ASTM D561-82(2003)

(Specification)Standard Specification for Carbon Black Pigment for Paint

Standard Specification for Carbon Black Pigment for Paint

SCOPE

1.1 This specification covers the pigment commercially known as carbon black, which is suitable for use in the manufacture of protective or decorative coatings.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 561 – 82 (Reapproved 2003)

Standard Specification for

Carbon Black Pigment for Paint

This standard is issued under the fixed designation D 561; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

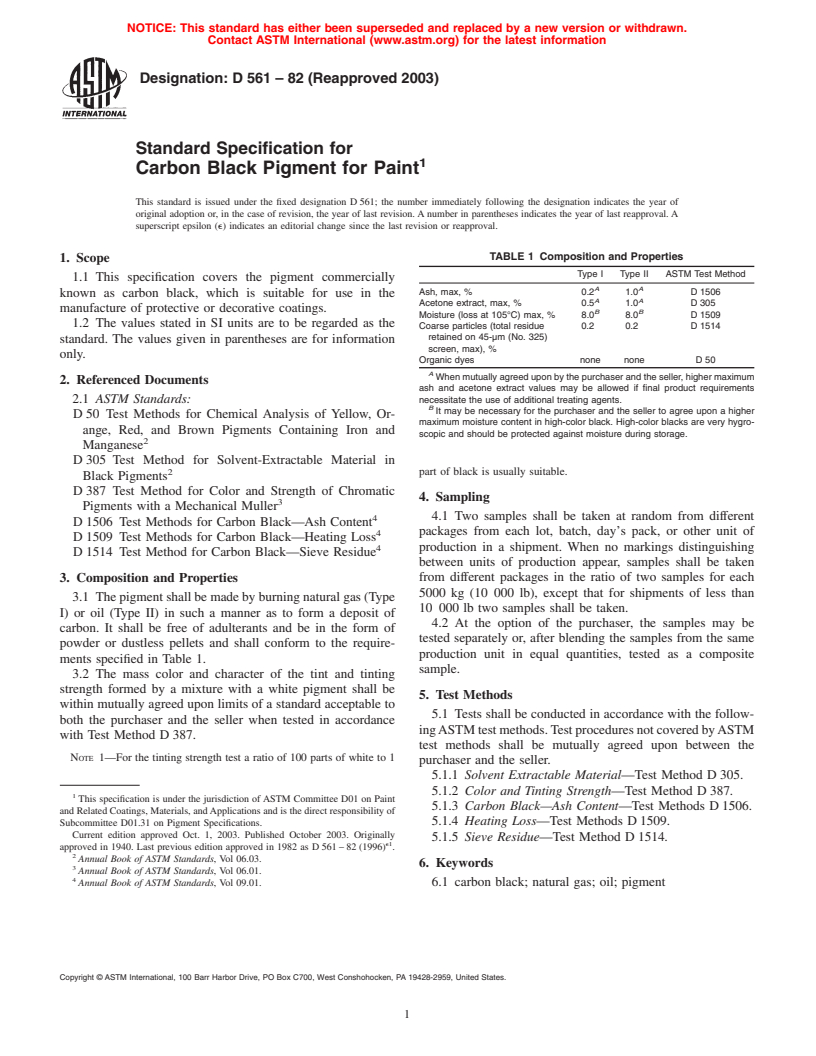

TABLE 1 Composition and Properties

1. Scope

Type I Type II ASTM Test Method

1.1 This specification covers the pigment commercially

A A

Ash, max, % 0.2 1.0 D 1506

known as carbon black, which is suitable for use in the

A A

Acetone extract, max, % 0.5 1.0 D 305

manufacture of protective or decorative coatings.

B B

Moisture (loss at 105°C) max, % 8.0 8.0 D 1509

1.2 The values stated in SI units are to be regarded as the

Coarse particles (total residue 0.2 0.2 D 1514

retained on 45-µm (No. 325)

standard. The values given in parentheses are for information

screen, max), %

only.

Organic dyes none none D 50

A

When mutually agreed upon by the purchaser and the seller, higher maximum

2. Referenced Documents

ash and acetone extract values may be allowed if final product requirements

necessitate the use of additional treating agents.

2.1 ASTM Standards:

B

It may be necessary for the purchaser and the seller to agree upon a higher

D 50 Test Methods for Chemical Analysis of Yellow, Or-

maximum moisture content in high-color black. High-color blacks are very hygro-

ange, Red, and Brown Pigments Containing Iron and

scopic and should be protected against moisture during storage.

Manganese

D 305 Test Method for Solvent-Extractable Material in

part of black is usually suitable.

Black Pigments

D 387 Test Method for Color and Strength of Chromatic

4. Sampling

Pigments with a Mechanical Muller

4 4.1 Two samples shall be taken at random from different

D 1506 Test Methods for Carbon Black—Ash Content

4 packages from each lot, batch, day’s pack, or other unit of

D 1509 Test Methods for Carbon Black—Heating Loss

production in a shipment. When no markings distinguishing

D 1514 Test Method for Carbon Black—Sieve Residue

between units of production appear, samples shall be taken

from different packages in the ratio of two samples for each

3. Composition and Properties

5000 kg (10 000 lb), except that for shipments of less than

3.1 The pigment shall be made by burning natural gas (Type

10 000 lb two samples shall be taken.

I) or oil (Type II) in such a manner as to form a deposit of

4.2 At the option of the purchaser, the samples may be

carbon. It shall be free of adulterants and be in the form of

tested separately or, after blending the samples from the same

powder or dustless pellets and shall conform to the require-

production un

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.