ASTM C1432-03(2008)

(Test Method)Standard Test Method for Determination of Impurities in Plutonium: Acid Dissolution, Ion Exchange Matrix Separation, and Inductively Coupled Plasma-Atomic Emission Spectroscopic (ICP/AES) Analysis

Standard Test Method for Determination of Impurities in Plutonium: Acid Dissolution, Ion Exchange Matrix Separation, and Inductively Coupled Plasma-Atomic Emission Spectroscopic (ICP/AES) Analysis

SCOPE

1.1 This specification covers blended uranium trioxide (UO3), U3O8, or mixtures of the two, powders that are intended for conversion into a sinterable uranium dioxide (UO2) powder by means of a direct reduction process. The UO2 powder product of the reduction process must meet the requirements of Specification C 753 and be suitable for subsequent UO2 pellet fabrication by pressing and sintering methods. This specification applies to uranium oxides with a 235U enrichment less than 5 %.

1.2 This specification includes chemical, physical, and test method requirements for uranium oxide powders as they relate to the suitability of the powder for storage, transportation, and direct reduction to UO2 powder. This specification is applicable to uranium oxide powders for such use from any source.

1.3 The scope of this specification does not comprehensively cover all provisions for preventing criticality accidents, for health and safety, or for shipping. Observance of this specification does not relieve the user of the obligation to conform to all international, national, state, and local regulations for processing, shipping, or any other way of using uranium oxide powders (see 2.2 and 2.3).

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 The following safety hazards caveat pertains only to the test methods portion of the annexes in this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1432 − 03 (Reapproved2008)

Standard Test Method for

Determination of Impurities in Plutonium: Acid Dissolution,

Ion Exchange Matrix Separation, and Inductively Coupled

Plasma-Atomic Emission Spectroscopic (ICP/AES) Analysis

This standard is issued under the fixed designation C1432; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Nuclear-Grade Plutonium Nitrate Solutions

C1168 PracticeforPreparationandDissolutionofPlutonium

1.1 This test method covers the determination of 25 ele-

Materials for Analysis

ments in plutonium (Pu) materials.The Pu is dissolved in acid,

D1193 Specification for Reagent Water

the Pu matrix is separated from the target impurities by an ion

exchange separation, and the concentrations of the impurities

3. Summary of Test Method

aredeterminedbyinductivelycoupledplasma-atomicemission

spectroscopy (ICP-AES).

3.1 A sample of plutonium metal is dissolved in a small

volume of 6 M hydrochloric acid (HCl). Then, 10 M (HNO )/

1.2 This test method is specific for the determination of 3

0.03 M hydrofluoric acid (HF) is added to the dissolved

impurities in8MHNO solutions. Impurities in other pluto-

plutonium to oxidize the plutonium to the Pu (IV) state. The

nium materials, including plutonium oxide samples, may be

sample solution is loaded onto a nitrate anion exchange resin

determined if they are appropriately dissolved (see Practice

and eluted with8MHNO /0.006 M HF.The rinses contain the

C1168) and converted to8MHNO solutions.

target metallic impurities and less than 15 µg/mL Pu. The

1.3 The values stated in SI units are to be regarded as

plutonium is stripped from the anion exchange resin with 0.1

standard. No other units of measurement are included in this

M HCl. The rinses containing the metallic impurities are

standard.

analyzed by ICP-AES.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

4.1 This test method can be used on plutonium matrices in

priate safety and health practices and determine the applica-

nitrate solutions.

bility of regulatory limitations prior to use.

4.2 This test method has been validated for all elements

2. Referenced Documents listed in Test Methods C757 except sulfur (S) and tantalum

(Ta).

2.1 ASTM Standards:

C757 Specification for Nuclear-Grade Plutonium Dioxide

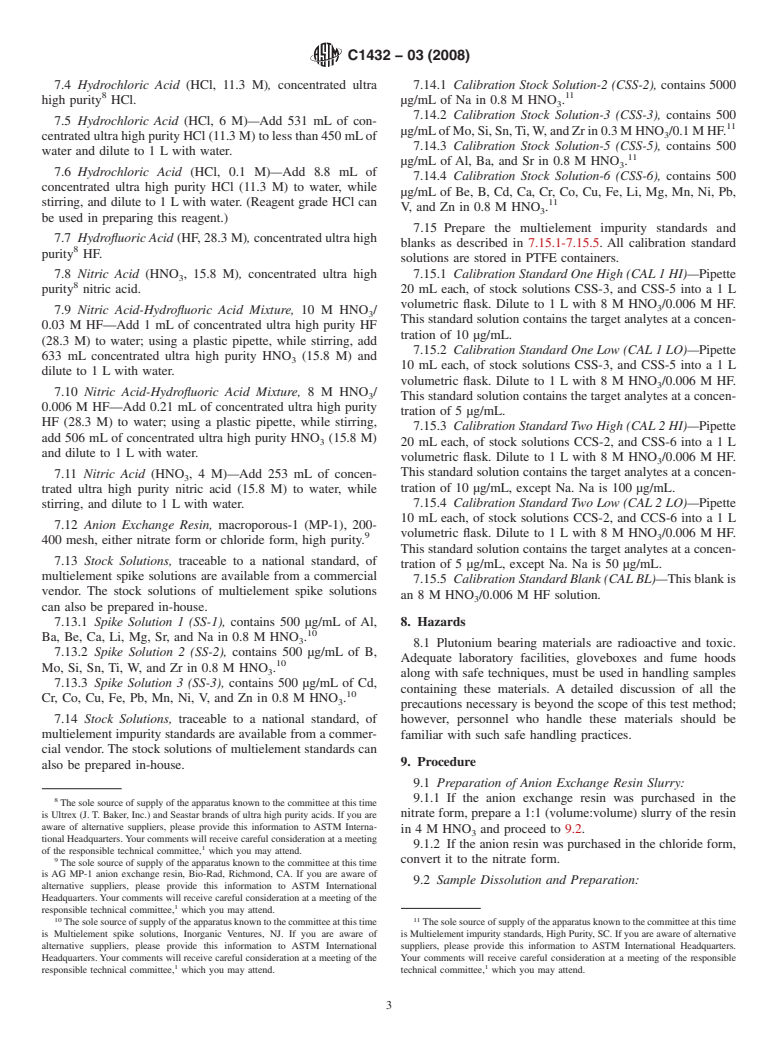

4.3 This test method has been validated for all of the cation

Powder, Sinterable

elements measured in Table 1. Phosphorus (P) requires a

C758 Test Methods for Chemical, Mass Spectrometric,

vacuum or an inert gas purged optical path instrument.

Spectrochemical, Nuclear, and RadiochemicalAnalysis of

Nuclear-Grade Plutonium Metal

5. Interferences

C759 Test Methods for Chemical, Mass Spectrometric,

5.1 Plutonium concentrations of less than 50 µg/mL in the

Spectrochemical, Nuclear, and RadiochemicalAnalysis of

final aqueous phase do not significantly affect the analytical

results for most elements. Interference studies should be made

todeterminethedegreeofPuandotherelementalinterferences

This test method is under the jurisdiction ofASTM Committee C26 on Nuclear

onthetargetanalytes;backgroundandinterelementcorrections

Fuel Cycle and is the direct responsibility of Subcommittee C26.05 on Methods of

Test.

may be required.

Current edition approved Dec. 1, 2008. Published January 2009. Originally

approved in 1999. Last previous edition approved in 2003 as C1432 – 03. DOI:

6. Apparatus

10.1520/C1432-03R08.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1 An ICP-AES equipped with a Charge Injection Device

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

(CID) detector or an ICP-AES with a spectral bandpass of 0.05

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. nm or less is required to provide the necessary spectral

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1432 − 03 (2008)

TABLE 1 Percent Recovery and Repeatability Standard Deviation for Sixteen Spiked Samples

Wavelength/Order Actual Conc Mean Conc Average R.S.D.

Element

(nm) (µg/mL) (µg/mL) (%R) (%)

Aluminum Al 396.152 {67} 2.5 2.4 95 6

Barium Ba 455.403 {58} 2.5 2.4 95 5

Beryllium Be 313.042 {84} 2.5 2.3 94 6

Boron B 249.773 {106} 2.5 2.5 100 7

Cadmium Cd 226.502 {116} 2.5 2.5 101 12

Calcium Ca 396.847 {66} 2.5 2.6 104 20

Chromium Cr 283.563 {93} 2.5 2.3 92 8

Cobalt Co 228.616 {115} 2.5 2.5 101 6

Copper Cu 324.754 {81} 2.5 2.4 97 6

Iron Fe 259.940 {101} 2.5 2.5 101 12

Lead Pb 220.353 {120} 2.5 3.1 122 12

Lithium Li 670.784 {39} 2.5 2.2 87 6

Magnesium Mg 280.270 {94} 2.5 2.4 95 6

Manganese Mn 257.610 {102} 2.5 2.5 98 5

Molybdenum Mo 202.030 {130} 2.5 2.6 103 10

Nickel Ni 231.604 {114} 2.5 2.5 100 11

Silicon Si 251.612 {104} 2.5 2.3 92 16

Sodium Na 588.995 {45} 25.0 24.7 97 16

Strontium Sr 421.552 {62} 2.5 2.4 95 5

Tin Sn 189.989 {139} 2.5 2.7 109 19

Titanium Ti 334.941 {79} 2.5 2.5 102 8

Tungsten W 207.911 {127} 2.5 2.5 99 11

Vanadium V 292.402 {90} 2.5 2.0 82 7

Zinc Zn 213.856 {123} 2.5 2.5 100 8

Zirconium Zr 339.198 {78} 2.5 2.5 101 10

resolution. The spectrometer may be either a simultaneous 6.7 1000 mL plastic volumetric flasks.

multielement or a sequential spectrometer. The spectrometer

may be either an inert gas-path or vacuum instrument; the 7. Reagents and Materials

appropriate spectral lines should be selected for each specific

7.1 Purity of Reagents—Reagent grade chemicals shall be

instrument. Either an analog or digital readout system may be

used in all tests. Unless otherwise indicated, it is intended that

used.

all reagents shall conform to the specifications of the Commit-

6.2 The ICP-AES is interfaced to a glovebox.The torch box

tee on Analytical Reagents of the American Chemical Society

is glovebox enclosed, since plutonium containing materials

(ACS), where such specifications are available. Other grades

comeindirectcontactwiththetorch.Thissetupisdescribedin

could be used, provided it is first ascertained that the reagent is

ASTM STP 951.

of sufficiently high purity to permit its use without lessening

the accuracy of the determination.

6.3 Vacuum manifold set at approximately 23 cm Hg (9 in.

Hg) is optional. A gravity system is also acceptable.

7.2 Purity of Water—Unless otherwise indicated, references

6.4 15 mL plastic disposable ion exchange columns. to water shall be understood to mean laboratory accepted

demineralized or deionized water as described by Type 1 of

6.5 50 mL plastic vials.

Specification D1193.

6.6 Plastic micro and macro pipettes.

7.3 Ultra high purity acids shall be used for sample disso-

lution and calibration standards preparation unless otherwise

The sole source of supply of the apparatus known to the committee at this time

noted.

is Thermo Jarrell Ash PolyScan Iris spectrometer (Thermo Electron Spectroscopy,

Franklin, MA), or an Applied Research Laboratories 3580 ICP-AES instrument

NOTE 1—The molarity of ultra high purity acids may vary from

(Dearborn, MI). If you are aware of alternative suppliers, please provide this

standard ACS specifications for concentrated acids.

information to ASTM International Headquarters. Your comments will receive

1 NOTE 2—All reagents are prepared and stored in polytetrafluoroethyl-

careful consideration at a meeting of the responsible technical committee, which

ene (PTFE) containers.

you may attend.

Edellson, M. C., and Daniel, J. Leland, “Plasma Spectroscopy of the Analysis

of Hazardous Materials: Design and Application of Enclosed Plasma Sources,”

Conference Proceedings, ASTM STP 951, ASTM, 1986.

The sole source of supply of the apparatus known to the committee at this time

is Eichrom Technologies Vacuum Box System (Part # AC-24-BOX), Eichrom

Technologies Inc., Darien. IL. If you are aware of alternative suppliers, please

provide this information toASTM International Headquarters. Your comments will

receive careful consideration at a meeting of the responsible technical committee,

which you may attend. Reagent Chemicals, American Chemical Society Specifications, American

The sole source of supply of the apparatus known to the committee at this time Chemical Society, Washington, DC. For suggestions on the testing of reagents not

is Ion exchange columns from eitherApplied Separation or Bio-Rad Inc. If you are listed by the American Chemical Society, see Analar Standards for Laboratory

aware of alternative suppliers, please provide this information to ASTM Interna- Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

tional Headquarters.Your comments will receive careful consideration at a meeting and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

of the responsible technical committee, which you may attend. MD.

C1432 − 03 (2008)

7.4 Hydrochloric Acid (HCl, 11.3 M), concentrated ultra 7.14.1 Calibration Stock Solution-2 (CSS-2), contains 5000

8 11

high purity HCl. µg/mL of Na in 0.8 M HNO .

7.14.2 Calibration Stock Solution-3 (CSS-3), contains 500

7.5 Hydrochloric Acid (HCl, 6 M)—Add 531 mL of con-

µg/mLofMo,Si,Sn,Ti,W,andZrin0.3MHNO /0.1MHF.

centrated ultra high purity HCl (11.3 M) to less than 450 mLof

7.14.3 Calibration Stock Solution-5 (CSS-5), contains 500

water and dilute to 1 L with water.

µg/mL of Al, Ba, and Sr in 0.8 M HNO .

7.6 Hydrochloric Acid (HCl, 0.1 M)—Add 8.8 mL of

7.14.4 Calibration Stock Solution-6 (CSS-6), contains 500

concentrated ultra high purity HCl (11.3 M) to water, while

µg/mL of Be, B, Cd, Ca, Cr, Co, Cu, Fe, Li, Mg, Mn, Ni, Pb,

stirring, and dilute to 1 L with water. (Reagent grade HCl can

V, and Zn in 0.8 M HNO .

be used in preparing this reagent.)

7.15 Prepare the multielement impurity standards and

7.7 Hydrofluoric Acid (HF, 28.3 M), concentrated ultra high

blanks as described in 7.15.1-7.15.5. All calibration standard

purity HF.

solutions are stored in PTFE containers.

7.15.1 Calibration Standard One High (CAL 1 HI)—Pipette

7.8 Nitric Acid (HNO , 15.8 M), concentrated ultra high

purity nitric acid. 20 mL each, of stock solutions CSS-3, and CSS-5 into a 1 L

volumetric flask. Dilute to 1 L with8MHNO /0.006 M HF.

7.9 Nitric Acid-Hydrofluoric Acid Mixture, 10 M HNO /

This standard solution contains the target analytes at a concen-

0.03 M HF—Add 1 mL of concentrated ultra high purity HF

tration of 10 µg/mL.

(28.3 M) to water; using a plastic pipette, while stirring, add

7.15.2 Calibration Standard One Low (CAL 1 LO)—Pipette

633 mL concentrated ultra high purity HNO (15.8 M) and

10 mL each, of stock solutions CSS-3, and CSS-5 into a 1 L

dilute to 1 L with water.

volumetric flask. Dilute to 1 L with8MHNO /0.006 M HF.

7.10 Nitric Acid-Hydrofluoric Acid Mixture, 8 M HNO /

This standard solution contains the target analytes at a concen-

0.006 M HF—Add 0.21 mL of concentrated ultra high purity

tration of 5 µg/mL.

HF (28.3 M) to water; using a plastic pipette, while stirring,

7.15.3 Calibration Standard Two High (CAL 2 HI)—Pipette

add 506 mL of concentrated ultra high purity HNO (15.8 M)

20 mL each, of stock solutions CCS-2, and CSS-6 intoa1L

and dilute to 1 L with water.

volumetric flask. Dilute to 1 L with8MHNO /0.006 M HF.

This standard solution contains the target analytes at a concen-

7.11 Nitric Acid (HNO,4M)—Add 253 mL of concen-

tration of 10 µg/mL, except Na. Na is 100 µg/mL.

trated ultra high purity nitric acid (15.8 M) to water, while

7.15.4 Calibration Standard Two Low (CAL 2 LO)—Pipette

stirring, and dilute to 1 L with water.

10 mL each, of stock solutions CCS-2, and CCS-6 intoa1L

7.12 Anion Exchange Resin, macroporous-1 (MP-1), 200-

volumetric flask. Dilute to 1 L with8MHNO /0.006 M HF.

400 mesh, either nitrate form or chloride form, high purity.

This standard solution contains the target analytes at a concen-

7.13 Stock Solutions, traceable to a national standard, of

tration of 5 µg/mL, except Na. Na is 50 µg/mL.

multielement spike solutions are available from a commercial

7.15.5 Calibration Standard Blank (CAL BL)—Thisblankis

vendor. The stock solutions of multielement spike solutions

an 8 M HNO /0.006 M HF solution.

can also be prepared in-house.

7.13.1 Spike Solution 1 (SS-1), contains 500 µg/mL of Al,

8. Hazards

Ba, Be, Ca, Li, Mg, Sr, and Na in 0.8 M HNO .

8.1 Plutonium bearing materials are radioactive and toxic.

7.13.2 Spike Solution 2 (SS-2), contains 500 µg/mL of B,

Adequate laboratory facilities, gloveboxes and fume hoods

Mo, Si, Sn, Ti, W, and Zr in 0.8 M HNO .

along with safe techniques, must be used in handling samples

7.13.3 Spike Solution 3 (SS-3), contains 500 µg/mL of Cd,

containing these materials. A detailed discussion of all the

Cr, Co, Cu, Fe, Pb, Mn, Ni, V, and Zn in 0.8 M HNO .

precautions necessary is beyond the scope of this test method;

7.14 Stock Solutions, traceable to a national standard, of

however, personnel who handle these materials should be

multielement impurity standards are available from a commer- familiar with such safe handling practices.

cial vendor. The stock solutions of multielement standards can

9. Procedure

also be prepared in-house.

9.1 Preparation of Anion Exchange Resin Slurry:

8 9.1.1 If the anion exchange resin was purchased in the

The sole source of supply of the apparatus known to the committee at this time

is Ultrex (J. T. Baker, Inc.) and Seastar brands of ultra high purity acids. If you are nitrate form, prepare a 1:1 (volume:volume) slurry of the resin

aware of alternative suppliers, please provide this information to ASTM Interna-

in 4 M HNO and proceed to 9.2.

tional Headquarters.Your comments will receive careful consideration at a meeting

9.1.2 If the anion resin was purchased in the chloride form,

of the responsible technical committee, which you may attend.

convert it to the nitrate form.

The sole source of supply of the apparatus known to the committee at this time

is AG MP-1 anion exchange resin, Bio-Rad, Richmond, CA. If you are aware of

9.2 Sample Dissolution and Preparation:

alternative suppliers, please provide this information to ASTM International

Headquarters.Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend.

10 11

Thesolesourceofsupplyoftheapparatusknowntothecommitteeatthistime Thesolesourceofsupplyoftheapparatusk

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1432–03 Designation: C 1432 – 03 (Reapproved 2008)

Standard Test Method for

Determination of Impurities in Plutonium: Acid Dissolution,

Ion Exchange Matrix Separation, and Inductively Coupled

Plasma-Atomic Emission Spectroscopic (ICP/AES) Analysis

This standard is issued under the fixed designation C 1432; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of 25 elements in plutonium (Pu) materials. The Pu is dissolved in acid, the Pu

matrix is separated from the target impurities by an ion exchange separation, and the concentrations of the impurities are

determined by inductively coupled plasma-atomic emission spectroscopy (ICP-AES).

1.2 This test method is specific for the determination of impurities in8MHNO solutions. Impurities in other plutonium

materials, including plutonium oxide samples, may be determined if they are appropriately dissolved (see Practice C 1168) and

converted to 8 M HNO solutions.

1.3

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C 757 Specification for Nuclear-Grade Plutonium Dioxide Powder, Sinterable

C 758 Test Methods for Chemical, Mass Spectrometric, Spectrochemical, Nuclear, and Radiochemical Analysis of Nuclear-

Grade Plutonium Metal

C 759 Test Methods for Chemical, Mass Spectrometric, Spectrochemical, Nuclear, and Radiochemical Analysis of Nuclear-

Grade Plutonium Nitrate Solutions

C 1168 Practice for Preparation and Dissolution of Plutonium Materials for Analysis

D 1193 Specification for Reagent Water

3. Summary of Test Method

3.1 Asample of plutonium metal is dissolved in a small volume of 6 M hydrochloric acid (HCl). Then, 10 M (HNO )/0.03 M

hydrofluoric acid (HF) is added to the dissolved plutonium to oxidize the plutonium to the Pu (IV) state. The sample solution is

loadedontoanitrateanionexchangeresinandelutedwith8MHNO /0.006MHF.Therinsescontainthetargetmetallicimpurities

and less than 15 µg/mL Pu. The plutonium is stripped from the anion exchange resin with 0.1 M HCl. The rinses containing the

metallic impurities are analyzed by ICP-AES.

4. Significance and Use

4.1 This test method can be used on plutonium matrices in nitrate solutions.

4.2 This test method has been validated for all elements listed in Test Methods C 757 except sulfur (S) and tantalum (Ta).

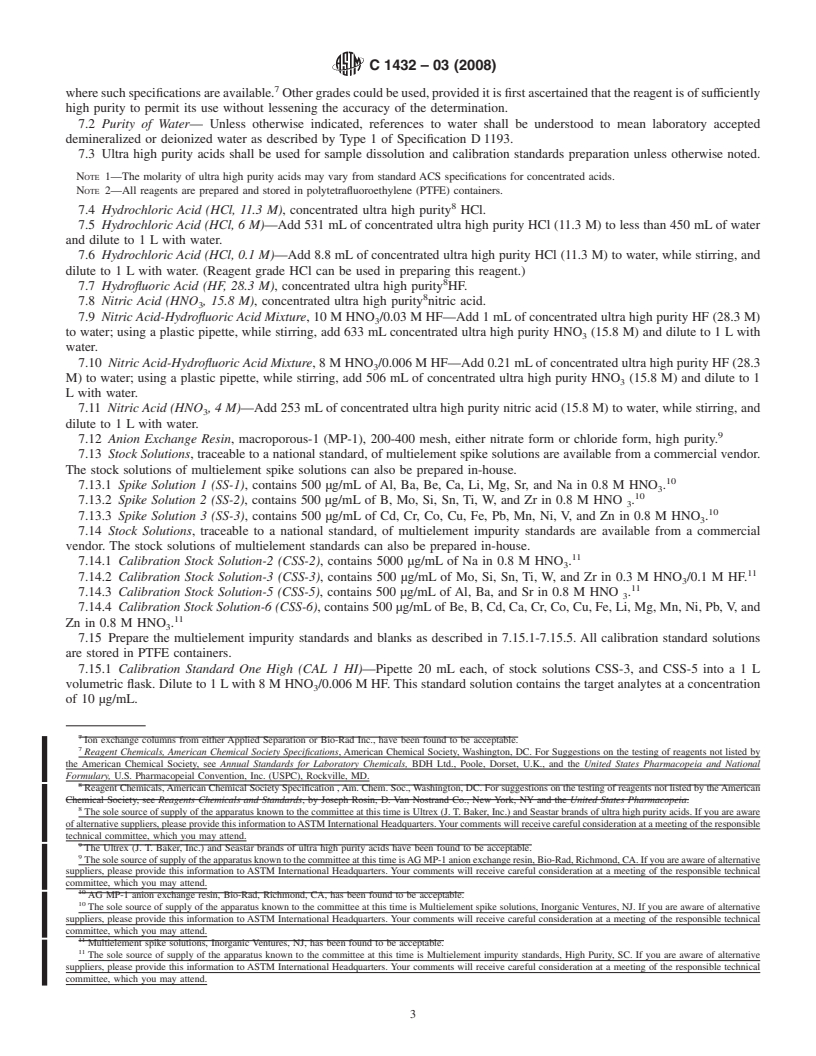

4.3 This test method has been validated for all of the cation elements measured in Table 1. Phosphorus (P) requires a vacuum

or an inert gas purged optical path instrument.

5. Interferences

5.1 Plutonium concentrations of less than 50 µg/mL in the final aqueous phase do not significantly affect the analytical results

This test method is under the jurisdiction ofASTM Committee C26 on Nuclear Fuel Cycle and is the direct responsibility of Subcommittee C26.05 on Methods of Test.

Current edition approved Feb. 10, 2003. Published April 2003. Originally approved in 1999. Last previous edition approved in 1999 as C1432–99.

Current edition approved Dec. 1, 2008. Published January 2009. Originally approved in 1999. Last previous edition approved in 2003 as C 1432 – 03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 12.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 1432 – 03 (2008)

TABLE 1 Percent Recovery and Repeatability Standard Deviation for Sixteen Spiked Samples

Wavelength/Order Actual Conc Mean Conc Average R.S.D.

Element

(nm) (µg/mL) (µg/mL) (%R) (%)

Aluminum Al 396.152 {67} 2.5 2.4 95 6

Barium Ba 455.403 {58} 2.5 2.4 95 5

Beryllium Be 313.042 {84} 2.5 2.3 94 6

Boron B 249.773 {106} 2.5 2.5 100 7

Cadmium Cd 226.502 {116} 2.5 2.5 101 12

Calcium Ca 396.847 {66} 2.5 2.6 104 20

Chromium Cr 283.563 {93} 2.5 2.3 92 8

Cobalt Co 228.616 {115} 2.5 2.5 101 6

Copper Cu 324.754 {81} 2.5 2.4 97 6

Iron Fe 259.940 {101} 2.5 2.5 101 12

Lead Pb 220.353 {120} 2.5 3.1 122 12

Lithium Li 670.784 {39} 2.5 2.2 87 6

Magnesium Mg 280.270 {94} 2.5 2.4 95 6

Manganese Mn 257.610 {102} 2.5 2.5 98 5

Molybdenum Mo 202.030 {130} 2.5 2.6 103 10

Nickel Ni 231.604 {114} 2.5 2.5 100 11

Silicon Si 251.612 {104} 2.5 2.3 92 16

Sodium Na 588.995 {45} 25.0 24.7 97 16

Strontium Sr 421.552 {62} 2.5 2.4 95 5

Tin Sn 189.989 {139} 2.5 2.7 109 19

Titanium Ti 334.941 {79} 2.5 2.5 102 8

Tungsten W 207.911 {127} 2.5 2.5 99 11

Vanadium V 292.402 {90} 2.5 2.0 82 7

Zinc Zn 213.856 {123} 2.5 2.5 100 8

Zirconium Zr 339.198 {78} 2.5 2.5 101 10

for most elements. Interference studies should be made to determine the degree of Pu and other elemental interferences on the

target analytes; background and interelement corrections may be required.

6. Apparatus

6.1 An ICP-AES equipped with a Charge Injection Device (CID) detector or an ICP-AES with a spectral bandpass of 0.05 nm

or less is required to provide the necessary spectral resolution. The spectrometer may be either a simultaneous multielement or

a sequential spectrometer. The spectrometer may be either an inert gas-path or vacuum instrument; the appropriate spectral lines

should be selected for each specific instrument. Either an analog or digital readout system may be used.

6.2 The ICP-AES is interfaced to a glovebox. The torch box is glovebox enclosed, since plutonium containing materials come

in direct contact with the torch. This setup is described in ASTM STP 951.

6.3 Vacuum manifold set at approximately 23 cm Hg (9 in. Hg) is optional. A gravity system is also acceptable.

6.4 15 mL plastic disposable ion exchange columns.

6.5 50 mL plastic vials.

6.6 Plastic micro and macro pipettes.

6.7 1000 mL plastic volumetric flasks.

7. Reagents and Materials

7.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society (ACS),

Annual Book of ASTM Standards, Vol 11.01.

The sole source of supply of the apparatus known to the committee at this time is Thermo Jarrell Ash PolyScan Iris spectrometer (Thermo Electron Spectroscopy,

Franklin, MA), or anApplied Research Laboratories 3580 ICP-AES instrument (Dearborn, MI). If you are aware of alternative suppliers, please provide this information to

ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may attend.

A Thermo Jarrell Ash PolyScan Iris spectrometer (Thermo Electron Spectroscopy, Franklin, MA), or an Applied Research Laboratories 3580 ICP-AES instrument

(Dearborn, MI) have been found to be acceptable.

Edellson, M. C., and Daniel, J. Leland, “Plasma Spectroscopy of the Analysis of Hazardous Materials: Design and Application of Enclosed Plasma Sources,”

Conference Proceedings, ASTM STP 951, ASTM, 1986.

Edellson, M. C., and Daniel, J. Leland, “Plasma Spectroscopy of theAnalysis of Hazardous Materials: Design andApplication of Enclosed Plasma Sources,” Conference

Proceedings, ASTM STP 951, ASTM, 1986.

ThesolesourceofsupplyoftheapparatusknowntothecommitteeatthistimeisEichromTechnologiesVacuumBoxSystem(Part#AC-24-BOX),EichromTechnologies

Inc., Darien. IL. If you are aware of alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful

consideration at a meeting of the responsible technical committee, which you may attend.

Eichrom Technologies Vacuum Box System (Part # AC-24-BOX), Eichrom Technologies Inc., Darien. IL, has been found to be acceptable.

The sole source of supply of the apparatus known to the committee at this time is Ion exchange columns from eitherApplied Separation or Bio-Rad Inc. If you are aware

ofalternativesuppliers,pleaseprovidethisinformationtoASTMInternationalHeadquarters.Yourcommentswillreceivecarefulconsiderationatameetingoftheresponsible

technical committee, which you may attend.

C 1432 – 03 (2008)

wheresuchspecificationsareavailable. Othergradescouldbeused,provideditisfirstascertainedthatthereagentisofsufficiently

high purity to permit its use without lessening the accuracy of the determination.

7.2 Purity of Water— Unless otherwise indicated, references to water shall be understood to mean laboratory accepted

demineralized or deionized water as described by Type 1 of Specification D 1193.

7.3 Ultra high purity acids shall be used for sample dissolution and calibration standards preparation unless otherwise noted.

NOTE 1—The molarity of ultra high purity acids may vary from standard ACS specifications for concentrated acids.

NOTE 2—All reagents are prepared and stored in polytetrafluoroethylene (PTFE) containers.

7.4 Hydrochloric Acid (HCl, 11.3 M), concentrated ultra high purity HCl.

7.5 Hydrochloric Acid (HCl, 6 M)—Add 531 mL of concentrated ultra high purity HCl (11.3 M) to less than 450 mL of water

and dilute to 1 L with water.

7.6 Hydrochloric Acid (HCl, 0.1 M)—Add 8.8 mL of concentrated ultra high purity HCl (11.3 M) to water, while stirring, and

dilute to 1 L with water. (Reagent grade HCl can be used in preparing this reagent.)

7.7 Hydrofluoric Acid (HF, 28.3 M), concentrated ultra high purity HF.

7.8 Nitric Acid (HNO , 15.8 M), concentrated ultra high purity nitric acid.

7.9 Nitric Acid-Hydrofluoric Acid Mixture,10MHNO /0.03 M HF—Add 1 mLof concentrated ultra high purity HF (28.3 M)

to water; using a plastic pipette, while stirring, add 633 mL concentrated ultra high purity HNO (15.8 M) and dilute to 1 L with

water.

7.10 Nitric Acid-Hydrofluoric Acid Mixture,8MHNO /0.006 M HF—Add 0.21 mLof concentrated ultra high purity HF (28.3

M) to water; using a plastic pipette, while stirring, add 506 mL of concentrated ultra high purity HNO (15.8 M) and dilute to 1

L with water.

7.11 Nitric Acid (HNO ,4M)—Add 253 mLof concentrated ultra high purity nitric acid (15.8 M) to water, while stirring, and

dilute to 1 L with water.

7.12 Anion Exchange Resin, macroporous-1 (MP-1), 200-400 mesh, either nitrate form or chloride form, high purity.

7.13 Stock Solutions, traceable to a national standard, of multielement spike solutions are available from a commercial vendor.

The stock solutions of multielement spike solutions can also be prepared in-house.

7.13.1 Spike Solution 1 (SS-1), contains 500 µg/mL of Al, Ba, Be, Ca, Li, Mg, Sr, and Na in 0.8 M HNO .

7.13.2 Spike Solution 2 (SS-2), contains 500 µg/mL of B, Mo, Si, Sn, Ti, W, and Zr in 0.8 M HNO .

7.13.3 Spike Solution 3 (SS-3), contains 500 µg/mL of Cd, Cr, Co, Cu, Fe, Pb, Mn, Ni, V, and Zn in 0.8 M HNO .

7.14 Stock Solutions, traceable to a national standard, of multielement impurity standards are available from a commercial

vendor. The stock solutions of multielement standards can also be prepared in-house.

7.14.1 Calibration Stock Solution-2 (CSS-2), contains 5000 µg/mL of Na in 0.8 M HNO .

7.14.2 Calibration Stock Solution-3 (CSS-3), contains 500 µg/mL of Mo, Si, Sn, Ti, W, and Zr in 0.3 M HNO /0.1 M HF.

7.14.3 Calibration Stock Solution-5 (CSS-5), contains 500 µg/mL of Al, Ba, and Sr in 0.8 M HNO .

7.14.4 Calibration Stock Solution-6 (CSS-6), contains 500 µg/mLof Be, B, Cd, Ca, Cr, Co, Cu, Fe, Li, Mg, Mn, Ni, Pb, V, and

Zn in 0.8 M HNO .

7.15 Prepare the multielement impurity standards and blanks as described in 7.15.1-7.15.5. All calibration standard solutions

are stored in PTFE containers.

7.15.1 Calibration Standard One High (CAL 1 HI)—Pipette 20 mL each, of stock solutions CSS-3, and CSS-5 intoa1L

volumetric flask. Dilute to 1 Lwith 8 M HNO /0.006 M HF. This standard solution contains the target analytes at a concentration

of 10 µg/mL.

Ion exchange columns from either Applied Separation or Bio-Rad Inc., have been found to be acceptable.

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For Suggestions on the testing of reagents not listed by

the American Chemical Society, see Annual Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

Reagent Chemicals,American Chemical Society Specification ,Am. Chem. Soc., Washington, DC. For suggestions on the testing of reagents not listed by theAmerican

Chemical Society, see Reagents Chemicals and Standards, by Joseph Rosin, D. Van Nostrand Co., New York, NY and the United States Pharmacopeia.

The sole source of supply of the apparatus known to the committee at this time is Ultrex (J. T. Baker, Inc.) and Seastar brands of ultra high purity acids. If you are aware

ofalternativesuppliers,pleaseprovidethisinformationtoASTMInternationalHeadquarters.Yourcommentswillreceivecarefulconsiderationatameetingoftheresponsible

technical committee, which you may attend.

The Ultrex (J. T. Baker, Inc.) and Seastar brands of ultra high purity acids have been found to be acceptable.

ThesolesourceofsupplyoftheapparatusknowntothecommitteeatthistimeisAGMP-1anionexchangeresin,Bio-Rad,Richmond,CA.Ifyouareawareofalternative

suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical

committee, which you may attend.

AG MP-1 anion exchange resin, Bio-Rad, Richmond, CA, has been found to be acceptable.

The sole source of supply of the apparatus known to the committee at this time is Multielement spike solutions, Inorganic Ventures, NJ. If you are aware of alternative

suppliers, please provide this information to ASTM International Headquarters. Y

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1432–99 Designation: C 1432 – 03 (Reapproved 2008)

Standard Test Method for

Determination of Impurities in Plutonium: Acid Dissolution,

Ion Exchange Matrix Separation, and Inductively Coupled

Plasma-Atomic Emission Spectroscopic (ICP/AES) Analysis

This standard is issued under the fixed designation C 1432; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of 25 elements in plutonium (Pu) materials. The Pu is dissolved in acid, the Pu

matrix is separated from the target impurities by an ion exchange separation, and the concentrations of the impurities are

determined by inductively coupled plasma-atomic emission spectroscopy (ICP-AES). The elements determined are listed in Table

2.

1.2 This test method is specific for the determination of impurities in Pu in 8 M nitric acid (HNOHNO ) solutions. Impurities

in other plutonium materials, including plutonium oxide samples, may be determined if they are appropriately dissolved (see

PracticesPractice C 1168) and converted to8MHNO solutions.

1.3Plutonium bearing materials are radioactive and toxic. Adequate laboratory facilities, glove boxes, and fume hoods, along

with safe techniques, must be used in handling samples containing these materials. A detailed discussion of all the precautions

necessary is beyond the scope of this test method; however, personnel who handle these materials should be familiar with such

safe handling practices.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

oftheuserofthismethodstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatory

limitations prior to use of this standard.use.

2. Referenced Documents

2.1 ASTM Standards:

C697Test Methods for Chemical, Mass Spectrometric, and Spectrochemical Analysis of Nuclear-Grade Plutonium Dioxide

Powers and Pellets

C 757 Specification for Nuclear-Grade Plutonium Dioxide Powder, Sinterable

C 758 Test Methods for Chemical, Mass Spectrometric, Spectrochemical, Nuclear, and Radiochemical Analysis of Nuclear-

Grade Plutonium Metal

C 759 Test Methods for Chemical, Mass Spectrometric, Spectrochemical, Nuclear, and Radiochemical Analysis of Nuclear-

Grade Plutonium Nitrate Solutions

C 1168 Practice for Preparation and Dissolution of Plutonium Materials for Analysis

D 1193 Specification for Reagent Water

3. Summary of Test Method

3.1 A sample of Puplutonium metal is dissolved in a small volume of 6 M hydrochloric acid (HCl). Then, 1 mL of 10 M

(HNO )/0.2)/0.03 M hydrofluoric acid (HF) is added to the dissolved Puplutonium to oxidize the Puplutonium to the Pu (IV) state.

The sample solution is loaded onto a nitrate anion exchange resin and eluted with 8 M HNO /0.2/0.006 M HF. The rinses contain

the target metallic impurities and less than 15 µg/mL Pu. The Puplutonium is stripped from the anion exchange resin with 0.1 M

HCl. The rinses containing the metallic impurities are analyzed by ICP-AES.

This guide is under the jurisdiction of ASTM Committee C-26 on Nuclear Fuel Cycle and is the direct responsibility of Subcommittee C26.05 on Methods of Test.

Current edition approved June 10, 1999. Published August 1999.

This test method is under the jurisdiction ofASTM Committee C26 on Nuclear Fuel Cycle and is the direct responsibility of Subcommittee C26.05 on Methods of Test.

Current edition approved Dec. 1, 2008. Published January 2009. Originally approved in 1999. Last previous edition approved in 2003 as C 1432 – 03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

, Vol 12.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 1432 – 03 (2008)

4. Significance and Use

4.1This test method measures all elements listed in Specification C757, except sulfur (S) and tantalum (Ta).

4.2This test method measures all of the cation elements measured in Test Methods C697, except silver (Ag), gold (Au), and

bismuth (Bi). Phosphorus (P) requires a vacuum instrument.

4.1 This test method can be used on plutonium matrices in nitrate solutions.

4.2 This test method has been validated for all elements listed in Test Methods C 757 except sulfur (S) and tantalum (Ta).

4.3 This test method has been validated for all of the cation elements measured in Table 1. Phosphorus (P) requires a vacuum

or an inert gas purged optical path instrument.

5. Interferences

5.1 Plutonium concentrations of less than 50 µg/mL in the final aqueous phase do not significantly affect the analytical results

for most elements. Interference studies should be made to determine the degree of Pu and other elemental interferences on the

target analytes; background and interelement corrections may be required.

6. Apparatus

6.1An ICP-AES with a spectral bandpass of 0.05 nm or less is required to provide the necessary spectral resolution.

6.1 An ICP-AES equipped with a Charge Injection Device (CID) detector or an ICP-AES with a spectral bandpass of 0.05 nm

or less is required to provide the necessary spectral resolution. The spectrometer may be either a simultaneous multielement or

a sequential spectrometer. The spectrometer may be either an inert gas-path or vacuum instrument; the appropriate spectral lines

should be selected for each specific instrument. Either an analog or digital readout system may be used.

6.2The ICP-AES is interfaced to a glovebox. The torchbox is glovebox enclosed since Pu containing materials come in direct

contact with the torch. The torchbox offers several safety features, such as a shielded window for observing the plasma, which

Annual Book of ASTM Standards, Vol 11.01.

The sole source of supply of the apparatus known to the committee at this time is Thermo Jarrell Ash PolyScan Iris spectrometer (Thermo Electron Spectroscopy,

Franklin, MA), or anApplied Research Laboratories 3580 ICP-AES instrument (Dearborn, MI). If you are aware of alternative suppliers, please provide this information to

ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may attend.

TABLE 1 ICP-AES Opercent Recovery and Repeatability Stang Condard Deviation for Sixteen Spiked SamplesA

Wavelength/Order Actual Conc Mean Conc Average R.S.D.

ParaElementer

(nm) (µg/mL) (µg/mL) (%R) (%)

Valueminum Al 396.152 {67} 2.5 2.4 95 6

Aluminum Al 396.152 {67} 2.5 2.4 95 6

Forward rf power 1.4 kW03 {58} 2.5 2.4 95 5

Barium Ba 455.403 {58} 2.5 2.4 95 5

Reflectedrf power <10 W42 {84} 2.5 2.3 94 6

Beryllium Be 313.042 {84} 2.5 2.3 94 6

Outer argon flow 106} 2.5 L/min 2.5 100 7

Boron B 249.773 {106} 2.5 2.5 100 7

Auxiliary argon flow 02 {116} 2.8L/min5 2.5 101 12

Cadmium Cd 226.502 {116} 2.5 2.5 101 12

Carrier argon flow 0.7 L/min {66} 2.5 2.6 104 20

Calcium Ca 396.847 {66} 2.5 2.6 104 20

Observation height 15 mm above load coil63 {93} 2.5 2.3 92 8

Chromium Cr 283.563 {93} 2.5 2.3 92 8

Nebulizer Cross flow type 228.616 {115} 2.5 2.5 101 6

Cobalt Co 228.616 {115} 2.5 2.5 101 6

Solution uptakerate 1} 2.5 2.4 97 6

Copper Cu 324.754 {81} 2.5 2.4 97 6

Iron Fe 259.940 {101} 2.5 2.5 101 12

Lead Pb 220.353 {120} 2.5 3.1 122 12

Lithium L/i 670.784 {39} 2.5 2.2 87 6

Lithium Li 670.784 {39} 2.5 2.2 87 6

Magnesium Mg 280.270 {94} 2.5 2.4 95 6

Manganese Mn 257.610 {102} 2.5 2.5 98 5

Molybdenum Mo 202.030 {130} 2.5 2.6 103 10

Nickel Ni 231.604 {114} 2.5 2.5 100 11

Silicon Si 251.612 {104} 2.5 2.3 92 16

Sodium Na 588.995 {45} 25.0 24.7 97 16

Strontium Sr 421.552 {62} 2.5 2.4 95 5

Tin Sn 189.989 {139} 2.5 2.7 109 19

Titanium Ti 334.941 {79} 2.5 2.5 102 8

Tungsten W 207.911 {127} 2.5 2.5 99 11

Vanadium V 292.402 {90} 2.5 2.0 82 7

Zinc Zn 213.856 {123} 2.5 2.5 100 8

Zirconium Zr 339.198 {78} 2.5 2.5 101 10

A

These conditions are typical for an ARL #3580.

C 1432 – 03 (2008)

allows the operator to view the plasma without risking damage to the eyes. The torchbox is equipped with an interlock that shuts

off high voltage power to the torchbox when the torchbox door is open. The interlock prevents the operator from being exposed

to high voltages during routine cleaning. This setup is described in ASTM STP 951.

6.2 The ICP-AES is interfaced to a glovebox. The torch box is glovebox enclosed, since plutonium containing materials come

in direct contact with the torch. This setup is described in ASTM STP 951.

6.3 Vacuum manifold set at approximately 23 cm Hg (9 in. Hg) is optional.

6.3Vacuum manifold set at approximately 9 in. Hg (optional).A gravity system is also acceptable.

6.4 15 mL plastic disposable ion exchange columns. A gravity system is acceptable.

6.415-mL plastic disposable ion exchange columns.

6.530-mL plastic vials.

6.5 50 mL plastic vials.

6.6 Plastic micro and macro pipettes.

6.7A 500-mL fritted column.

6.7 1000 mL plastic volumetric flasks.

7. Reagents and Materials

7.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society (ACS),

where such specifications are available. Other grades shouldcould be used, provided it is first ascertained that the reagent is of

sufficiently high purity to permit its use without lessening the accuracy of the determination.

7.2 Purity of Water— Unless otherwise indicated, references to water shall be understood to mean laboratory accepted

demineralized or deionized water as described by Type 1 of Specification D 1193.

7.3 Ultra high purity acids shall be used for sample dissolution and calibration standards preparation unless otherwise noted.

NOTE1—All reagents are prepared and stored in polytetrafluoroethylene (PTFE) containers. 1—The molarity of ultra high purity acids may vary from

standard ACS specifications for concentrated acids.

NOTE 2—All reagents are prepared and stored in polytetrafluoroethylene (PTFE) containers.

7.4 Hydrochloric Acid ((HCl) (sp gr 1.18))(HCl, 11.3 M), concentrated ultra high purity HCl.

7.5 Hydrochloric Acid (HCl, 6 M)—Add 500531 mL of concentrated ultra high purity HCl (sp gr 1.18) (11.3 M) to less than

500450 mL of water and dilute to 1 L with water.

7.6 HydrochloricAcid (HCl, 0.1 M)—Add 8.38.8 mLof concentrated ultra high purity HCl (sp gr 1.18)(11.3 M) to water, while

stirring, and dilute to 1 L with water. (Reagent grade HCl can be used in preparing this reagent.)

9 8

7.7 Hydrofluoric Acid ((HF) (sp gr 1.15)), concentrated ultra high purity (HF, 28.3 M), concentrated ultra high purity HF.

7.8Nitric Acid ((HNO ) (sp gr 1.42)), concentrated ultra high purity HNO .

3 3

7.8 Nitric Acid (HNO , 15.8 M), concentrated ultra high purity nitric acid.

7.9 Nitric Acid-Hydrofluoric Acid Mixture,10MHNO /0.2 M HF—Add 7.2 mL of concentrated ultra high purity HF (sp gr

1.15) to water, using a plastic pipet, while stirring; add 637-mLconcentrated ultra high purity HNO

/0.03 M HF—Add 1 mL of concentrated

ultra high purity HF (28.3 M) to water; using a plastic pipette, while stirring, add 633 mL concentrated ultra high purity HNO (sp gr 1.42);(15.8 M) and dilute

to 1 L with water.

An Applied Research Laboratories 3580 ICP-AES instrument (Fisons Instruments, Dearborn, MI) has been found to be acceptable. The ARL 3580 is a combination

Pashen-Runge type spectrometer containing a 58 channel simultaneous spectrometer and a sequential spectrometer, both with a 1-m focal length and capable of operating

in the 165 to 800-nm range.

Edellson, M. C., and Daniel, J. Leland, “Plasma Spectroscopy of theAnalysis of Hazardous Materials: Design andApplication of Enclosed Plasma Sources,” Conference

Proceedings, ASTM STP 951, ASTM, 1986.

Edelson, M. C., and Daniel, J. Leland, “Plasma Spectroscopy of theAnalysis of Hazardous Materials: Design andApplication of Enclosed Plasma Sources,” Conference

Proceedings, ASTM STP 951, ASTM, 1986.

ThesolesourceofsupplyoftheapparatusknowntothecommitteeatthistimeisEichromTechnologiesVacuumBoxSystem(Part#AC-24-BOX),EichromTechnologies

Inc., Darien. IL. If you are aware of alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful

consideration at a meeting of the responsible technical committee, which you may attend.

Speed Mate 10 Vacuum Extraction System, Applied Separations, Bethlehem, PA, has been found to be acceptable.

The sole source of supply of the apparatus known to the committee at this time is Ion exchange columns from eitherApplied Separation or Bio-Rad Inc. If you are aware

ofalternativesuppliers,pleaseprovidethisinformationtoASTMInternationalHeadquarters.Yourcommentswillreceivecarefulconsiderationatameetingoftheresponsible

technical committee, which you may attend.

Ion exchange columns from either Applied Separation or Bio-Rad Inc. have been found to be acceptable.

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For Suggestions on the testing of reagents not listed by

the American Chemical Society, see Annual Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, D.C. For suggestions on the testing of reagents not listed by

the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

The sole source of supply of the apparatus known to the committee at this time is Ultrex (J. T. Baker, Inc.) and Seastar brands of ultra high purity acids. If you are awar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.