ASTM A405-91

(Specification)Specification for Seamless Ferritic Alloy-Steel Pipe Specially Heat Treated for High-Temperature Service (Withdrawn 1995)

Specification for Seamless Ferritic Alloy-Steel Pipe Specially Heat Treated for High-Temperature Service (Withdrawn 1995)

General Information

Standards Content (Sample)

ASTM A'+05 91 - 07595LO 0077975 l, H

AMERICAN SOCIETY FOR ESTING AND MATERIALS

Designation: A 405 - 91

1 916 Race St Philadelphia, Pa IQ1 03

Reprinted from the Annual Book of AS’lM Standards. Copyright ASTM

If not listed in the current combined index, will appear in the next edition.

Standard Specification for

Seamless Ferritic Alloy-Steel Pipe Specially Heat Treated for

High-Temperature Service’

This standard is issued under the fixed designation A 405; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (J indicates an editorial change since the last revision or reapproval.

4. Ordering Information

1. Scope

4.1 Orders for material under this specification should

1.1 This specification covers nominal (average) wall seam-

include the following, as required, to describe the desired

less, annealed or normalized and tempered alloy steel pipe

material adequately:

intended for high-temperature service after special heat

4.1.1 Quantity (feet, centimetres, or number of lengths),

treatment. Pipe ordered to this specification shall be suitable

4.1.2 Name of material (alloy steel pipe),

for bending, flanging (vanstoning), and similar forming

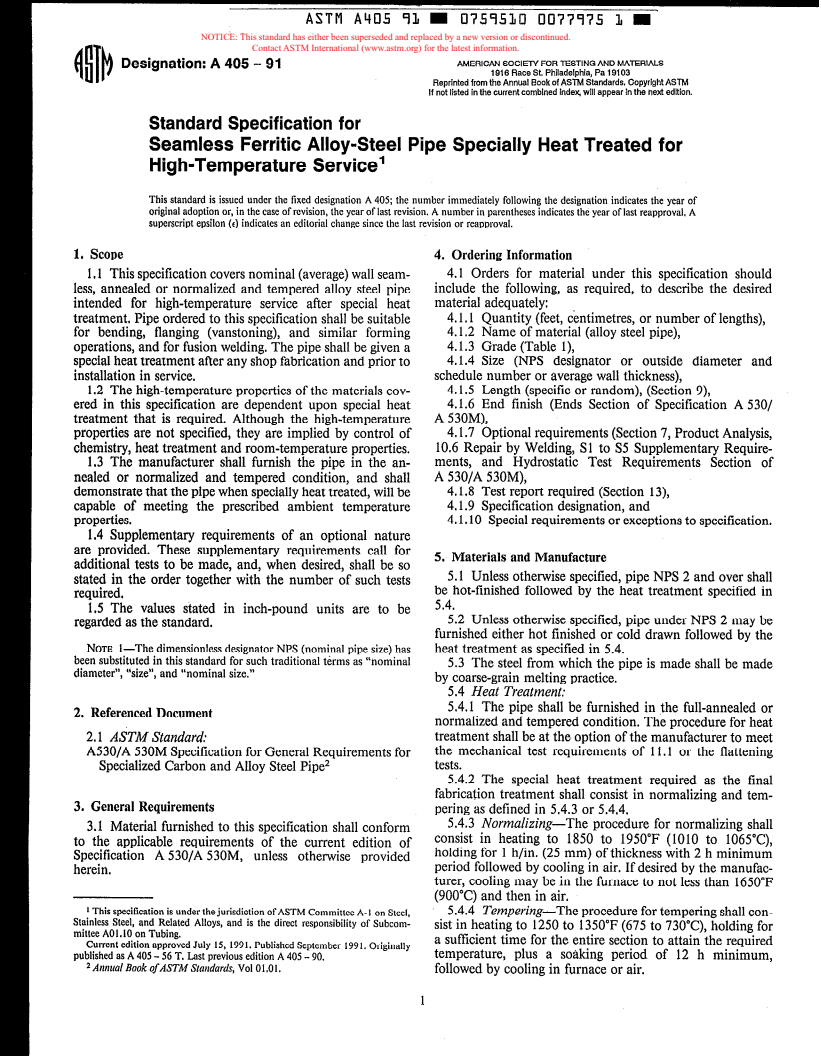

4.1.3 Grade (Table l),

operations, and for fusion welding. The pipe shall be given a

4.1.4 Size (NPS designator or outside diameter and

special heat treatment after any shop fabrication and prior to

schedule number or average wall thickness),

installation in service.

1.2 The high-temperature properties of the materials cov- 4.1.5 Length (specific or random), (Section 9),

4.1.6 End finish (Ends Section of Specification A 5301

ered in this specification are dependent upon special heat

A 530M),

treatment that is required. Although the high-temperature

4.1.7 Optional requirements (Section 7, Product Analysis,

properties are not specified, they are implied by control of

10.6 Repair by Welding, Sl to S5 Supplementary Require-

chemistry, heat treatment and room-temperature properties.

ments, and Hydrostatic Test Requirements Section of

1.3 The manufacturer shall furnish the pipe in the an-

A 530/A 530M),

nealed or normalized and tempered condition, and shall

4.1.8 Test report required (Section 13),

demonstrate that the pipe when specially heat treated, will be

4.1.9 Specification designation, and

capable of meeting the prescribed ambient temperature

properties. 4.1.10 Special requirements or exceptions to specification.

1.4 Supplementary requirements of an optional nature

are provided. These supplementary requirements call for

5. Materials and Manufacture

additional tests to be made, and, when desired, shall be so

5.1 Unless otherwise specified, pipe NPS 2 and over shall

stated in the order together with the number of such tests

be hot-finished followed by the heat treatment specified in

required.

5.4.

1.5 The values stated in inch-pound units are to be

5.2 Unless otherwise specified, pipe under NPS 2 may be

regarded as the standard.

furnished either hot finished or cold drawn followed by the

NOTE I-The dimensionless designator NPS (nominal pipe size) has heat treatment as specified in 5.4.

been substituted in this standard for such traditional terms as “nominal

5.3 The steel from which the pipe is made shall be made

diameter”, “size”, and “nominal size.”

by coarse-grain melting practice.

5.4 Heat Treatment:

5.4.1 The pipe shall be furnished in the full-annealed or

2. Referenced Document

normalized and tempered condition. The procedure for heat

treatment shall be at the option of the manufacturer to meet

2.1 AsTM Standard:

the mechanical test requirements of 11.1 or the flattening

A530fA 530M Specification for General Requirements for

tests.

Specialized Carbon and Alloy Steel Pipe*

5.4.2 The special heat treatment required as the final

fabrication treatment shall consist in normalizing and tem-

3. General Requirements

pering as defined in 5.4.3 or 5.4.4.

5.4.3 Normalizing-The procedure for normalizing shall

3.1 Material furnished to this specification shall conform

consist in heating to 1850 to 1950°F (1010 to 1065”C),

to the applicable requirements of the current edition of

holding for 1 h/in. (25 mm) of thickness with 2 h minimum

Specification A 530/A 530M, unless otherwise provided

period followed by cooling in air. If desired by the manufac-

herein.

turer, cooling may be in the furnace to not less than 1650°F

(9OO’C) and then in air.

5.4.4 Tempering-The procedure for tempering shall con-

* This specification is under the-jurisdiction of ASTM Committee A-l on Steel,

Stainless Steel, and Related Alloys, and is the direct responsibility of Subcom-

sist in heating to 1250 to 1350°F (675 to 73O”C), holding for

mittee AOl.10 on Tubing.

a sufftcient time for the entire section to attain the required

Current edition appro

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.