ASTM F1807-99

(Specification)Standard Specification for Metal Insert Fittings Utilizing a Copper Crimp Ring for SDR9 Cross-linked Polyethylene (PEX) Tubing

Standard Specification for Metal Insert Fittings Utilizing a Copper Crimp Ring for SDR9 Cross-linked Polyethylene (PEX) Tubing

SCOPE

1.1 This specification covers metal insert fittings and copper crimp rings for four sizes of cross-linked polyethylene (PEX) plastic tubing. These fittings are intended for use in 100 psi (689.5 kPa) cold-and hot-water distribution systems operating at temperatures up to and including 180°F (82°C). Included are the requirements for materials, workmanship, dimensions, burst pressure, sustained pressure, excessive temperature and pressure, temperature cycling tests, and markings to be used on the fittings and rings.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI values stated in parentheses are provided for information purposes.

1.3 The following precautionary caveat pertains only to the test methods portion, Section 10, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

An American National Standard

Designation: F 1807 – 99

Standard Specification for

Metal Insert Fittings Utilizing a Copper Crimp Ring for SDR9

Cross-linked Polyethylene (PEX) Tubing

This standard is issued under the fixed designation F 1807; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 618 Practice for Conditioning Plastics for Testing

D 1598 Test Method for Time-To-Failure of Plastic Pipe

1.1 This specification covers metal insert fittings and copper

Under Constant Internal Pressure

crimp rings for four sizes of cross-linked polyethylene (PEX)

D 1599 Test Method for Short-Time, Hydraulic Failure

plastic tubing. These fittings are intended for use in 100 psi

Pressure of Plastic Pipe, Tubing, and Fittings

(689.5 kPa) cold- and hot-water distribution systems operating

D 1600 Terminology for Abbreviated Terms Relating to

at temperatures up to and including 180°F (82°C). Included are

Plastics

the requirements for materials, workmanship, dimensions,

D 2122 Test Method for Determining Dimensions of Ther-

burst pressure, sustained pressure, excessive temperature and

moplastic Pipe and Fittings

pressure, temperature cycling tests, and markings to be used on

E 18 Test Methods for Rockwell Hardness and Superficial

the fittings and rings.

Hardness of Metallic Materials

1.2 The values stated in inch-pound units are to be regarded

F 412 Terminology Relating to Plastic Piping Systems

as the standard. The SI values stated in parentheses are

F 876 Specification for Cross-linked Polyethylene (PEX)

provided for information purposes.

Tubing

1.3 The following precautionary caveat pertains only to the

F 877 Specification for Cross-linked Polyethylene (PEX)

test methods portion, Section 10, of this specification. This

Plastic Hot- and Cold-Water Distribution Systems

standarddoesnotpurporttoaddressallofthesafetyconcerns,

2.2 ASME Standards:

ifany,associatedwithitsuse.Itistheresponsibilityoftheuser

B1.20.1 Pipe Threads General Purpose (Inch)

of this standard to establish appropriate safety and health

B16.18 Cast Copper Alloy Solder Joint Pressure Fittings

practices and determine the applicability of regulatory limita-

B16.22 Wrought Copper and Copper Alloy Solder Joint

tions prior to use.

Pressure Fittings

2. Referenced Documents

2.3 Manufacturer’s Standardization Society Standard:

SP-104 Wrought Copper Solder Joint Pressure Fittings

2.1 ASTM Standards:

2.4 NSF International Standard:

B 16 Specification for Free-Cutting Brass Rod, Bar, and

Standard No. 14 for Plastic Piping Components and Related

Shapes for Use in Screw Machines

Materials

B 62 Specification for Composition Bronze or Ounce Metal

Standard No. 61 for Drinking Water System Components-

Castings

Health Effects

B 75 Specification for Seamless Copper Tube

B 88 Specification for Seamless Copper Water Tube

3. Terminology

B 140/B140M Specification for Copper-Zinc-Lead (Leaded

3.1 Definitions are in accordance with Terminology F 412

Red Brass or Hardware Bronze) Rod, Bar, and Shapes

and abbreviations are in accordance withTerminology D 1600,

B 283 SpecificationforCopperandCopper-AlloyDieForg-

unless otherwise indicated.

ings (Hot-Pressed)

B 584 Specification for Copper Alloy Sand Castings for

General Applications

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 08.04.

Annual Book of ASTM Standards, Vol 03.01.

1 6

This standard is under the jurisdiction of ASTM Committee F-17 on Plastic Available from American Society of Mechanical Engineers, 345 E. 47th St.,

Piping Systems and is the direct responsibility of Subcommittee F17.26 on Olefin New York, NY 10017.

Based Pipe. Available from Manufacturer’s Standardization Society of the Valve and

Current edition approved April 10, 1999. Published July 1999. Originally Fittings Industry, 5203 Leesburg Pike, Suite 502, Falls Church, VA 22041.

published as F 1807–97. Last previous edition F 1807–98a. Available from the National Sanitation Foundation International, P.O. Box

Annual Book of ASTM Standards, Vol 02.01. 1468, Ann Arbor, MI 48106.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1807–99

TABLE 2 Minimum Hydrostatic Sustained Pressure

4. Classification

Requirements for Fitting, Crimp Ring and PEX Tubing

4.1 This specification covers one class of fittings and copper A,B

Assemblies

crimp rings suitable for use with four sizes of PEX tubing that

A

Nominal Tubing Size Pressure Required for Test, psi (kPa)

meet the requirements of Specifications F 876 or F 877.

in. mm 180°F (82.2°C)

⁄8 10 250 (1724)

5. Materials and Manufacture ⁄2 13 195 (1344)

⁄4 and larger 16 and larger 190 (1310)

5.1 Fittings—The fittings shall be made from one of the

A

The fiber stress to derive this test pressure is: 770 psi (5.31 MPa) at 180°F

following metals:

(82.2°C).

B

5.1.1 Wrought Copper—Wrought copper fittings shall be

Test duration is 1000 h.

made from material meeting the requirements of Specification

B 75or B 88 for one of the following coppers: copper UNS

6.5 Excessive Temperature-Pressure Capability:

C10200, C10300, C10800, or C12200.

6.5.1 General—Assemblies shall have adequate strength to

5.1.2 Cast Copper Alloys—Cast copper alloy fittings shall

accommodate short-term conditions, 30 days of 210°F (99°C)

be made from material meeting the requirements of Specifica-

and 150 psi (1034 kPa).

tion B 584, copper alloy UNS C84400, C83800 or C89844 or

6.5.2 Excessive Temperature Hydrostatic Sustained

Specification B 62 copper alloy UNS C83600.

Pressure—Assemblies shall meet sustained pressure require-

5.1.3 Machined Brass—Machined brass fittings shall be

ments shown in Table 3 when tested in accordance with 10.8.

made from material meeting the requirements of Specification

B 140 copper alloy UNS C31400 or Specification B 16 copper

7. Dimensions

alloy UNS C36000.

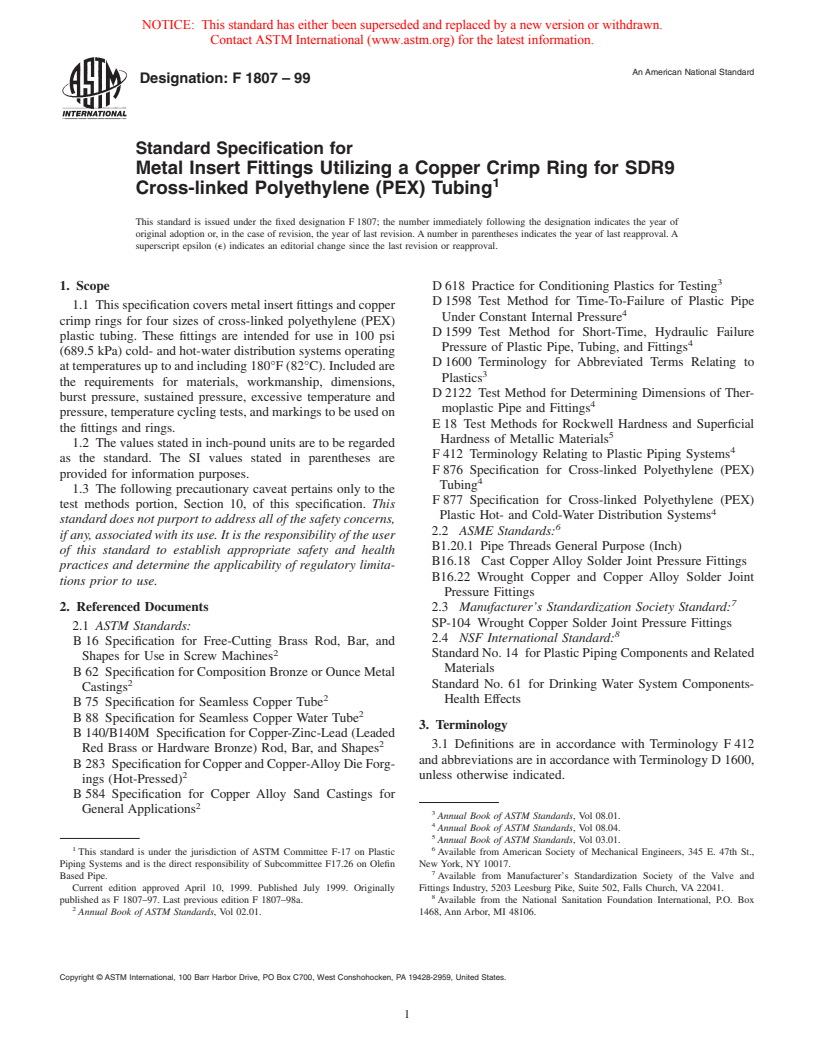

7.1 Dimensions and Tolerances—The dimensions and tol-

5.1.4 Forged Brass—Forged brass fittings shall be made

erances of fittings and crimp rings shall be as shown in Fig. 1,

from material meeting the requirements of Specification B 283

Fig. 2, Fig. 3, and Fig. 4 when measured in accordance with

copper alloy UNS C37700.

10.4.

5.2 Crimp Rings—Crimp rings shall be made from copper

7.1.1 Alignment—The maximum angular variation of any

UNS C10200, or C12200. The crimp rings shall have a

opening shall not exceed 1° off the true centerline axis.

minimum allowable hardness of 35 and a maximum allowable

7.1.2 Fittings with Solder Joint Ends— Solder joint ends

hardness of 45 on the Rockwell 15T scale when measured

shall be in accordance with ASME B16.22, ASME B16.18, or

according to Test Methods E 18.

MSS SP-104.

7.1.3 Tapered Threaded Ends—Fitting threads shall be

6. Performance Requirements

right-hand conforming to ASME B1.20.1. They shall be taper

6.1 General—All performance tests shall be performed on

threads (NPT).

assembliesoffittings,crimpringsandPEXtubing.Fittingsand

crimp rings shall meet the material and dimensional require-

8. Workmanship, Finish, and Appearance

ments of this specification. PEX tubing shall meet the require-

8.1 The sealing surfaces of the insert shall be smooth and

ments of Specification F 876 or F 877. Assembly of test

free of foreign material. Fitting walls shall be free of cracks,

specimens shall be in accordance with 9.1.1. Each assembly

holes, blisters, voids, foreign inclusions, or other defects that

shall contain at least two (2) joints. Use separate sets of

are visible to the unaided eye, that affect the wall integrity.

assemblies for each performance test requirement.

6.2 Hydrostatic Burst—Assemblies shall meet the mini-

9. Assembly

mum hydrostatic burst requirements shown in Table 1 when

9.1 Crimp Joints—Insert fittings shall be joined to PEX

tested in accordance with 10.5.

tubing by the compression of a copper crimp ring around the

6.3 Hydrostatic Sustained Pressure Strength—Assemblies

outer circumference of the tubing, forcing the tubing material

shall meet the hydrostatic sustained pressure requirements

into annular spaces formed by ribs on the fitting. Insert fittings

shown in Table 2 when tested in accordance with 10.6.

and crimp rings shall meet the dimensional and material

6.4 Thermocycling—Assemblies shall not leak or separate

requirements of this standard. PEX tubing shall meet the

when thermocycled 1000 cycles between the temperatures of

requirements of Specifications F 876 or F 877.The dimensions

60°F (16°C) and 180°F (82°C) when tested in accordance with

and out-of-roundness of the crimp ring, after it has been

10.7.

crimped, shall be in accordance with Table 4.

9.1.1 Crimping Procedure—The crimping procedure shall

TABLE 1 Minimum Hydrostatic Burst Strength Requirements for

be as follows: slide the crimp ring onto the tubing, insert the

Fitting, Crimp Ring and PEX Tubing Assemblies

ribbed end of the fitting into the end of the tubing until the

Minimum Burst Pressures at Different

Nominal Tubing Size

Temperatures

A A

psi at (kPa) at psi at (kPa) at

TABLE 3 Excessive Temperature and Pressure Requirements for

in. mm

73.4°F (23°C) 180°F (82.2°C)

Fitting, Crimp Ring and PEX Tubing Assemblies

⁄8 10 620 (4275) 275 (1896)

⁄2 13 480 (3309) 215 (1482) Hydrostatic Test Pressure Air Bath Temperature° F

Test Duration, h

A

⁄4 and larger 16 and larger 475 (3275) 210 (1448) Air Bath, psi (kPa) (°C)

720 150 (1034) 210 (99)

A

The fiber stress to derive this test pressure is:

A

at 73.4°F (23.0°C) 1900 psi (13.10 MPa), The fiber stress used to derive this test pressure is 595 psi (4.10 MPa) at

at 180°F (82.2°C) 850 psi (5.86 MPa). 210°F (99°C).

F1807–99

Maximum

A L S Flash and

B D H G T1 T2 R

Outside Min Number of W Minimum Mismatch,

Size Minimum Distance to Min Rib Rib Spacing Minimum Minimum Minimum

C D

Diameter Insert Ribs Rib Width Average Total on

B E E

ID First Rib Height Typical Wall Wall Radius

A A F

of Rib Length Diameter Crest Di-

G,H

ameter

⁄8 in. 0.345 6 0.004 0.230 0.180-0.224 0.625 0.013 2 0.03–0.05 0.120–0.145 0.025 0.025 0.02 0.369 0.005

⁄2 in. 0.471 6 0.004 0.350 0.180-0.224 0.625 0.013 2 0.03–0.05 0.120–0.145 0.028 0.028 0.02 0.495 0.005

⁄4 in. 0.667 6 0.004 0.530 0.180-0.224 0.625 0.013 2 0.03–0.05 0.120–0.145 0.037 0.032 0.02 0.691 0.005

1 in. 0.856 6 0.004 0.710 0.180-0.224 0.795 0.015 3 0.03–0.05 0.120–0.145 0.041 0.035 0.02 0.880 0.005

A

Measured from shoulder of rib to tube stop.

B

Fitting shall be designed with sufficient overall dimensions to allow proper use of crimp tool without interference with previously completed crimps on the same fitting.

C

Lead chamfer area is not considered a rib.

D

Rib sides may be angled.

E

Applies to entire fitting, not just insert area.

F

The raised area serves as a tube stop for wrought copper fittings that do not have a shoulder.

G

The maximum flash and mismatch at the root diameter between the ribs may not exceed 30 % of the rib height.

H

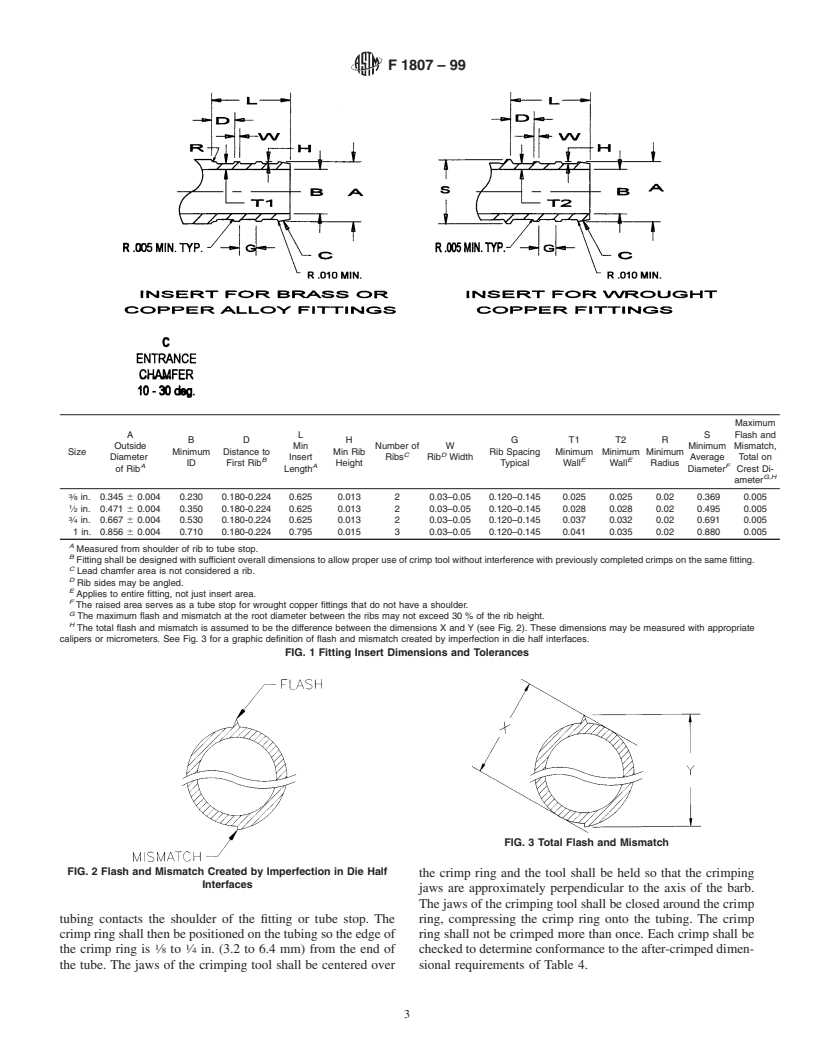

The total flash and mismatch is assumed to be the difference between the dimensions X and Y (see Fig. 2). These dimensions may be measured with appropriate

calipers or micrometers. See Fig. 3 for a graphic definition of flash and mismatch created by imperfection in die half interfaces.

FIG. 1 Fitting Insert Dimensions and Tolerances

FIG. 3 Total Flash and Mismatch

FIG. 2 Flash and Mismatch Created by Imperfection in Die Half

the crimp ring and the tool shall be held so that the crimping

Interfaces

jaws are approximately perpendicular to the axis of the barb.

The jaws of the crimping tool shall be closed around the crimp

tubing contacts the shoulder of the fitting or tube stop. The ring, compressing the crimp ring onto the tubing. The crimp

crimp ring shall then be positioned on the tubing so the edge of ring shall not be crimped more than once. Each crimp shall be

1 1

the crimp ring is ⁄8 to ⁄4 in. (3.2 to 6.4 mm) from the end of checked to determine conformance to the after-crimped dimen-

the tube. The jaws of the crimping tool shall be centered over sional requirements of Table 4.

F1807–99

A B C

Size

A,B B C,D

Avg Outside Diameter Wall Thickness Average Wall Width

⁄8 in. 0.6306 0.003 0.058 6 0.0035 60.002 0.3256 0.020

⁄2 in. 0.7506 0.003 0.056 6 0.0035 60.002 0.3256 0.020

⁄4 in. 1.0006 0.003 0.0566 0.0035 6 0.002 0.3256 0.020

1 in. 1.250 6 0.003 0.049 6 0.0035 6 0.002 0.365 6 0.020

A

All dimensions shall be measured with appropriate micrometers, such as pin or ball micrometers for wall and outside diameter micrometers with flat anvils or vernier

calipers shall be used to measure outside diameters and width of rings.

B

The average measurement is obtained from measurements taken in at least two different circumferential positions which are equally spaced around the circumference.

C

The average wall measurement is obtained from measurements taken in eight different positions which are equally spaced around the circumference.

D

The maximum out-of-roundness of the crimp ring shall not inhibit assembly with the fitting and tubing. The crimp ring dimensions after crimping shall comply with Table

4.

A ,B,C,D

FIG. 4 Copper Crimp Ring Dimensions Before Crimping

TABLE 4 Crimp Ring Dimensions After Crimping on Tube/Fitting

assemblies for each temperature in Table 2. Leakage or

Assembly

separation at any of the joints tested, at less than the minimum

Final Crimped Outside

burst requirements for the temperatures specified in Table 1,

Nominal Tube Size

A,B

Diameter Minimum, Maximum, in. (mm)

Insert End shall constitute a failure in this test.

in. (mm)

10.6 Hydrostatic Sustained Pressure— Perform the test on

⁄8 0.580 (14.7) 0.595 (15.1)

1 at least six assemblies in accordance withTest Method D 1598,

⁄2 0.700 (17.8) 0.715 (18.2)

⁄4 0.945 (24.0) 0.960 (24.4)

except for the following:

1 1.175 (29.8) 1.190 (30.2)

10.6.1 Test temperature shall be 180 6 4°F (82 6 2°C).

A

For all diameters except for the area of scoring caused by the crimping tool.

10.6.2 The external test environment shall be air or water.

B

The maximum out-of-roundness as measured by the difference between the

minimum crimped outside diameter and the maximum crimped outside diameter 10.6.3 Fill the specimens with water at a temperature of at

shall not exceed 0.006 in. (0.150 mm).

least 120°F (50°C).

10.6.4 Leakage or separation at any joint tested, at less than

10. Test Methods

1000 h at the sustained pressure as given in Table 2, shall

10.1 Conditioning—Condition specimens at 73 6 4°F (23

constitute failure in this test.

6 2°C) and 50 6 5 % relative humidity for not less than 4 h

10.7 Thermocycling:

prior to testing. Practice D 618 shall be used as applicable, as

10.7.1 Summary of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.