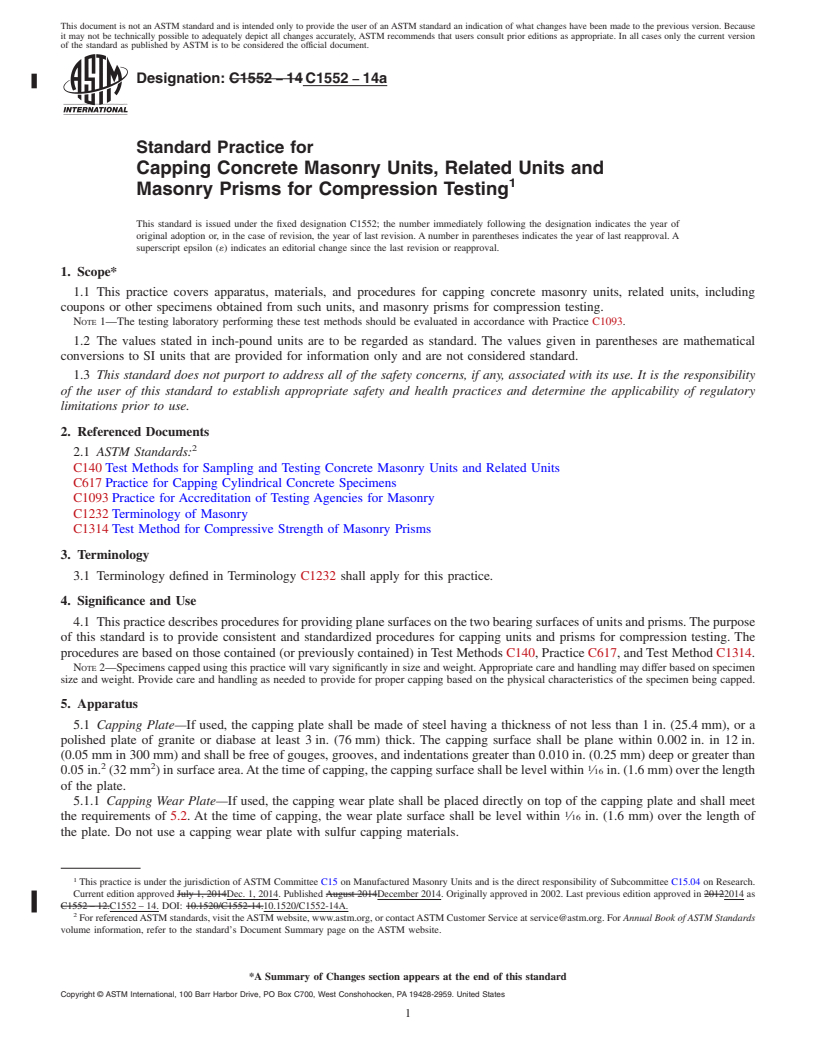

resurface the capping plate. See Fig. 1 for a schematic of capping setup

when using gypsum cement materials.

5.2 Casting Plate—If used, the casting plate shall be of

This practice is under the jurisdiction of ASTM Committee C15 on Manufac-

transparent glass with a thickness of not less than ⁄2 in. (13

tured Masonry Units and is the direct responsibility of Subcommittee C15.04 on

Research.

mm). The casting plate shall be plane within 0.002 in. in 12 in.

Current edition approved Dec. 1, 2014. Published December 2014. Originally

(0.05 mm in 300 mm).

approved in 2002. Last previous edition approved in 2014 as C1552 – 14. DOI:

10.1520/C1552-14A.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6. Materials

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1 Capping Materials:

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 6.1.1 High Strength Gypsum Cement Capping Materials:

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1552 − 14a

FIG. 1 Gypsum Capping Schematic

6.1.1.1 In addition to the compressive strength testing re- material from the molds not more than 15 min prior to testing.

quired in 6.2, qualification tests shall be made to determine the Test cubes at an age of 2 h 6 10 min after completing the

effects of water-cement ratio and age on compressive strength. filling of the molds.

Procedures used for preparing the high strength gypsum 6.2.1 The strength of the capping material shall be deter-

cement capping materials shall ensure that water-cement ratios mined on receipt of a new lot and at intervals not exceeding

used for each batch provide the required strength. three months. If a given test of the capping material fails to

conform to the strength requirements, the package from which

NOTE 4—The water-gypsum cement ratio should typically be between

the material was sampled shall not be used unless two

0.26 and 0.30. Use of low water-gypsum cement ratios and vigorous

additional subsequent samples are taken from the same pack-

mixing will usually permit development of 3500 psi (24.1 MPa) at ages of

one or two hours. Higher water-gypsum cement ratios extend working

age and both of these subsequent samples conform to the

time, but reduce strength.

strength requirements. If the strength tests from an individual

6.1.1.2 Do not add fillers or extenders to the high strength package are inadequate, randomly obtain and test three addi-

gypsum cement. tional samples from the lot. These additional samples shall be

taken from separate packages, if available. Unless these three

NOTE 5—Retarders extend working time for capping materials but their

samplesconformtothestrengthrequirements,nopartofthelot

effects on required water-cement ratio should be determined prior to use.

shall be used.

NOTE 6—See Appendix X1 for more information on high-strength

gypsum capping materials and product recommendations.

7. Procedure

6.1.2 Sulfur Capping Materials:

6.1.2.1 Proprietary or laboratory prepared sulfur mixtures 7.1 Preparation of Specimens for Capping—Useanabrasive

shall contain 40 to 60 % sulfur by weight, the remainder being stone to remove loose protrusions from the surfaces of the

ground fire clay or other suitable inert material passing a No. specimens to be capped. Refer to the appropriate compression

100 (150-µm) sieve with or without a plasticizer. test method (Test Methods C140 or Test Method C1314) for

6.1.3 Use only capping materials identified in 6.1.1 and other specimen preparation requirements.

6.1.2. Do not use other capping materials.

7.2 Capping Test Specimens—Cap top and bottom bearing

surfaces of specimens by one of the methods in 7.2.1 or 7.2.2.

NOTE 7—Examples of materials that have been found to be unsuitable

for capping purposes include, but are not limited to: low-strength molding

Use alignment devices as needed to make sure the caps meet

plaster, plaster of paris, mixtures of plaster of paris and portland cement,

the requirements of 7.4.

and other cement-based materials.

NOTE 8—Various alignment devices have been demonstrated to be

6.2 Compressive Strength of Capping Materials—The com-

effective. For capping with sulfur materials, which sets quickly, alignment

pressive strength of the capping material shall be at least

jigs make sure that the specimen is placed on the capping plate correctly

3500 psi (24.1 MPa) at an age of 2 h. The cube molds and

in the first motion. For capping with gypsum cement materials, levels

placed across the top of specimen have proven to work well. Bullseye

methods of preparing and testing the cubes shall be in

levels work particularly well with smaller specimens.

accordance with Practice C617. The capping material shall be

placed in the cube at capping consistency. Store the filled 7.2.1 Capping Using Gypsum Cement Materials—See

molds in laboratory air. Remove cubes of sulfur material after Fig. 1 for capping setup. Spread the gypsum cement capping

solidification is complete and remove cubes of gypsum cement material evenly on the capping plate or capping wear plate that

C1552 − 14a

has been lightly coated with oil or sprayed with a TFE- 7.2.2.6 Form a rectangular mold on the capping plate whose

fluorocarbon coating (Note 9). Bring the surface of the speci- dimensions are approximately ⁄2 in. (13 mm) greater than the

mentobecappedintocontactwiththecappingmaterial;firmly overall dimensions of the specimen. The mold must be

press down the specimen with a single motion, holding it so sufficiently rigid to not move or deflect during the capping

that its axis is at right angles to the capping surface to comply operation, and large enough to accommodate the specimen to

with the requirements of 7.4. Do not disturb the specimen until be capped and the sulfur capping material without overflow.

the capping material has solidified. (See Note 11.) Fill the mold to a depth of ⁄4 in. (6 mm) with

7.2.1.1 Alternative Capping Method Using Gypsum Cement the hot sulfur compound. Bring the surface of the specimen to

be capped quickly into contact with the liquid, holding the

Materials—See Fig

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1552 − 14 C1552 − 14a

Standard Practice for

Capping Concrete Masonry Units, Related Units and

Masonry Prisms for Compression Testing

This standard is issued under the fixed designation C1552; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice covers apparatus, materials, and procedures for capping concrete masonry units, related units, including

coupons or other specimens obtained from such units, and masonry prisms for compression testing.

NOTE 1—The testing laboratory performing these test methods should be evaluated in accordance with Practice C1093.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C140 Test Methods for Sampling and Testing Concrete Masonry Units and Related Units

C617 Practice for Capping Cylindrical Concrete Specimens

C1093 Practice for Accreditation of Testing Agencies for Masonry

C1232 Terminology of Masonry

C1314 Test Method for Compressive Strength of Masonry Prisms

3. Terminology

3.1 Terminology defined in Terminology C1232 shall apply for this practice.

4. Significance and Use

4.1 This practice describes procedures for providing plane surfaces on the two bearing surfaces of units and prisms. The purpose

of this standard is to provide consistent and standardized procedures for capping units and prisms for compression testing. The

procedures are based on those contained (or previously contained) in Test Methods C140, Practice C617, and Test Method C1314.

NOTE 2—Specimens capped using this practice will vary significantly in size and weight. Appropriate care and handling may differ based on specimen

size and weight. Provide care and handling as needed to provide for proper capping based on the physical characteristics of the specimen being capped.

5. Apparatus

5.1 Capping Plate—If used, the capping plate shall be made of steel having a thickness of not less than 1 in. (25.4 mm), or a

polished plate of granite or diabase at least 3 in. (76 mm) thick. The capping surface shall be plane within 0.002 in. in 12 in.

(0.05 mm in 300 mm) and shall be free of gouges, grooves, and indentations greater than 0.010 in. (0.25 mm) deep or greater than

2 2

0.05 in. (32 mm ) in surface area. At the time of capping, the capping surface shall be level within ⁄16 in. (1.6 mm) over the length

of the plate.

5.1.1 Capping Wear Plate—If used, the capping wear plate shall be placed directly on top of the capping plate and shall meet

the requirements of 5.2. At the time of capping, the wear plate surface shall be level within ⁄16 in. (1.6 mm) over the length of

the plate. Do not use a capping wear plate with sulfur capping materials.

This practice is under the jurisdiction of ASTM Committee C15 on Manufactured Masonry Units and is the direct responsibility of Subcommittee C15.04 on Research.

Current edition approved July 1, 2014Dec. 1, 2014. Published August 2014December 2014. Originally approved in 2002. Last previous edition approved in 20122014 as

C1552 – 12.C1552 – 14. DOI: 10.1520/C1552-14.10.1520/C1552-14A.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1552 − 14a

FIG. 1 Gypsum Capping Schematic

NOTE 3—A capping wear plate has been found to reduce the potential of damage to the capping plate. The capping wear plate is typically more resistant

to scratches and can be replaced at less cost than that required to resurface the capping plate. See Fig. 1 for a schematic of capping setup when using

gypsum cement materials.

5.2 Casting Plate—If used, the casting plate shall be of transparent glass with a thickness of not less than ⁄2 in. (13 mm). The

casting plate shall be plane within 0.002 in. in 12 in. (0.05 mm in 300 mm).

6. Materials

6.1 Capping Materials:

6.1.1 High Strength Gypsum Cement Capping Materials:

6.1.1.1 In addition to the compressive strength testing required in 6.2, qualification tests shall be made to determine the effects

of water-cement ratio and age on compressive strength. Procedures used for preparing the high strength gypsum cement capping

materials shall ensure that water-cement ratios used for each batch provide the required strength.

NOTE 4—The water-gypsum cement ratio should typically be between 0.26 and 0.30. Use of low water-gypsum cement ratios and vigorous mixing will

usually permit development of 3500 psi (24.1 MPa) at ages of one or two hours. Higher water-gypsum cement ratios extend working time, but reduce

strength.

6.1.1.2 Do not add fillers or extenders to the high strength gypsum cement.

NOTE 5—Retarders extend working time for capping materials but their effects on required water-cement ratio should be determined prior to use.

NOTE 6—See Appendix X1 for more information on high-strength gypsum capping materials and product recommendations.

6.1.2 Sulfur Capping Materials:

6.1.2.1 Proprietary or laboratory prepared sulfur mixtures shall contain 40 to 60 % sulfur by weight, the remainder being ground

fire clay or other suitable inert material passing a No. 100 (150-μm) sieve with or without a plasticizer.

6.1.3 Use only capping materials identified in 6.1.1 and 6.1.2. Do not use other capping materials.

NOTE 7—Examples of materials that have been found to be unsuitable for capping purposes include, but are not limited to: low-strength molding plaster,

plaster of paris, mixtures of plaster of paris and portland cement, and other cement-based materials.

6.2 Compressive Strength of Capping Materials—The compressive strength of the capping material shall be at least 3500 psi

(24.1 MPa) at an age of 2 h. The cube molds and methods of preparing and testing the cubes shall be in accordance with Practice

C617. The capping material shall be placed in the cube at capping consistency. Store the filled molds in laboratory air. Remove

cubes of sulfur material after solidification is complete and remove cubes of gypsum cement material from the molds not more

than 15 min prior to testing. Test cubes at an age of 2 h 6 10 min after completing the filling of the molds.

6.2.1 The strength of the capping material shall be determined on receipt of a new lot and at intervals not exceeding three

months. If a given test of the capping material fails to conform to the strength requirements, the package from which the material

was sampled shall not be used unless two additional subsequent samples are taken from the same package and both of these

subsequent samples conform to the strength requirements. If the strength tests from an individual package are inadequate,

randomly obtain and test three additional samples from the lot. These additional samples shall be taken from separate packages,

if available. Unless these three samples conform to the strength requirements, no part of the lot shall be used.

C1552 − 14a

7. Procedure

7.1 Preparation of Specimens for Capping—Use an abrasive stone to remove loose protrusions from the surfaces of the

specimens to be capped. Refer to the appropriate compression test method (Test Methods C140 or Test Method C1314) for other

specimen preparation requirements.

7.2 Capping Test Specimens—Cap top and bottom bearing surfaces of specimens by one of the methods in 7.2.1 or 7.2.2. Use

alignment devices as needed to make sure the caps meet the requirements of 7.4.

NOTE 8—Various alignment devices have been demonstrated to be effective. For capping with sulfur materials, which sets quickly, alignment jigs make

sure that the specimen is placed on the capping plate correctly in the first motion. For capping with gypsum cement materials, levels placed across the

top of specimen have proven to work well. Bullseye levels work particularly well with smaller specimens.

7.2.1 Capping Using Gypsum Cement Materials—See

Fig. 1 for capping setup. Spread the gypsum cement capping material evenly on the capping plate or capping wear plate that has

been lightly coated with oil or sprayed with a TFE-fluorocarbon coating (Note 9). Bring the surface of the specimen to be capped

into contact with the capping material; firmly press down the specimen with a single motion, holding it so that its axis is at right

angles to the capping surface to comply with the requirements of 7.4. Do not disturb the specimen until the capping material has

solidified.

7.2.1.1 Alternative Capping Method Using Gypsum Cement Materials—See Fig. 1 for capping setup. Spread the gypsum

cement capping material evenly on the top surface of the specimen. Bring the casting plate, which has been lightly coated with

oil or sprayed with TFE-fluorocarbon coating (Note 9), into contact with the capping paste; firmly press down the plate with a

single motion holding it so it is at right angles to the specimen. Within 30 s, lightly adjust the plate to achieve a resulting cap that

will comply with the requirements of 7.4. Do not further disturb the specimen or casting plate until the capping material has

solidified.

NOTE 9—The use of oil or TFE-fluorocarbon coatings on capping or casting plates is not necessary if it is found that the plate and specimen can be

separated without damaging the cap.

NOTE 10—Generally, specimens can be removed from capping or casting plates after 30 min without damaging the cap. However, the le

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.