ASTM E262-97

(Test Method)Standard Method for Determining Thermal Neutron Reaction and Fluence Rates by Radioactivation Techniques

Standard Method for Determining Thermal Neutron Reaction and Fluence Rates by Radioactivation Techniques

SCOPE

1.1 The purpose of this method is to define a general procedure for determining an unknown thermal neutron-fluence rate by neutron activation techniques. It is not practicable to describe completely a technique applicable to the large number of experimental situations that require the measurement of a thermal-neutron fluence rate. Therefore, this method is presented so that the user may adapt to his particular situation the fundamental procedures of the following techniques:

1.1.1 Absolute counting technique using pure cobalt, pure gold, or cobalt-aluminum or gold-aluminum alloy,

1.1.2 Standard foil technique using pure gold, or gold-aluminum alloy, and

1.1.3 Secondary standard foil techniques using pure indium, indium-aluminum alloy, and dysprosium-aluminum alloy.

1.2 The techniques presented are limited to measurements at room temperatures. However, special problems when making thermal-neutron fluence rate measurements in high-temperature environments are discussed in 8.2. For those circumstances where the use of cadmium as a thermal shield is undesirable because of potential spectrum perturbations or of temperatures above the melting point of cadmium, the method described in Test Method E481 can be used in some cases. Alternatively, gadolinium filters may be used instead of cadmium. For high temperature applications in which aluminum alloys are unsuitable, other alloys such as cobalt-nickel or cobalt-vanadium have been used.

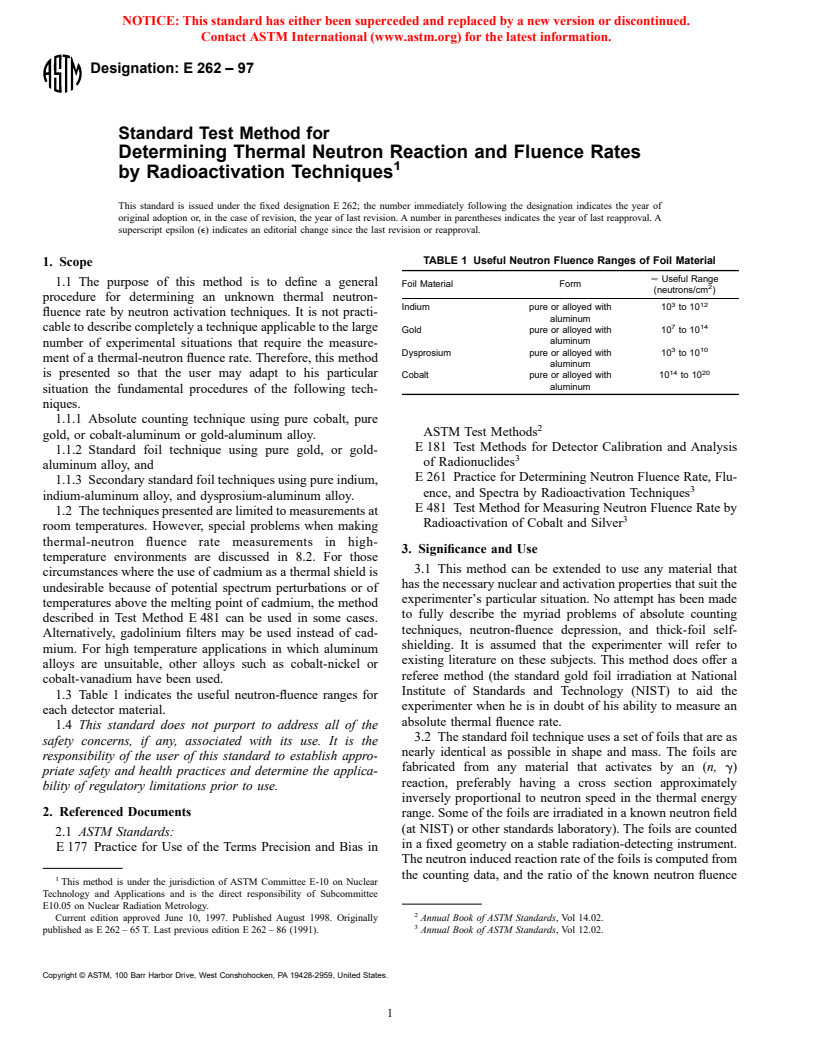

1.3 Table 1 indicates the useful neutron-fluence ranges for each detector material.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard may involve hazardous materials, operations and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 262 – 97

Standard Test Method for

Determining Thermal Neutron Reaction and Fluence Rates

by Radioactivation Techniques

This standard is issued under the fixed designation E 262; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

TABLE 1 Useful Neutron Fluence Ranges of Foil Material

1. Scope

’ Useful Range

1.1 The purpose of this method is to define a general

Foil Material Form

(neutrons/cm )

procedure for determining an unknown thermal neutron-

3 12

Indium pure or alloyed with 10 to 10

fluence rate by neutron activation techniques. It is not practi-

aluminum

7 14

cable to describe completely a technique applicable to the large

Gold pure or alloyed with 10 to 10

aluminum

number of experimental situations that require the measure-

3 10

Dysprosium pure or alloyed with 10 to 10

ment of a thermal-neutron fluence rate. Therefore, this method

aluminum

14 20

is presented so that the user may adapt to his particular Cobalt pure or alloyed with 10 to 10

aluminum

situation the fundamental procedures of the following tech-

niques.

1.1.1 Absolute counting technique using pure cobalt, pure

ASTM Test Methods

gold, or cobalt-aluminum or gold-aluminum alloy.

E 181 Test Methods for Detector Calibration and Analysis

1.1.2 Standard foil technique using pure gold, or gold-

of Radionuclides

aluminum alloy, and

E 261 Practice for Determining Neutron Fluence Rate, Flu-

1.1.3 Secondary standard foil techniques using pure indium,

ence, and Spectra by Radioactivation Techniques

indium-aluminum alloy, and dysprosium-aluminum alloy.

E 481 Test Method for Measuring Neutron Fluence Rate by

1.2 The techniques presented are limited to measurements at

Radioactivation of Cobalt and Silver

room temperatures. However, special problems when making

thermal-neutron fluence rate measurements in high-

3. Significance and Use

temperature environments are discussed in 8.2. For those

3.1 This method can be extended to use any material that

circumstances where the use of cadmium as a thermal shield is

has the necessary nuclear and activation properties that suit the

undesirable because of potential spectrum perturbations or of

experimenter’s particular situation. No attempt has been made

temperatures above the melting point of cadmium, the method

to fully describe the myriad problems of absolute counting

described in Test Method E 481 can be used in some cases.

techniques, neutron-fluence depression, and thick-foil self-

Alternatively, gadolinium filters may be used instead of cad-

shielding. It is assumed that the experimenter will refer to

mium. For high temperature applications in which aluminum

existing literature on these subjects. This method does offer a

alloys are unsuitable, other alloys such as cobalt-nickel or

referee method (the standard gold foil irradiation at National

cobalt-vanadium have been used.

Institute of Standards and Technology (NIST) to aid the

1.3 Table 1 indicates the useful neutron-fluence ranges for

experimenter when he is in doubt of his ability to measure an

each detector material.

absolute thermal fluence rate.

1.4 This standard does not purport to address all of the

3.2 The standard foil technique uses a set of foils that are as

safety concerns, if any, associated with its use. It is the

nearly identical as possible in shape and mass. The foils are

responsibility of the user of this standard to establish appro-

fabricated from any material that activates by an (n, g)

priate safety and health practices and determine the applica-

reaction, preferably having a cross section approximately

bility of regulatory limitations prior to use.

inversely proportional to neutron speed in the thermal energy

2. Referenced Documents range. Some of the foils are irradiated in a known neutron field

(at NIST) or other standards laboratory). The foils are counted

2.1 ASTM Standards:

in a fixed geometry on a stable radiation-detecting instrument.

E 177 Practice for Use of the Terms Precision and Bias in

The neutron induced reaction rate of the foils is computed from

the counting data, and the ratio of the known neutron fluence

This method is under the jurisdiction of ASTM Committee E-10 on Nuclear

Technology and Applications and is the direct responsibility of Subcommittee

E10.05 on Nuclear Radiation Metrology.

Current edition approved June 10, 1997. Published August 1998. Originally Annual Book of ASTM Standards, Vol 14.02.

published as E 262 – 65 T. Last previous edition E 262 – 86 (1991). Annual Book of ASTM Standards, Vol 12.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 262

rate to the computed reaction rate is determined. For any given ~R ! 5 n gs v 5 gs f (3)

s 0 th 0 0 0 0

foil, neutron energy spectrum, and counting set-up, this ratio is

where g is a correction factor that accounts for the departures

a constant. Other foils from the identical set can now be

from the ideal 1/v detector cross section in the thermal energy

exposed to an unknown neutron field. The magnitude of the

range. The same factor appears in the Westcott convention Ref

fluence rate in the unknown field can be obtained by comparing

(1), and is usually referred to as the Westcott g factor. g

the reaction rates as determined from the counting data from

depends on the neutron temperature, T, and is defined as

the unknown and reference field, with proper corrections to

follows:

account for spectral differences between the two fields (see

3 3/2 2

1 ‘ 4 v T v T

0 0

Section 4). One important feature of this technique is that it

g 5 · exp – s~v!dv

S D S D F S D S DG

* 1/2

v s v T v T

0 0 p 0 0

eliminates the need for absolute counting.

(4)

4. Theory 4.2.3 If the thermal neutron spectrum truly follows the

Maxwellian distribution and if the neutron temperature is

4.1 1/v Cross Sections—It is not possible using radioactiva-

known, it is possible to calculate the true thermal neutron

tion techniques to determine the true thermal neutron fluence

fluence rate by multiplying the conventional (equivalent 2200

rate, without making some assumptions about the spectral

m/s) thermal fluence rate by the factor

shapes of both the thermal and epithermal components of the

1/2

neutron density. For most purposes, however, the information

v¯ 4T

5 (5)

S D

v pT

required is only that needed to make calculations of activation

0 0

and other reaction rates for various materials exposed to the

where v¯ is the Maxwellian mean speed for neutron tempera-

neutron field. For reactions in which the cross section varies

ture T, and T is the standard temperature of 293.4°K. This

inversely as the neutron speed (1/v cross sections) the reaction

conversion is most often unnecessary and is usually not made

rates are proportional to the total neutron density and do not

because the temperature T may be unknown. Naturally, it is

depend on the spectrum shape. Many radioactivation detectors

essential when reporting results to be absolutely clear whether

have reaction cross sections in the thermal energy range which

the true thermal fluence rate or the equivalent 2200 m/s thermal

approximate to 1/v cross sections (1/v detectors). Departures

fluence rate or the equivalent 2200 m/s total (Westcott) fluence

from the 1/v shape can be accounted for by means of correction

rate is used. If the true thermal fluence rate is used, then its

factors.

value must be accompanied by the associated temperature

4.2 Fluence Conventions:

value.

4.2.1 The purpose of a fluence convention (formerly called“

4.3 Epithermal Neutrons—In order to determine the effects

flux convention”) is to describe a neutron field in terms of a

of epithermal neutrons, that are invariably present together

few parameters that can be conveniently used to calculate

with thermal neutrons, cadmium covered foil irradiations are

reaction rates. The best known fluence conventions relating to

made. It is important to realize that some epithermal neutrons

thermal neutron fields are the Westcott convention (1) and the

can have energies below the effective cadmium cut-off energy,

Stoughton and Halperin convention (2). Both make use of the

E . The lowest energy of epithermal neutrons is usually taken

cd

concept of an equivalent 2200 m/s fluence rate, that is equal to

to be equal to 5kT (where k is Boltzmann’s constant) which is

the product of the neutron density and the standard speed, v ,

equal to 0.13eV for room temperature (293°K) neutrons (1),

equal to 2200 m/s which is the most probable speed of

though 4 kT has been recommended for some reactors (3).In

Maxwellian thermal neutrons when the characteristic tempera-

order to correct for these, it is necessary to make some

ture is 293.4°K. In the Westcott convention, it is the total

assumption about the epithermal neutron spectrum shape, and

neutron density (thermal plus epithermal) which is multiplied

the assumption made in Refs 1 and 2 is that the epithermal

by v to form the “Westcott flux”, but in the Stoughton and

neutron fluence rate per unit energy is proportional to 1/E:

Halperin convention, the conventional fluence rate is the

f ~E!5f /E,E $ 5kT (6)

e e

product of the Maxwellian thermal neutron density and v . The

latter convention is the one followed in this method:

where f is an epithermal fluence parameter equal to the

e

fluence rate per unit energy, f (E), at 1 eV. This assumption is

f 5 n v (1)

e

0 th 0

usually adequate for the purpose of correcting thermal neutron

where f is the equivalent 2200 m/s thermal fluence rate and

fluence rate measurements for epithermal neutrons at energies

n represents the thermal neutron density, which is propor-

th

below the cadmium cut-off. To represent the epithermal fluence

tional to the reaction rate per atom in a 1/v detector exposed to

more correctly, however, many authors have shown that the use

thermal neutrons:

(1+a)

of a 1/E spectrum shape is preferable, where a is an

~R ! 5 n s v 5s f (2)

s 0 th 0 0 0 0 empirical parameter. Refs (4-10).

4.2.2 (R ) represents only that part of the reaction rate that 4.4 Resonance Integral:

s 0

is induced by thermal neutrons, which have the Maxwellian

4.4.1 The resonance integral for an ideal dilute detector is

spectrum shape. s is the 2200 m/s cross section. For a non-1/v

defined as follows:

detector Eq 2 needs to be replaced by:

‘ dE

I 5 s~E! (7)

*

E

E

cd

4.4.2 The cadmium cut-off energy is taken to be 0.55eV for

The boldface numbers in parentheses refer to the list of references appended to

this method. a cylindrical cadmium box of wall thickness 1 mm. (11). The

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 262

TABLE 3 Resonance Self-Shielding Data for Cobalt Foils

data needed to correct for epithermal neutron reactions in the

(Reference (30))

methods described are the values of I /gs for each reaction

0 0

Foil Thickness

(see Table 2). These values, taken from Refs (26-28), are based

G8

res

G

res

(132 eV)

(in.) (cm)

on integral measurements.

4.5 Reaction Rate:

0.0004 0.001018 0.8264 0.864

0.0010 0.02254 0.7000 0.765

4.5.1 The reaction rate per atom, for an isotope exposed to

0.0025 0.00635 0.5470 0.645

a mixed thermal and epithermal neutron field is given by:

0.0050 0.0127 0.4395 0.561

0.0075 0.01905 0.3831 0.517

R 5f gs 1f gs @f 1 w8 /g 1 I /gs # (8)

s 0 0 e 0 1 0 0

0.010 0.0254 0.3476 0.489

f is a function that describes the epithermal activation of a 0.015 0.0381 0.3028 0.454

0.020 0.0508 0.2744 0.432

1/v detector in the energy range 5kT to E :

cd

1/2

E

cd kT dE

f 5 (9)

S D

1 *

E E

5kT

gs

G 5 G8 1 ~1– G8 ! 0.429 (14)

res res res

I

4.5.2 For E equal to 0.55eV and T equal to 293.4°K, f 5 0

cd 0 1

0.468. w8 in Eq 8 is a function which accounts for departure of

4.7 Fluence Depression Factors—Thermal fluence depres-

the cross section from the 1/v law in the energy range 5kT to

sion is an additional perturbation that occurs when an absorber

E :

is surrounded by a moderator. Because the effects are sensitive

cd

1/2 to the details of individual situations, it is not possible to

1 E kT dE

cd

w8 5 s~E!– gs (10)

F S D G

* 0

provide correction factors here. References (12-20) describe

s E E

5kT

these effects. The problem is avoided when foils are exposed in

Some values of w8 for T equal 293.4°K are given in Table 2.

cavities of vary large volume compared to the detector volume.

4.5.3 For a cadmium covered foil, the reaction rate is given

In other cases, a rough guide is that the external perturbation

as:

effect is usually less than the thermal self-shielding effect, and

R 5f I (11)

s,Cd e 0

much less when the hydrogenous moderator is absent.

4.5.4 This can be used to eliminate the unknown epithermal

5. Apparatus

fluence rate parameter, f , from Eq 8. After rearrangement, one

e

5.1 Radiation-Detection Instruments:

obtains an expression for the saturation activity due to thermal

5.1.1 The radiation detectors that may be used in neutron

neutrons only:

activation techniques are described in the Standard Methods,

gs s w8

0 0

f gs 5 ~R ! 5 R – R 1 1 f 1 (12) E 181. In addition, or as an alternative, a calibration high-

S D

0 0 s 0 s s,Cd 1

I I

0 0

pressure ionization chamber may be used. Details for its

4.6 Neutron Self-Shielding:

construction and calibration may be found in Ref (21).

4.6.1 Unless extremely thin or dilute alloy materials are

5.2 Precision Punch:

used, all of the measurement methods are subject to the effects

5.2.1 A precision punch is required to fabricate a set of

of neutron self-shielding. The modified version of Eq 12 which

identical foils for the standard foil technique. The punch must

takes into account both a thermal self-shielding factor G , and

th

cut foils that have smooth edges. Since finding such a punch

an epithermal self shielding factor G is:

res

commercially available is difficult, it is recommended that the

~R !

punch be custom made. It is possible to have several dies made

s 0

f gs 5 (13)

0 0

G

th to fit one punch so that a variety of foil sizes can be obtained.

Normally, foil diameters are 12.7 mm (0.500 in.) or less. The

1 gs s w8

0 0

5 R – R 1 1 f 1

F s s,Cd S 1 DG

precision punch is one of the most important items in the

G G I G I

th res 0 res 0

standard foil technique particularly if the counting technique

4.6.2 Values of the self-shieldi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.